Thermo Forma 3950 Operating instructions

Models 3950 and 3951

29 cu. ft. Capacity

Reach-In CO2Incubator

Operating and Maintenance Manual

Manual No: 7003950 Rev. 6

Model 3950/3951 _______________________________________________________________________________________

i

Read This Instruction Manual.

Failure to read, understand and follow the instructions in

this manual may result in damage to the unit, injury to operat-

ing personnel, and poor equipment performance.

All internal adjustments and maintenance must be

performed by qualified service personnel.

Refer to the serial tag on the back of this manual.

The material in this manual is for information purposes only.

The contents and the product it describes are subject to change

without notice. Thermo Forma makes no representations or war-

ranties with respect to this manual. In no event shall Thermo

Forma be held liable for any damages, direct or incidental, aris-

ing out of or related to the use of this manual.

MANUAL NUMBER 7003950

-- 20883/IN-3034 6/12/02 Clarified p-trap alignment on page 1-3. ccs

-- 20651/IN-3019 2/26/02 Updated 1900008-06-1 to rev. 5, chg in control panel mounting hardware ccs

6 19617 12/18/00 New door - updated electrical schematics ccs

5 19105/IN-2808 7/24/00 Updated 1900008-06-1 to rev. 4, chg in standoffs ccs

4 -- 5/00 Changed to Quark format ccs

3 18843/SI-7759 2/00 Shaker support chg; casters w/o brakes, lg. feet ccs

2 18594/IN-2740 1/00 Updated exploded parts list drawings ccs

1 -- 11/99 Updates from the 3960 release (common parts) ccs

REV ECR/ECN DATE DESCRIPTION By

If the incubator is not used in the manner speci-

fied in this operating manual, the protection pro-

vided by the equipment design may be impaired.

Model CO2Sensor* Voltage**

3950 T/C 100-120

3951 T/C 200-230

* T/C is a thermal conductivity sensor.

** All units are 50/60 Hz.

Model 3950/3951 _______________________________________________________________________________________

ii

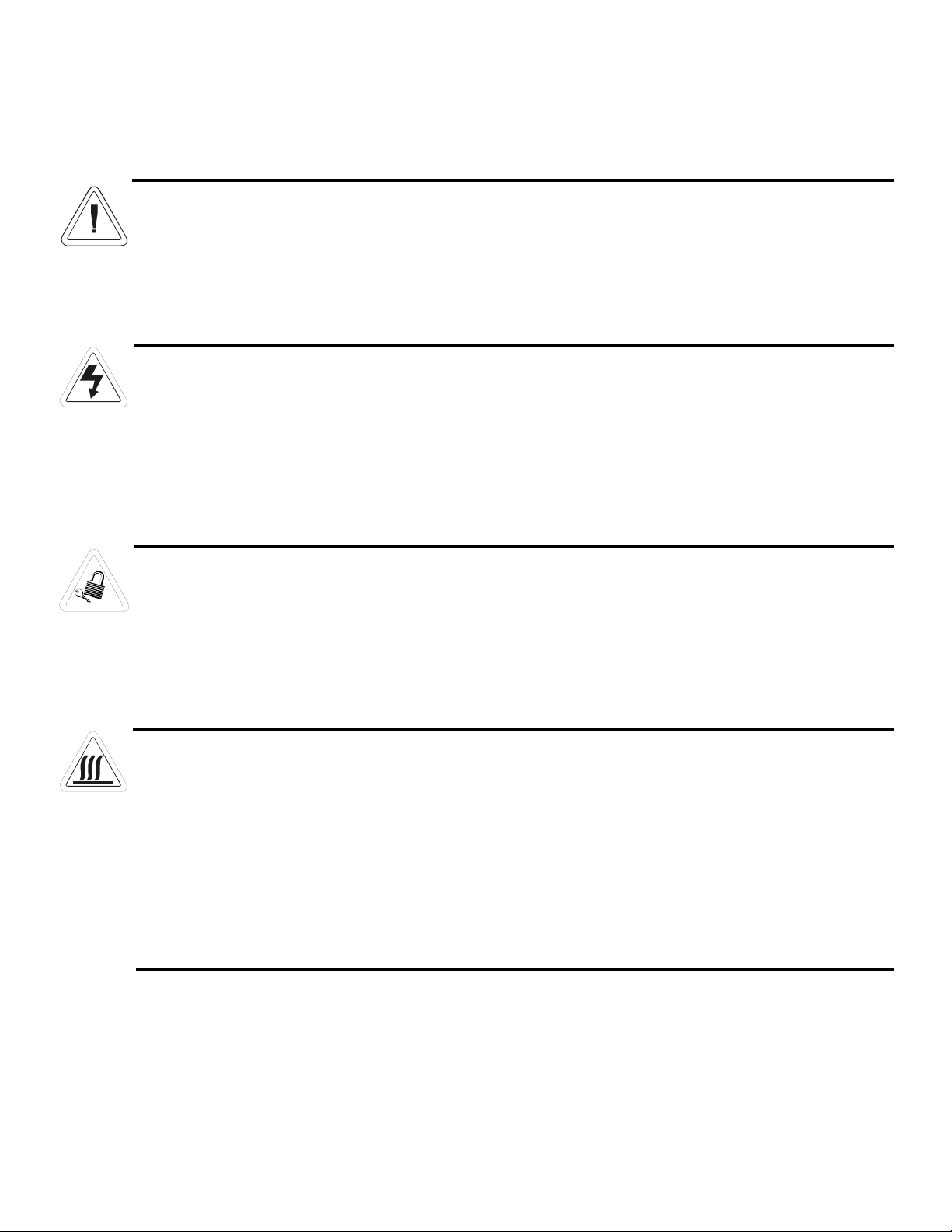

Important operating and/or maintenance instructions. Read the accompanying text carefully.

Ce symbole attire l'attention de l'utilisateur sur des instructions importantes de fonctionnement et/ou d'entretien. Il

peut être utilisé seul ou avec d'autres symboles de sécurité. Lire attentivement le texte d'accompagnement.

Wichtige Betriebs- und/oder Wartungshinweise. Lesen Sie den nachfolgenden Text sorgfältig.

Importante instruccions de operacion y/o mantenimiento. Lea el texto acompanante cuidadosamente.

Potential electrical hazards. Only qualified persons should perform procedures associated with this symbol.

Ce symbole attire l'attention de l'utilisateur sur des risques électriques potentiels. Seules des personnes qualifiées

doivent appliquer les instructions et les procédures associées à ce symbole.

Gefahr von Stromschlägen. Nur qualifizierte Personen sollten die Tätigkeiten ausführen, die mit diesem Symbol beze-

ichnet sind.

Potencial de riesgos electricos. Solo personas das capacitadadas deben ejecutar los procedimientos asociadas con este

simbulo.

Equipment being maintained or serviced must be turned off and locked off to prevent possible injury.

Risques potentiels liés à l'énergie. L'équipement en entretien ou en maintenance doit être éteint et mis sous clé pour

éviter des blessures possibles.

Geräte, an denen Wartungs- oder Servicearbeiten durchgeführt werden, müssen abgeschaltet und abgeschlossen wer-

den, um Verletzungen zu vermeiden.

El equipo recibiendo servicio o mantenimiento debe ser apagado y segurado para prevenir danos.

Hot surface(s) present which may cause burns to unprotected skin, or to materials which may be damaged by elevated

temperatures.

Présence de surface(s) chaude(s) pouvant causer des brûlures sur la peau non protégée, ou sur des matières pouvant

être endommagées par des températures élevées.

Heiße Oberfläche(n) können ungeschützter Haut Verbrennungen zufügen oder Schäden an Materialien verursachen,

die nicht hitzebeständig sind.

Superficias calientes que pueden causar quemaduras a piel sin proteccion o a materiales que pueden estar danados

por elevadas temperaturas.

√ Always use the proper protective equipment (clothing, gloves, goggles, etc.)

√ Always dissipate extreme cold or heat and wear protective clothing.

√ Always follow good hygiene practices.

√ Each individual is responsible for his or her own safety.

Model 3950/3951 _______________________________________________________________________________________

iii

Model 3950/3951 _______________________________________________________________________________________

iv

Table of Contents

Section 1 - Installation and Start-Up . . . . . . . . . . . . . . .1 - 1

1.1 Control Panel Keys, Displays and Indicators . . . . . .1 - 2

1.2 Operation of the Keypad . . . . . . . . . . . . . . . . . . . . .1 - 2

1.3 Installing the Unit . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 3

a. Choosing the Location . . . . . . . . . . . . . . . . . . . . .1 - 3

b. Preliminary Cleaning and Disinfecting . . . . . . . .1 - 3

c. Installing the Shelves . . . . . . . . . . . . . . . . . . . . . .1 - 3

d. Leveling the Unit . . . . . . . . . . . . . . . . . . . . . . . .1 - 3

e. Attaching the Drain Lines . . . . . . . . . . . . . . . . . .1 - 3

f. The Water Supply . . . . . . . . . . . . . . . . . . . . . . . .1 - 4

g. Filling the Humidity Reservoir . . . . . . . . . . . . . .1 - 4

h. Connecting the Unit to Electrical Power . . . . . . .1 - 4

i. Connecting the CO2Gas Supply . . . . . . . . . . . . . .1 - 5

1.4 Incubator Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 5

a. Setting the Operating Temperature . . . . . . . . . . .1 - 5

b. Setting the Overtemp Setpoint . . . . . . . . . . . . . .1 - 6

c. Setting the CO2Setpoint . . . . . . . . . . . . . . . . . . .1 - 6

Section 2 - Calibration . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 1

2.1 Calibration Mode . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 1

a. Calibrating the Temperature . . . . . . . . . . . . . . . .2 - 1

b. Calibrating the CO2System . . . . . . . . . . . . . . . .2 - 1

Section 3 - Configuration . . . . . . . . . . . . . . . . . . . . . . . .3 - 1

3.1 Configuration Mode . . . . . . . . . . . . . . . . . . . . . . . .3 - 1

a. Disabling the ADD WATER Alarm . . . . . . . . . .3 - 1

b. Turning All Audible Alarms ON/OFF . . . . . . . .3 - 1

c. Setting an Access Code . . . . . . . . . . . . . . . . . . .3 - 1

d. Setting Low Temp Alarm Limit (tracking alarm) 3 - 1

e. Enabling Temp Alarms to Trip Relay Contacts . .3 - 1

f. Setting Low CO2Alarm Limit (tracking alarm) .3 - 2

g. Setting High CO2Alarm Limit (tracking alarm) .3 - 2

h. Enabling CO2Alarms to Trip Relay Contacts . . .3 - 2

i. Setting New Zero Number for New CO2Sensors .3 - 2

j. Setting New Span Number for CO2Sensors . . . .3 - 2

k. Enabling the High Humidity Feature . . . . . . . . .3 - 2

l. Selecting a Primary Tank w/ Gas Guard Option .3 - 3

m. Enabling the Gas Guard System . . . . . . . . . . . .3 - 3

n. Setting RS485 Communications Address

(1535 compatible only) . . . . . . . . . . . . . . . . . . . . . .3 - 3

Section 4 - Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 1

4.1 Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 1

4.2 Sensor Fault Alarms . . . . . . . . . . . . . . . . . . . . . . . .4 - 1

Section 5 - Maintenance . . . . . . . . . . . . . . . . . . . . . . . .5 - 1

5.1 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 1

5.2 Cleaning the Glass Doors . . . . . . . . . . . . . . . . . . . .5 - 1

5.3 Cleaning the Humidity Reservoir . . . . . . . . . . . . . .5 - 1

5.4 Replacing the Power Fuses . . . . . . . . . . . . . . . . . . . .5 - 2

Table 5-1, Fuse Replacement Chart . . . . . . . . . . . . .5 - 2

5.5 Discarding or Taking the Incubator out of Service . .5 - 2

Section 6 - Factory Options . . . . . . . . . . . . . . . . . . . . . .6 - 1

6.1 Connections to External Equipment . . . . . . . . . . . . .6 - 1

a. Connecting the Remote Alarm Contacts . . . . . . .6 - 1

b. Connecting the RS485 Interface . . . . . . . . . . . . .6 - 1

c. Connecting Analog Output Boards . . . . . . . . . . .6 - 1

6.2 CO2Gas Guard . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 2

a. Connecting the CO2Gas Supplies . . . . . . . . . . . .6 - 2

b. Activating the Gas Guard . . . . . . . . . . . . . . . . . .6 - 2

c. Operation of the CO2Gas Guard . . . . . . . . . . . . .6 - 2

6.3 Inner Doors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 1

6.4 Shaker Support Shelves . . . . . . . . . . . . . . . . . . . . . .7 - 1

Section 7 – Specifications . . . . . . . . . . . . . . . . . . . . . . .7 - 1

7.1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 1

Section 8 - Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . .8 - 1

Exploded Parts Drawings . . . . . . . . . . . . . . . . . . . . .8 - 2

Section 9 - Electrical Schematics . . . . . . . . . . . . . . . . . . .9 -1

Section 10 - Warranty and Supplemental Information . .10 - 1

Model 3950/3951 ____________________________________________________________________Installation and Start-Up

Section 1 - Installation and Start-Up

1 - 1

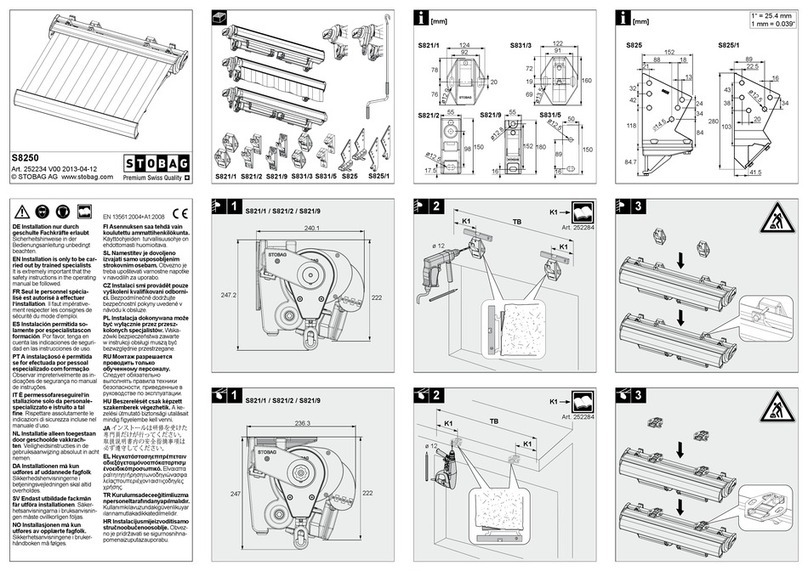

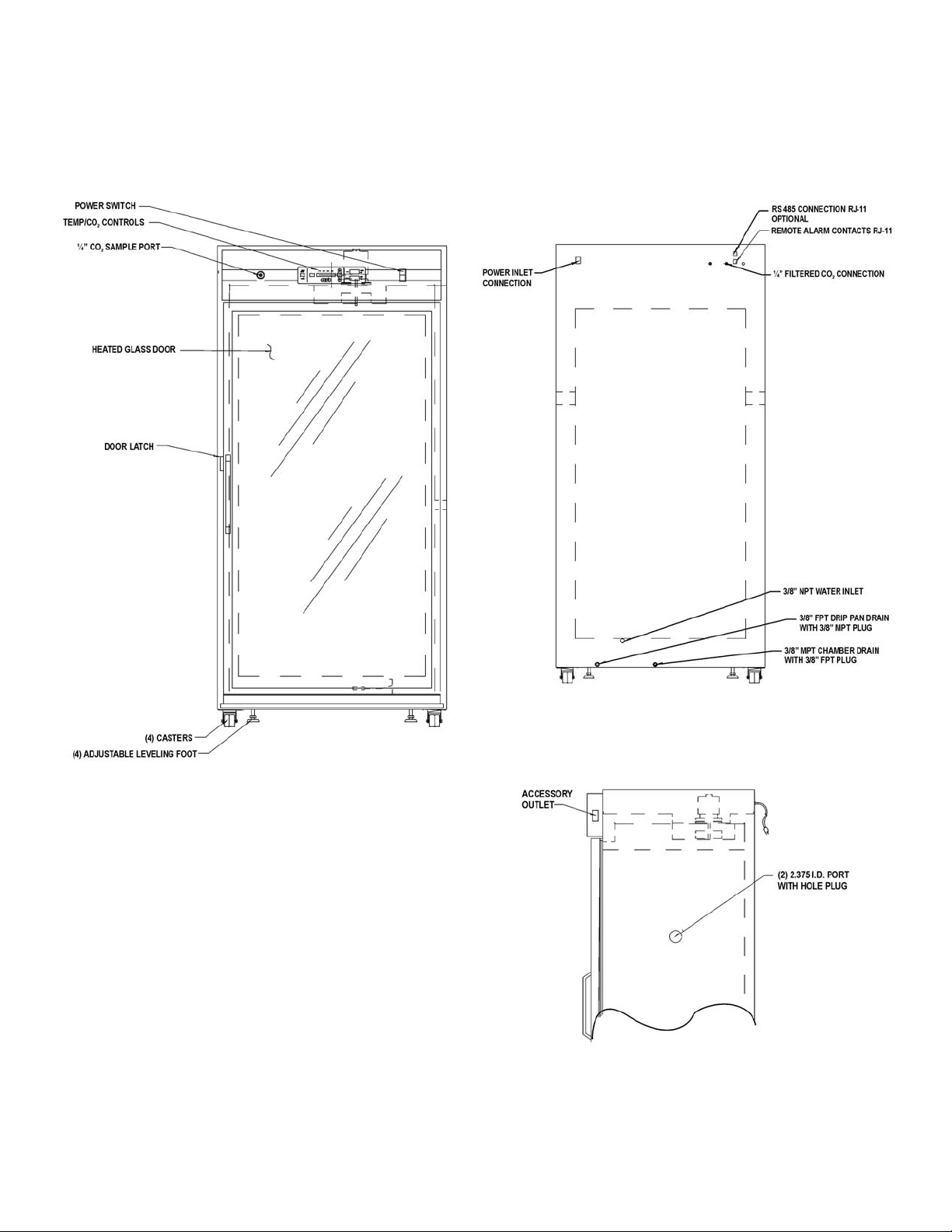

Figure 1-1

Front View

Figure 1-2

Back View

Figure 1-3

Side View

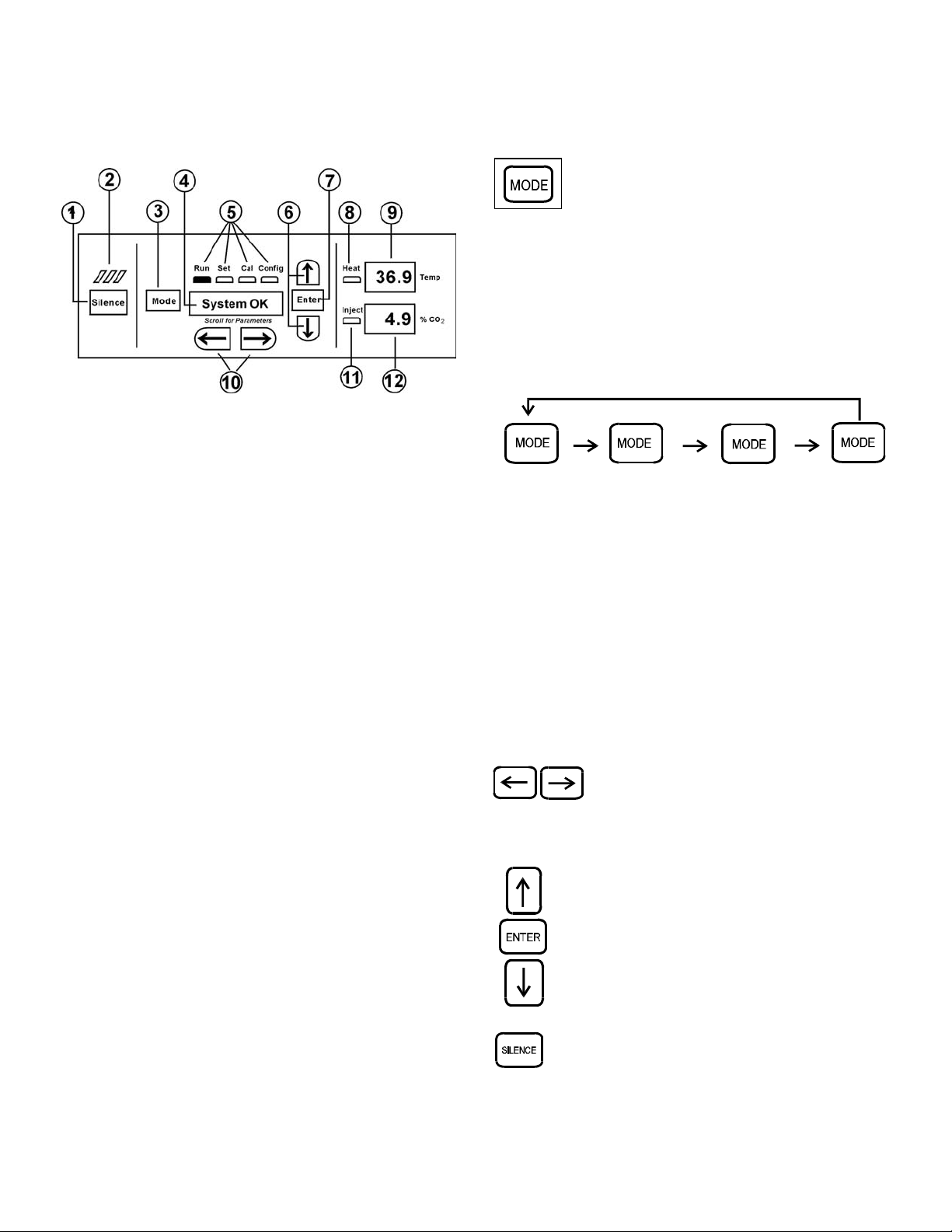

1.1 Control Panel Keys, Displays and Indicators

1. Silence - Silences the audible alarm.

2. Alarm Indicator - Light pulses on/off during an alarm

condition in the cabinet.

3. Mode Select Switch - Used to select Run, Setpoints,

Calibration and System Configuration Modes.

4. Message Center - Displays system status.

5. Mode Select Indicators -

• Run: Run Menu

• Set: Set Points Menu

• Cal: Calibrate Menu

• Config:: Configuration Menu

6. Up and Down Arrows - Increases or decreases the num-

ber values, toggles between choices.

7. Enter - Stores the value into computer memory.

8. Heat Indicator - Lights when power is applied to the

heaters.

9. Temp Display – Displays temperature continuously

10. Scroll for Parameters Arrows - Moves the operator

through the choices of the selected mode.

11.CO

2Inject Indicator - Lights when CO2is being injected

into the incubator.

12.%CO

2Display - Displays CO2percentage continuously.

Model 3950/3951 ____________________________________________________________________Installation and Start-Up

1 - 2

1.2 Operation of the Keypad

The Model 3950 Series Reach-In Incubator has

four basic modes that allow incubator setup: Run,

Setpoints, Calibration and System Configuration.

• Run is the default mode during normal operation.

• Set is used to enter system setpoints.

• Calibration is used to calibrate various system parameters.

• Configuration allows for custom setup of various options.

The chart below shows the selections under each of the

modes.

Scroll for Parameters Arrows: Steps the

operator through the parameters of SET, CAL

and CONFIG Modes. The right arrow goes to

the next parameter, the left arrow returns to

the previous parameter.

Up Arrow: Increases or toggles the parameter val-

ues that have been selected in the SET, CAL, and

CONFIG Modes.

Enter: Must press Enter key to save to memory all

changed values.

Down Arrow: Decreases or toggles the parameter

values that have been selected in the SET, CAL and

CONFIG Modes.

Silence Key: Press to silence the audible alarm.

See Section 4 for alarm ringback times.

Figure 1-4

RUN

SETPOINT

CALIBRATION

CONFIGURATION

Default Mode

Temperature

Temp Offset

Audible

Overtemp

CO2Cal

Access Code

CO2

Temp Lo Alarm

Temp Relay

CO2Lo Alarm

CO2Hi Alarm

CO2Relay

CO2Z & S #’s

RH High On/Off

H2O Alarm On/Off

Tank Select

Gas Guard

RS485 Address

Basic Unit Displays

Option Displays

1.3 Installing the Unit

a. Choosing the Location

Units must be installed against a wall or similar

structure. Maintain a three inch clearance behind

the incubator for electrical, water and gas hook-

ups.

• Locate the unit on a firm level surface capable of support-

ing the unit weight of approximately 500 lbs.

• Locate the unit away from doors and windows and heating

and air conditioning ducts.

This incubator weighs approximately 500 lbs.

Have sufficient personnel available when moving.

b. Preliminary Cleaning and Disinfecting

Remove the shipping tape securing the screws to the side-

wall of the chamber. Disinfect all interior surfaces with a gener-

al-use laboratory disinfectant. Rinse thoroughly with sterile dis-

tilled water, then 70% ethanol. Dry with a sterile cloth as need-

ed.

Disinfect the shelf channels and shelves, then rinse with

distilled water before installing.

Before using any cleaning or decontamination

method except those recommended by the manu-

facturer, users should check with the manufactur-

er that the proposed method will not damage the

equipment.

Accidental spills of hazardous materials on or

inside this unit are the responsibility of the user.

c. Installing the Shelves

The shelves may be

installed at any level in

the incubator. Install a

shelf channel on each

side. With the tabs point-

ing up, attach the channel

by locating the rivet into a

slotted hole, far end first.

Pull the channel toward

the front and slide the

front rivet on the channel into the slotted hole and press down.

Make sure that the channels are opposite each other so that the

installed shelf will be level.

d. Leveling the Unit

Place a bubble-type level on a shelf inside the incubator.

Adjust the feet as needed; counterclockwise to lengthen or

clockwise to shorten. Level the unit front-to-back and left-to-

right.

e. Attaching the Drain Lines

NOTE: Drain connections on the back of the unit are shipped

capped. If humidity is not required, the caps should be left on

the drains.

If manual or gravity feed method is used for humidity in

the cabinet, connecting the drains is optional.

If an in-house distilled water supply is used to fill the

reservoir, it is recommended that the drains be connected to a

floor drain.

Model 3950/3951 ____________________________________________________________________Installation and Start-Up

1 - 3

Figure 1-5

Figure 1-6

f. The Water Supply

For best operation of the incubator, sterilized distilled,

demineralized or de-ionized water should be used in the humid-

ity reservoir. Water purity should be in the resistance range of

50K Ohm/cm to 1M Ohm/cm, or a conductivity range of 20.0

uS/cm to 1.0 uS/cm. Refer to ASTM Standard D5391-93 or

D4195-88 for measuring water purity.

Distillation systems, as well as some types of reverse

osmosis water purity systems, can produce water in the quality

range specified. Tap water is not recommended as it may con-

tain chlorine, which can deteriorate the stainless steel. Tap

water may also have a high mineral content, which would pro-

duce a build-up of scale in the reservoir. High purity, ultra pure

or milli-q water is not recommended as it is an extremely

aggressive solvent and will deteriorate the stainless steel. High

purity water has a resistance of above 1M Ohm to 18M Ohm.

Even high purity water can contain bacteria and organic con-

taminants. Water should always be sterilized or treated with a

decontaminant, safe for use with stainless steel as well as safe

for the product, prior to being introduced into the humidity

reservoir.

The incubator is equipped with a liquid level float switch

that detects low water levels in the humidity reservoir and pro-

duces an alarm condition. As all applications do not require

humidity, this alarm can be disabled. To disable the ADD

WATER alarm, see Section 3.1a. If humidity is required in the

current application, press the Silence key on the control panel

to mute the alarm while the humidity reservoir is being filled.

Distilled or de-ionized water used in the humidity

reservoir must be within a quality resistance range

of 50K Ohm/cm to 1M Ohm/cm to protect and

prolong the life of the stainless steel. Use of water

outside the specified range will decrease the oper-

ating life of the unit and may void the warranty.

g. Filling the Humidity Reservoir

1. In-house “distilled” water supply

All incubators provide a connection for using an in-house

water supply. Connect a low pressure (not more than 30 PSI)

water line, equipped with a manual shut-off valve, to the inlet

fitting on the float valve reservoir. The 1/4” hose connection is

located on the rear of the incubator cabinet. With the water

turned on, a float valve inside the incubator regulates the water

level in the humidity reservoir. When the reservoir is full, a 10-

second audible tone is heard and the ADD WATER message no

longer displays.

2. Manual method

This fill system consists of a funnel attached to the side

duct sheet and tubing located inside the incubator. Disinfect the

funnel and rinse with sterile water before using. This funnel

may be moved to a preferred location by unscrewing the well

nuts and disconnecting it from the sidewall. Tighten the nuts

after relocation. The holes allotted for funnel use are slightly

larger and in a centralized area. See Figure 1-6.

To fill the reservoir, pour sterile distilled water (approxi-

mately 2.5 gallons) into the funnel. When the float switch trips,

a 10-second audible tone sounds and the ADD WATER mes-

sage no longer displays. Add 1 gallon after the 10-second tone

is heard.

3. Gravity feed method

An optional carboy water fill system is also available. The

carboy option kit includes an instruction sheet that details the

installation of the system.

h. Connecting the Unit to Electrical Power

See the serial tag on the side of the unit for electrical speci-

fications or refer to the electrical schematics at the end of this

manual.

Connect the incubator to a grounded, dedicated

circuit. The power cord connector is the mains

disconnect device for the incubator. Position the

incubator so the unit can be easily disconnected.

Plug the provided power cord into the power inlet connec-

tor on the back of the cabinet, then into the grounded, dedicated

electrical circuit.

The 3950 Series also has an internal outlet located on the

right side of the interior back wall. The outlet is to provide

power (230W maximum) to accessory equipment. This outlet is

not to be used when the temperature is above 40°C and the RH

more than 50%.

Model 3950/3951 ____________________________________________________________________Installation and Start-Up

1 - 4

Figure 1-6

i. Connecting the CO2Gas Supply

High concentrations of CO2gas can cause

asphyxiation.

OSHA Standards specify that employee exposure

to carbon dioxide in any 8-hour shift of a 40-

hour work week shall not exceed the 8-hour time

weighted average of 5000 PPM (0.5% CO2). The

short-term exposure limit for 15 minutes or less is

30,000 ppm (3% CO2). Carbon dioxide monitors

are recommended for confined areas where con-

centrations of carbon dioxide gas can accumu-

late.

This incubator is designed for CO2gas only.

Connecting a flammable or toxic gas could result

in a hazardous condition.

Gases other than CO2should not be connected to

this equipment. CO2gas cylinders have a UN1013

label on the cylinder and are equipped with a

CGA 320 outlet valve. Check the gas cylinder for

the proper identification labels. The CO2gas sup-

ply being connected to the incubator should be

industrial grade, 99.5% pure. Do not use CO2gas

cylinders equipped with siphon tubes. A siphon

tube is used to extract liquid CO2from the cylin-

der, which can damage the pressure regulator.

Consult with your gas supplier to ensure that the

CO2cylinder does not contain a siphon tube. Gas

cylinders should also be secured to a wall or

other stationary object to prevent them from tip-

ping.

A two-stage CO2pressure regulator is required to

be installed on the outlet valve of the gas cylinder.

Input pressure to the incubator must be main-

tained at 15 psig (103.4 kPa) for proper perform-

ance of the CO2control system. A single stage

CO2pressure regulator will not maintain 15 psig

(103.4 kPa) to the incubator as the pressure in

the CO2cylinder decreases; therefore, a two-stage

regulator is recommended.

If higher purity CO2is desired inside the incuba-

tor (greater than 99.5% pure), the pressure regu-

lator should be constructed with a stainless steel

diaphragm, along with specifying the purity of the

CO2from the gas supplier. Follow the manufac-

turer’s instructions to ensure proper and safe

installation of the pressure regulator on the gas

cylinder.

Consult your facility safety officer to ensure that

the equipment is installed in accordance with the

codes and regulations that are applicable in your

area.

The CO2gas supply being connected should be industrial

grade 99.5% pure and should not contain siphon tubes. Install a

two-stage pressure regulator at the cylinder outlet. The high

pressure gauge at the tank should have 0-2000 psig range. The

low pressure gauge, at the incubator inlet, should have a 0-30

psig range. Input pressure to the incubator must be maintained

at 15 psig (103.4 kPa).

Each tank should be connected to one incubator

only.

The incubator has serrated fittings on the back of the cabi-

net to connect the gas supply. Refer to Figure 1-2. The fitting is

labeled CO2Inlet #1 Tank. Make sure that the connections are

secured with clamps. Check all fittings for leaks.

For units having the CO2Gas Guard option, refer to

Section 6.2.

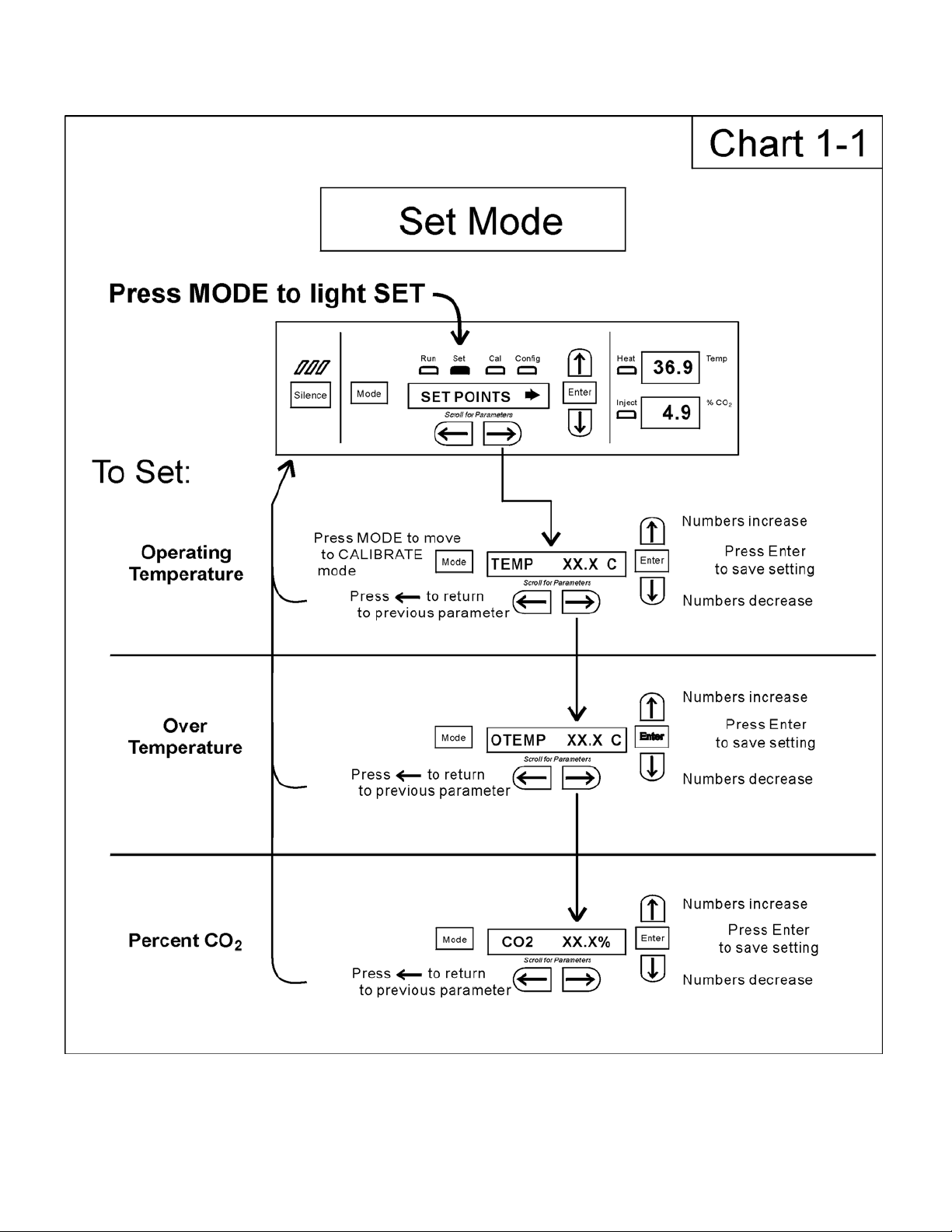

1.4 Incubator Start-Up

With the incubator properly installed, connected to power,

the humidity reservoir filled and the unit connected to a gas

supply, system setpoints can be entered. The following set-

points can be entered in Set Mode: Temperature,

Overtemperature and CO2. To enter Set Mode, press the Mode

key until the Set indicator lights. Press the right and/or left

arrow keys until the proper parameter appears in the message

display center. See Chart 1-1 for more detail.

a. Setting the Operating Temperature

This incubator has an operating temperature range of

10.0°C to 60.0°C, depending on ambient temperature. It is

shipped from the factory with a temperature setpoint of 10.0°

C. At this setting, all heaters are turned off. To change the

operating temperature setpoint:

1. Press the Mode key until the Set indicator lights.

2. Press the right arrow until “Temp XX.X” is displayed in

the message center.

3. Press up/down until the desired temperature setpoint is

displayed.

4. Press Enter to save the setpoint.

5. Press the Mode key until the Run indicator lights for

Run mode or press the right/left arrow keys to go to

next/previous parameter.

Any equipment placed inside chamber must be

rated for unit operating temperature and humidity.

Model 3950/3951 ____________________________________________________________________Installation and Start-Up

1 - 5

b. Setting the Overtemp Setpoint

The independent overtemp system is designed as a

safety to protect the incubator only. It is not

intended to protect or limit the maximum tempera-

ture of the cell cultures or customer’s equipment

inside the incubator if an overtemp condition

occurs.

All Thermo Forma 3950 Series incubators are equipped

with a secondary temperature monitoring system to monitor the

air temperature inside the cabinet. This system is designed as a

safety device to turn off all heaters in the event of a temperature

control failure. The temperature control point in the incubator

will be approximately ±1°C of the overtemp setpoint.

The overtemp setpoint is set by the factory (default) at

40°C. However, the overtemp can be reset over a range from

0.5°C above the operating temperature setpoint to 65°C.

If the incubator’s operating temperature setpoint is set

above the overtemp setpoint, the overtemp setpoint will auto-

matically update to 1°C above the temperature setpoint. It is

recommended that the overtemp setpoint be maintained at 1°C

over the operating temperature setpoint.

To set the Overtemp setpoint:

1. Press the Mode key until the Set indicator lights.

2. Press the right arrow until Otemp XX.X is displayed in

the message center.

3. Press the up or down arrow until the desired Otemp set-

point is displayed.

4. Press Enter to save the setting.

5. Press the Mode key until the Run indicator lights, or

press the right or left arrow to go to the next or previous

parameter.

c. Setting the CO2Setpoint

All CO2cells are calibrated at the factory at 37°C,

medium humidity and 10% CO2. Therefore, if a temperature

setpoint of 37°C has been entered, the humidity reservoir has

been filled and the CO2control is set to run between 0-10%, the

CO2setpoint may be entered immediately. Otherwise, it is

important to allow the unit 12 hours to stabilize at the tempera-

ture setpoint before entering the CO2setpoint.

All models of the incubator have a CO2setpoint range of

0.0% to 20.0%. The incubator is shipped from the factory with

a CO2setpoint of 0.0%. At this setting, all CO2control and

alarms are turned off.

To change the CO2setpoint:

1. Press the Mode key until the Set indicator lights.

2. Press the right arrow until “CO2 XX.X” is displayed in

the message center.

3. Press the up/down arrow until the desired CO2setpoint

is displayed.

4. Press Enter to save the setpoint.

5. Press the Mode key until the Run indicator lights to go

to Run mode, or press the right/left arrow keys to go to

next/previous parameter.

Model 3950/3951 ____________________________________________________________________Installation and Start-Up

1 - 6

Model 3950/3951 ____________________________________________________________________Installation and Start-Up

1 - 7

Section 2 - Calibration

2.1 Calibration Mode

After the unit has stabilized, several different systems can

be calibrated. In the calibration mode, the air temperature, CO2

and RH levels can be calibrated to reference instruments. To

access the calibration mode, press the Mode key until the Cal

indicator lights. Press the right and/or left arrow until the prop-

er parameter appears in the message center. See Chart 2-1 at the

end of this section for more detail.

Calibration frequency is dependent on use, ambient condi-

tions and accuracy required. A good laboratory practice would

require at least an annual calibration check. On new installa-

tions, all parameters should be checked after the stabilization

period.

Prior to calibration, the user should be aware of the follow-

ing system functions. While the unit is in the calibration mode,

all system control functions are stopped so the unit remains sta-

ble. Readout of the system being calibrated will appear on the

message center. If no keys are pressed for approximately five

minutes while in Calibration mode, the system will reset to Run

mode so control functions are reactivated.

Before making any calibration or adjustments to

the unit, it is imperative that all reference instru-

ments be properly calibrated.

a. Calibrating the Temperature

Before calibration, allow the cabinet temperature to stabi-

lize. Place the calibrated instrument in the center of the cham-

ber. The instrument should be in the airflow, not against the

shelf.

Temperature Stabilization Periods

Start-Up - Allow 12 hours for the temperature in the cabinet to

stabilize before proceeding.

Presently Operating - Allow at least 2 hours after the display

reaches setpoint for temperature to stabilize before proceeding.

1. Press the Mode key until Cal indicator lights.

2. Press the right arrow until “TEMPCAL XX.X” appears

in the message center.

3. Press the up/down arrow to match the display to the cal-

ibrated instrument.

4. Press Enter to store calibration.

5. Press the Mode key to return to Run or the right/left

arrow to go to next/previous parameter.

b. Calibrating the CO2System

Model 3950 Series incubators have a CO2sensor. The incu-

bator atmosphere is not only effected by the quantity of CO2

present but also by the air temperature and water vapor present

in the incubator atmosphere. In monitoring the effects of CO2,

air temperature and absolute humidity must be held constant so

any change is caused by a change in CO2concentration.

Changing temperature or changing from elevated humidity

to room ambient humidity levels will require re-calibration of

the CO2control.

CO2Sensor Stabilization Periods

Start -Up - The CO2sensor has been calibrated at the factory

for 37°C and elevated humidity. Allow the temperature, humid-

ity and CO2levels in the chamber to stabilize at least 12 hours

before checking the CO2concentration with an independent

instrument.

Presently Operating - Make sure the chamber doors are

closed. Allow at least 2 hours after the temperature and CO2

displays reach their setpoints for chamber atmosphere stabiliza-

tion.

1. Make sure the stabilization periods outlined above are

followed.

2. Sample the chamber atmosphere through the sample port

with an independent instrument. Sample the atmosphere

at least 3 times to ensure accuracy of the instrument.

3. Press the Mode key until the Cal indicator lights.

4. Press the right arrow until “CO2 CAL XX.X” is dis-

played in the message center.

5. Press the up /down arrows to change the display to

match the independent instrument.

6. Press Enter to store the calibration.

7. Press the Mode key to return to Run or the right or left

arrows to go to the next/ previous parameter.

Model 3950/3951 _____________________________________________________________________________Calibration

2 - 1

Model 3950/3951 _____________________________________________________________________________Calibration

2 - 2

Section 3 - Configuration

3.1 Configuration Mode

Several features available in the Configuration Mode allow

custom setup of the incubator. These features are listed and

described below. All features may not be necessary in all appli-

cations, but are available if needed. To enter Configuration

mode, press the Mode key until the Config indicator lights.

Press the right and/or left arrow until the appropriate parameter

appears in the message center. See Chart 3-1 at the end of this

section for more detail.

a. Disabling the ADD WATER Alarm

All applications do not require humidity. For this reason,

the ADD WATER alarm can be disabled. The factory default

for the ADD WATER alarm is ON.

1. Press the Mode key until the Config indicator lights.

2. Press the right arrow until H2O ALM XXX is displayed

in the message center.

3. Press up/down arrow to toggle H2O ALM ON or OFF.

4. Press Enter to save the setting.

5. Press the Mode key to return to run mode or right/left to

go to next/previous parameter.

Note: Verify that the RH HIGH feature is set to OFF after dis-

abling the ADD WATER alarm.

b. Turning All Audible Alarms ON/OFF

The audible alarms can be turned on or off. The factory

setting is ON.

1. Press the Mode key until the Config indicator lights.

2. Press the right arrow until Audible XXX is displayed in

the message center.

3. Press up/down arrow to toggle Audible ON/OFF.

4. Press Enter to save the setting.

5. Press the Mode key to return to run mode or right/left to

go to next/previous parameter.

c. Setting an Access Code

A 3-digit Access Code can be entered to avoid unautho-

rized personnel from changing the setpoints, calibration, or con-

figuration. A setting of 000 will bypass the access code. The

factory setting is 000.

1. Press the Mode key until the Config indicator lights.

2. Press the right arrow until Acc Code XXX is displayed

in the message center.

3. Press up or down arrow to change the access code.

4. Press Enter to save the access code.

5. Press the Mode key to return to the Run mode or

right/left to go to next/previous parameter.

d. Setting Low Temp Alarm Limit (tracking alarm)

The low temp alarm limit is the deviation from the temper-

ature setpoint, which will cause a low temp alarm. The low

temp alarm is variable from 0.5° below setpoint to 5.0° below

setpoint. The factory setting is 1.0° below setpoint. A minus

sign in the display indicates that the alarm setting is below the

setpoint.

1. Press the Mode key until the Config indicator lights.

2. Press the right arrow until Temp Lo -X.X is displayed

in the message center.

3. Press up/down arrow to change the low temp alarm

limit.

4. Press Enter to save the low temp alarm limit.

5. Press the Mode key to return to Run mode or right/left

to go to next/previous parameter.

e. Enabling Temperature Alarms to Trip Relay

Contacts

The temperature alarms can be programmed to trip the

remote alarm contacts. A setting of ON will cause this, a set-

ting of OFF will not allow temperature alarms to trip the con-

tacts. The factory setting is ON.

1. Press the Mode key until the Config indicator lights.

2. Press the right arrow until TMP RLY XXX is displayed.

3. Press the up/down arrow to toggle the setting ON/OFF.

4. Press Enter to save the setting

5. Press the Mode key to return to Run or the right/left

arrow key to go to next/previous parameter.

Model 3950/3951 _____________________________________________________________________________Configuration

3 - 1

f. Setting Low CO2Alarm Limit (tracking alarm)

The low CO2alarm limit is the deviation from the CO2set-

point, which will cause a low CO2alarm. The setpoint is vari-

able from 0.5 % CO2below setpoint to 5.0 % CO2below set-

point. The factory setting is 1.0 % CO2below setpoint. A

minus in the display indicates that the alarm setting is below

the setpoint.

1. Press the Mode key until the Config indicator lights.

2. Press the right arrow until CO2 LO -X.X is displayed in

the message center.

3. Press up/down arrow to change the low CO2 alarm

limit.

4. Press Enter to save the low CO2 alarm limit.

5. Press the Mode key to return to Run mode or right/left

to go to next/previous parameter.

g. Setting High CO2Alarm Limit (tracking alarm)

The high CO2alarm limit is the deviation from the CO2set-

point, which will cause a high CO2alarm. The setpoint is vari-

able from 0.5 % CO2above setpoint to 5.0 % CO2above set-

point. The factory setting is 1.0 % CO2above setpoint.

1. Press the Mode key until the Config indicator lights.

2. Press the right arrow until CO2 HI X.X is displayed in

the message center.

3. Press up/down arrow to change the high CO2alarm

limit.

4. Press Enter to save the high CO2alarm limit.

5. Press the Mode key to return to run mode or right/left to

go to next/previous parameter.

h. Enabling CO2Alarms to Trip Relay Contacts

High and Low CO2alarms can be programmed to trip the

remote alarm contacts. A setting of ON will cause this, a set-

ting of OFF will not allow CO2alarms to trip the contacts. The

factory setting is ON.

1. Press the Mode key until the Config indicator lights.

2. Press the right arrow until CO2 RLY XXX is displayed

in the message center.

3. Press up/down arrow to toggle the setting ON/OFF.

4. Press Enter to save the setting.

5. Press the Mode key to return to Run Mode or right/left

to go to next/previous parameter.

i. Setting New Zero Number for New CO2Sensors

If a new CO2sensor is being installed, the two numbers on

the factory installed sticker on the cell must be entered to cali-

brate the CO2in the unit.

Note: For the technician’s convenience, a label containing the

two numbers on the cell is affixed inside the electronics drawer.

1. Press the Mode key until the Config indicator lights.

2. Press the right arrow until Z# XXXX is displayed in the

message center.

3. Press up/down arrow to change the zero number to

match the sticker.

4. Press Enter to save the setting.

5. Press the Mode key to return to Run mode or right/left

to go to next/previous parameter.

j. Setting New Span Number for CO2Sensors

If a new CO2sensor is being installed, the two numbers on

the factory installed sticker on the cell must be entered to cali-

brate the CO2in the unit.

Note: For the technician’s convenience, a label containing the

two numbers on the cell is affixed inside the electronics drawer.

1. Press the Mode key until the Config indicator lights.

2. Press the right arrow until S# XXXX is displayed in the

message center.

3. Press up/down arrow to change the span number to

match the sticker.

4. Press Enter to save the setting.

5. Press the Mode key to return to Run mode or right/left

to go to next/previous parameter.

k. Enabling the High Humidity Feature

In normal operation, the incubator will maintain the humid-

ity level above 80%. If a higher RH level is required, the RH

HIGH feature may be turned ON. This allows the heater

attached to the humidity reservoir to be enabled, resulting in

RH levels above 90%. The factory default for the RH HIGH

feature is OFF.

1. Press the Mode key until the Config indicator lights.

2. Press the right arrow until RH HIGH XXX is displayed

in the message center.

3. Press up/down arrow to toggle RH HIGH ON or OFF.

4. Press Enter to save the setting.

5. Press the Mode key to return to Run mode or right/left

to go to next/previous parameter.

Note: Verify that the ADD WATER alarm is set to ON after

enabling the RH HIGH feature.

Model 3950/3951 _____________________________________________________________________________Configuration

3 - 2

l. Selecting a Primary Tank w/ Gas Guard Option

On units equipped with the Gas Guard option, a primary

tank can be selected. The primary tank will be either Tank 1 or

2. The factory setting is Tank 1 .

1. Press the Mode key until the Config indicator lights.

2. Press the right arrow until Tank Sel X is displayed in the

message center.

3. Press the up/down arrow to toggle the setting between 1

and 2 .

4. Press Enter to save the setting.

5. Press the Mode key to return to Run mode or right/left

to go to next/previous parameter.

m. Enabling the Gas Guard System

On units equipped with the Gas Guard option, the Gas

Guard system may be turned ON or OFF if it is not in use. The

factory setting is OFF.

1. Press the Mode key until the Config indicator lights.

2. Press the right arrow until Gas Grd XX is displayed in

the message center.

3. Press up/down arrow to toggle the setting ON/OFF.

4. Press Enter to save the setting.

5. Press the Mode key to return to Run mode or right/left

to go to next/previous parameter.

n. Setting RS485 Communications Address

(1535 compatible only)

On units that have the RS485 option, direct communication

with the Thermo Forma 1535 Model alarm system can be

established. Each piece of equipment connected to the 1535

must have a unique address. An address of 0-24 can be entered

for the incubator. A setting of 0 is an invalid address that the

1535 will ignore. The factory setting for the RS485 address is

0.

1. Press the Mode key until the Config indicator lights.

2. Press the right arrow until RS485 XX is displayed in the

message center.

3. Press up/down arrow to move the RS485 address.

4. Press Enter to save the RS485 address.

5. Press the Mode key to return to Run mode or right/left

to go to next/previous parameter.

Model 3950/3951 _____________________________________________________________________________Configuration

3 - 3

Model 3950/3951 _____________________________________________________________________________Configuration

3 - 4

Model 3950/3951 _____________________________________________________________________________Configuration

3 - 5

Section 4 - Alarms

4.1 Alarms

The Model 3950 Series incubator is equipped with a sys-

tem which notifies the user of an alarm condition inside the

incubator. All alarms are displayed in the control panel message

center. The following table contains information on all possible

systems alarms.

To avoid alarms going off in day-to-day use, some alarms

are equipped with a time delay feature. For this to function cor-

rectly, the alarm condition must exist for the specified length of

time before the message center will display the alarm. This

allows for interruptions, such as door openings, to occur with-

out the incubator going into a continuous state of alarm.

When an alarm condition exists, the Silence key can be

pressed to temporarily mute the audible alarm. The message

center will continue to show the alarm condition. If the alarm

condition is not corrected within a specified length of time, the

alarm will sound again or “ringback” to remind the user.

When multiple alarm conditions occur, active messages are

displayed in the display center one at a time, updating at 5-sec-

ond intervals. Pressing Silence during multiple alarms causes

all active alarms to be muted and to ringback in 15 minutes.

The temperature alarms are disabled when the Temp set

point is 10°C. The CO2alarms are disabled when the CO2set

point is 0.0%.

Model 3950/3951 _________________________________________________________________________________Alarms

4 - 1

4.2 Sensor Fault Alarms

The microprocessor in 3950 Series incubators continually

scans all available sensors to ensure that they are operating

properly. Should an error be detected, the incubator will sound

an alarm and display the appropriate message. If such an alarm

occurs, contact your local distributor or the Thermo Forma

Service department at 740-373-4763 or 1-888-213-1790

(U.S.A. and Canada) or fax 740-373-4189.

Description Message Code Delay Ringback Relay

No alarm condition exists SYSTEM OK ----- ----- -----

Temp > Otemp Set point SYS IN OTEMP 0 min. 15 min. Yes

Air Temp Sensor Fault (See Section 4.2) TMP SENS ERR 0 min. 15 min. No

Temperature Controller Failure (See Section 4.2) TMP CTRL ERR 0 min. 15 min. YES

CO2Sensor Fault (See Section 4.2) CO2 SENS ERR 0 min. 15 min. No

Water Level in Reservoir is Low ADD WATER 0 min. 15 min. No

Inner Door is Open DOOR OPEN 15 min. 15 min. No

CO2> CO2 High Tracking Alarm CO2 IS HIGH 15 min. 15 min. Programmable

CO2< CO2 Low Tracking Alarm CO2 IS LOW 15 min. 15 min. Programmable

TEMP < TEMP Low Tracking Alarm TEMP IS LOW 15 min. 15 min. Programmable

Tank 1 is low, switch to Tank 2 (Gas Guard only) TANK1 LOW 0 min. ---- No

Tank 2 is low, switch to Tank 1 (Gas Guard only) TANK2 LOW 0 min. ---- No

Both tanks are low (Gas Guard only) TANK 1 and 2 LOW 0 min. 15 min. No

- All alarm delays and ringback times are + 30 seconds -

This manual suits for next models

1

Table of contents

Other Thermo Forma Accessories manuals

Popular Accessories manuals by other brands

Philips

Philips P-5722-C Specifications

Solar Plus

Solar Plus Ajax GlassProtect manual

Refteco

Refteco RPS Series Installation and maintenance instruction

elsner elektronik

elsner elektronik P04i-W Technical specifications and installation instructions

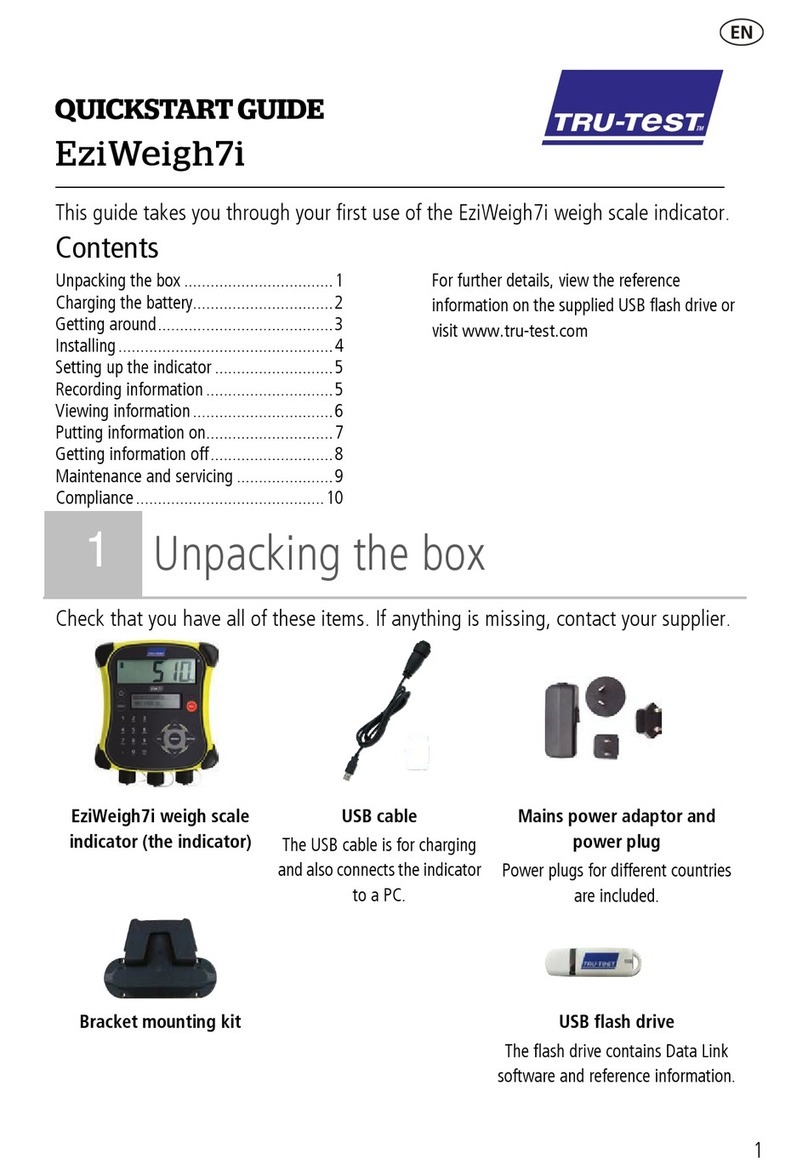

Tru-Test

Tru-Test EziWeigh7i quick start guide

Squirrel

Squirrel OUTLAW user manual