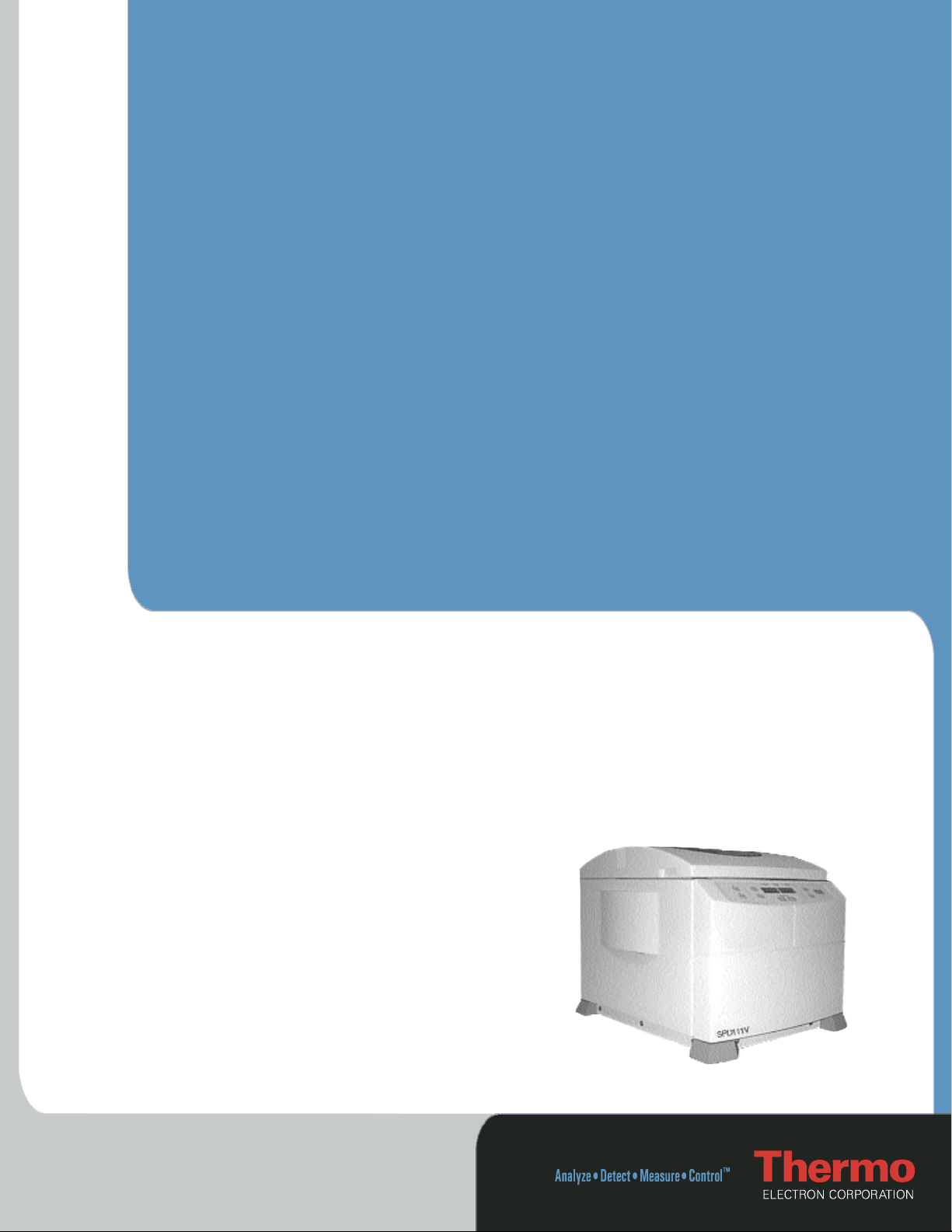

Thermo Electron Savant SPD111V User manual

Instruction Manual

Savant SPD111V

SpeedVac Concentrator

197-3001-00 Rev. C

®

®

Contents

Section Overview Page

1.0 Overview of the SPD111V Unit 1

1.1 Installation of the SPD111V Unit 2

1.2 How to Hook Up the SPD111V Unit 2

Section Control Panel Page

2.0 The Control Panel 3

2.1 Description of the Control Panel 3

Section Auto & Manual Run Page

3.0 The Manual Run 4

3.1 The Auto Run 5

Section Rotor Selection Page

4.0 Rotor Selection Guide 6

Section Guidelines Page

5.0 Guideline for Solvent Choice 7

Section Maintenance Page

6.0 Maintenance & Service 8

Section Specifications Page

7.0 Specifications & Warranty 9

Appendix 1 - Additional SPD111V System Set-ups 10

Disclaimer:

All statements, information and data given herein are believed to be accurate and reliable but are presented without guarantee, or respon-

sibility of any kind, expressed or implied. Statements or suggestions concerning possible use of our products are made without representa-

tion that any such use is free of patent infringement and are not recommendations to infringe any patent. The user should not assume that

all safety measures are indicated, or that other measures may not be required.

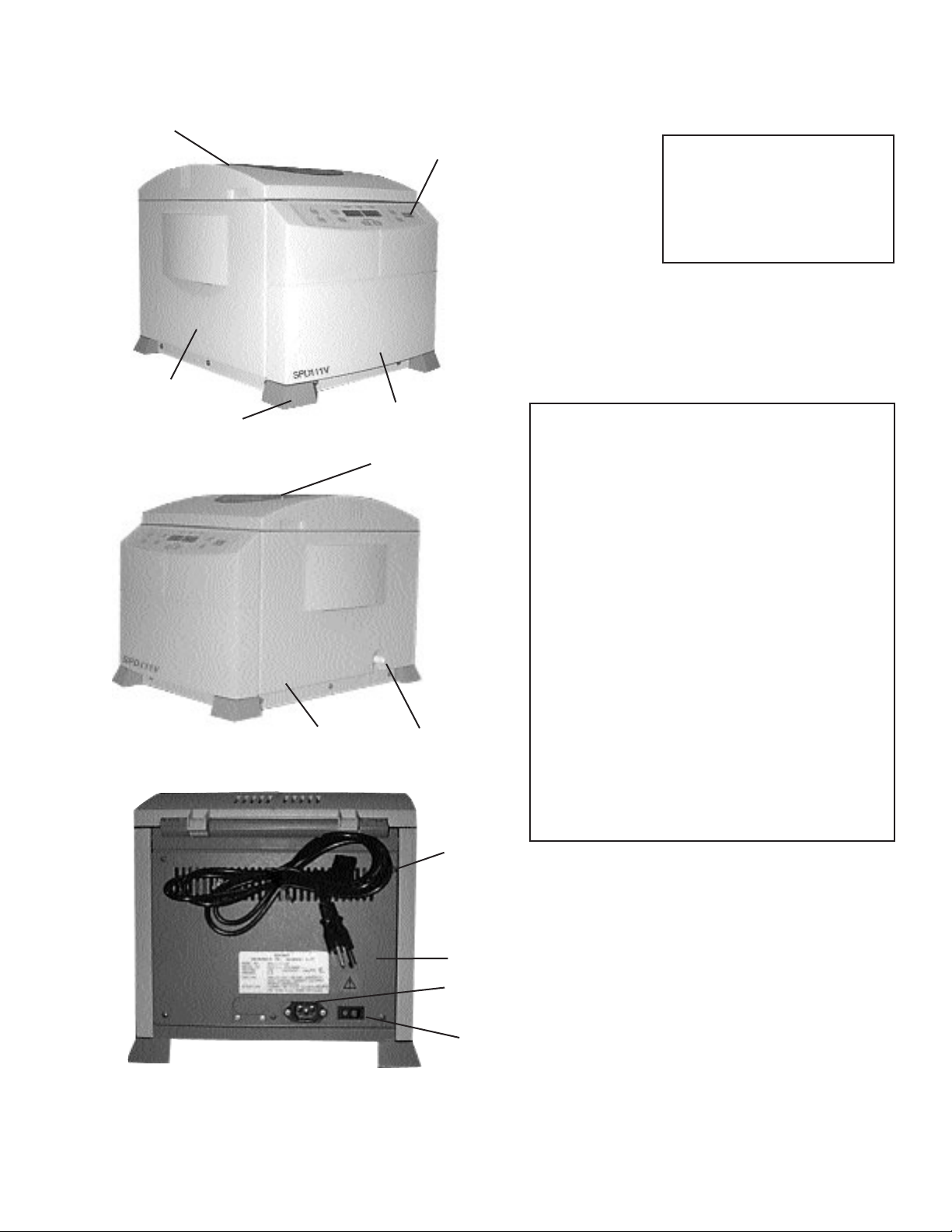

1. Top Cover (Radiant

Cover Optional)

2. Control Panel

3. Front Panel

4. Left Side Panel

5. Anti Skid/Vibration

6. Right Side Panel

7. Chamber View Window

8. Vacuum Port

9. AC Socket

10. Main On/Off Switch

11. Manual Cover

Lock Release

12. Rear Access Panel

1

2

3

4

5

6

12

8

9

10

11

7

Figure 1 = Front View

Figure 2 = Side View

Figure 3 = Back View

1.0 Overview of the SPD111V Unit

Fig. 1

Fig. 2

Fig. 3

1

1.1 INSTALLATION OF THE SPD111V

1. Unpack unit from the box and verify that all the parts match packing list.

2. Read instruction manual carefully! If assistance is required, contact

Thermo

3. If the unit is part of a larger system, use the vacuum tubing supplied to

hook up unit (See Figure 4).

4. Vacuum clamps must be put on vacuum ports of pump and SPD unit

(See item 8 on Figure 2 and Figure 4).

5. If being hooked up to existing system, simply attach vacuum tubing

to port on side of unit (See item 8, figure 2-vacuum port).

CAUTION - Cold trap should be in line between the vacuum source

and the SPD Unit.

RVT4104-

Refrigerated VaporTrap

VLP Vacuum

Pump SPD111V-

SpeedVac®

Concentrator

2

1.2 HOW TO HOOK UP THE SPD111V SPEEDVAC®SYSTEM

Figure 4-Rear View of System

Vacuum

Tubing

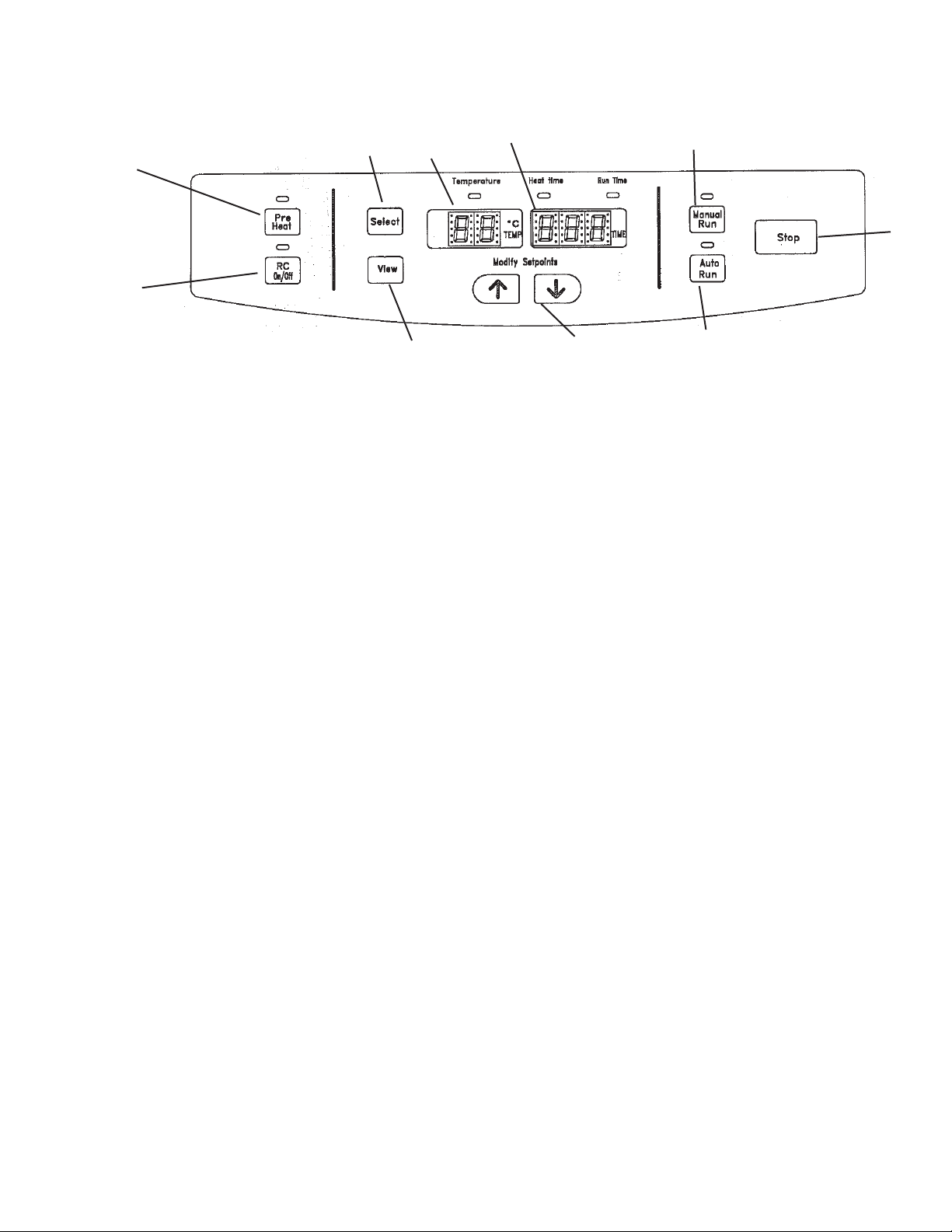

1. PRE-HEAT - use to pre-heat chamber to 45 °C prior to or between runs.

Once run is initiated the pre-heat stops.

2. RC ON/OFF - Use to add radiant heat to chamber.

Manual activation ON/OFF at any point during run.

Also will turn off at end of run.

3. SELECT - (located above temperature/time indicator), press this button to

select the parameters to be modified. Selection is from left to right.

GREEN light indicates the parameter to be modified.

4. MODIFY SETPOINT UP/DOWN - Modifies selected parameter.

5. AUTO RUN - Starts an automated run (See page 5).

6. MANUAL RUN - Starts a manual run (See page 4).

7. STOP - Terminates manual or auto run.

8. VIEW - Press to view. Displays preset parameters (during a run), displays

actual values when not running.

9. TEMPERATURE DISPLAY (GREEN DISPLAY) - Indicates set temperature or

actual temperature during a run in °C.

10. TIME DISPLAY (GREEN DISPLAY) - Indicates heat timer or run timer

setpoints. If in the process of a run it indicates elapsed time or time left.

19

7

6

5

4

3

2

10

8

2.0 SPD111V CONTROL PANEL

2.1 DESCRIPTION OF SPD111V CONTROL PANEL

3

This type of run will allow continuous running of the unit until it is turned off by

the user. The heat timer is activate and can be set to a user defined time.

1. Connect the unit to its required voltage.

2. Turn the power switch to ON, located on the back of the unit.

The cover lock, unlocks, allowing the top cover to be opened.

The display lights up, showing the following default values:

Temperature: 35 °C

Run Time: 2.00 HRS

Press “SELECT” to “HEAT TIME”: 1.00 HR default.

3. Place sample tubes in rotor so load is balanced.

Secure it with rotor supplied knob (hand tight). Close cover.

4. Using the “SELECT” button and the up/down keys, set temperature

between 35-80 °C, or “no”, for no heat.

5. Using the “SELECT” button and the up/down keys, select and modify

“HEAT TIME” to between 0.01and 9.59 hours or CCC (for continual

heating). When the heat timer expires, the heater will shut off, no matter

what the temperature setpoint is (except if CCC).

6. Press the “MANUAL RUN” button. The cover locks and rotor starts

turning. The decimal point blinks and the time display begins counting

up. The temperature rises to the set temperature. The “HEAT TIME”

will count down, and the SAV valve will actuate, applying vacuum to

the chamber.

NOTE: If the cover is not closed, the display will show “LID” and the

run will not start.

7. Press R/C for radiant cover heat. (Optional)

Press at any time to turn OFF and ON.

8. To end the manual run press “STOP” button. The display will show

”End”, the SAV valve will click allowing air to bleed into the chamber.

9. After the rotor stops spinning, the cover lock unlocks and the display

reverts to last set parameters.

10. Open cover and remove samples.

4

3.0 THE MANUAL RUN

3.1 THE AUTO RUN

An automated run will run the unit for a pre-defined time as selected by the

user.

1. Refer to the “MANUAL RUN” section for start up.

2. Place sample tubes in rotor so load is balanced. Secure it with

rotor supplied knob (hand tight). Close cover

3. To execute “AUTO RUN” perform the following steps:

a) Use “SELECT” button and up/down keys to select and modify

“TEMPERATURE, “HEAT TIME, “RUN TIME” parameters.

“RUN and HEAT TIME” can be set from 0.01 to 9.59 hours

(HEAT TIME also has CCC”).

b) Press “AUTO RUN” button to start the run. GREEN light above

“Auto Run” is on. The cover locks, and the rotor starts turning.

The time display is counting down in 1 minute intervals and the

decimal point blinks. The heat time is counting down (use select

button to view “HEAT TIME”). The temperature rises in 1 °C

increments to the set temperature. The SAV valve will actuate,

applying vacuum to the chamber.

c) Press R/C for radiant cover heat. (optional*)

Press at any time to turn OFF and ON.

NOTE: If the cover is not closed, the display will show “Lid” and the

run will not start.

d) Once the time decrements to 0.00 HRS. the run will automatically

stop, the display will show “End”. The SAV valve will click

allowing air to bleed into the chamber.

e) After the rotor stops spinning, the cover unlocks and the display

reverts to last set parameters.

f) Open the cover and remove samples.

GENERAL: During the run, display shows actual parameters.

To check set parameters, press “VIEW” button and

“SELECT”. The display will revert temporarily to set points.

5

*only units fitted with RCSPD.

6

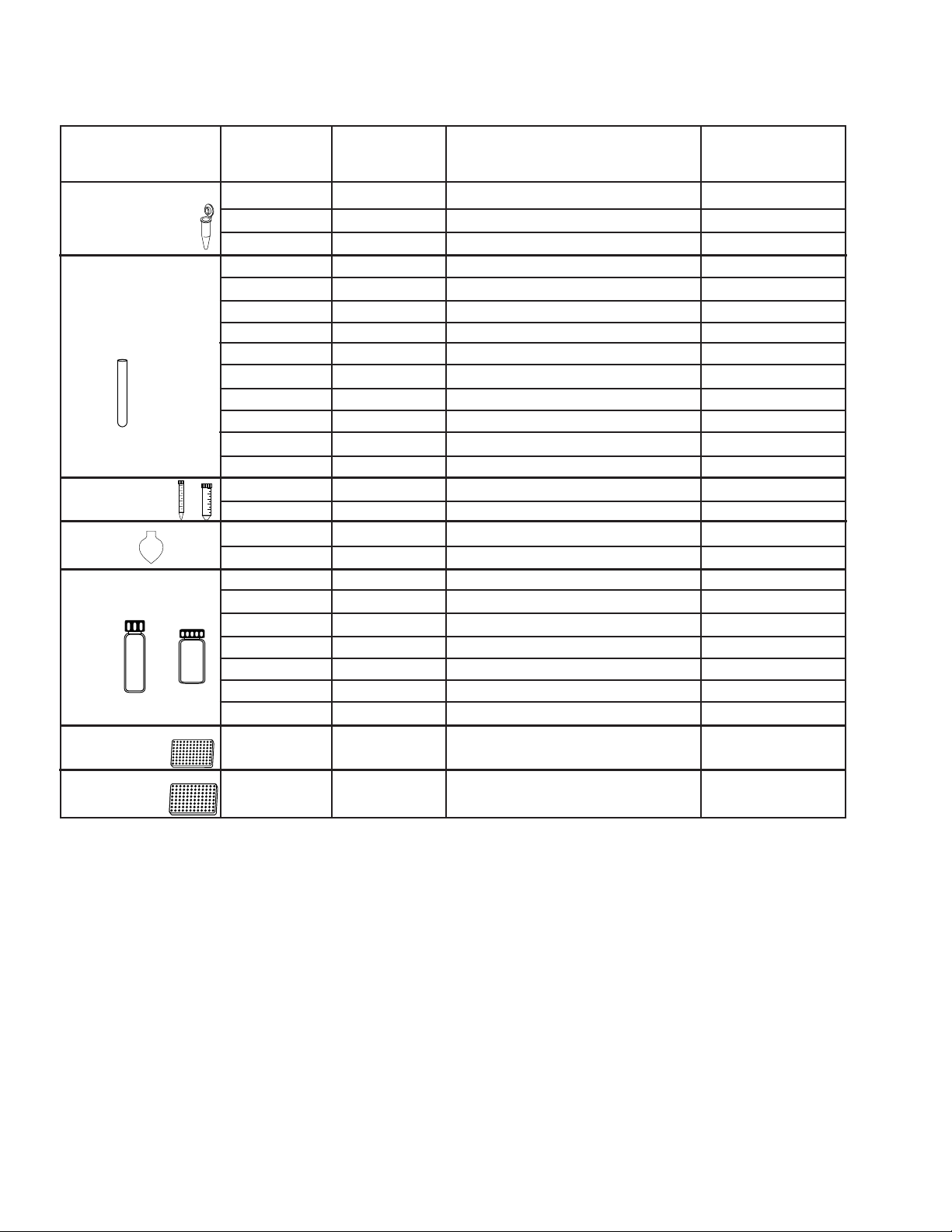

CENTRIFUGE

TUBES

4.0 ROTOR SELECTION GUIDE

Working

Volume (ml)

Number

of Tubes

Description Rotor

Model

RH40-11

RH64-11

RH120-11

RH100-8

RH40-6

RH100-6

RH20-12

RH40-12

RH72-12

RH20-12

RH32-13

RH8-18

RH6-18-150

RH10-15

RH6-50

RH8-50

RH4-100

RH60-12-40

RH60-12-40

RH12-20

RH24-15

RH12-20

RH24-18

RH12-28

RH2MP

RHSW6M6

RHDW2MP

1.5 - 2.0 ml

1.5 - 2.0 ml

1.5 - 2.0 ml

0.5ml (8 x 29mm)

0.4ml (6x 50mm)

0.4ml (6 x 50mm)

12 x 75mm

1.5 - 2.0 (12 x 75mm)

12 x 75mm

13 x 100mm

13 x 100mm

18 x 100mm, 17 x 95, 16 x 100

18 x 150 mm

15ml conical (16 x 120mm)

50ml conical (28 x 115mm)

50ml pear shaped flask

100ml pear shaped flask

12 x 32mm

12 x 40mm vials

20 x 47mm v-vials

1 dram vials (15 x 45mm), 4ml

20 x 60mm v-vials

18 x 52mm mini-scintillation vials

28 x 60mm scintillation vials

Microplates

Microplates

Deepwell Microplates

40

64

120

100

40

100

20

40

72

10

32

8

6

10

6

8

4

60

60

12

24

12

24

12

2 plates

6 plates

2 plates

1.2 - 1.6

1.2 - 1.6

1.2 - 1.6

0.3

0.3

0.3

4

4

4

8

8

10

25

12

40

35

80

2

2.0

2.4

3

4

5.6

16

0.3

0.3

2.0

MICROCENTRIFUGE

TUBES

MICROTITER

PLATES(Shallow)

VIALS

GLASS AND

PLASTIC TUBES

FLASKS

DEEPWELL

PLATES

7

*The SPD units (SPD121P and SPD111V with a radiant cover) are better suited for limited

intermittent use of the solvents listed in Part II. Use of these solvents with the SPD111V

(without a radiant cover) and SPD101B may cause the lid material to become discolored and

cause potential damage. For additional technical assistance with respect to your solvent

choice, please contact the Applications Support Specialists at Thermo.

5.0 GUIDELINES FOR SOLVENT CHOICE

Part I: Solvents suited for the SPD111V unit

• Ethanol

• Methanol

• Water

• Acetonitrile

Part II: Solvents NOT suited for the SPD111V unit

• Methylene Chloride

• Chloroform

• Ethyl Acetate

• Hydrochloric Acid

• Trifluoroacetic Acid (TFA)

• Dimethyl Sulfoxide (DMSO)

Part III: All other solvents not listed above

Call Thermo application specialists to see if your solvent can

be used in the SPD111V concentrator.

8

6.0 MAINTENANCE/SERVICE

1. Maintenance: The SPD111V SpeedVac®requires no scheduled

maintenance.

2. Cleaning: The SPD111V SpeedVac®should be cleaned if solvents spill on

or inside the unit. Always clean up any spills immediately using

absorbent paper towels.

Always wear gloves when cleaning and dispose of paper towel in

appropriate designated refuse containers.

3. Replace chamber seal if cracked (Part number is 197-6020-00).

4. Outside of unit can be cleaned with dilute solution of soap and water.

5. For any other maintenance or service issues or service problems, please

contact Thermo.

9

7.0 SPECIFICATIONS/WARRANTY

Model: SPD111V

Bleeder Valve: Integrated Automatic Bleeder Valve

Temperature Range: 35 °C-80 °C

Volume Range/Tube: 18 x 150 mm

Maximum Tube Capacity: 6

Maximum Carrier Capacity: 2 (96-deepwell plates) see chart on page 6

Dimensions: (W x D x H) in.: 14 x 18 x 13

cm: 36 x 45 x 33

Weight: lbs. (kg) 31 (14)

Power requirements: 115 VAC/60Hz, 5.0A

(Part number SPD111V-115)

or

230 VAC/50Hz, 3.0A

(Part number SPD111V-230)

All Thermo products mentioned in this manual (except glassware) are warrant-

ed against defects in material and workmanship for one year after the date of

delivery to the original purchaser. Thermo’s warranty is limited to defective

materials and workmanship, and does not cover incidental or consequential

damages. Warranty work is subject to our inspection of the unit.

No instruments, equipment, or accessories will be accepted without a Return

Material Authorization (RMA) number issued by Thermo. Costs of shipping the

unit are not covered under warranty.

The warranty obliges you to follow the precautions in this manual. It is the

responsibility of the user to dispose of ALL materials in a manner in accordance

with all federal, state and local regulations. ALL RETURNED UNITS MUST BE

DECONTAMINATED AND FREE OF RADIOACTIVITY AND SHOULD BE

ACCOMPANIED WITH A DECONTAMINATION FORM. PLEASE CONTACT

THERMO TO HAVE THIS FORM FAXED TO YOU!

Under no circumstances shall Thermo be liable for damages due to the improp-

er handling or use of its products. Thermo assumes no liability, express or

implied, for your use of this equipment.

10

APPENDIX 1

Additional SPD111V System Set-ups

SEMI-INTEGRATED SYSTEM

SpeedVac®Concentrator

SPD111V

UVS400

Universal Vacuum Source

ANT100

Vacuum

Tubing

COMPONENT HIGH VACUUM SYSTEM

Flexible

Vacuum

Tubing

DVG50

SpeedVac®Concentrator

SPD111V

RVT400

Cold Trap

SCT120

Chemical Trap

VLP120

Vacuum Pump

Bleeder

Valve

Bleeder

Valve

SPD-SERIES SPEEDVAC®FAMILY

SPD101B

SPD111V

SPD121P

Belgium

Brussels

+32 2 482 30 30

Fax: +32 2 482 30 31

France

Cergy Pontoise Cedex

+33 1 34 32 51 51

Fax: +33 1 34 32 51 59

Germany

Dreieich

+49 6103 408 0

Fax: +49 6103 408 1222

Netherlands

Breda

+31 76 571 4440

Fax: +31 76 587 9757

Russia

Saint-Petersburg

+7 812 325 8045

Fax: +7 812 186 1194

Moscow

+7 095 755 9045

Fax: +7 095 755 9046

+34 93 2233154

Fax: +34 93 2230857

Barcelona

Spain

+46 8 742 03 90

Fax: +46 8 742 09 47

Stockholm

Sweden

+46 46 90 96 60

Fax: +46 46 32 87 70

Lund

+44 01256 81782

Fax: +44 01256 81792

Basingstoke, Hampshire

United Kingdom

+8610 5850 3588

Fax: +8610 6621 0847

Beijing

China

+8621 5465 7588

Fax: +8621 6445 7830

Shanghai

+852 2885 4613

Fax: +852 2567 4447

Wanchai

Hong Kong

+91 22 2778 1101

Fax: +91 22 2778 1103

Bangaalore

India

+81 45 453 9122

Fax: +81 45 453 9222

Yokohama-City

Japan

International Sales Office Locations

Bioscience

Technologies

Thermo Electron Corporation

866.9.THERMO (866.984.3766)

Molecular Biology

info.molbio@thermo.com

Sample Preparation

info.sampleprep@thermo.com

New Labs

newlabs@thermo.com

Services

services.biosciencetech@thermo.com

Laboratory Pipetting and Consumables

info.pipettes@thermo.com

Microplate Instrumentation

info.microplatei[email protected]

Laboratory Automation & Integration

info.labautomation@thermo.com

Controlled Environment

info.controlenv@thermo.com

Milford, MA 01757

Fax: 508.634.2199

450 Fortune Boulevard

Bioscience Technologies

www.thermo.com

© 2001-2004 Thermo Electron Corporation, All rights reserved.

Thermo Electron Corporation, SpeedVac, and Analyze, Detect, Measure,

Control, are trademarks of Thermo Electron Corporation.

Table of contents