Thermionics e-Gun RCRF-0325 User manual

thermionics laboratory, inc

3kW Rod fed e-gun manual Page 1

Model RCRF-0325/0338

3 kW Rod Fed e-Gun

Evaporation Source Manual

Thermionics Laboratory, Inc.

Modesto CA 95351

Phone: 209/529-8357

Fax: 209/529-8449

www.thermionics.com

thermionics laboratory, inc

3kW Rod fed e-gun manual Page 2

Safety Instructions

DANGER: HIGH VOLTAGE

A. Before servicing or operating this equipment, read this manual and the associated e-Gun

power supply manual paying special attention to ALL SAFETY PRECAUTIONS.

B. The high voltage used by these evaporation sources can be INSTANTLY FATAL.

Furthermore, due to internal capacitance in the power supply, THIS LETHAL VOLTAGE

CAN PERSIST EVEN AFTER THE POWER SUPPLY HAS BEEN TURNED OFF. Before

entering the chamber make sure that the power supply is off and then use a grounding

hook on the high voltage leads from the e-gun. Do not touch the high voltage leads

unless the power supply is turned off and the grounding hook is attached to the part to be

serviced. All grounding hooks are supplied with Thermionics brand power supplies.

C. E-gun systems must be clean. Use lint free gloves when handling vacuum components.

As the e-gun source is operated coating will build up in the vacuum system and in time

create particulates (“flaking of the coating”). A periodic cleaning procedure should be

employed to prevent shorting and/or contamination of the e-gun source. Aluminum foil is

a popular way of shielding the vacuum system from unwanted coating build up with an

inexpensive, disposable material.

D.Operation of an e-gun source without proper water-cooling WILL result in failure of the

source. A water flow interlock switch should always be used to assure proper water flow.

THEORY OF OPERATION

An electron beam evaporation source uses a beam of focused electrons to vaporize

material in a high vacuum environment. The vaporized material then condenses on an

object (called a substrate) in the same high vacuum chamber to form a thin film of

material. The material, which is evaporated to create the film, can be anything that is solid

in the vacuum environment, such as gold, silicon dioxide, or some mixture of substances,

depending on the specific application. The vapor emitted from an e-gun source can be

roughly calculated using cosine distribution as a model. Small deviations do exist from

this model due to the e-guns magnetic field and the ability of many materials to become

ionized during the evaporation process.

To evaporate a material with an e-gun source, a load (or “charge”) of material is placed in

a water-cooled copper crucible inside a vacuum chamber. Then a substrate is placed

above the crucible to receive the vapor (normally 10 to 14 inches for a 3kW source). The

chamber is evacuated. A filament, held in a cathode assembly is given a high negative

potential relative to the grounded crucible. The filament is heated to the point of

thermionic emission by an electric current. The liberated electrons are then accelerated

away from the filament by a grounded anode plate placed just outside of the cathode

assembly. The accelerated electrons are injected into a permanent magnetic field that

directs and focuses the electrons to the water-cooled crucible. The accelerated electrons

kinetic energy is transformed to thermal energy as they impact the evaporant material

placed in the crucible. Temperature in excess of 3500 degrees Celsius can be easily

achieved allowing the direct evaporation of virtually any material.

thermionics laboratory, inc

3kW Rod fed e-gun manual Page 3

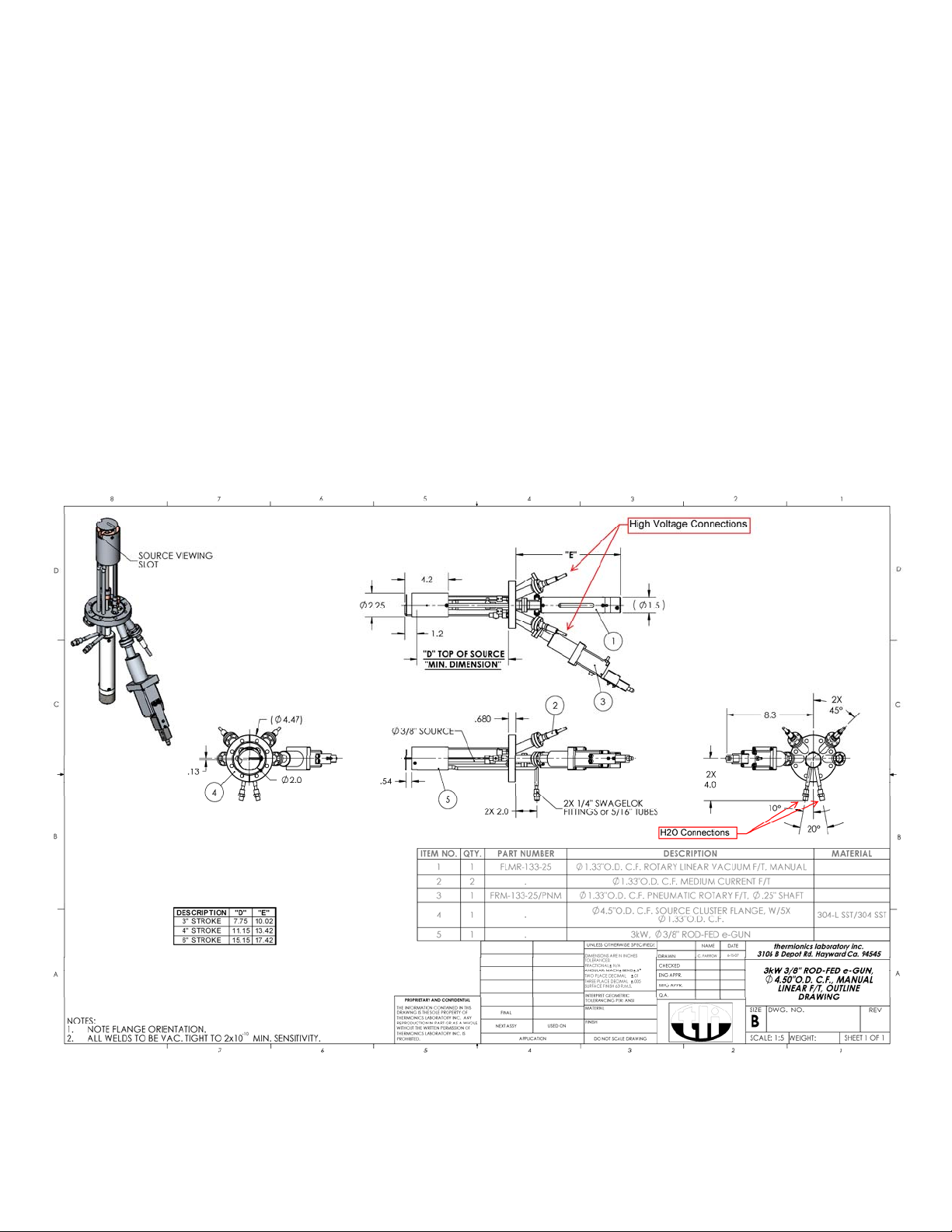

INSTALLATION

The following components are required for customer installed rod fed e-gun systems:

A. Interlock switches: water, vacuum and high voltage access.

B. Filtered water at 1 gpm at 50 psi.

C. High Voltage power supply. TLI model 150-0040 or equivalent.

TO INSTALL THE E-GUN SYSTEM

1. Mount the e-gun in the chamber. Make sure that the source is grounded to the

chamber.

2. Connect all interlocks.

3. Connect external grounds (mandatory power supply ground and independent earth

ground); high Voltage cables and sweep cables per power supply manual(s).

4. Assure water flow of 1 gpm with a pressure of 30 psi or above.

thermionics laboratory, inc

3kW Rod fed e-gun manual Page 4

OPERATION

CRUCIBLE PREPARATION

Cleanliness is critical for high quality films and trouble free operation. CLEAN the crucible

thoroughly before each new material is used. Heavy buildup of the previous material on

the crucible can cause contamination of the melt. The crucible should be cleaned with an

abrasive pad (“scotch bright”) and then vacuumed out. It should then be wiped out with

acetone and alcohol. Cleaning by glass bead blasting is another alternative. When using

a glass bead blaster make sure to keep the air pressure at 40psi. The source should be

disassembled prior to glass bead blasting and special attention should be given to

removal of all glass from the parts after cleaning (glass is a dielectric material and will

cause severe arcing if left on the source). Inspect the crucible bore and ensure that it is

clear of any material that may prevent advancement of the material rod.

CHOOSING EVAPORATION MATERIAL

Material for evaporation comes in a variety of forms and purities. Typically the process

will determine purity. The Rod fed eGun requires material in a rod form. This material

form is readily available and allows you to advance the material as the material is

evaporated. Recommended sizes: RCRF-0325: 0.245 +0.000”/-0.005”; RCRF-0338:

0.374 +0.000”/-0,005”

LOADING THE CRUCIBLE

Running the e-Gun with an empty crucible will destroy the source. Insert the rod into

the crucible and slide it until it seats in the coupling on the linear feedthrough. Retract the

rod until 2-3 mm is left showing above the crucible.

thermionics laboratory, inc

3kW Rod fed e-gun manual Page 5

FINAL CHECK PRIOR TO PUMPDOWN

1. Turn on the water and check visually for leaks.

2. Make sure the crucible is loaded with material.

3. Visually check the high voltage and sweep leads making sure you have ½ inch

clearance around all high voltage leads. Make sure the sweep leads do no pass

directly behind the source (if they must make sure to install a grounded shield around

them).

At this point you are ready to pump down the system.

WARNING: e-GUN SYSTEMS REQUIRE AN INDEPENDENT EARTH GROUND IN

ADDITION TO POWER SUPPLY RETURN AND SAFETY GROUND. SEE APPENDIX B

FOR DETAILS.

e-GUN OPERATION

1. Make sure the vacuum chamber is operating at a pressure less than 5x10^-4 Torr.

2. Make certain all interlocks are operating properly. All grounds must be secure.

3. Turn on the e-GUN cooling water (this should be interlocked to the high voltage

power supply).

4. Assure desired crucible is selected and properly located.

5. Set the power supply emission current potentiometer to zero.

6. Turn on the power supply and check to see that all interlocks are satisfied.

7. Turn on the high voltage. Thermionics 150-0040 3kW power supplies use a fixed

voltage. If using a variable voltage power supply, slowly bring up voltage to negative

4,200 volts DC.

8. Turn on the emission current and slowly increase the potentiometer until you see a

slight glow on the tip of the rod. This will normally appear as a blue glow at an

emission current of about 20 to 30 milliamperes. Slowly increase the power to 50

milliamperes, or until you can clearly see the beam spot.

9. Advance the rod as the material melts down to the crucible. Typical advancement

is 2-3mm.

Note: The e-gun is factory set to locate the beam just off the center of the crucible. If

the crucible is not close to center you must make adjustments. If you have a variable

voltage power supply, adjust the voltage to center the beam. If you do not have

variable voltage, you will need to make magnetic adjustments to the e-gun. Contact

the factory for adjustment procedures.

DEPOSITING MATERIALS THAT MELT

After following the above procedure (steps 1 through 8), continue to slowly increase

power in 20 to 30 milliamp increments. If the material appears unstable (flickering light or

waves in the melt) stop and let it set until it re-stabilizes (you may have to reduce power if

stability cannot be restored). Arcing will occur and is normal in e-Gun evaporation. Stop

increasing power when arcing is observed and let the source soak until arcing stops (on

melting materials arcing is normally caused by outgassing). Continue to increase power

until reaching the desired rate.

thermionics laboratory, inc

3kW Rod fed e-gun manual Page 6

Note: Oxide formation can prevent an evaporant charge from melting in some cases.

Some metals (aluminum and copper are examples) will form an oxide that prevents

melting and causes the beam to appear unfocused. When this occurs you can invert the

melted slug and re-melt it to remove the oxide -or- replace the charge with fresh material.

DEPOSITING MATERIALS THAT DO NOT MELT (SUBLIME OR SEMI-SUBLIME)

Subliming materials may require that you defocus the beam to make it broader so that

you cover the tip of the rod. This will require removal of the dipoles. Try with the

standard configuration and if it does not work well, contact the factory for information on

the dipole removal.

Note: some subliming materials will not support electrical current until heated. This

causes surface charging on the material that results in arcing. The surface charging

effects can also cause the beam to be “scattered” behind the crucible and onto the top

plate of the e-gun. This is normal with some materials. The e-gun top plate is designed to

dissipate this energy. To evaporate materials that have surface charging effects you must

increase the “soak” times of the electron beam as you increase power. If you allow the

source to set at a power level of ~50 to ~75 milliamperes for an extended time (make

sure arcing is not severe) the material will eventually be heated sufficiently to “fire” and

the beam will stop scattering beyond the crucible. You will in many cases still see some

hazing on the e-gun source (this is normal) during evaporation. As the e-gun becomes

coated with these materials hazing may increase.

e-GUN SHUT DOWN

Once the desired rate is achieve; close shutter (if so equipped) or reduce emission

current to zero. Turn off high voltage. Allow adequate cooling time prior to venting the

system. The e-Gun must be allowed to cool of for at least 5 minutes unless venting to an

inert gas to protect the filament. Most metals will cool down quickly ~5 minutes unless

they are used in a crucible liner. Subliming and dielectric materials or metals used in

insulating liners require additional cool down time. Normally 20 minutes will be adequate

although conditions can vary.

CHANGING THE FILAMENT

Filament life is greatly affected by the vacuum level and the types of gas present in the

vacuum system (example: Oxygen partial pressures will reduce filament life). Normally

filaments will last between 200 and 800 hours. To change a filament follow the procedure

listed below (also see Appendix C):

1. Remove screws around the circumference of the shield then lower the shield.

2. Remove the emitter assembly by disconnecting the high voltage leads from the

cathode blocks (#8, #9) and then removing the set screws (#4). (See figure below)

3. Loosen both leg attachment screws (#10) and remove the anode (#15) exposing

the filament

4. Remove the filament clamp screws (#6)

5. Remove the old filament and clean the surface where the filament contacted the

cathode blocks (use a clean abrasive pad)

6. Install a new filament and replace the filament clamp screws. Snug the filament

clamp screws (#15) to allow the filament to be located but still move. Adjust the

thermionics laboratory, inc

3kW Rod fed e-gun manual Page 7

filament so you have an even gap of .010 inches between the filament and the

beam former (see figure below). Tighten the filament clamp screws.

7. The gap between the beam former and the anode should be checked to assure a

spacing of .040 inches.

8. When looking down on the filament you should see ~1/3rd of the filament exposed.

The filament, beam former and anode should all be parallel to each other. This

spacing is very important to assure proper focusing of the electron beam.

9. Replace the emitter assembly and reconnect the high voltage leads.

10.Replace the shield.

thermionics laboratory, inc

3kW Rod fed e-gun manual Page 8

WARRANTY STATEMENT

Thermionics warrants each item it manufactures to be free from defects in workmanship

and material for a period of one year from date of shipment. HM2 e-Gun evaporation

sources are warranted for a period of five years from date of shipment. Minor deviations

that do not affect the performance of the equipment shall not be deemed to constitute

defects of workmanship or materials, or failure to comply with the specifications.

Not withstanding the foregoing, Thermionics shall have no warranty responsibility for

expendable items such as vacuum tubes, diodes, transistors, batteries, lamps,

mechanical pump shaft seals and oil, diffusion pump oil, gaskets, of filaments. In

addition, all vacuum gauge sensing devices such as thermocouple tubes, Pirani tubes,

ionization gauge tubes, etc. are warranted against defects in manufacture in normal use,

as determined by seller's inspection, for a period of ninety (90) days from date of

shipment, provided the defective gauge tube is returned to the seller’s plant for

inspection.

Equipment made or modified to Purchaser’s specifications on special orders shall carry

the above warranties with respect to material and workmanship, but shall be specifically

excluded from any other warranties, express or implied, including those related to

performance specifications, and any special components manufactured by others shall

carry only the original manufacturer’s warranties.

This warranty does not extend to Thermionics products that have been subject to misuse,

neglect, accident, or improper application, nor shall it extend to units that have been

substantially altered outside the seller’s plant except by Thermionics service engineers.

This warranty is expressly in lieu of all other obligations or liabilities on the part of

Thermionics unless such additional warranty is either agreed to in writing, appears in a

separate warranty statement provided to the customer, or appears in a warranty

statement accompanying the product shipped to the customer. Under no circumstance

will Thermionics be liable for consequential or resulting loss or damage, neither of nor

due to causes covered by Thermionics’ warranty. Thermionics neither assumes nor

authorizes any other person to make any other representation or warranty on its behalf,

or assume for it any liability in connect with the sale of its products.

WARRANTY REPAIR

Notice of any claim that a product is in any way defective shall be given to Thermionics

immediately upon discovery. Before any items are returned for repair and/or adjustment,

the customer must obtain Thermionics’ approval. Written authorization for the return and

instructions as to how these times should be shipped will be provided. If any Thermionics

products must be returned to the factory, they must be sent prepaid via the means of

transportation indicated as being acceptable in the written authorization. Thermionics

reserves the right to reject and warranty claim on any product that has been shipped by a

non-acceptable means of transportation.

thermionics laboratory, inc

3kW Rod fed e-gun manual Page 9

When Thermionics products are returned for examination and inspection, it is important

that they be properly packed for shipment. Use the original packing material or

equivalent. The sender and the shipping agency must assume the responsibility for

damage resulting from improper packing, handling, or loss of transit.

When products are returned, it is very important that the customer provide Thermionics

with the data on the operating conditions and any other pertinent information, which will

enable us to determine the cause of failure. In all cases, Thermionics has sole

responsibility for determining the cause of failure, and sole discretion in determining the

nature and extent of adjustment, if any, to which a customer may be entitled.

If it is found that our product has been returned without cause and is still serviceable, the

customer will be notified and the product be returned. All shipping costs on products

returned for warranty repair shall be the customer’s responsibility. Thermionics’ sole

liability hereunder shall be the correction and/or replacement of defective materials and

workmanship.

Thermionics Laboratory, Inc. Thermionics Laboratory, Inc.

P.O. Box 3711 23950 Clawiter Rd.

Hayward, CA 94545 Hayward, CA 94540

PH: (510) 538-3304 FX: (510) 538-2889

This manual suits for next models

1

Table of contents