Thermo Forma 370 Series Operating instructions

Models:

370/371 and 380/381

Steri-Cycle Incubator

Direct Heat with Sterilization Cycle

Operating and Maintenance Manual

Manual No: 7000370 Rev. 2

Model 370 and 380 Series _______________________________________________________________________________

i

If the incubator is not used in the manner speci-

fied in this operating manual, the protection pro-

vided by the equipment design may be impaired.

Read This Instruction Manual.

Failure to read, understand and follow the instructions in

this manual may result in damage to the unit, injury to operat-

ing personnel, and poor equipment performance.

CAUTION! All internal adjustments and maintenance must

be performed by qualified service personnel.

Refer to the serial tag on the back of this manual.

The material in this manual is for information purposes only.

The contents and the product it describes are subject to change

without notice. Thermo Forma makes no representations or war-

ranties with respect to this manual. In no event shall Thermo

Forma be held liable for any damages, direct or incidental, aris-

ing out of or related to the use of this manual.

Model Sensor* Voltage**

370 T/C 115

371 T/C 230

380 IR 115

381 IR 230

*T/C is a thermal conductivity sensor. IR is an infrared sensor.

**All units are 50/60 Hz.

MANUAL NUMBER 7000370

2 20276/IN-2970 9/24/01 Clarified Step 2 of Section 4.4 ccs

1 19948/IN-2947 9/10/01 Updated CO2inlet labels, 200-9 exploded parts drawing ccs

-- -- 6/28/01 Updates per J. Leach

(art & list on page 5-4 and reference to 4-3, not 4-4 in Alarm section) ccs

0 -- 3/1/01 Original manual ccs

REV ECR/ECN DATE DESCRIPTION By

Contains Parts and Assemblies

Susceptible to Damage by

Electrostatic Discharge (ESD)

CAUTION

Model 370 and 380 Series _________________________________________________________________________Warnings

ii

Important operating and/or maintenance instructions. Read the accompanying text carefully.

Potential electrical hazards. Only qualified persons should perform procedures associated with this symbol.

Hot surface(s) present which may cause burns to unprotected skin or to materials which may be damaged by elevated

temperatures

√ Always use the proper protective equipment (clothing, gloves, goggles, etc.)

√ Always dissipate extreme cold or heat and wear protective clothing.

√ Always follow good hygiene practices.

√ Each individual is responsible for his or her own safety.

Model 370 and 380 Series ___________________________________________________________________________Service

iii

Model 370 and 380 Series __________________________________________________________________Table of Contents

iv

Table of Contents

Section 1 - Installation and Start-up . . . . . . . . . . . . . .1 - 1

1.1 Incubator Components . . . . . . . . . . . . . . . . . . . . . . .1 - 1

1.2 Control Panel Keys, Displays and Indicators . . . . . .1 - 1

1.3 Operation of the Keypad . . . . . . . . . . . . . . . . . . . . .1 - 2

1.4 Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 2

1.5 Installing the Incubator . . . . . . . . . . . . . . . . . . . . . .1 - 2

a. Choosing the Location . . . . . . . . . . . . . . . . . . . .1 - 2

b. Stacking the Incubators . . . . . . . . . . . . . . . . . . .1 - 3

c. Preliminary Cleaning and Disinfecting . . . . . . . .1 - 4

d. Installing the Shelves . . . . . . . . . . . . . . . . . . . . .1 - 4

e. Installing the Access Port Filter and CO2Sensor Cover

Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 4

f. Installing the HEPA Filter . . . . . . . . . . . . . . . . . .1 - 4

g. Installing the Air Sample Filter . . . . . . . . . . . . . .1 - 5

h. Leveling the Unit . . . . . . . . . . . . . . . . . . . . . . . .1 - 5

i. Connecting the Unit to Electrical Power . . . . . . .1 - 5

j. Filling the Humidity Pan . . . . . . . . . . . . . . . . . . .1 - 5

k. Connecting the CO2Gas Supply . . . . . . . . . . . . .1 - 6

1.6 Incubator Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 6

a. Setting the Operating Temperature . . . . . . . . . . .1 - 6

b. Setting the Overtemp Setpoint . . . . . . . . . . . . . .1 - 6

c. Setting the CO2Setpoint . . . . . . . . . . . . . . . . . . .1 - 7

Section 2 - Calibration . . . . . . . . . . . . . . . . . . . . . . . . .2 - 1

2.1 Calibration Mode . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 1

a. Calibrating the Temperature . . . . . . . . . . . . . . . .2 - 1

b. Calibrating Thermal Conductivity CO2System . .2 - 1

c. Calibrating the Infrared CO2System . . . . . . . . . .2 - 1

d. Calibrating Relative Humidity . . . . . . . . . . . . . .2 - 2

Section 3 - Configuration . . . . . . . . . . . . . . . . . . . . . . .3 - 1

3.1 Configuration Mode . . . . . . . . . . . . . . . . . . . . . . . .3 - 1

a. Turning the Audible Alarm ON/OFF . . . . . . . . .3 - 1

b. New HEPA Filter . . . . . . . . . . . . . . . . . . . . . . . .3 - 1

c. Setting the REPLACE HEPA filter reminder . . .3 - 1

d. Setting an Access Code . . . . . . . . . . . . . . . . . . .3 - 1

e. Setting a Low Temp Alarm Limit . . . . . . . . . . . .3 - 1

f. Enabling Low Temp Alarm to Trip Contacts . . . .3 - 2

g. Setting a Low CO2Alarm Limit . . . . . . . . . . . . .3 - 2

h. Setting a High CO2Alarm Limit . . . . . . . . . . . . .3 - 2

i. Enabling CO2Alarms to Trip Contacts . . . . . . . .3 - 2

j. Setting New Zero Number for T/C CO2Sensors . .3 - 2

k. Setting New Span Number for T/C CO2Sensors .3 - 2

l. Setting a Low RH Alarm Limit . . . . . . . . . . . . . .3 - 3

m. Enabling RH Alarms to Trip Contacts . . . . . . . .3 - 3

n. Enabling Temp/RH to be Displayed . . . . . . . . . .3 - 3

o. Selecting a Primary Tank w/ Gas Guard Option .3 - 3

p. Enabling the Gas Guard System . . . . . . . . . . . . .3 - 3

q. Setting a RS485 Communications Address . . . . .3 - 3

Section 4 - Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 1

4.1 Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 1

4.2 Temperature Controller Failure . . . . . . . . . . . . . . . . .4 - 1

4.3 Sensor Fault Alarms . . . . . . . . . . . . . . . . . . . . . . . .4 - 1

Section 5 - Routine Maintenance . . . . . . . . . . . . . . . . .5 - 1

5.1 Disinfecting the Incubator Interior . . . . . . . . . . . . . .5 - 1

5.2 Cleaning the Cabinet Exterior . . . . . . . . . . . . . . . . . .5 - 1

5.3 Cleaning the Glass Doors . . . . . . . . . . . . . . . . . . . .5 - 1

5.4 Cleaning the Humidity Pan . . . . . . . . . . . . . . . . . . .5 - 2

5.5 Reversing the Door Swing . . . . . . . . . . . . . . . . . . . .5 - 2

5.6 HEPA Filter Maintenance . . . . . . . . . . . . . . . . . . . . .5 - 3

5.7 Replacing the Power Fuses . . . . . . . . . . . . . . . . . . .5 - 3

5.8 Replacing Air Sample Filter . . . . . . . . . . . . . . . . . .5 - 3

5.9 The Electronics Section . . . . . . . . . . . . . . . . . . . . .5 - 3

a. Major Components . . . . . . . . . . . . . . . . . . . . . . . .5 - 4

5.10 Sterilization Cycle . . . . . . . . . . . . . . . . . . . . . . . . .5 - 5

Section 6 - Factory Options . . . . . . . . . . . . . . . . . . . . .6 - 1

6.1 Connections to External Equipment . . . . . . . . . . . . .6 - 1

a. Connecting the Remote Alarm Contacts . . . . . . .6 - 1

b. Connecting the RS485 Interface . . . . . . . . . . . . .6 - 1

c. Connecting the Analog Output Boards . . . . . . . .6 - 1

6.2 CO2Gas Guard . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 2

a. Connecting the CO2Gas Supplies . . . . . . . . . . . .6 - 2

b. Activating the Gas Guard . . . . . . . . . . . . . . . . . .6 - 2

c. Operation of the CO2Gas Guard . . . . . . . . . . . . .6 - 3

6.3 Humidity Readout . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 3

a. Factors Affecting Humidity Level in Chamber . .6 - 3

b. Accuracy of the Humidity Readout . . . . . . . . . . .6 - 3

Section 7 - Specifications . . . . . . . . . . . . . . . . . . . . . . . .7 -1

Section 8 - Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . .8 - 1

Section 9 - Electrical Schematics . . . . . . . . . . . . . . . . .9 - 1

Section 10 - Warranty Information . . . . . . . . . . . . .10 - 1

Section 1 - Installation and Start-up

1.1 Incubator Components

Figure 1-1

Model 370 Series Incubator

• Outer Door - Reversible to opposite swing, see Section 5.5

• Inner Door - Reversible to opposite swing, see Section 5.5

• Chamber Gas Sample Port - Used for sampling chamber

CO2content using a FYRITE or similar instrument.

• Main Power Switch

• Control Panel - Keypad, Displays & indicators (Figure 1-2)

• Leveling Legs - Used to level the unit

• Power Switch - Mains disconnect

• Sterilization Cycle Button - Switch to initiate sterilization

cycle

Note: The incubators are stackable. See Section 1.5.b.

1.2 Control Panel Keys, Displays and Indicators

(See Figure 1-2)

1. Silence - Silences the audible alarm.

2. Alarm Indicator - Light pulses on/off during an alarm

condition in the cabinet.

3. Mode Select Switch - Used to select Run, Setpoints,

Calibration and System Configuration Modes.

4. Message Center - Displays system status.

5. Mode Select Indicators -

Run: Run Menu

Set: Set Points Menu

Cal: Calibrate Menu

Config: Configuration Menu

6. Up and Down Arrows - Increases or decreases the num-

ber values, toggles between choices.

7. Enter - Stores the value into computer memory.

8. Heat Indicator - Lights when power is applied to the

heaters.

9. Temp Display - Program to display temperature continu-

ously, RH continuously (with RH option), or toggle

between temperature and humidity (with RH option).

See Section 3.1, Configuration.

10. Scroll for Parameters Arrows - Moves the operator

through the choices of the selected mode.

11. CO2Inject Indicator - Lights when CO2is being injected

into the incubator.

12. % CO2 Display - Displays CO2percentage continuously.

Model 370 and 380 Series ____________________________________________________________Installation and Start-Up

1 - 1

Silence Mode SYSTEM OK

36.9

4.9

Enter

Run Set Cal Config Heat Temp

Inject % CO 2

Scroll for Parameters

2

3

4

56

7

8 9

11

10 12

Figure 1-2, Control Panel

1.3 Operation of the Keypad

The Model 370 Series incubator has four

basic modes which allow incubator setup: Run,

Setpoints, Calibration and System Configuration.

Run is the default mode which the incubator will normally

be in during operation.

Set is used to enter system setpoints for incubator opera-

tion.

Calibration is used to calibrate various system parameters.

Configuration allows for custom setup of various options.

The chart below shows the selections under each of the

modes.

1T/C units only Base Unit Displays

2IR units only Option Displays

*T/C units only

Scroll for Parameters Arrows: Steps the

operator through the parameters of SET, CAL

and CONFIG Modes. The right arrow goes to

the next parameter, the left arrow returns to the

previous parameter.

Up Arrow: Increases or toggles the parameter value

that has been selected in the SET, CAL, and CONFIG

Modes.

Enter: Must press Enter key to save to memory all

changed values.

Down Arrow: Decreases or toggles the parameter

values that have been selected in the SET, CAL and

CONFIG Modes.

Silence Key: Press to silence the audible alarm. See

Section 4 for alarm ringback times.

1.4 Displays

Message Center: Displays the system sta-

tus (Mode) at all times. Displays CLASS

100 or SYSTEM OK during normal opera-

tion, or alarm messages if the system detects

an alarm condition. See Section 4.1, Alarms. The dis-

play message CLASS 100 is a timing mechanism indi-

cating that, under normal operating conditions with the

HEPA filter installed, the air inside the chamber meets

the Class 100 air cleanliness standard for particulates of

0.5 micron size or larger per cubic foot of air. (For fur-

ther information on the Class 100 classification of air

quality, see Appendix A.)

Upper and Lower Displays: These 7 seg-

ment displays vary depending upon the

options present and the configuration chosen.

The upper display can display temp or RH, or

toggle between them. The bottom display

shows CO2continuously.

1.5 Installing the Incubator

a. Choosing the Location

Single and stacked units must be installed against

a wall or similar structure.

1. Maintain a three-inch clearance behind the incubator for

electrical and gas hook-ups. In addition, a three-inch

ventilation space is needed on each side of the unit.

2. Locate the unit on a firm level surface capable of sup-

porting the unit’s weight of 260 lbs.

3. Locate the unit away from doors and windows and heat-

ing and air conditioning ducts.

4. Lift the unit only by the sides of the cabinet base. Do

not attempt to lift it by the front and back. This places

stress on the outer door hinges.

Model 370 and 380 Series ____________________________________________________________Installation and Start-Up

1 - 2

RUN

SETPOINT

CALIBRATION

CONFIGURATION

Default Mode

Temperature

Temp Offset

Audible

Overtemp

CO2Cal1

New HEPA Timer

CO2

IR Cal2

Replace HEPA Reminder

RH Cal

Access Code

Temp Lo Alarm

Temp Relay

CO2Lo Alarm

CO2Hi Alarm

CO2Relay

CO2Z & S #’s *

RH Lo Alarm

RH Relay

Display Temp

Display RH

Tank Select

Gas Guard

RS485 Address

SYSTEM OK

Run

Set

Cal

Config

36.9

4.9

Temp

% CO

2

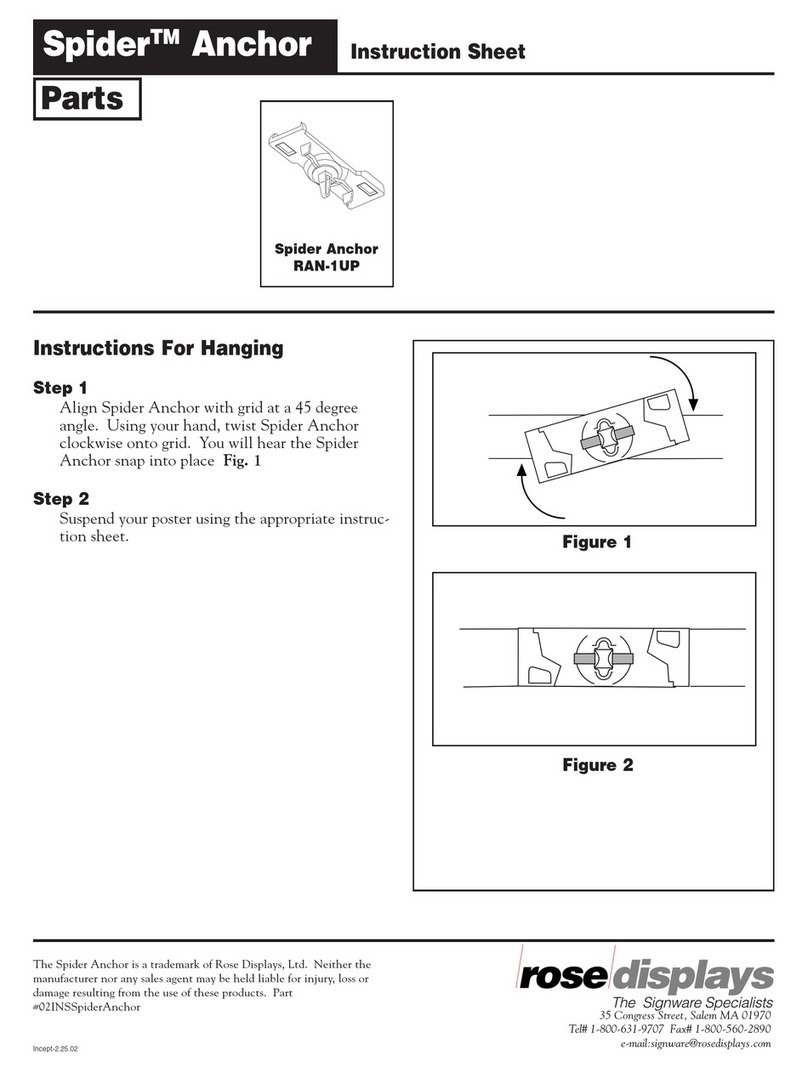

b. Stacking the Incubators

With incubators in a stacked configuration, do not

leave both exterior doors open at the same time.

If the units have been in operation,

turn them both off and disconnect the

power before beginning any service

work.

Two stacking brackets (shown at left)

are included in the parts bag shipped

with each incubator.

Figure 1-3

1. Remove the cover

plate securing the

door cord from the

incubator to be on

top. See Figure 1-4.

Disconnect the plug

from the connector.

2. Remove the four screws securing the door hinges to the

unit. Remove the door and set it aside.

3. Unscrew the two hole plugs from the top cover of the

incubator to be the bottom of the stack (Figure 1-5).

4. Unscrew and remove the 4 leveling feet

from the unit to be stacked on top and

lift it onto the bottom unit. Align all

sides.

This incubator weighs 260 lbs. Have sufficient

personnel available when lifting. Lift the unit by

the sides of the cabinet base to avoid placing

stress on the outer door hinge.

5. Insert the stacking brackets

into the slots at the back of the

stacked units as shown in

Figure 1-7.

6. Align the slotted holes in the

brackets with the mounting

holes on the back of the

top incubator. Secure the

brackets with the screws

and washers provided in the parts bag. See Figure 1-8.

7. Thread one 1/4 x 20

bolt and washer includ-

ed with the stacking

brackets, into the hole

behind the cover plate.

Do not tighten. Refer to

Figure 1-9.

8. Remove the cover plate

from the same area on

the other side of the top

unit.

9. Thread the other 1/4 x

20 bolt and washer into

this hole.

10. Tighten the bolts on

both sides.

11. Assemble the door hinges to the unit. Secure with the

screws.

12. Plug the door cord into the connector, as previously.

Secure the cover plate.

13. Install the cover plate on the other side of the unit.

14. The stacked incubators are ready for service.

Model 370 and 380 Series ____________________________________________________________Installation and Start-Up

1 - 3

Figure 1-4

Figure 1-5

Figure 1-9

Figure 1-7

Figure 1-8

Figure 1-6

c. Preliminary Cleaning and Disinfecting

1. Using a suitable laboratory disinfectant, disinfect all

interior surfaces.

d. Installing the Shelves

1. Install the large sheet metal side ducts with the tabs fac-

ing into the center of the chamber with their slots up.

There are no right side or left side ducts, simply turn one

of them to fit the opposite side. Tilt the side ducts as

they are placed into the chamber so the tops fit into the

top air duct, then guide them into the vertical position.

Figure 1-10 shows the side duct as it would be oriented

for the right side of the chamber.

2. Note that there is no difference in the left and right side

shelf channels.

3. Install the shelf channels by placing the channel’s rear

slot over the appropriate rear tab on the side duct. Pull

the shelf channel forward and engage the channel’s front

slot into the side duct’s appropriate forward tab. Refer to

Figure 1-11.

4. Figure 1-12 shows one of the

channels installed on the right

side duct.

e. Installing the Access Port Filter and CO2

Sensor Cover Plate

1. Locate the opening in the top left corner on the inside of

the chamber. Remove the tape covering the opening on

the outside of the unit.

2. Locate the stopper with filter in the hardware bag. Lift

the metal port cover and install the assembly in the

opening inside the chamber. See Figure 1-13.

3. Also in the hardware bag is the CO2sensor cover plate.

Install, using the 1/4 turn fasteners. Refer to Figure 1-13

for the location.

Figure 1-13

f. Installing the HEPA Filter

Use caution when handling the filter. The media

can be damaged if it is mishandled.

To avoid damage to the incubator, do not operate

the unit without the HEPA filter in place.

1. Remove the filter from the shipping box.

2. Remove the plastic coating from the filter, using caution

not to touch the filter media.

3. Install the filter as shown in Figure 1-13. Refer to

Section 5.6 for HEPA filter maintenance.

Model 370 and 380 Series ____________________________________________________________Installation and Start-Up

1 - 4

Side Duct

Shelf Channels

Side toward shelf

Side duct

tab

shelf channel

rear slot

shelf channel

front slot

Side duct

tab

Figure 1-11

Figure 1-10

Figure 1-12

g. Installing the Air Sample Filter

1. Remove the filter from the shipping bag.

2. Install the air sample filter assembly to the black hose

barb behind the top duct.

3. Insert the other end of the filter assembly onto the metal

tubing on the top duct. Refer to Figure 1-13.

h. Leveling the Unit

Check for level by placing a bubble-style level on one of

the shelves. Turn the hex nut on the leveler counterclockwise to

lengthen the leg or clockwise to shorten it. Level the unit front-

to-back and left-to-right.

i. Connecting the Unit to Electrical Power

See the serial tag on the side of the unit for electrical speci-

fications or refer to the electrical schematics at the end of this

manual.

The serial tag amp rating is based on the amper-

age draw during the sterilization cycle. Normal

operating amperage is much less. Ensure that the

electrical circuit will handle the amp draw of the

sterilization cycle.

Connect the incubator to a grounded, dedicated

circuit.

The power cord connector is the mains disconnect

device for the incubator. Position the incubator so

the unit can be easily disconnected.

Plug the provided power cord into the power inlet connec-

tor on the back of the cabinet (See Figure 1-14), then into the

grounded, dedicated, electrical circuit.

j. Filling the Humidity Pan

Fill the humidity pan with sterile distilled water to within

1/2” of the top. Place the pan directly in the center of the incu-

bator floor.

For applications requiring high humidity, the pan should be

placed against the left side wall of the incubator. The side ducts

have been modified to allow the pan to be placed against the

wall. Optimum humidity is achieved by capping the CO2sam-

ple port. This will, however, cause condensation in the cham-

ber. To enhance RH recovery from door openings, place a sec-

ond humidity pan in the right side duct.

For best operation of the incubator, sterilized distilled,

demineralized or de-ionized water should be used in the humid-

ity pan. Water purity should be in the resistance range of 50K

Ohm/cm to 1M Ohm/cm, or a conductivity range of 20.0 uS/cm

to 1.0 uS/cm. Refer to ASTM Standard D5391-93 or D4195-88

for measuring water purity.

Distillation systems, as well as some types of reverse

osmosis water purity systems, can produce water in the quality

range specified. Tap water is not recommended as it may con-

tain chlorine, which deteriorates stainless steel. Tap water may

also have a high mineral content, which would produce a build-

up of scale in the reservoir. High purity, ultra pure or milli-q

water is not recommended as it is an extremely aggressive sol-

vent and will deteriorate stainless steel. High purity water has a

resistance of above 1M Ohm to 18M Ohm. Even high purity

water can contain bacteria and organic contaminants. Water

should always be sterilized or treated with a decontaminant,

safe for use with stainless steel as well as safe for the product,

prior to being introduced into the humidity pan.

Check the level and change the water frequently to avoid

contamination. Do not allow the water level to fluctuate signifi-

cantly. “Dry-outs” will have an adverse effect on the humidity

level and CO2calibration of the T/C units.

Distilled or de-ionized water used in the humidity

pan must be within a water quality resistance

range of 50K Ohm/cm to 1M Ohm/cm to protect

and prolong the life of the stainless steel. Use of

water outside the specified range will decrease the

operating life of the unit and may void the

warranty.

Model 370 and 380 Series ____________________________________________________________Installation and Start-Up

1 - 5

ACCESS ORY

75 WATTSMAX.

RS 485

ALAR M CONTACTS

30V M AX / 1A MAX

#2

CO inject

15 p.s.i. Regula ted

(103.4 kPa)

2

#1

CO inject

15 p.s.i. Regula ted

(103. 4 kPa)

2

a

b

RJ-ll telephone style connectors

Used with the optional Gas Guard System

bOptional

RS 485 bCO2 Inlet

#1 Tank

aCO2 Inlet

#2 Tank

aRemote

Alarm Contacts

30V max/1A max

Power Cord

Connector

Figure 1-14

k. Connecting the CO2Gas Supply

High concentrations of CO2gas can cause asphyx-

iation! OSHA Standards specify that employee

exposure to carbon dioxide in any eight-hour shift

of a 40-hour work week shall not exceed the eight-

hour time weighted average of 5000 PPM (0.5%

CO2). The short term exposure limit for 15 min-

utes or less is 30,000 ppm (3% CO2). Carbon diox-

ide monitors are recommended for confined areas

where concentrations of carbon dioxide gas can

accumulate.

This incubator is designed to be operated with

CO2gas only. Connecting a flammable or toxic

gas can result in a hazardous condition.

Gases other than CO2should not be connected to

this equipment. CO2gas cylinders have a UN1013

label on the cylinder and are equipped with a

CGA 320 outlet valve. Check the gas cylinder for

the proper identification labels. The CO2gas sup-

ply being connected to the incubator should be

industrial grade, 99.5% pure. Do not use CO2gas

cylinders equipped with siphon tubes. A siphon

tube is used to extract liquid CO2from the cylin-

der which can damage the pressure regulator.

Consult with your gas supplier to ensure that the

CO2cylinder does not contain a siphon tube. Gas

cylinders should also be secured to a wall or other

stationary object to prevent them from tipping.

A two-stage CO2pressure regulator is required to

be installed on the outlet valve of the gas cylinder.

Input pressure to the incubator must be main-

tained at 15 psig (103.4 kPa) for proper perform-

ance of the CO2control system. A single stage CO2

pressure regulator will not maintain 15 psig

(103.4 kPa) to the incubator as the pressure in the

CO2 cylinder decreases; therefore, a two stage

regulator is recommended.

If higher purity CO2is desired inside the incuba-

tor (greater than 99.5% pure), the pressure regu-

lator should be constructed with a stainless steel

diaphragm, along with specifying the purity of the

CO2from the gas supplier. Follow the manufac-

turer’s instructions to ensure proper and safe

installation of the pressure regulator on the gas

cylinder.

Consult your facility safety officer to ensure that

the equipment is installed in accordance with the

codes and regulations that are applicable in your

area.

Model 370 and 380 Series ____________________________________________________________Installation and Start-Up

The CO2gas supply being connected should be industrial

grade 99.5% pure and should not contain siphon tubes. Install a

two-stage pressure regulator at the cylinder outlet. The high

pressure gauge at the tank should have 0-2000 psig range. The

low pressure gauge, at the incubator inlet, should have a 0-30

psig range. Input pressure to the incubator must be maintained

at 15 psig (103.4 kPa).

The incubator has serrated fittings on the back of the cabi-

net to connect the gas supply. Refer to Figure 1-14. The fitting

is labeled CO2Inlet #1 Tank. Make sure that the connections

are secured with clamps. Check all fittings for leaks.

For units having the CO2Gas Guard option, refer to

Section 6.2.

1.6 Incubator Start-Up

With the incubator properly installed and connected to

power, the humidity pan filled, and the unit connected to gas

supplies, system setpoints can be entered. The following set-

points can be entered in Set mode: Temperature,

Overtemperature and CO2. To enter Set mode, press the Mode

key until the Set indicator lights. Press the right and/or left

arrow keys until the proper parameter appears in the message

center. See Chart 1-1 for more detail.

a. Setting the Operating Temperature

All 370/380 Series incubators have an operating tempera-

ture range of 10°C to 50°C, depending on ambient temperature.

The incubator is shipped from the factory with a temperature

setpoint of 10°C. At this setting, all heaters are turned off. To

change the operating temperature setpoint:

1. Press the Mode key until the Set indicator lights.

2. Press the right arrow until “Temp XX.X” is displayed in

the message center.

3. Press the up/down arrow key until the desired tempera-

ture setpoint is displayed.

4. Press Enter to save the setpoint.

5. Press the Mode key until the Run indicator lights for

Run mode or press the right/left arrow keys to go to

next/previous parameter.

b. Setting the Overtemp Setpoint

The independent overtemp system is designed as

a safety to protect the incubator only. It is not

intended to protect or limit the maximum temper-

ature of the cell cultures or customer’s equipment

inside the incubator if an overtemp condition

occurs.

1 - 6

370/380 Series incubators are equipped with a secondary

temperature monitoring system to monitor the air temperature

inside the cabinet. This system is designed as a safety device to

turn off all heaters in the event of a temperature control failure.

Temperature control in the incubator will be ±1° of the

overtemp setpoint.

The overtemperature is set by the factory (default) at 40°C.

However, the overtemp can be set up to 55°C in 0.5° incre-

ments.

If the incubator’s operating temperature setpoint is set

above the overtemp setpoint, the overtemp setpoint will auto-

matically update to 1°C above the temperature setpoint. It is

recommended that the overtemp setpoint be maintained at 1°C

over the operating temperature setpoint.

To set the Overtemp setpoint:

1. Press the Mode key until the Set indicator lights

2. Press the right arrow until Otemp XX.X is displayed in

the message center

3. Press the up or down arrow key until the desired

Overtemp setpoint is displayed

4. Press Enter to save the setting

5. Press the Mode key until the Run indicator lights or

press the right or left arrow to go to the next or previous

parameter.

c. Setting the CO2Setpoint

All T/C CO2cells are calibrated at the factory at 37°C, high

humidity, and 10% CO2. Therefore, if a temperature setpoint of

37° C has been entered, the humidity pan has been filled and

the CO2control is to run between 0-10% with a T/C CO2sen-

sor, the CO2setpoint may be entered immediately. Otherwise, it

is important to allow the unit 12 hours to stabilize at the tem-

perature setpoint before entering the CO2setpoint.

All models of the incubator have a CO2setpoint range of

0.0% to 20.0%. The incubator is shipped from the factory with

a CO2setpoint of 0.0%. At this setting, all CO2control and

alarms are turned off. To change the CO2setpoint:

1. Press the Mode key until the Set indicator lights.

2. Press the right arrow until “CO2 XX.X” is displayed in

the message center.

3. Press the up/down arrows until the desired CO2setpoint

is displayed.

4. Press Enter to save the setpoint.

5. Press the Mode key until the Run indicator lights to go

to Run mode or press the right/left arrow keys to go to

next/previous parameter.

Model 370 and 380 Series ____________________________________________________________Installation and Start-Up

1 - 7

Model 370 and 380 Series ____________________________________________________________Installation and Start-Up

1 - 8

Section 2 - Calibration

2.1 Calibration Mode

After the unit has stabilized, several different systems can

be calibrated. In the calibration mode, the air temperature, CO2

and RH levels can be calibrated to reference instruments. To

access the calibration mode, press the Mode key until the Cal

indicator lights. Press the right and/or left arrow until the

appropriate parameter appears in the message center. See Chart

2-1 at the end of this section for more detail.

Calibration frequency is dependent on use, ambient condi-

tions and accuracy required. A good laboratory practice would

require at least an annual calibration check. On new installa-

tions, all parameters should be checked after the stabilization

period.

Prior to calibration, the user should be aware of the follow-

ing system functions. While the unit is in the calibration mode,

all system control functions are stopped so the unit remains sta-

ble. Readout of the system being calibrated will appear on the

message center. If no keys are pressed for approximately five

minutes while in calibration mode, the system will reset to Run

mode so control functions are reactivated.

Before making any calibration or adjustments to

the unit, it is imperative that all reference instru-

ments be properly calibrated.

a. Calibrating the Temperature

Before calibration, allow the cabinet temperature to stabi-

lize. Place the calibrated instrument in the center of the cham-

ber. The instrument should be in the air flow, not against the

shelf.

Temperature Stabilization Periods

Startup - Allow 12 hours for the temperature in the cabinet to

stabilize before proceeding.

Already Operating - Allow at least 2 hours after the display

reaches setpoint for temperature to stabilize before proceeding.

1. Press the Mode key until Cal indicator lights.

2. Press the right arrow until “TEMPCAL XX.X” appears

in the message center.

3. Press up/down arrow to match display to calibrated

instrument.

4. Press Enter to store calibration.

5. Press the Mode key to return to Run or the right/left

arrow to go to next/previous parameter.

b. Calibrating Thermal Conductivity CO2System

Models 370 and 371 have a thermal conductivity (T/C)

CO2sensor. Thermal conductivity of the incubator atmosphere

is not only effected by the quantity of CO2present but also by

the air temperature and water vapor present in the incubator

atmosphere. In monitoring the effects of CO2, air temperature

and absolute humidity must be held constant so any change in

thermal conductivity is caused by a change in CO2concentra-

tion.

Changing temperature or changing from elevated humidity

to room ambient humidity levels will necessitate a re-calibra-

tion of the CO2control.

T/C CO2Sensor Stabilization Periods

Some T/C CO2sensors go through an aging period, espe-

cially on new installations. Calibration should be checked on a

weekly basis and adjusted as necessary. When stabilization

occurs, checks may become less frequent.

Start -Up - The CO2sensor has been calibrated at the factory

for 37°C and elevated humidity. Allow the temperature, humid-

ity, and CO2levels in the chamber to stabilize at least 12 hours

before checking the CO2concentration with an independent

instrument.

Presently Operating - Make sure the chamber doors are

closed. Allow at least 2 hours after the temperature and CO2

displays reach their setpoints for chamber atmosphere stabiliza-

tion.

1. Make sure the stabilization periods outlined above are

followed.

2. Sample the chamber atmosphere through the sample port

with an independent instrument. Sample the atmosphere

at least 3 times to ensure accuracy of the instrument.

3. Press the Mode key until the Cal indicator lights.

4. Press the right arrow until “CO2 CAL XX.X” is dis-

played in the message center.

5. Press the up /down arrows to change the display to

match the independent instrument.

6. Press Enter to store the calibration.

7. Press the Mode key to return to Run or the right or left

arrows to go to the next/ previous parameter.

Model 370 and 380 Series _________________________________________________________________________Calibration

2 - 1

c. Calibrating the Infrared CO2System

Models 380 and 381 have an infrared (IR) CO2sensor.

Infrared CO2sensors are not effected by chamber atmosphere

temperature or humidity. However, the light detector in the sen-

sor is effected by wide temperature changes. Therefore, chang-

ing temperature setpoints could necessitate a recalibration of

the CO2. Chamber temperature should be allowed to stabilize

before checking CO2concentrations with an independent instru-

ment, especially on start-up.

IR CO2Sensor Stabilization Times

Start-Up- Allow the temperature and the CO2of the cabinet to

stabilize at least 12 hours before proceeding.

Presently Operating - Allow CO2to stabilize at least 2 hours

at setpoint before proceeding.

1. Measure the CO2concentration in the chamber through

the gas sample port with a Fyrite or other independent

instrument. Several readings should be taken to ensure

accuracy.

2. Press the Mode key until the Cal indicator lights.

3. Press the right arrow until “IR CAL XX.X” appears in

the message center.

4. Press the up/down arrow to adjust the display to match

the independent instrument reading.

5. Press Enter to store the calibration.

6. Press the Mode key to return to Run mode.

d. Calibrating Relative Humidity

All 370/380 Series incubators can be equipped with an

optional direct-readout relative humidity sensor. This is a read-

out only of the chamber relative humidity level. It does not pro-

vide any control of the relative humidity in the cabinet.

Relative Humidity Stabilization Times

Start-Up - Allow 12 hours for the relative humidity and tem-

perature in the chamber to stabilize before proceeding.

Already Operating - Allow at least 2 hours after temperature

display reaches setpoint for relative humidity to stabilize before

proceeding.

1. Place an accurate independent instrument in the center

of the chamber. Allow at least 30 minutes for RH to sta-

bilize.

2. Press the Mode key until the Cal indicator lights.

3. Press the right arrow key until “RH CAL XX” appears

in the message center.

4. Press the up/down arrow to match the display to the

independent instrument.

5. Press Enter to store the calibration.

6. Press the Mode key to return to Run mode.

If a reliable RH measuring device is not available, you may

calibrate the display to a typical level;

1. Follow the RH stabilization periods outlined above.

2. With a full humidity pan and stable temperature, the rel-

ative humidity in the chamber will be 95%.

3. Using Step 3-5 of the relative humidity sensor adjust-

ment, adjust the display to 95%.

This calibration method should be accurate to within 5%.

Model 370 and 380 Series ________________________________________________________________________Calibration

2 - 2

Model 370 and 380 Series ________________________________________________________________________Calibration

2 - 3

1. Press the Mode key until the Config indicator lights.

2. Press the right arrow until REPL HEPA XX is dis-

played.

3. Press the up/down arrow to choose the number of

months desired.

4. Press Enter to save the number.

5. Press the Mode key to return to Run Mode or right/left

to go to next/previous parameter.

Note: After the reminder has been set, check the allotted time

remaining by going to Config Mode, then pressing the right

arrow until NEW HEPA XXX displays. This number is the

remaining days before the filter replacement time specified runs

out. For example, if 12 months was chosen in the REPL HEPA

XX message screen, the NEW HEPA number would be 365

days.

d. Setting an Access Code

A 3-digit Access Code can be entered to avoid unautho-

rized personnel from changing the setpoints, calibration, or con-

figuration. A setting of 000 will bypass the access code. The

factory setting is 000.

1. Press the Mode key until the Config indicator lights.

2. Press the right arrow until ACC CODE XXX is dis-

played in the message center.

3. Press up/down arrow to change the access code.

4. Press Enter to save the access code.

5. Press the Mode key to return to the Run mode or

right/left to go to next/previous parameter.

e. Setting a Low Temp Alarm Limit (tracking

alarm)

The low temp alarm limit is the deviation from the

temperature setpoint which will cause a low temp alarm. The

low temp alarm is variable from 0.5° below setpoint to 5°

below setpoint. The factory setting is 1° below setpoint. A

minus sign (-) in the display indicates that the alarm setting is

below the setpoint.

1. Press the Mode key until the Config indicator lights.

2. Press the right arrow until TEMP LO -X.X is displayed

in the message center.

3. Press up/down arrow to change the low temp alarm

limit.

4. Press Enter to save the low temp alarm limit.

5. Press the Mode key to return to Run mode or right/left

to go to next/previous parameter.

Section 3 - Configuration

3.1 Configuration Mode

Several features available in the Configuration Mode allow

custom setup of the incubator. These features are listed and

described below. All features may not be necessary in all appli-

cations, but are available if needed. To enter Configuration

mode, press the Mode key until the Config indicator lights.

Press the right and/or left arrow until the appropriate parameter

appears in the message center. See Chart 3-1 for more detail.

a. Turning the Audible Alarm ON/OFF

The audible alarm can be turned on or off. The factory set-

ting is ON.

1. Press the Mode key until the Config indicator lights.

2. Press the right arrow until AUDIBLE XXX is displayed

in the message center.

3. Press up/down arrow to toggle AUDIBLE ON/OFF.

4. Press Enter to save the setting.

5. Press the Mode key to return to run mode or right/left to

go to next/previous parameter.

b. New HEPA Filter

When the REPLACE HEPA reminder is displayed and the

visual alarm flashes, the specified time has elapsed and the

HEPA filter should be replaced. To clear the display and reset

the timer after replacing the HEPA filter with a new one, follow

the steps below.

1. Press the Mode key until the Config indicator lights.

2. Press the right arrow until NEW HEPA is displayed in

the message center.

3. Press Enter to restart the timer and clear the REPLACE

HEPA alarm.

4. Press the Mode key to return to Run Mode.

c. Setting the REPLACE HEPA filter reminder

A HEPA filter replacement timer can be set for a specific

amount of time, from 1 to 12 months of actual unit running

time. Time will not accrue when the unit is turned off. The

default time is 6 months. When the allotted time has run out,

REPLACE HEPA appears in the display and the visual alarm

flashes. To set the reminder, use the following procedure.

Model 370 and 380 Series ______________________________________________________________________Configuration

3 - 1

i. Enabling CO2Alarms to Trip Contacts

High and Low CO2alarms can be programmed to trip the

remote alarm contacts. A setting of ON will cause this, a set-

ting of OFF will not allow CO2alarms to trip the contacts. The

factory setting is ON.

1. Press the Mode key until the Config indicator lights.

2. Press the right arrow until CO2 RLY XXX is displayed

in the message center.

3. Press up/down arrow to toggle the setting ON/OFF.

4. Press Enter to save the setting.

5. Press the Mode key to return to Run Mode or right/left

to go to next/previous parameter.

j. Setting a New Zero Number for T/C CO2

Sensors

If a new T/C CO2sensor is being installed, the two num-

bers on the factory installed sticker on the T/C cell must be

entered to calibrate the CO2in the unit.

Note: For the technician’s convenience, a label containing the

two numbers on the T/C cell is affixed inside the electronics

drawer.

1. Press the Mode key until the Config indicator lights.

2. Press the right arrow until T/CZ# XXXX is displayed in

the message center.

3. Press up/down arrow to change the zero number to

match the sticker.

4. Press Enter to save the setting.

5. Press the Mode key to return to Run mode or right/left

to go to next/previous parameter.

k. Setting New Span Number for T/C CO2Sensors

If a new T/C CO2sensor is being installed, the two num-

bers on the factory installed sticker on the T/C cell must be

entered to calibrate the CO2in the unit.

Note: For the technician’s convenience, a label containing the

two numbers on the T/C cell is affixed inside the electronics

drawer.

1. Press the Mode key until the Config indicator lights.

2. Press the right arrow until T/CS# XXXX is displayed in

the message center.

3. Press up/down arrow to change the span number to

match the sticker.

4. Press Enter to save the setting.

5. Press the Mode key to return to Run mode or right/left

to go to next/previous parameter.

f. Enabling the Low Temperature Alarm to Trip

Contacts

The low temperature alarm can be programmed to trip

the remote alarm contacts. A setting of ON will cause this, a

setting of OFF will not allow temp alarm to trip the contacts.

The factory setting is ON.

1. Press the Mode key until the Config indicator lights.

2. Press the right arrow until TMP RLY XXX is displayed.

3. Press the up/down key to toggle the setting ON/OFF.

4. Press Enter to save the setting

5. Press the Mode key to return to Run or the right/left

arrow key to go to next/previous parameter.

g. Setting a Low CO2Alarm Limit (tracking

alarm)

The low CO2alarm limit is the deviation from the CO2set-

point which will cause a low CO2alarm. The setpoint is vari-

able from 0.5% CO2below setpoint to 5.0% CO2below set-

point. The factory setting is 1.0% CO2below setpoint. A minus

sign (-) in the display indicates that the alarm setting is below

the setpoint.

1. Press the Mode key until the Config indicator lights.

2. Press the right arrow until CO2 LO -X.X is displayed in

the message center.

3. Press up/down arrow to change the low CO2alarm limit.

4. Press Enter to save the low CO2alarm limit.

5. Press the Mode key to return to Run mode or right/left

to go to next/previous parameter.

h. Setting a High CO2Alarm Limit (tracking alarm)

The high CO2alarm limit is the deviation from the CO2set-

point which will cause a high CO2alarm. The setpoint is vari-

able from 0.5% CO2above setpoint to 5.0% CO2above set-

point. The factory setting is 1.0% CO2above setpoint.

1. Press the Mode key until the Config indicator lights.

2. Press the right arrow until CO2 HI X.X is displayed in

the message center.

3. Press up/down arrow to change the high CO2 alarm

limit.

4. Press Enter to save the high CO2 alarm limit.

5. Press the Mode key to return to run mode or right/left to

go to next/previous parameter.

Model 370 and 380 Series ______________________________________________________________________Configuration

3 - 2

l. Setting a Low RH Alarm Limit

On units that have the RH option installed, a low RH alarm

limit may be entered. The low RH alarm limit is the %RH in

the cabinet which will cause a low RH alarm. The setpoint is

variable from setpoint 0 to 90% RH The factory setting is 0%

RH which will disable the alarm.

1. Press the Mode key until the Config indicator lights.

2. Press the right arrow until RH LO XX is displayed in

the message center.

3. Press up/down arrow to change the RH low alarm limit.

4. Press Enter to save the RH low alarm limit.

5. Press the Mode key to return to Run mode or right/left

to go to next/previous parameter.

m. Enabling RH Alarms to Trip Contacts

The low RH alarm can be programmed to trip the remote

alarm contacts. A setting of ON will cause this, a setting of

OFF will not allow the RH alarm to trip the contacts. The fac-

tory setting is ON.

1. Press the Mode key until the Config indicator lights.

2. Press the right arrow until RH RLY XXX is displayed in

the message center.

3. Press up/down arrow to toggle the setting ON/OFF.

4. Press Enter to save the setting.

5. Press the Mode key to return to Run mode or right/left

to go to next/previous parameter.

n. Enabling Temp/RH to be Displayed

On units that are equipped with the RH option, the upper

seven segment display on the control panel can be configured

to display Temp continuously, RH continuously, or toggle

between Temp and RH. If the units does not have RH, the

upper display will always display temperature. If temperature

is set to ON, and the RH is set OFF, temperature will be dis-

played continuously. If temperature is set to OFF and RH is set

to ON, RH will be displayed continuously. If both are turned

ON, the display will toggle between the two. The factory set-

ting will default to toggle mode if the RH option is present.

1. Press the Mode key until the Config indicator lights.

2. Press the right arrow until DISP TMP XXX or DISP RH

XXX is displayed in the message center.

3. Press up/down arrow to toggle the setting ON/OFF.

4. Press Enter to save the setting.

5. Press the Mode key to return to Run mode or right/left

to go to next/previous parameter.

Model 370 and 380 Series ______________________________________________________________________Configuration

3 - 3

o. Selecting a Primary Tank w/ Gas Guard Option

On units equipped with the Gas Guard option, a primary

tank can be selected. The primary tank will be either Tank 1 or

2. The factory setting is Tank1 .

1. Press the Mode key until the Config indicator lights.

2. Press the right arrow until TNK SEL X is displayed in

the message center.

3. Press up/down arrow to toggle setting between 1 and 2 .

4. Press Enter to save the setting.

5. Press the Mode key to return to Run mode or right/left

to go to next/previous parameter.

p. Enabling the Gas Guard System

On units equipped with the Gas Guard option, the Gas

Guard system may be turned ON or OFF if it is not in use. The

factory setting is OFF.

1. Press the Mode key until the Config indicator lights.

2. Press the right arrow until GAS GRD XX is displayed in

the message center.

3. Press up/down arrow to toggle the setting ON/OFF.

4. Press Enter to save the setting.

5. Press the Mode key to return to Run mode or right/left

to go to next/previous parameter.

q. Setting a RS485 Communications Address

(1535 compatible only)

On units that have the RS485 option, direct communication

with the Forma 1535 Model alarm system can be established.

Each piece of equipment connected to the 1535 must have a

unique address. An address of 0-24 can be entered for the incu-

bator. A setting of 0 is an invalid address that the 1535 will

ignore. The factory setting for the RS485 address is 0.

1. Press the Mode key until the Config indicator lights.

2. Press the right arrow until RS485 XX is displayed in the

message center.

3. Press up/down arrow to move the RS485 address.

4. Press Enter to save the RS485 address.

5. Press the Mode key to return to Run mode or right/left

to go to next/previous parameter.

Model 370 and 380 Series _______________________________________________________________________Configuration

3 - 4

This manual suits for next models

3

Table of contents

Other Thermo Forma Accessories manuals

Popular Accessories manuals by other brands

Merkury Innovations

Merkury Innovations Smart Wi-Fi Essential Oil Diffuser Start guide

Baumer

Baumer 10161026 manual

Steca

Steca HS200 Datasheet and Operating Instructions

Gin Gliders

Gin Gliders Gingo Airlite XS manual

Daikin

Daikin FWHSK Installation and operation manual

Sport-thieme

Sport-thieme 113 5985 Assembly & instruction manual