Thermo Forma 3033 Operating instructions

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

REMOTE INSPECTION

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

View

Instra

Models:

3033 and 3035

3860 and 3862

Steri-Cult Incubators

Operating and Maintenance Manual

Manual No: 7073033 Rev. 6

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Model 3033 and 3860 Series ________________________________________________________________________

i

Read This Instruction Manual.

Failure to read, understand and follow the instructions in

this manual may result in damage to the unit, injury to operat-

ing personnel, and poor equipment performance.

CAUTION! All internal adjustments and maintenance must

be performed by qualified service personnel.

Refer to the serial tag on the back of this manual.

The material in this manual is for information purposes only.

The contents and the product it describes are subject to change

without notice. Thermo Forma makes no representations or war-

ranties with respect to this manual. In no event shall Thermo

Forma be held liable for any damages, direct or incidental, aris-

ing out of or related to the use of this manual.

MANUAL NUMBER 7073033

6 20122/IN-2948 6/18/01 Updated electrical schematics to meet EMC standards ccs

5 Updates from 2 4/16/01 Updated Accessories list (caster dollies) ccs

4 19588/SI-8132 12/21/00 Changed power switch P/N 360146 to 363033 (elec. schematics) aks

3 -- 5/19/00 Quark format ccs

2 18501/SI-7634 8/17/99 Added securing bracket in Section 2 ccs

REV ECR/ECN DATE DESCRIPTION By

Contains Parts and Assemblies

Susceptible to Damage by

Electrostatic Discharge (ESD)

CAUTION

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Model 3033 and 3860 Series ________________________________________________________________________

ii

Important operating and/or maintenance instructions. Read the accompanying text carefully.

Ce symbole attire l'attention de l'utilisateur sur des instructions importantes de fonctionnement et/ou d'entretien. Il

peut être utilisé seul ou avec d'autres symboles de sécurité. Lire attentivement le texte d'accompagnement.

Wichtige Betriebs- und/oder Wartungshinweise. Lesen Sie den nachfolgenden Text sorgfältig.

Importante instruccions de operacion y/o mantenimiento. Lea el texto acompanante cuidadosamente.

Potential electrical hazards. Only qualified persons should perform procedures associated with this symbol.

Ce symbole attire l'attention de l'utilisateur sur des risques électriques potentiels. Seules des personnes qualifiées

doivent appliquer les instructions et les procédures associées à ce symbole.

Gefahr von Stromschlägen. Nur qualifizierte Personen sollten die Tätigkeiten ausführen, die mit diesem Symbol beze-

ichnet sind.

Potencial de riesgos electricos. Solo personas das capacitadadas deben ejecutar los procedimientos asociadas con este

simbulo.

Equipment being maintained or serviced must be turned off and locked off to prevent possible injury.

Risques potentiels liés à l'énergie. L'équipement en entretien ou en maintenance doit être éteint et mis sous clé pour

éviter des blessures possibles.

Geräte, an denen Wartungs- oder Servicearbeiten durchgeführt werden, müssen abgeschaltet und abgeschlossen wer-

den, um Verletzungen zu vermeiden.

El equipo recibiendo servicio o mantenimiento debe ser apagado y segurado para prevenir danos.

!""""Always use the proper protective equipment (clothing, gloves, goggles, etc.)

!"""Always dissipate extreme cold or heat and wear protective clothing.

!"""Always follow good hygiene practices.

!"""Each individual is responsible for his or her own safety.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Model 3033 and 3860 Series ________________________________________________________________________

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Model 3033 and 3860 Series ______________________________________________________________Table of Contents

iv

Table of Contents

Section 1 - Receiving . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 1

1.1 Preliminary Inspection . . . . . . . . . . . . . . . . . . . . . .2 - 1

1.2 Visible Loss or Damage . . . . . . . . . . . . . . . . . . . . .2 - 1

1.3 Responsibility for Shipping Damage . . . . . . . . . . .2 - 1

Section 2 - Installation and Start-up . . . . . . . . . . . . . .2 - 1

2.1 Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 1

2.2 Securing the Unit . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 1

2.3 Leveling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 2

2.4 Connecting to Power . . . . . . . . . . . . . . . . . . . . . . . .2 - 2

2.5 Connecting the Water Drain Line . . . . . . . . . . . . . .2 - 2

2.6 Preliminary Disinfecting . . . . . . . . . . . . . . . . . . . . .2 - 2

2.7 Installing the Diffuser Pans and Pilasters . . . . . . . . .2 - 2

2.8 Installing the Shelves . . . . . . . . . . . . . . . . . . . . . . .2 - 2

2.9 Connecting the CO2 Supply . . . . . . . . . . . . . . . . . .2 - 3

a. To connect the CO2 supply: . . . . . . . . . . . . . . . .2 - 3

2.10 Connecting the Temp/Alarm Back-Up Battery . . .2 - 3

2.11 Filling the Humidity Reservoir . . . . . . . . . . . . . . .2 - 4

2.12 Setting the Over/Under Temperature Safety . . . . . .2 - 4

2.13 Setting the CO2 . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 5

2.14 Setting the Relative Humidity . . . . . . . . . . . . . . . .2 - 5

2.15 Setting the Chamber Temperature . . . . . . . . . . . . . .2 - 5

2.16 Connecting to the Recorder Jack . . . . . . . . . . . . . .2 - 5

2.17 Connecting to the Remote Alarm Contacts . . . . . . .2 - 6

2.18 Convenience/Accessory Outlet . . . . . . . . . . . . . . . .2 - 6

Section 3 - Operation . . . . . . . . . . . . . . . . . . . . . . . . .3 - 1

3.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 1

3.2 Power Control Panel . . . . . . . . . . . . . . . . . . . . . . . . .3 - 1

a. Main Power Switch . . . . . . . . . . . . . . . . . . . . . .3 - 1

b. Program/Run Key Switch . . . . . . . . . . . . . . . . .3 - 1

c. Door Ajar Light . . . . . . . . . . . . . . . . . . . . . . . . .3 - 1

d. Sample Port . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 1

3.3 Temperature Alarm/Monitor . . . . . . . . . . . . . . . . . .3 - 2

a. LED Temp Display . . . . . . . . . . . . . . . . . . . . . . .3 - 2

b. High and Low Temp Limit Switch . . . . . . . . . . .3 - 2

c. Temp Alarm Lights, Audible Alarm, Normal/Standby

Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 2

3.4 CO2 Control Panel . . . . . . . . . . . . . . . . . . . . . . . . .3 - 2

a. CO2 LCD Display . . . . . . . . . . . . . . . . . . . . . . .3 - 2

b. CO2 Inject Light . . . . . . . . . . . . . . . . . . . . . . . .3 - 2

c. CO2 Alarm Light and Audible Alarm . . . . . . . .3 - 2

3.5 Auto Zero Function . . . . . . . . . . . . . . . . . . . . . . . . .3 - 2

3.6 Auto Zero Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 3

3.7 RH Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 3

a. Relative Humidity Liquid Crystal Display . . . . .3 - 3

b. Humidity Indicator Light . . . . . . . . . . . . . . . . . .3 - 3

3.8 Temperature Control Panel . . . . . . . . . . . . . . . . . . .3 - 3

a. Temperature LCD Display . . . . . . . . . . . . . . . . .3 - 3

b. Heat Indicator Light . . . . . . . . . . . . . . . . . . . . . .3 - 3

Section 4 - Routine Maintenance . . . . . . . . . . . . . . . . .4 - 1

4.1 Disinfecting the Incubator Interior . . . . . . . . . . . . . .4 - 1

4.2 Cleaning the Cabinet Exterior . . . . . . . . . . . . . . . . .4 - 1

4.3 Cleaning Stainless Steel . . . . . . . . . . . . . . . . . . . . .4 - 1

4.4 Draining the Humidity Reservoir . . . . . . . . . . . . . . .4 - 1

Section 5 - Service . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 1

5.1 Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 1

5.2 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 1

a. CO2 Calibration . . . . . . . . . . . . . . . . . . . . . . . .5 - 1

b. RH Calibration . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 2

c. Temperature Calibration . . . . . . . . . . . . . . . . . .5 - 2

5.3 Changing the CO2 Filter . . . . . . . . . . . . . . . . . . . . . .5 - 3

5.4 Changing the Zero Sample Filter . . . . . . . . . . . . . . .5 - 3

5.5 Changing the Microbiological Filter . . . . . . . . . . . . .5 - 3

5.6 Changing the Air Pump . . . . . . . . . . . . . . . . . . . . . .5 - 4

5.7 Changing the Inline Water Filter . . . . . . . . . . . . . . . .5 - 4

5.8 Changing the Blower Motor . . . . . . . . . . . . . . . . . . .5 - 4

5.9 Replacing the IR Sensor . . . . . . . . . . . . . . . . . . . .5 - 5

5.10 Silencing the Audible Alarm . . . . . . . . . . . . . . . . .5 - 5

5.11 Service Calibration Guide . . . . . . . . . . . . . . . . . . .5 - 5

a. Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 5

b. Functional checks . . . . . . . . . . . . . . . . . . . . . . . .5 - 5

c. Has the cabinet defaulted? . . . . . . . . . . . . . . . . .5 - 5

5.12 Temperature Alarm/Monitor Calibration . . . . . . . .5 - 6

5.13 Reheat Calibration . . . . . . . . . . . . . . . . . . . . . . . . .5 - 6

5.14 RH Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 6

5.15 Temperature Offset Adjustment . . . . . . . . . . . . . . .5 - 6

5.16 CO2 Calibration Procedure . . . . . . . . . . . . . . . . . .5 - 6

5.17 Returning the Cabinet from Total Default . . . . . . .5 - 7

5.18 Drying out the Humidity Reservoir . . . . . . . . . . . . .5 - 8

Section 6 - Specifications . . . . . . . . . . . . . . . . . . . . . . .6 - 1

a. Electrical Requirements . . . . . . . . . . . . . . . . . . .6 - 1

b. Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 1

c. Temperature Control . . . . . . . . . . . . . . . . . . . . . .6 - 1

d. Temperature Alarm . . . . . . . . . . . . . . . . . . . . . .6 - 1

e. CO2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 1

f. Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 1

g. Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 1

h. Shelves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 1

i. Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 2

j. Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 2

k. Environmental Conditions . . . . . . . . . . . . . . . . .6 - 2

Section 7 - Accessories . . . . . . . . . . . . . . . . . . . . . . . . .7 - 1

7.1 Incubator Accessories . . . . . . . . . . . . . . . . . . . . . . . .7 - 1

7.2 General Accessories . . . . . . . . . . . . . . . . . . . . . . . . .7 - 1

Section 8 - Parts List . . . . . . . . . . . . . . . . . . . . . . . . . .8 - 1

Section 9 - Electrical Schematics . . . . . . . . . . . . . . . . .9 - 1

Section 10 - Warranty Information . . . . . . . . . . . . . .10 - 1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Section 1 - Receiving

1.1 Preliminary Inspection

This unit was thoroughly inspected and carefully packed

prior to shipment and all necessary precautions were taken to

ensure safe arrival. Immediately upon receipt, before the unit is

moved from the receiving area, carefully examine the shipment

for loss or damage. Unpack the shipment and inspect both inte-

rior and exterior for any in-transit damage.

1.2 Visible Loss or Damage

If any loss or damage is discovered, note any discrepancies

on the delivery receipt and call the delivering carrier and

request that their representative perform an inspection. Do not

discard any of the packing material and do not move the ship-

ment from the receiving area.

1.3 Responsibility for Shipping Damage

For products shipped F.O.B. Marietta, Ohio, the responsi-

bility of Thermo Forma ends when the merchandise is loaded

onto the carrier’s vehicle.

On F.O.B. Destination shipments, Thermo Forma and the

carrier’s responsibility ends when your Receiving Department

personnel sign a free and clear delivery receipt.

Whenever possible, Thermo Forma will assist in settling

claims for loss or in-transit damage.

Section 2 - Installation and Start-up

2.1 Location

Locate the incubator in a draft-free area away from doors,

windows, and air conditioning or heating ductwork. To help

prevent microbial contamination, the incubator should also be

removed from areas of high personnel traffic.

Place the unit on a firm, level surface capable of support-

ing the unit with humidity reservoir water (Approximate weight

with water = 278 lbs or 125 kg).

Allow enough clearance on the left side of the unit for easy

access to view the reservoir water level, the filters and electrical

components. Adequate space is also required behind the incuba-

tor for electrical and gas connections.

2.2 Securing the Unit

Shipped with the shelf channels is a securing bracket and

mounting hardware. Retain these for future use, if not required

at this time.

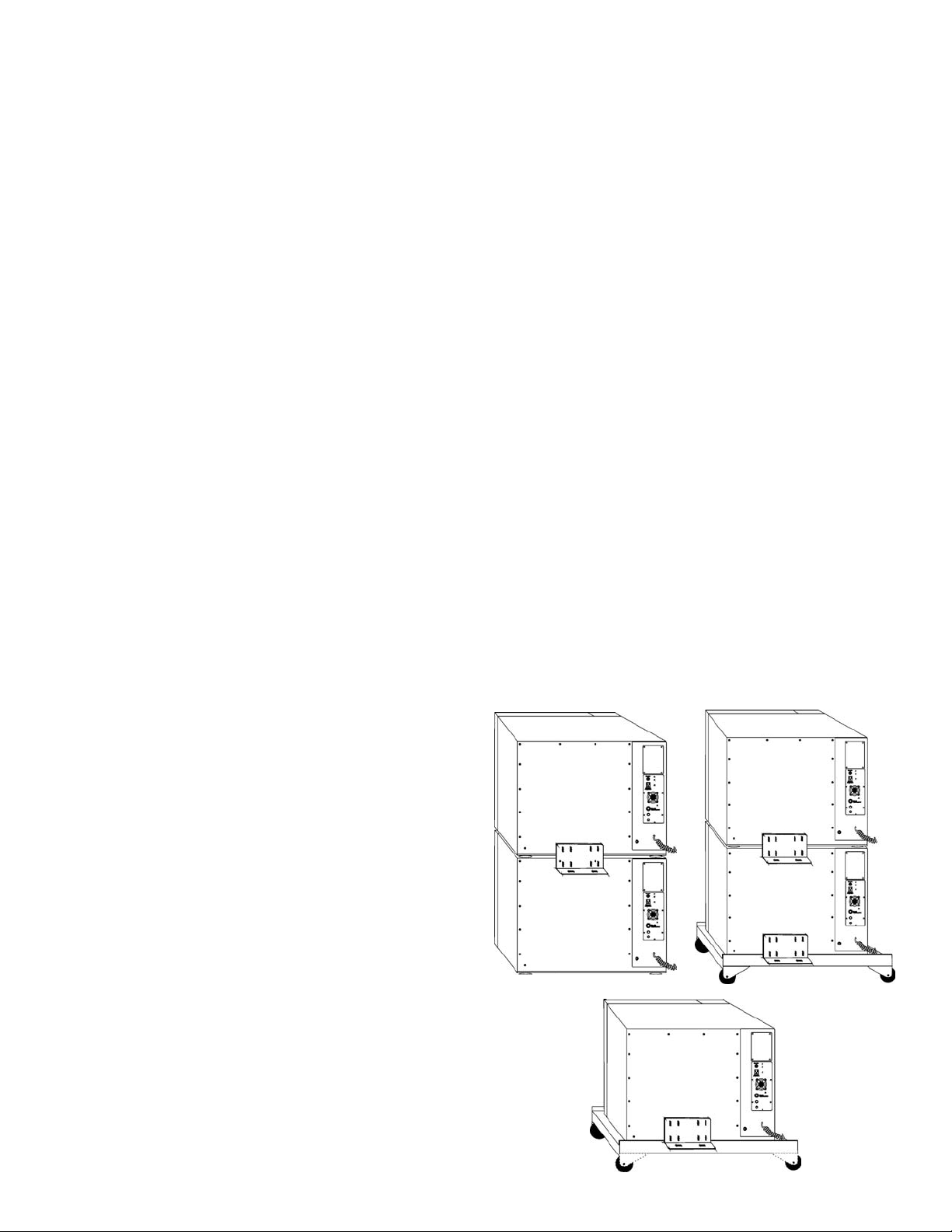

All 3033/3860 Series units require a securing bracket, with

the exception of a single unit standing on the floor. All incuba-

tors must be secured to each other if stacked, and/or to the cast-

er dolly when used. The securing brackets mount to the back of

the unit, using holes already drilled. See the illustrations below.

The screws in these locations can be discarded and the screws

and flatwashers included with the bracket installed in their

place.

Model 3033 and 3860 Series ____________________________________________________Installation and Start-Up

2 - 1

Units

stacked on

floor

Units

stacked on

a dolly

Single

unit on a

dolly

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2.3 Leveling

Before filling the humidity system, check the level of the

unit by placing a bubble-type level on one of the shelves.

Turning the leveling feet counterclockwise lengthens them,

clockwise shortens them. Level the unit front-to-back and left-

to-right.

To prevent injury to personnel and/or damage to

equipment, lock the inner glass door and secure

outer door before tipping unit to adjust leveling

feet.

Do not attempt to tilt the incubator without assis-

tance.

2.4 Connecting to Power

See the serial tag on the left side panel of the unit for elec-

trical specifications.

Connect the incubator to a grounded dedicated

circuit only.

The power switch is the mains disconnect device

for the incubator.

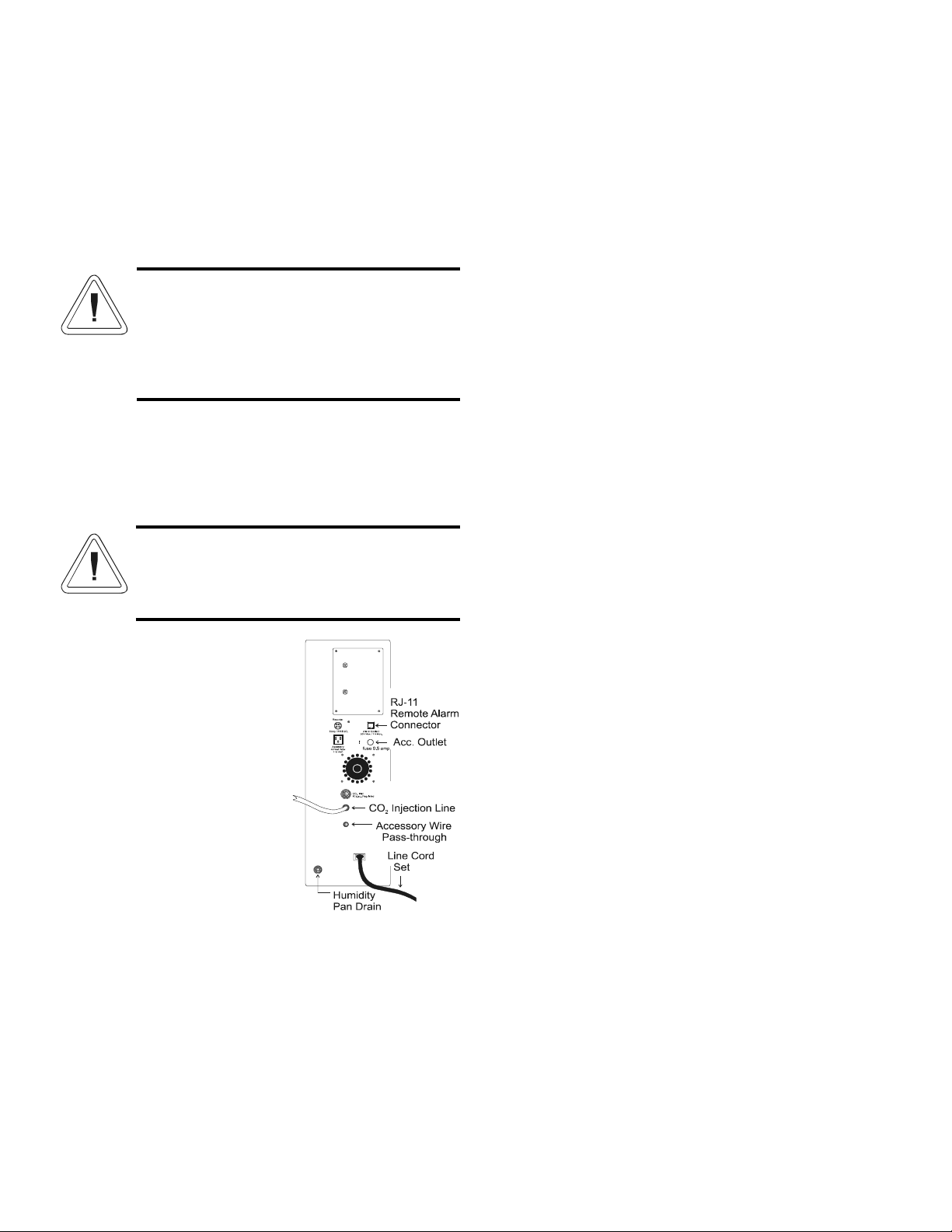

Plug the power cord provided

into the power connector and into a

grounded dedicated circuit. See

Figure 2-1.

2.5 Connecting the Water

Drain Line

A barb-type fitting on the back

of the incubator (beneath and to the

left of the power cord) is the drain

connection for the humidity reser-

voir. (Refer to Figure 2-1.)

Connect one end of the 1/4”

tubing supplied with the incubator to

the barb fitting. Place the other end of the tubing into a contain-

er capable of holding at least 1.5 gallons of water or route the

tubing to a suitable drain.

2.6 Preliminary Disinfecting

Disinfect all interior surfaces, including both door gaskets,

by washing with an appropriate laboratory disinfectant. Rinse

the surfaces with sterile distilled water. Repeat rinsing until all

of the disinfectant-detergent has been removed.

Remove the protective plastic film from the shelf brackets.

Wash the shelf brackets, diffuser pans, pilasters and shelves

with the laboratory disinfectant and rinse with sterile distilled

water.

It is recommended that the incubator run for 24 hours to

assure removal of all trace vapors.

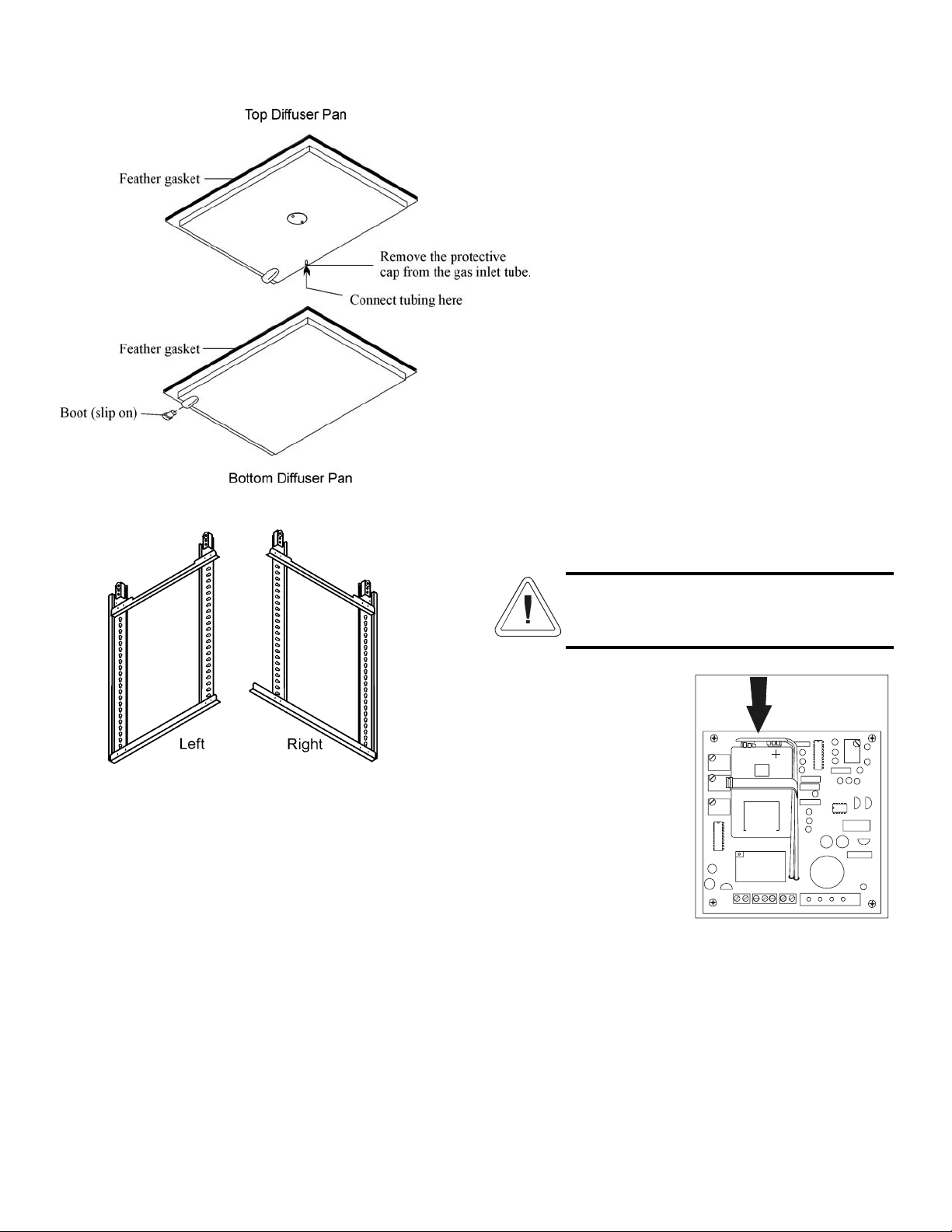

2.7 Installing the Diffuser Pans and Pilasters

1. Install the boots onto the top and bottom diffuser pans.

The diffuser pans are the flat, metal shelf-type assem-

blies that form the top and bottom of the incubator

chamber. (Refer to Figure 2-2).

2. The diffuser pans must be installed with the feather gas-

ket contacting the chamber top or bottom and the boots

matching the holes in the chamber wall.

3. Place the bottom diffuser pan into the incubator chamber

by positioning the left side first to align the boot with

the hole in the chamber wall.

4. Place the left and right pilasters into the chamber with

the vertical keyholes at the front (Figure 2-3). Allow the

top of the right pilaster to lay diagonally across the

chamber, resting upon the left pilaster. Pilasters are the

assemblies that hold the shelves inside the incubator

chamber.

5. Place top diffuser pan into the incubator chamber. While

supporting the top diffuser pan, raise the right pilaster up

until it is vertical.

6. Lock the retainers on the pilasters into place.

7. Remove the protective cap from the gas inlet tube locat-

ed on the bottom of the top diffuser pan. (Figure 2-2).

8. Connect the incoming CO2tubing to the gas inlet tube.

The CO2tubing is routed through the stopper in the back

wall of the incubator chamber.

2.8 Installing the Shelves

The shelves are easily installed and removed for cleaning.

1. Slide the rivets on the shelf channel into the keyholes on

the pilasters.

2. Slide the shelf into the channel.

Model 3033 and 3860 Series ____________________________________________________Installation and Start-Up

2 - 2

Figure 2-1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2.9 Connecting the CO2Supply

A main supply of liquid CO2is recommended. The liquid

CO2should be supplied from tanks without siphon tubes to

ensure that only CO2gas enters the incubator injection system.

It is also recommended that a two-stage pressure regulator with

indicating gauges be installed at the supply cylinder outlet.

The high pressure gauge should have an indicating range of

0 to 2000 PSIG to monitor tank pressure and the low pressure

gauge should have an indicating range of 0 to 30 PSIG to moni-

tor the input pressure to the incubator injection system. A suit-

able two-stage pressure regulator is available from Forma,

Stock #965010.

The CO2source must be regulated at a pressure level of 5

to 10 PSIG. Higher pressure levels may damage the CO2sys-

tem. Pressure levels lower than 5 PSI will not affect the opera-

tion of the incubator, but will increase the CO2recovery time.

a. To connect the CO2 supply:

The CO2supply fitting (labeled CO2 inlet) is locat-

ed on the back of the incubator. Securely attach the

vinyl CO2line to the barbed fitting and check the con-

nection for leaks.

2.10 Connecting the Temp/Alarm Back-Up

Battery

The temperature alarm back-up battery has been

disconnected to prevent it from discharging during

shipment. To connect the battery:

1. Turn the incubator off. Remove the Temperature

Alarm module.

2. Locate the 9-volt battery and its connector on the

back of the module (Figure 2-4).

3. Snap the battery connector onto the battery termi-

nals and reinstall the module.

Note: If the alarm sounds, turn the alarm switch to the Standby

position until the incubator is turned on.

Replace batteries with a rechargeable type only.

Dispose of the old battery in an environmentally

safe manner.

Model 3033 and 3860 Series ____________________________________________________Installation and Start-Up

2 - 3

Figure 2-2

Figure 2-3

SE NS O RRE C RE M A LM

ZER O

1 2 3 4 5

9 volt

Ni-C ad

Battery

Figure 2-4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2.11 Filling the Humidity Reservoir

For best operation of the incubator, sterilized distilled,

demineralized or de-ionized water should be used in the humid-

ity reservoir. Water purity should be in the resistance range of

50K to 1M Ohm/cm, or a conductivity range of 20.0 to 1.0

uS/cm. Refer to ASTM Standard D5391-93 or D4195-88 for

measuring water purity.

Distillation systems, as well as some types of reverse

osmosis water purity systems, can produce water in the quality

range specified. Tap water is not recommended as it may con-

tain chlorine, which can deteriorate the stainless steel. Tap

water may also have a high mineral content, which would pro-

duce a build-up of scale in the reservoir. High purity, ultra pure

or milli-q water is not recommended as it is an extremely

aggressive solvent and will deteriorate the stainless steel. High

purity water has a resistance of above 1M Ohm to 18M

Ohm/cm. Even high purity water can contain bacteria and

organic contaminants. Water should always be sterilized or

treated with a decontaminant, safe for use with stainless steel as

well as safe for the product, prior to being introduced into the

humidity reservoir.

Distilled or de-ionized water used in the humidity

reservoir must be within a water quality resistance

range of 50K to 1M Ohm/cm to protect and pro-

long the life of the stainless steel. Use of water

outside the specified range will decrease the oper-

ating life of the unit and may void the warranty.

The humidity reservoir fill port fitting is located on the

upper left side of the incubator. A viewing window built into

the side panel allows the reservoir bottle water level to be seen.

1. Remove the brass plug from the fill port using a 1/4”

Allen wrench.

2. Attach the threaded fitting, tubing and funnel to the fill

port.

3. Add 3 liters of sterile distilled water to the reservoir. If

the humidity reservoir is overfilled, water will escape

through the overflow drain.

Note: With the power switch ON, the Add Water alarm may

activate if the reservoir is not filled within 10 minutes. Silence

the alarm by pressing any “sensi-touch” key.

No modification to the Add Water system should

be made, such as attaching to a pressurized sup-

ply, without first consulting the Forma Service

department. The water valve is rated to 5 PSIG.

Pressure in excess of this may damage or override

the valve and cause flooding of the incubator

chamber.

2.12 Setting the Over/Under Temperature Safety

(Refer to Figure 2-5)

The over/under temperature safety settings are made on the

Temperature Alarm/Monitor control panel. Power to the incuba-

tor must be turned on.

To make these adjustments, a screwdriver is provided. Pull

on the black knob located to the right of the sample port on the

power control panel. The knob is the handle of the

screwdriver.

Refer to the control panel illustration in Figure

2-5 and look for this screwdriver symbol:

To set the overtemperature safety limit:

1. Slide the Set Hi/Actual/Set Low switch on the

Temperature Alarm Monitor to the Set Hi position.

2. Using the screwdriver turn the adjustment screw labeled

Set Hi until the desired high limit temperature is dis-

played.

Note: The incubator will likely overshoot 2 or 3°C on initial

start-up. The Set Hi should be set to allow for this. It may later

be set closer to the setpoint.

To set the under temperature safety limit:

1. Slide the switch to the Set Lo position and turn the Set

Lo adjustment screw until the desired low limit tempera-

ture is displayed on the LCD display.

Note: On initial start-up, the Set Lo should be set below ambi-

ent to avoid an alarm condition. When the incubator has stabi-

lized, the Set Lo may be adjusted closer to setpoint tempera-

ture. the high and low setpoint temperature limits should not be

set within 0.2°C of the desired temperature to avoid nuisance

alarms.

2. Return the slide switch to the center Actual position to

display the chamber temperature.

Model 3033 and 3860 Series ____________________________________________________Installation and Start-Up

2 - 4

Figure 2-5

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2.13 Setting the CO2

When setting the CO2, the incubator power must be on and

the key switch set to Program. Refer to the power control mod-

ule illustration in Figure 2-6 and the CO2control module illus-

tration, Figure 2-7.

1. With the Program/Run key switch turned to Program,

press the inverted Y touch button on the CO2control

panel until the word SET appears on the left side of the

CO2display.

2. Using the up arrow or down arrow touch buttons, set the

CO2concentration percentage. The CO2may be set in

0.1% increments within a range of 0% to 20%.

3. When the CO2concentration has been selected, press the

inverted Y button again to return to the display mode.

(SET will disappear from the window).

4. When programming is complete, turn the Program/Run

key switch to Run and remove the key to secure the set-

points.

2.14 Setting the Relative Humidity

1. With the Program/Run key switch turned to Program,

press the inverted Y touch button on the RH Control

panel until the word SET appears on the left side of the

display.

2. Using the arrow keys, increase or decrease the setpoint

until the desired humidity percentage appears. The RH

may be set in 1% increments from 5% above ambient to

98%.

3. When the RH level has been selected, press the inverted

Y button. (SET will disappear from the window).

4. When programming is complete, return the Program/Run

key switch to Run and remove the key to protect the set-

points from unauthorized tampering.

Note: The incubator will not attempt to control the RH until the

chamber temperature is within 1°C of setpoint. During this time

the value displayed in the RH control panel will be “—”. The

RH recorder output will be the RH setpoint value.

2.15 Setting the Chamber Temperature (Refer to

Figure 2-9)

Note: The Temperature Control panel displays the temperature

setpoint. The Temperature Alarm/Monitor displays the actual

chamber temperature.

1. Turn the Program/Run key switch to Program and press

the arrow keys to increase or decrease the temperature

setpoint.

Note: The temperature may be set in 0.1°C increments within a

range of 4°C above ambient to +45°C.

2. When the temperature setpoint has been selected, return

the key switch to Run and remove the key to secure the

setpoints.

2.16 Connecting to the Recorder Jack

A recorder jack,

capable of an input signal

from 0 to 999mV, is pro-

vided for connecting elec-

tronic recorders. The

TEMP/RH/CO2jack is

located on the back panel

of the incubator. Refer to

Figure 2-1 for the jack

location and Figure 2-10 for the pin descriptions.

Model 3033 and 3860 Series ____________________________________________________Installation and Start-Up

2 - 5

Figure 2-6 Figure 2-7

Figure 2-8 Figure 2-9

Figure 2-10

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

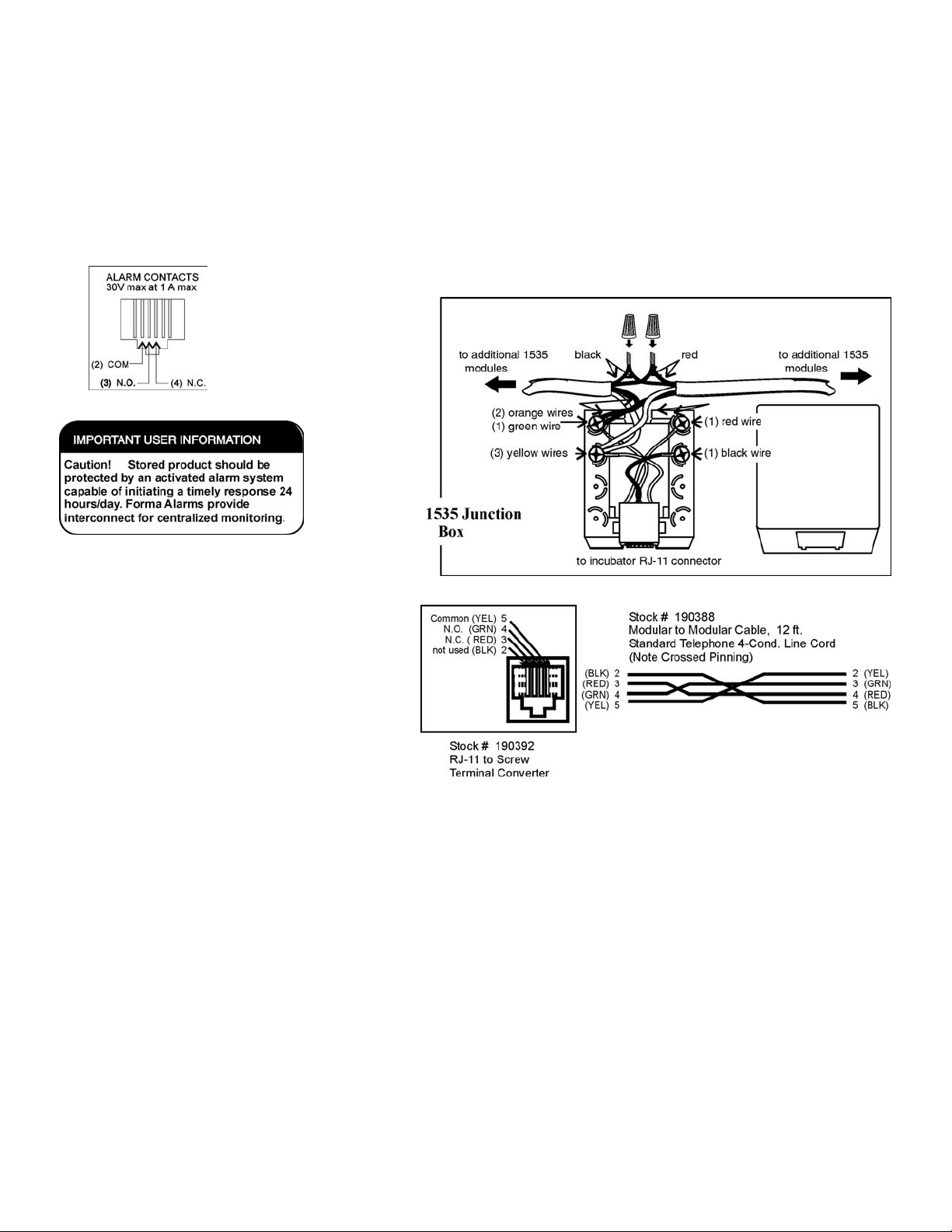

2.17 Connecting to the Remote Alarm Contacts

An internal DPDT relay is provided on the Temperature

Alarm/Monitor to monitor alarms and is connected to an RJ-11

(telephone style) jack on the back of the cabinet. Figure 2-10

identifies the pin contacts, Figure 2-1 shows the location of the

Remote Alarm Connector.

Figure 2-11

The remote contacts are “dry” contacts, rated at

30V, 1A maximum.

A modular to modular cable (Forma Stock No.

190388) and an RJ-11 telephone style terminal con-

verter (Stock No. 190392) or equivalent may be used

to convert the remote alarm output to a screw terminal

connection. Refer to Figure 2-12.

Model 3033 and 3860 Series ____________________________________________________Installation and Start-Up

2 - 6

Figure 2-12

2.18 Convenience/Accessory Outlet

An electrical outlet is located on the back of the incubator,

providing 115VAC 0.35A max for lights and accessories. The

maximum allowable leakage current for the product plugged

into the outlet is 3 mA. The outlet is protected by an adjacent

fuse 0.5 amp, 250V, T (time-lag), Forma P/N 230120. Refer to

the electrical schematic in Section 9 of this manual.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Section 3 - Operation

3.1 Description

The Steri-Cult Series CO2incubator provides perfect cul-

ture conditions in a state-of-the-art, microprocessor controlled

incubator. During operation, the chamber air is drawn through

the top diffuser pan and into the chamber outlet duct where it

passes over a temperature probe. The temperature controller

then cycles the heaters which surround the incubator chamber.

Next, the air passes through the blower and onto a micro-

biological filter. The filter scrubs the circulating air, trapping

spores and other airborne contaminants. The “scrubbed” air

exits the filter and continues along the sensing/conditioning

path. A sample of this air is routed through the infrared CO2

sensing unit where precise CO2levels are monitored.

Periodically, the Air Inject solenoid opens, allowing fil-

tered outside air to pass across the IR sensor. This serves as an

Auto-Zero to eliminate possible sensor or electrical component

drift. During this time, the CO2inject solenoid will not cycle.

Signals from the IR sensor are sent to the CPU Board where

they are compared to the CO2setpoint. If a difference exists

between the actual value and the setpoint, the microprocessor

computes the appropriate solenoid on/off times. This creates a

proportional CO2controller when the actual value is within 1%

of setpoint.

The recirculated chamber air continues into the humidity

reservoir. The air passes below the water level and is humidi-

fied as it bubbles through the water. The microprocessor looks

at the air temperature and selected humidity level and calculates

the necessary water temperature required to obtain the desired

RH. Water in the reservoir is heated by an external heater and

the temperature is monitored by an immersed temperature

probe.

Note: The Steri-Cult incubators are designed to minimize the

amount of condensation on the glass door. However, the units

are not condensate-free, specifically if the chamber interior is

operated above an absolute RH average of 85%. It is normal to

have a small amount of condensate form across the bottom and

in the corners of the glass door if the RH setpoint is equal to or

greater than 90% RH.

No attempt to control RH will occur until the chamber

temperature is within 1°C of setpoint. During this time the

value displayed in the RH Control module will be “—”. The

RH recorder output will be the RH setpoint value.

The humidified and CO2enhanced air then passes across

another heater which is controlled by a third temperature probe.

The purpose of this heater is to restore lost heat to the air before

entering the chamber.

Air enters the chamber beneath the bottom diffuser pan and

is forced up through the holes into the chamber.

When the outer door is opened, power to the heaters, CO2

inject solenoid and humidity reservoir is interrupted.

When the outer door is closed, power is restored.

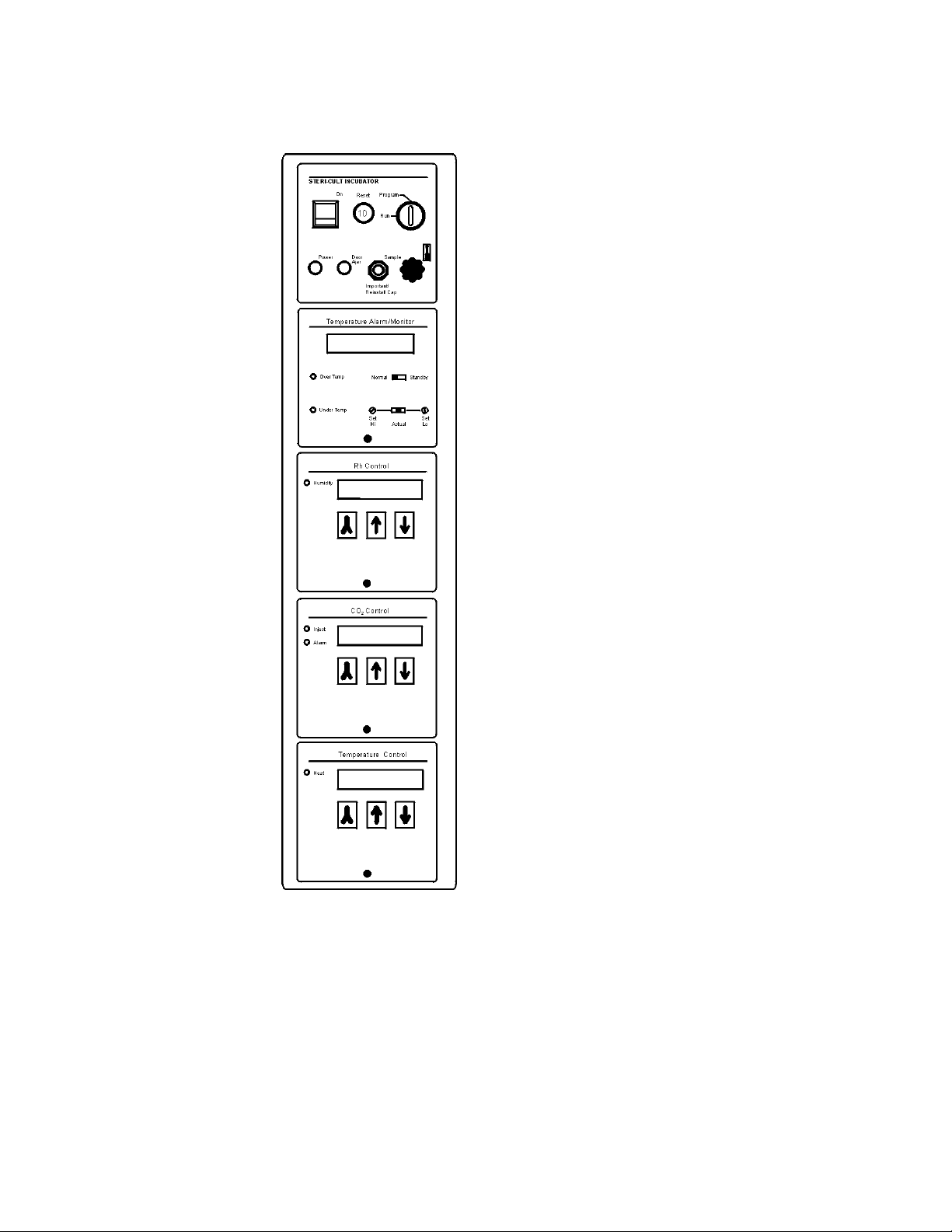

3.2 Power Control Panel (Figure 3-1)

The Power Control Panel houses the Main Power switch,

Program/Run key switch, Door Ajar light (red), Sample Port

and Adjustment Screwdriver.

a. Main Power Switch

The Main Power switch controls all electrical power to the

incubator. The switch must be on for any of the incubator sys-

tems to be functional.

b. Program/Run Key Switch

The Program/Run key switch determines the operating

mode of the incubator.

When the switch is set to Program, the operator may set

the chamber temperature, relative humidity and CO2.

When the switch is set to Run, the programmed setpoints

are locked. The setpoints may be viewed but not changed.

c. Door Ajar Light

The red Door Ajar light warns that the outer door is open

or has not been securely closed.

When the Door Ajar light is on, power to the heaters and

the CO2injection solenoid is interrupted.

d. Sample Port

The Sample Port is used to draw a sample of chamber

atmosphere so CO2content may be measured by an independent

source.

For proper operation and to prevent CO2loss, the

sample port must be capped when not in use.

Model 3033 and 3860 Series _______________________________________________________________Operation

3 - 1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

3.3 Temperature Alarm/Monitor

The Temperature

Alarm/Monitor contains a liquid

crystal display (LCD), red

Overtemp and red UnderTemp

lights, a Normal/Standby alarm

switch, Set Hi and Set Lo adjust-

ment screws and a three-position

selector switch.

a. LED Temp Display

The LCD display will show

actual chamber temperature, high

alarm limit or low alarm limit,

depending upon the position of

the three position switch.

b. High and Low Temp

Limit Switch

The High and Low tempera-

ture limits are set by placing the

three position switch to Set Hi or

Set Lo and turning the proper

adjustment screw until the desired

temperature appears in the LCD

window. When the switch is

returned to Actual the LCD dis-

plays the actual chamber tempera-

ture.

c. Temp Alarm Lights,

Audible Alarm and

Normal/Standby Switch

If the chamber temperature

exceeds the programmed high or

low limits, the appropriate red

LED lights and an audible alarm

will sound.

The audible alarm is silenced by turning the Normal/

Standby switch to the Standby position. The red LED will

remain lit until the alarm condition has been corrected.

Note: The alarm will ring back when the alarm condition has

been corrected as a reminder to turn the Normal/Standby switch

to the Normal position.

3.4 CO2Control Panel

The CO2Control Panel contains an amber LED inject light,

a red alarm light, an LCD readout and three “Sensi-Touch”

touch pad buttons.

a. CO2LCD Display

The LCD readout displays either the actual chamber CO2

content or the CO2setpoint. Touching the inverted Y button

selects the mode of the display.

When the unit is in the Set mode the word SET appears on

the left side of the display. With the key switch turned to

Program, the CO2setpoint is set by pressing the up arrow or

down arrow buttons. Touching the inverted Y button again will

change the display to read the actual chamber CO2.

b. CO2Inject Light

When CO2is being injected, the amber Inject light will be

lit.

c. CO2Alarm Light and Audible Alarm

If the incubator CO2concentration deviates from the set-

point by +/- 1% (nominal) for more than 30 minutes, the red

LED alarm light will be activated and a pulsing audible alarm

will sound.

Pressing any of the nine Sensi-Touch buttons on the control

panel will silence the alarm and turn off the red alarm light.

If the alarm is not silenced, and the actual CO2concentra-

tion returns to within +/- 1% of the setpoint, the audible alarm

will turn off, but the alarm light will stay lit until a touch pad

button is pressed.

A CO2setpoint of 00.0 will disable the deviation alarm.

3.5 Auto Zero Function

The CO2Auto Zero Function compensates for any drift in

the CO2sensing system.

The Auto Zero solenoid activates approximately every four

hours to allow room air supplied by the air pump to enter the

CO2sensor cell. (The reading from the room air is considered

to be 0% CO2.) The calibration value is automatically adjusted

to make the actual reading 0%.

Note: The “%” indicator in the %CO2 display is turned off dur-

ing the Auto Zero cycle, which takes 3-4 minutes.

Model 3033 and 3860 Series _______________________________________________________________Operation

3 - 2

Figure 3-1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

3.6 Auto Zero Alarm

If the calibration correction value is larger than that of a

typical instrument drift, it is considered an error and the calibra-

tion value will not be changed.

This indicates a problem such as elevated ambient,

CO2component failure, plugged lines, electrical

noise, etc. Therefore, the incubator will continue

to use the last correct zero value.

Four consecutive errors are considered an alarm condi-

tion. The %CO2 in the CO2display will then flash and the audi-

ble alarm will sound.

Note: If a subsequent auto zero calibration value is within the

range, the alarms will be turned off.

A CO2setpoint of 00.0 will disable the Auto Zero alarm.

3.7 RH Control Panel

The Relative Humidity (RH) Control Panel contains an

amber LED, an LCD readout and three Sensi-Touch buttons.

a. Relative Humidity Liquid Crystal (LCD) Display

The LCD readout displays either the actual chamber RH or

the RH setpoint. Touching the inverted Y button selects the dis-

play mode.

When the inverted Y button is pressed, the word SET

appears on the left side of the LCD window. With the key

switch turned to Program, the RH level can be set by touching

the up arrow or the down arrow. Pressing the inverted Y button

again changes the display to read the chamber humidity.

If the humidity reservoir runs low on water a steady audi-

ble alarm will sound and the symbol H2O will flash in the LCD

window. Pressing any of the nine Sensi-Touch buttons on the

control panel will silence the alarm for 10 minutes.

When a low water alarm occurs, add 3 liters of sterile dis-

tilled water to the humidity reservoir. Follow the instructions in

Section 2.10.

Note: No humidification will take place until the chamber tem-

perature is within 1° of the temperature setpoint. During this

time, the LCD reading will default to two dashes (“—”), and

the RH recorder output will be the RH setpoint value.

If no humidity control is desired, a 00.0 setpoint should be

selected. This will cause the display to show “—” and will also

defeat the H20 alarm.

b. Humidity Indicator Light

The amber LED will light as the unit calls for more mois-

ture to maintain the humidity setpoint.

3.8 Temperature Control Panel

The Temperature Control Panel contains an amber LED, an

LCD and three Sensi-Touch buttons.

a. Temperature LCD Display

The LCD readout displays the selected temperature set-

point.

Note: On this module the inverted y button performs no func-

tion.

With the key switch turned to Program, the temperature is

set by pressing the up arrow or down arrow buttons.

Note: This module displays setpoint - not actual temperature.

b. Heat Indicator Light

The amber Heat LED lights when the temperature con-

troller calls for more heat in the chamber.

Model 3033 and 3860 Series _______________________________________________________________Operation

3 - 3

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Millcreek Road, Box 649 Marietta, Ohio 45750 USA 740-373-4763

PREVENTIVE MAINTENANCE

Incubators

Your Thermo Forma equipment has been thoroughly tested and calibrated before shipment. Regular preventive maintenance is

important to keep your unit functioning properly. The operator should perform routine cleaning and maintenance on a regular basis.

For maximum performance and efficiency, it is recommended the unit be checked and calibrated periodically by a qualified service

technician.

The following is a condensed list of preventive maintenance requirements. See the specified section of the instruction manual for

further details.

Thermo Forma has qualified service technicians, using NIST traceable instruments, available in many areas. For more information on

Preventive Maintenance or Extended Warranties, please contact us at the number listed below.

Cleaning and calibration adjustment intervals are dependent upon use, environmental conditions and accuracy required.

Tips for all incubators:

# Do NOT use bleach or any disinfectant that has high chloros

# Use sterile, distilled or demineralized water.

# Avoid spraying cleaner on the CO2 sensor.

# Do not use powdered gloves for tissue cultures.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Incubators ______________________________________________________________________________ Preventive Maintenance

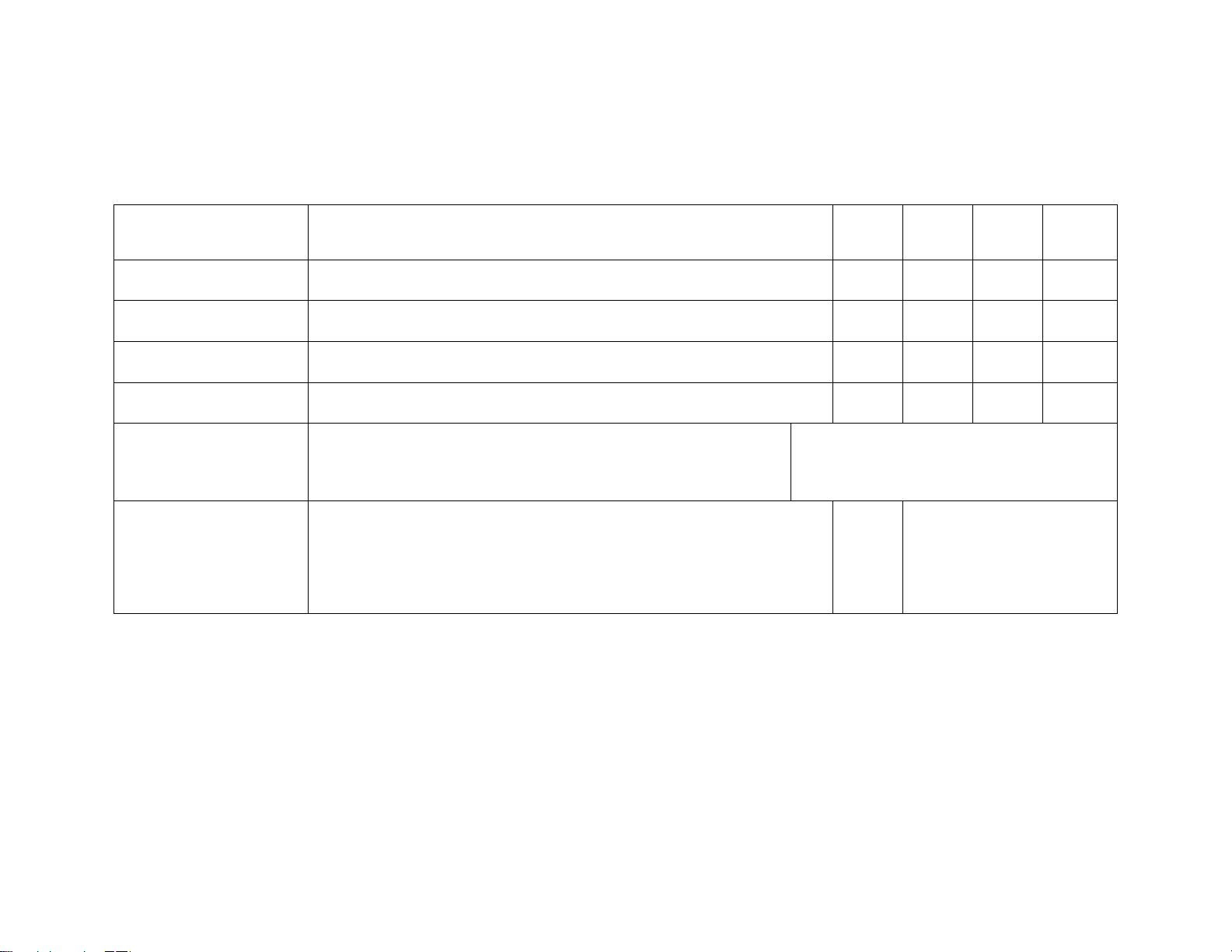

Preventive Maintenance for 3033 and 3860 Series Incubators

Refer to Manual Section Action Daily Weekly Yearly Every 2

Years

-- Check CO2 tank levels. !

-- Inspect door latch, hinges and door gasket seal. !

5.2 * Verify and document CO2, temperature and humidity calibration !

5.16 * Verify and document Auto Zero, at the minimum. !

4.1, 4.4 Perform a complete decontamination procedure. Wipe down interior,

shelves and side panels with disinfectant. Drain the water reservoir bottle

and rinse with disinfectant. Rinse all well with sterile distilled water.

Between experiments

More frequent decontamination may be required,

depending on use and environmental conditions

5.5 * Change HEPA, gas, water and air filters, as applicable !

More frequent changes may be

required, depending on use

and environmental conditions

* Qualified service technicians only

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Section 4 - Routine Maintenance

4.1 Disinfecting the Incubator Interior

The incubator can be disinfected in about 30 minutes using

an appropriate disinfectant diluted with sterile distilled water

(50K to 1M Ohm/cm) per manufacturer’s instructions.

Do not use strong alkaline or caustic agents.

Stainless steel is corrosion resistant, not corrosion

proof. do not use solutions of sodium hypochlorite

(bleach), as they may cause pitting and rust.

1. Turn the power switch off.

2. Remove the shelves, pilasters and diffuser pans and

clean all interior surfaces with disinfectant solution.

3. Rinse surfaces at least twice with sterile distilled water,

or until all of the disinfectant-detergent has been

removed.

4. Thoroughly clean the inner door gasket.

5. Clean the inside of the glass door with disinfectant solu-

tion and rinse with sterile distilled water.

6. Wash the shelves and rinse with sterile distilled water.

7. Reinstall the diffuser pans, pilasters and shelves. (See

Sections 2.6 and 2.7 if necessary.)

8. Turn the power switch on.

After decontamination, operate the unit for 24 hours to

remove trace vapors from the incubator chamber.

4.2 Cleaning the Cabinet Exterior

The incubator exterior may be cleaned with a general-use

laboratory disinfectant.

4.3 Cleaning Stainless Steel

Use the mildest cleaning procedure that will do the job

effectively. To insure maximum effectiveness and to avoid mar-

ring the surface, always rub in the direction of the finish polish

lines. Rinse the surface thoroughly and wipe the surface dry.

The use of aromatic solvents is not recommended for

cleaning cabinet interiors as residues could cause contamination

of the cabinet environment.

Do not use strong alkaline or caustic agents. Stainless steel

is corrosion-resistant, not corrosion-proof. Do not use solutions

of sodium hypochlorite (bleach) as they may cause pitting and

rust.

4.4 Draining the Humidity Reservoir

A drain valve has been provided for draining of the humid-

ity system.

1. Verify that there is a hose connected to the drain fitting

on the back of the incubator. Route the line to a large

container or suitable drain.

2. Turn the incubator on.

3. Remove the humidity reservoir fill port plug located on

the upper left side of the incubator using a 1/4” Allen

wrench. (Refer to Figure 4-1)

Model 3033 and 3860 Series ______________________________________________________________Maintenance

4 - 1

4. Remove the cover plate located directly beneath the

Temperature Control Module. The cover is released by

pulling the two black plastic locking pins. (Refer to

Figure 4-2)

Figure 4-2

Drain Valve Access Panel

Figure 4-1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

This manual suits for next models

3

Table of contents

Other Thermo Forma Accessories manuals