Thermo Forma 3110 Series Operating instructions

-~

ARTISAN

®

~I

TECHNOLOGY

GROUP

Your definitive source

for

quality

pre-owned

equipment.

Artisan Technology

Group

Full-service,

independent

repair

center

with

experienced

engineers

and

technicians

on staff.

We

buy

your

excess,

underutilized,

and

idle

equipment

along

with

credit

for

buybacks

and

trade-ins

.

Custom

engineering

so

your

equipment

works

exactly as

you

specify.

•

Critical

and

expedited

services

•

Leasing

/

Rentals/

Demos

• In

stock/

Ready-to-ship

•

!TAR-certified

secure

asset

solutions

Expert

team

ITrust

guarantee

I

100%

satisfaction

All

tr

ademarks,

br

a

nd

names, a

nd

br

a

nd

s a

pp

earing here

in

are

th

e property of

th

e

ir

r

es

pecti

ve

ow

ner

s.

Visit our website - Click HERE

Model: 3110 Series*

CO2Water Jacketed Incubator

Series II

Operating and Maintenance Manual

Manual No: 7033110 Rev. 9

*Refer to listing of all models on Page i.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Model 3110/3210 Series ___________________________________________________________________________

i

Read This Instruction Manual.

Failure to read, understand and follow the instructions in

this manual may result in damage to the unit, injury to operat-

ing personnel, and poor equipment performance.

CAUTION! All internal adjustments and maintenance must

be performed by qualified service personnel.

Refer to the serial tag on the back of this manual.

The material in this manual is for information purposes

only. The contents and the product it describes are subject to

change without notice. Thermo Forma makes no representations

or warranties with respect to this manual. In no event shall

Thermo Forma be held liable for any damages, direct or inciden-

tal, arising out of or related to the use of this manual.

Single Chamber Models

Model CO2 Sensor* O2Voltage**

3110 T/C No 115

3111 T/C No 230

3120 IR No 115

3121 IR No 230

3130 T/C Yes 115

3131 T/C Yes 230

3140 IR Yes 115

3141 IR Yes 230

*T/C is a thermal conductivity sensor. IR is an infrared

sensor.

**All units are 50/60 Hz.

MANUAL NUMBER 7033110

9 20221/IN-2959 3/4/02 Updated 200 drawing for use with Models 5050/5060 Series (display bd) ccs

-- 20581/IN-3015 1/21/02 Corrected temp sensor error sequence in chart on 4-1 ccs

-- 20484 11/21/01 Removed all specific references to Model 2095 bath ccs

8 20374/IN-2994 11/7/01 Updated 200 drawing - Kaizen, board hardware ccs

7 20336/PIP-034 10/10/01 Removed blower motor cover, added nylon cable clamps ccs

-- 20015/IN-2942 5/21/01 Removed top shelf tab from side duct for better HEPA fit ccs

6 19866/IN-2907 3/19/01 Updated O2fuel cell warranty info from 2 years to 1 ccs

5 19473 2/20/01 Added water jacket rust inhibitor information ccs

REV ECR/ECN DATE DESCRIPTION By

Contains Parts and Assemblies

Susceptible to Damage by

Electrostatic Discharge (ESD)

CAUTION

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Model 3110/3210 Series ___________________________________________________________________________

ii

Important operating and/or maintenance instructions. Read the accompanying text carefully.

Ce symbole attire l'attention de l'utilisateur sur des instructions importantes de fonctionnement et/ou d'entretien. Il

peut être utilisé seul ou avec d'autres symboles de sécurité. Lire attentivement le texte d'accompagnement.

Wichtige Betriebs- und/oder Wartungshinweise. Lesen Sie den nachfolgenden Text sorgfältig.

Importante instruccions de operacion y/o mantenimiento. Lea el texto acompanante cuidadosamente.

Potential electrical hazards. Only qualified persons should perform procedures associated with this symbol.

Ce symbole attire l'attention de l'utilisateur sur des risques électriques potentiels. Seules des personnes qualifiées

doivent appliquer les instructions et les procédures associées à ce symbole.

Gefahr von Stromschlägen. Nur qualifizierte Personen sollten die Tätigkeiten ausführen, die mit diesem Symbol beze-

ichnet sind.

Potencial de riesgos electricos. Solo personas das capacitadadas deben ejecutar los procedimientos asociadas con este

simbulo.

Equipment being maintained or serviced must be turned off and locked off to prevent possible injury.

Risques potentiels liés à l'énergie. L'équipement en entretien ou en maintenance doit être éteint et mis sous clé pour

éviter des blessures possibles.

Geräte, an denen Wartungs- oder Servicearbeiten durchgeführt werden, müssen abgeschaltet und abgeschlossen wer-

den, um Verletzungen zu vermeiden.

El equipo recibiendo servicio o mantenimiento debe ser apagado y segurado para prevenir danos.

Hot surface(s) present which may cause burns to unprotected skin, or to materials which may be damaged by elevated

temperatures.

Présence de surface(s) chaude(s) pouvant causer des brûlures sur la peau non protégée, ou sur des matières pouvant

être endommagées par des températures élevées.

Heiße Oberfläche(n) können ungeschützter Haut Verbrennungen zufügen oder Schäden an Materialien verursachen,

die nicht hitzebeständig sind.

Superficias calientes que pueden causar quemaduras a piel sin proteccion o a materiales que pueden estar danados

por elevadas temperaturas.

√ Always use the proper protective equipment (clothing, gloves, goggles, etc.)

√ Always dissipate extreme cold or heat and wear protective clothing.

√ Always follow good hygiene practices.

√ Each individual is responsible for his or her own safety.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Model 3110/3210 Series ___________________________________________________________________________

iii

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

q. Enabling O2Alarms to Trip Contacts . . . . . . . . . .3 - 3

r. Enabling Temp/RH to be Displayed . . . . . . . . . . .3 - 4

s. Enabling CO2/O2to be Displayed . . . . . . . . . . . . .3 - 4

t. Selecting a Primary Tank w/ Gas Guard Option . .3 - 4

u. Enabling the Gas Guard System . . . . . . . . . . . . . .3 - 4

v. Setting a RS485 Communications Address . . . . .3 - 4

Section 4 - Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 1

4.1 Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 1

4.2 Sensor Fault Alarms . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 2

a. REPL O2 SNSR (Alarm) . . . . . . . . . . . . . . . . . . .4 - 2

b. O2 SNSR ERR (Alarm) . . . . . . . . . . . . . . . . . . . .4 - 2

c. CO2 SNSR ERR . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 2

d. IR AUTOZ ERR . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 2

Section 5 - Routine Maintenance . . . . . . . . . . . . . . . . . . .5 - 1

5.1 Disinfecting the Incubator Interior . . . . . . . . . . . . . .5 - 1

5.2 Cleaning the Cabinet Exterior . . . . . . . . . . . . . . . . . .5 - 2

5.3 Cleaning the Humidity Pan . . . . . . . . . . . . . . . . . . . . .5 - 2

5.4 Reversing the Door Swing . . . . . . . . . . . . . . . . . . . . .5 - 2

a. Reversing the Hinges for Exterior Door . . . . . . . .5 - 2

5.5 Replacing Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 3

5.6 HEPA Filter Maintenance . . . . . . . . . . . . . . . . . . . . .5 - 6

5.7 Replacing the Air Sample Filter . . . . . . . . . . . . . . . .5 - 7

5.8 Replacing the Access Port Filter . . . . . . . . . . . . . . . .5 - 7

5.9 Draining Water Jacket . . . . . . . . . . . . . . . . . . . . . . . .5 - 7

5.10 O2Sensor Fuel Cell . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 7

5.11 Replacing the O2Sensor . . . . . . . . . . . . . . . . . . . . . .5 - 7

5.12 Adding or Replenishing the W/J Rust Inhibitor . . . .5 - 8

Section 6 - Factory Installed Options . . . . . . . . . . . . . . . .6 - 1

6.1 Connections to External Equipment . . . . . . . . . . . . .6 - 1

a. Connecting the Remote Alarm Contacts . . . . . . .6 - 1

b. Connecting the RS485 Interface . . . . . . . . . . . . . .6 - 1

c. Connecting the Analog Output Boards . . . . . . . . .6 - 1

6.2 Gas Guard for CO2or N2. . . . . . . . . . . . . . . . . . . . . .6 - 2

a. Connecting the CO2Gas Supplies . . . . . . . . . . . . .6 - 2

b. Connecting the N2Gas Supplies . . . . . . . . . . . . . .6 - 2

c. Activating the Built-in Gas Guard: . . . . . . . . . . . .6 - 3

d. Operation of the CO2or N2Gas Guard: . . . . . . . .6 - 3

6.3 Humidity Readout . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 3

a. Factors Affecting Humidity Level in Chamber: . .6 - 3

b. Accuracy of the Humidity Readout: . . . . . . . . . . .6 - 4

6.4 Factory Installed Cooling Coil . . . . . . . . . . . . . . . . .6 - 4

a. Installing the Cooling Coil Incubator . . . . . . . . . .6 - 4

Section 7 - Specifications . . . . . . . . . . . . . . . . . . . . . . . . .7 - 1

Section 8 - Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . .8 - 1

Section 9 - Electrical Schematics . . . . . . . . . . . . . . . . . . .9 - 1

Section 10 - Warranty Information . . . . . . . . . . . . . . . . . . . . . .

Appendix A - Supplements . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Model 3110/3210 Series ____________________________________________________________Table of Contents

Table of Contents

Section 1 - Installation and Start-up . . . . . . . . . . . . . . . . .1 - 1

1.1 Name and Description of Parts . . . . . . . . . . . . . . . . .1 - 1

1.2 Control Panel Keys, Displays and Indicators . . . . . . .1 - 2

1.3 Operating the Control Panel . . . . . . . . . . . . . . . . . . .1 - 2

1.4 Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 3

1.5 Installing the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 4

a. Choosing the Location . . . . . . . . . . . . . . . . . . . . .1 - 4

b. Stacking the Incubators . . . . . . . . . . . . . . . . . . . .1 - 4

c. Preliminary Cleaning and Disinfecting . . . . . . . .1 - 5

d. Installing the Access Port Filter . . . . . . . . . . . . . .1 - 5

e. Installing the Air Sample Filter . . . . . . . . . . . . . . .1 - 5

f. Installing the HEPA Filter . . . . . . . . . . . . . . . . . . .1 - 5

g. Installing the Shelves . . . . . . . . . . . . . . . . . . . . . . .1 - 6

h. Leveling the Unit . . . . . . . . . . . . . . . . . . . . . . . . .1 - 6

i. Connecting the Unit to Electrical Power . . . . . . . .1 - 6

j. Filling the Water Jacket . . . . . . . . . . . . . . . . . . . .1 - 6

k. Filling the Humidity Pan . . . . . . . . . . . . . . . . . . .1 - 6

l. Connecting the CO2Gas Supply . . . . . . . . . . . . . .1 - 7

m. Connecting the N2Gas Supply . . . . . . . . . . . . . . .1 - 8

1.6 Incubator Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 8

a. Setting the Operating Temperature . . . . . . . . . . . .1 - 8

b. Setting the Overtemp Setpoint . . . . . . . . . . . . . . .1 - 9

c. Setting the CO2Setpoint . . . . . . . . . . . . . . . . . . . .1 - 9

d. Setting the O2Setpoint . . . . . . . . . . . . . . . . . . . . .1 - 9

Section 2 - Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 1

2.1 Calibration Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 1

a. Calibrating the Temperature . . . . . . . . . . . . . . . . .2 - 1

b. Calibrating Thermal Conductivity CO2System . .2 - 1

c. Calibrating the Infra-Red CO2System. . . . . . . . .2 - 1

d. Calibrating the O2System . . . . . . . . . . . . . . . . . .2 - 2

e. Calibrating Relative Humidity . . . . . . . . . . . . . . .2 - 3

Section 3 - Configuration . . . . . . . . . . . . . . . . . . . . . . . . .3 - 1

3.1 Configuration Mode . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 1

a. Turning the Audible Alarm ON/OFF . . . . . . . . . .3 - 1

b. New HEPA Filter . . . . . . . . . . . . . . . . . . . . . . . . .3 - 1

c. Setting the REPLACE HEPA filter reminder . . . .3 - 1

d. Setting an Access Code . . . . . . . . . . . . . . . . . . . .3 - 1

e. Setting Low Temp Alarm Limit (tracking alarm) 3 - 1

f. Setting High Temp Alarm Limit (tracking alarm) 3 - 2

g. Enabling Temperature Alarms to Trip Contacts . .3 - 2

h. Setting Low CO2Alarm Limit (tracking alarm) .3 - 2

i. Setting High CO2Alarm Limit (tracking alarm) . .3 - 2

j. Enabling CO2Alarms to Trip Contacts . . . . . . . . .3 - 2

k. Setting New Zero Number for T/C CO2Sensors .3 - 2

l. Setting New Span Number for T/C CO2Sensors .3 - 3

m. Setting a Low RH Alarm Limit . . . . . . . . . . . . . .3 - 3

n. Enabling RH Alarms to Trip Contacts . . . . . . . . .3 - 3

o. Setting a Low O2Alarm Limit (tracking alarm) .3 - 3

p. Setting a High O2Alarm Limit (tracking alarm) .3 - 3

iv

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Model 3110/3210 Series ________________________________________________________Installation and Start-Up

1 - 1

Section 1 - Installation and Start-up

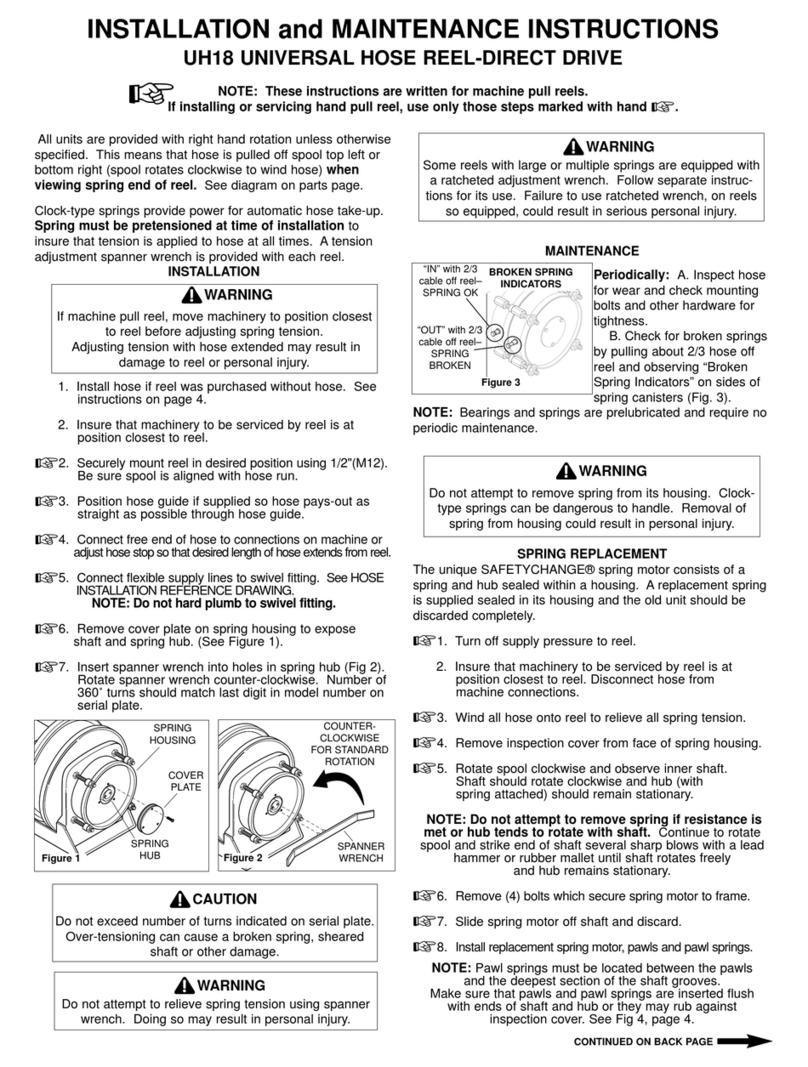

1.1 Name and Description of Parts

Heated Glass

Inner Door

Leveling

Legs (4)

Jacket Vent

Fill Port

Jacket

Drain

(remove plug

before using)*

Control Panel

Chamber Gas

Sample Port

Power

Switch

Hose

Barb

Insert

Figure 1-1

Water Jacket Incubator

• Outer Door - Reversible to opposite swing, see Section

5.4

• Heated Inner Door - Keeps chamber interior dry.

Reversible to opposite swing, see Section 5.4.

• Chamber Gas Sample Port - Used for sampling chamber

CO2content, using a Fyrite or similar instrument.

Should be capped when controlling O2.

• Main Power Switch

• Control Panel - Keypad, Displays and Indicators. (See

Figure 1-2).

• Fill Port - Used for filling the water jacket.

• Water Jacket Vent- Do not cover! Allows air to escape

from the water jacket during filling and normal expan-

sion and contraction when the incubator heats or cools.

• Leveling Legs - Used to level the unit.

• Water Jacket Drain – Remove plug and use hose barb

insert included. Plug when not in use.

Note: The incubators are stackable. See Section 1.5.

*When setting up the incubator, install the cover plate

packed inside the incubator shipping carton.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Model 3110/3210 Series ________________________________________________________Installation and Start-Up

1 - 2

KInject Indicator: Lights when gas is being injected into the

incubator. If the %CO2/O2display (item L) is continuously

displaying CO2, the light indicates CO2injection only. If

the %CO2/O2display is continuously displaying O2, light

indicates N2injection. If the %CO2/O2is toggling, either a

CO2or N2injection will cause the indicator to light.

L%CO2/O2display: Can be programmed to display CO2con-

tinuously or O2continuously (on units equipped with O2),

or toggle between CO2and O2(on units equipped with O2)

See Section 3.1, Configuration.

1.3 Operating the Control Panel

The Model 3110 Series water jacket incuba-

tor has four basic modes, which allow incubator

setup. The modes are as follows: Run, Setpoints,

Calibration and System Configuration.

•Run is the default mode that the incubator will normally be

in during operation.

•Set is used to enter system setpoints for incubator opera-

tion.

•Cal is used to calibrate various system parameters to the

customer’s satisfaction.

•Config is the system configuration mode that allows for

custom setup of various options.

1.2 Control Panel Keys, Displays and Indicators

Figure 1-2 Control Panel

CLASS 100

Silence Mode

36.9

4.9

Enter

Run Set Cal Config Heat Temp

Inject % CO2

Scroll for Parameters

ASILENCE - Silences the audible alarm.

BAlarm Indicator - Pulses on/off during an alarm condition

in the cabinet.

CMODE Select Switch - Used to select Run, Setpoints,

Calibration and System Configuration Modes.

DMessage Center - Displays system status.

EMode Select Indicators-

Run: Run Menu

Set: Set Points Menu

Cal: Calibrate Menu

Config: Configuration Menu

FUp and Down Arrows: Increases or decreases the parame-

ter values that are numbers, toggles the parameter values

that are choices.

GEnter: Accepts changes to the calibration settings

HHeat Indicator: Lights when power is applied to the

heaters.

ITemp Display: Can be programmed to display temperature

continuously, RH continuously (with RH option), or toggle

between temperature and humidity (with RH option). See

Section 3.1, Configuration.

JScroll for Parameters Keys: Scrolls the operator through

the parameters of the mode that is selected.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Silence Key: Press to silence the audible alarm.

See Section 4 for alarm ringback times.

1.4 Displays

Message Center

Displays the system status (Mode) at all times. Displays

CLASS 100 or SYSTEM OK during normal operation, or alarm

messages if the system detects an alarm condition. See Section

4.1, Alarms. The display message CLASS 100 is a timing mech-

anism indicating that, under normal operating conditions with the

HEPA filter installed, the air inside the chamber meets the Class

100 air cleanliness standard for particulates of 0.5 micron size or

larger per cubic foot of air. (For further information on the Class

100 classification of air quality, see Appendix A.)

Upper and Lower Displays

These 7-segment displays vary depending upon the options

present and the configuration chosen. The upper display can

display temp or RH, or toggle between them. The bottom dis-

play can display CO2or O2, or toggle between them. See

Section 3.1, Configuration.

Model 3110/3210 Series ________________________________________________________Installation and Start-Up

Scroll for Parameters Keys: Steps the

operator through the parameters of SET,

CAL and CONFIG Modes. The right

arrow goes to the next parameter, the

left arrow returns to the previous param-

eter.

Up Arrow: Increases or toggles the parameter

value that has been selected in the SET, CAL, and

CONFIG Modes.

Enter: Must press Enter key to save to memory

all changed values.

Down Arrow: Decreases or toggles the parameter

values that have been selected in the SET, CAL

and CONFIG Modes.

RUN SETPOINT CALIBRATION CONFIGURATION

Default Mode Temperature Temp Offset Audible

Overtemp CO2 Cal New HEPA timer

CO2 IR CO2 Span Replace HEPA reminder

O2 O2 Cal at 20.7% Access Code

O2 Offset Temp Lo Alarm

RH Offset Temp Hi Alarm

Temp Relay

CO2 Lo Alarm

CO2 Hi Alarm

CO2 Relay

CO2 Z & S #’s

RH Lo Alarm

RH Relay

O2 Lo Alarm

O2 Hi Alarm

O2 Relay

Display 1 Setup

Display 2 Setup

Gas Guard Setup

RS485 Address

**Base Unit Displays

**Option Displays

The chart below shows the selections under each of the modes.

1 - 3

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Model 3110/3210 Series ________________________________________________________Installation and Start-Up

1 - 4

1.5 Installing the Unit

a. Choosing the Location

1. Locate the unit on a firm, level surface capable of sup-

porting the unit’s operational weight of 365 lbs. (166kg).

2. Locate away from doors and windows and heating and

air conditioning ducts.

3. Allow enough clearance behind the unit for electrical

and gas hook-up.

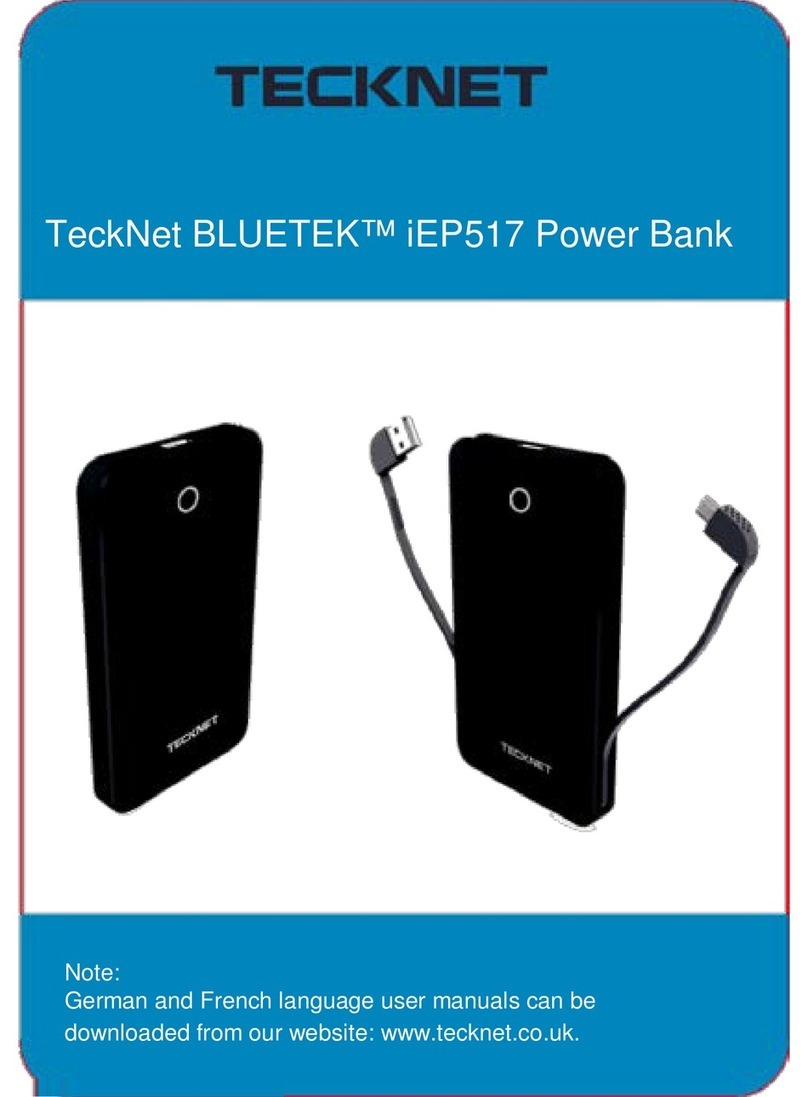

b. Stacking the Incubators

If the units have been in service,

disconnect the power cord connector

and drain the water jacket of the

designated top unit before stacking.

Note: Stacking brackets (shown at left)

stacking bolts, washers, and bolts for

stacking are included with each unit.

Figure 1-3 Stacking brackets

1. Designate one incubator to be the top unit and the other

as the bottom unit. Remove the base cover plate from

the top unit using the finger holes in the base or using a

slotted screwdriver. (Figure 1-4)

2. Note the two slots in the base of the incubator which

accommodate the stacking bolts. Refer to Figure 1-5.

3. Remove the two plastic plugs from the bolt holes in the

exterior top of the bottom unit. Install the 1/2” long

5/16-18 stacking bolts and washers into the bolt holes -

do not tighten the bolts at this time. Refer to Figure 1-6.

4. Unscrew and remove the leveling feet from the top unit

and lift it onto the bottom unit, off-setting the base of

the top unit approximately 2-3 inches behind the stack-

ing bolts and washers.

This incubator weighs 265 lbs (120kg) before

filling. Have sufficient personnel to lift it.

5. Align the sides of the top unit with the bottom unit and

slide the top unit forward until the slots in the base of

the top unit align with the 5/16” - 18 stacking bolts in

the exterior top of the bottom unit. Refer to Figure 1-7.

Front of top Incubator

Screwdriver slots

Finger holes

Base cover plate

Figure 1-4

Front of top Incubator, base cover plate removed

Slots for stacking bolts

Figure 1-5

5/16"-18 stacking bolt

and washer

Figure 1-6

(2) 5/16" bolts and flat washer

½” (13mm) wrench required

Figure 1-7

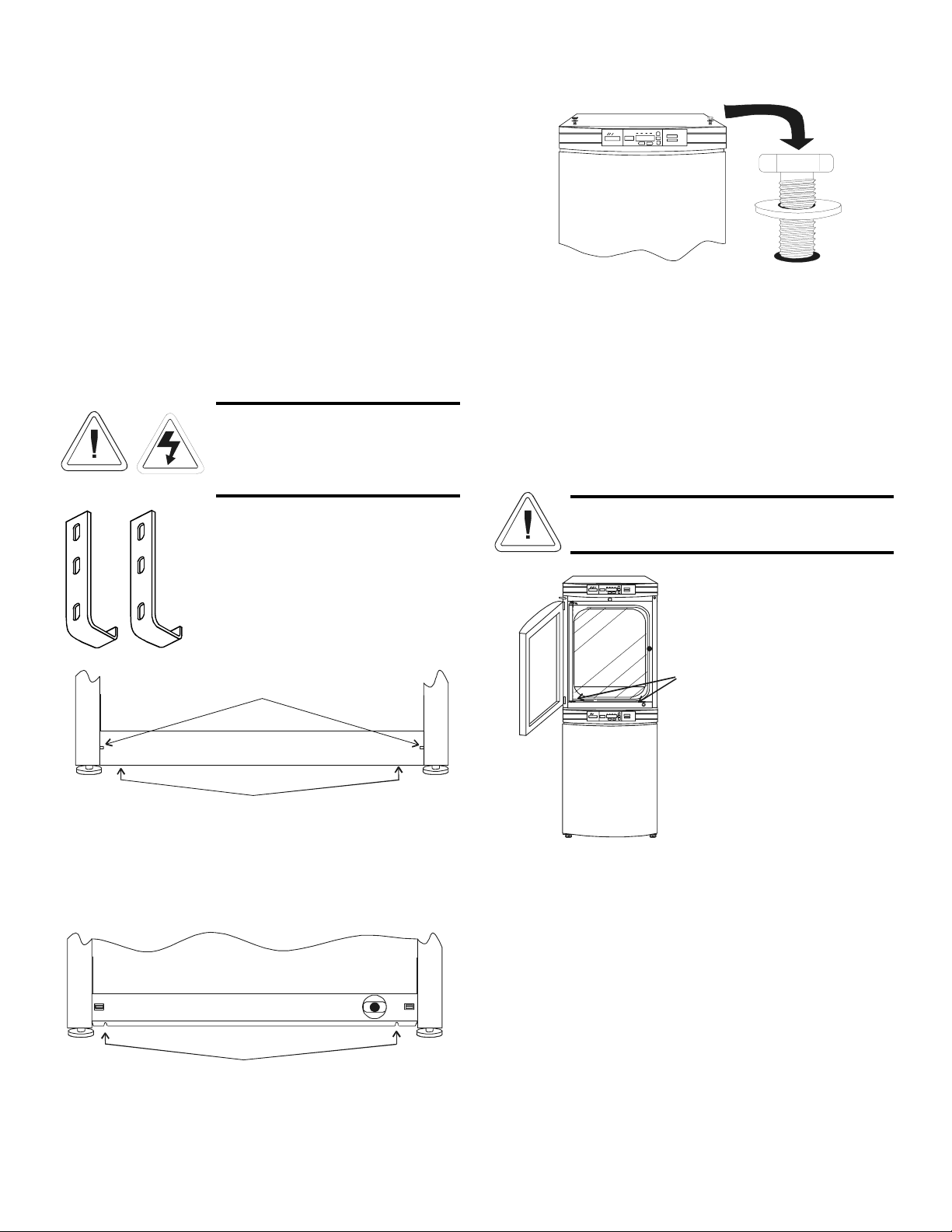

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

6. Remove and save the two screws from the back of the

control panel on the bottom unit as identified in Figure

1.8.

7. Insert the stacking brackets into the slots on the rear of

the control panel of the bottom unit as shown in Figure

1-5. Align the slots in the brackets with the mounting

holes on the rear of the incubators. Secure the brackets

with the screws saved above and the 1/4-20 bolts pro-

vided in the stacking kit. A 7/16” wrench or socket will

be required for the bolts.

8. Secure the base of the top unit to the exterior top of the

bottom unit by tightening the 5/16-18 stacking bolts

using a 1/2” (13mm) wrench or suitable tool.

9. Replace the base cover on the top unit.

10. The stacked units are ready to be placed into service.

c. Preliminary Cleaning and Disinfecting

1. Remove the protective plastic coating on the shelf sup-

ports and air duct, if present.

2. Using a suitable laboratory disinfectant, disinfect all

interior surfaces including shelves and shelf supports,

door gaskets, blower wheel and CO2sensor. Refer to

Section 5.1.

d. Installing the Access Port Filter

Locate the opening in the top left corner of the interior

chamber. Remove the tape from the opening on the outside of

the unit. Locate the stopper with filter in the hardware bag.

Install in the opening inside the chamber. See Figure 1-12.

e. Installing the Air Sample Filter

1. Remove the filter from the shipping bag.

2. Separate one section of the tubing from the filter. Install

this section to the fitting on the blower plate.

3. After installing the top duct, connect the filter assembly

to the tubing coming through the top duct.

4. Insert the free end of the air sample filter tubing into the

larger hole in the back of the blower scroll. See Figure

1-9 for completed configuration.

f. Installing the HEPA Filter

1. Remove the filter from the shipping box.

2. Remove the plastic coating from the filter, using caution

not to touch the filter media.

3. Install the filter as shown in Figure 1-9.

4. To set-up an automatic REPLACE HEPA reminder, see

Sections 3b and 3c.

Use caution when handling the filter. The media

can be damaged if it is mishandled.

To avoid damage to the incubator, do not operate

the unit without the HEPA filter in place.

Model 3110/3210 Series ________________________________________________________Installation and Start-Up

1 - 5

Back of top Incubator

Back of bottom Incubator

Figure 1-8

Insert 1/4-20 bolts

Remove this screw

and install bracket

Stacking brackets

Figure 1-9

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Model 3110/3210 Series ________________________________________________________Installation and Start-Up

1 - 6

g. Installing the Shelves

1. Install the side ducts with the tabs facing into the center

of the chamber with their slots up. There are no right

side or left side ducts, simply rotate one of them to fit

the opposite side. Tilt the side ducts as they are placed in

the chamber so the tops fit into the top air duct, then

guide them into the vertical position. Figure 1-10 shows

the duct as it would be oriented for the right side of the

chamber.

2. Referring to Figure 1-10, note that there is no difference

between left and right side shelf channels.

3. Install the shelf channels by placing the channel’s rear

slot over the appropriate rear tab on the side duct. Pull

the shelf channel forward and engage the channel’s front

slot into the side duct’s appro-

priate forward tab. Refer to

Figure 1-11.

4. Figure 1-12 shows one of the

channels installed on the right

side duct.

h. Leveling the Unit

Check the unit for being level by placing a bubble-style

level on one of the shelves. Turn the hex nut on the leveler

counterclockwise to lengthen the leg, or clockwise to shorten it.

Level the unit front-to-back and left-to-right.

i. Connecting the Unit to Electrical Power

See the serial tag on the side of the unit for electrical speci-

fications, or refer to the electrical schematics in Section 9 of

this manual.

Connect the incubator to a grounded dedicated

circuit only.

The power cord connector is the mains discon-

nect device for the incubator. Position the unit so

that it can be easily disconnected.

Plug the provided power cord into the power inlet connec-

tor (See Figure 1-13) and into the grounded dedicated circuit.

Electrical Specifications: Models 3110, 3120, 3130, 3140 -

115V, 50/60Hz, 3.6A, 1 PH, 2W

Models 3111, 3121, 3131, 3141 -

230V, 50/60Hz, 2.0A, 1 PH, 2W

.

j. Filling the Water Jacket

Turn the power switch on. ADD WATER will appear in the

message center. Press the Silence key to silence the alarm.

Note: The fill port has a plug that must be removed before fill-

ing and replaced after filling is complete.

Chlorine is detrimental to stainless steel. Using

chlorinated tap water will void the water-jacket

warranty!

Note: High purity water (1M to 18M ohm/cm resistivity) is a

very aggressive solvent and is considered slightly acidic. Ideal

pH for the water in the jacket is 7. Sodium hydroxide may be

used to change the pH of high purity water. It requires approxi-

mately 8ml of 0.05 normal sodium hydroxide per gallon of high

purity water to raise the pH to 7. The water jacket holds appox-

imately 12 gallons. Sodium hydroxide and the rust inhibitor

may be used in the same water jacket.

Side duct

tab

Shelf channel

rear slot

Shelf channel

front slot

Side duct

tab

Side Ducts

Shelf Channels

Side toward shelf

Figure 1-10

Figure 1-12

Figure 1-11

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Model 3110/3210 Series ________________________________________________________Installation and Start-Up

1 - 7

Fill the water jacket with 11.7 gallons (43.5 liters) of dis-

tilled water with a resistance range of 50K to 1M Ohm/cm

(conductivity range of 20.0 to 1.0 uS/cm). Vinyl tubing and a

funnel for filling are included in the accessory bag shipped with

the unit. Connect vinyl tubing to the fill port. See Figure 1.1.

When the jacket is full, the audible alarm will sound a con-

tinuous tone for 10 seconds and the alarm condition will be

cleared. Refer to Section 4.1, Table of Alarms.

Note: Model 3110 Series Water Jacketed Incubator is shipped

from the factory with a rust inhibitor added to the water inside

the unit. The rust inhibitor must be replenished every 2 years.

See Section 5.9 to drain the water jacket and Section 5.12 for

the correct proportion of rust inhibitor to the water.

k. Filling the Humidity Pan

For best operation of the incubator, sterilized distilled,

demineralized or de-ionized water should be used in the humid-

ity pan. Water purity should be in the resistance range of 50K

Ohm/cm to 1M Ohm/cm, or a conductivity range of 20.0 uS/cm

to 1.0 uS/cm. Refer to ASTM Standard D5391-93 or D4195-88

for measuring water purity.

Distillation systems, as well as some types of reverse

osmosis water purity systems, can produce water in the quality

range specified. Chlorinated tap water is not to be used as chlo-

rine can deteriorate the stainless steel. Tap water may also have

a high mineral content, which would produce a build-up of

scale in the reservoir. High purity, ultra pure or milli-q water is

not recommended as it is an extremely aggressive solvent and

will deteriorate the stainless steel. High purity water has a

resistance of above 1M to 18M Ohm/cm. Even high purity

water can contain bacteria and organic contaminants. Water

should always be sterilized or treated with a decontaminant,

safe for use with stainless steel as well as safe for the product,

prior to being introduced into the humidity pan.

Distilled or de-ionized water used in the humidity

pan must be within a water quality resistance

range of 50K to 1M Ohm/cm to protect and pro-

long the life of the stainless steel. Use of water

outside the specified range will decrease the oper-

ating life of the unit and void the warranty.

Fill the humidity pan to within 1/2 inch of the

top with sterile, distilled water. Place the pan directly on the

incubator floor to ensure optimum humidity and temperature

response.

For applications requiring higher humidity conditions, the

pan should be placed against the left side wall of the incubator.

The ductwork has been modified for this purpose. Also, on CO2

control models, the CO2sample port may be capped to assist in

achieving greater RH. In some ambients, this may cause con-

densation to form in the chamber.

Note: On CO2and O2control models, the gas sample port must

be capped for proper O2control. It is recommended that the

humidity pan be placed against the left side wall of the chamber

to aid humidity recovery after door openings.

Check the level and change the water frequently to avoid

contamination. Do not allow the water level to fluctuate signifi-

cantly. “Dry-outs” will have an adverse effect on the humidity

level.

Figure 1-13,

Rear Panel View, showing all options

l. Connecting the CO2Gas Supply

High concentrations of CO2gas can cause

asphyxiation! OSHA Standards specify that

employee exposure to carbon dioxide in any

eight-hour shift of a 40-hour work week shall not

exceed the eight-hour time weighted average of

5000 PPM (0.5% CO2). The short term exposure

limit for 15 minutes or less is 30,000 PPM (3%

CO2). Carbon dioxide monitors are recommended

for confined areas where concentrations of car-

bon dioxide gas can accumulate.

The CO2gas supply being connected should be industrial

grade 99.5% pure and should not contain siphon tubes. Install a

two-stage pressure regulator at the cylinder outlet. The high

pressure gauge at the tank should have 0-2000 psig range and

the low pressure gauge, at the incubator inlet, should have a 0-

30 psig range. Input pressure to the incubator must be main-

tained at 15 psig (103.4 kPa).

The incubator has serrated fittings on the back of the cabi-

net to connect the gas supply. Refer to Figure 1-13. The fitting

is labeled CO2 Inlet #1 Tank. Make sure that the connections

are secured with clamps. Check all fittings for leaks.

For units having the CO2Gas Guard option, refer to

Section 6.2.

Optional

RS 485

Exit for

Optional Analog

Wiring

CO inlet

#2 tank

RJ-11 telephone style connectors

Used with optional Gas Guard system

Used with optional O or IR sensors

CO inlet

#1 tank

Power Cord

Connector

2

2

Remote

Alarm

Air Make-up

Inlet b

b

a

a

a

c

c

c

N inlet

Convenience

Electrical

Outlet

2

2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Model 3110/3210 Series ________________________________________________________Installation and Start-Up

1 - 8

This incubator is designed to be operated with CO2gas only. Connecting a flammable or toxic gas can result in a haz-

ardous condition.

Gases other than CO2should not be connected to this equipment. CO2gas cylinders have UN1013 labeled on the

cylinder and are equipped with a CGA 320 outlet valve. Check the gas cylinder for the proper identification labels.

The CO2gas supply being connected to the incubator should be industrial grade, 99.5% pure. Do not use CO2gas

cylinders equipped with siphon tubes. A siphon tube is used to extract liquid CO2from the cylinder, which can damage

the pressure regulator. Consult with your gas supplier to ensure that the CO2cylinder does not contain a siphon tube.

Gas cylinders should also be secured to a wall or other stationary object to prevent them from tipping.

A two-stage CO2pressure regulator is required to be installed on the outlet valve of the gas cylinder. Input pressure to

the incubator must be maintained at 15 psig (103.4 kPa) for proper performance of the CO2control system. (A single

stage CO2pressure regulator will not maintain 15 psig (103.4 kP).

If higher purity CO2is desires inside the incubator (greater than 99.5% pure), the pressure regulator should be con-

structed with a stainless steel diaphragm along with specifying the purity of the CO2from the gas supplier. Follow the

manufacturer’s instructions to ensure proper and safe installation of the pressure regulator on the gas cylinder.

Consult your facility safety officer to ensure that the equipment is installed in accordance with the codes and regula-

tions that are applicable in your area.

m. Connecting the N2Gas Supply

This connection applies only to those units that have an O2

system. The N2gas supply being connected should be 99.99%

pure. Do not use liquid nitrogen. Follow the same steps as in

the section above for preparing the N2tank for hookup to the

incubator. For units having the N2Gas Guard option, refer to

Section 6.2. Connect the vinyl lines from the N2tank to the ser-

rated fitting labeled N2Inlet and secure with the provided

clamp. Check all fittings for leaks.

1.6 Incubator Start-Up

Now that the incubator has been properly installed,

connected to power, filled with water, humidity pan filled, and

connected to gas supplies, system setpoints can be entered. The

following setpoints can be entered in set mode: temperature,

over temperature, CO2, and O2. To enter Set Mode, press the

mode key until the Set indicator lights. Press the right and/or

left arrow keys until the proper parameter appears in the mes-

sage center. See Chart 1-1 for more detail.

a. Setting the Operating Temperature

Incubator Models 3110, 3111 have an operating tem-

perature range of 10 to 55°C, Models 3120, 3121 at 10 to 50°C,

and Models 3130, 3131, 3140, and 3141 at 10 to 45°C. All

units require the cooling coil option to run at any temperature

lower that 5°C above ambient. The incubator is shipped from

the factory with a temperature setpoint of 10°C. At this setting

all heaters are turned off.

To change the operating temperature setpoint:

1. Press the Mode key until the Set indicator lights.

2. Press the right arrow until Temp XX.X is displayed in

the message center.

3. Press the up/down arrow until the desired temperature

setpoint is displayed.

4. Press Enter to save the setpoint.

5. Press the Mode key until the Run Indicator lights to go

to run mode or right/left to go to next/previous parame-

ter.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Model 3110/3210 Series ________________________________________________________Installation and Start-Up

1 - 9

b. Setting the Overtemp Setpoint

The independent overtemp circuit is designed as a

safety to protect the incubator only. It is not

intended to protect or limit the maximum temper-

ature of the cell cultures or customer’s equipment

inside the incubator if an overtemp condition

occurs.

The incubator is equipped with an independent circuit that

monitors the air temperature in the cabinet. The independent

overtemp circuit is designed as a safety for the incubator only.

Should the system’s temperature control fail, this circuit would

cut out all heaters when the cabinet’s temperature reaches the

Overtemp setpoint. When an incubator is operating in an

overtemp condition, the temperature control in the incubator

will be ±1°C around the overtemp setpoint.

The overtemp’s function is to prevent abnormally high

temperatures that will occur if the heaters are locked on as a

result of a failure in the main temperature control. Although the

overtemp circuit will control the chamber temperature close to

the overtemp setpoint, it is not intended to protect or limit the

maximum temperature of the cell cultures or the equipment

inside the chamber when the overtemp condition occurs.

The factory setting for the Overtemp is 40°C. It can be set

over a range of temp setpoint + 0.5°C to 60°C. If the tempera-

ture setpoint is moved above the Overtemp setpoint, the

Overtemp will automatically update to 1.0°C + the temp set-

point. It is recommended that the Overtemp setpoint be 1°C

over the temp setpoint.

To set the Overtemp setpoint:

1. Press the Mode key until the Set indicator lights.

2. Press the right arrow until Otemp XX.X is displayed in

the message center.

3. Press the up/down arrow until the desired Overtemp set-

point is displayed.

4. Press Enter to save the setpoint.

5. Press the Mode key until the Run Indicator lights to go

to run mode or right/left to go to next/previous parame-

ter.

c. Setting the CO2Setpoint

All T/C CO2cells are precalibrated at the factory at 37°C,

high humidity, and 10% CO2. Therefore, if a temperature set-

point of 37°C has been entered, the humidity pan filled, and the

CO2control is to run between 0-10% with a T/C CO2sensor,

the CO2setpoint may be entered immediately. Otherwise, it is

important to allow the unit 12 hours to stabilize at the tempera-

ture setpoint before entering the CO2setpoint.

All models of the incubator have a CO2setpoint range of

0.0% to 20.0%. The incubator is shipped from the factory with

a CO2setpoint of 0.0%. At this setting, all CO2control and

alarms are turned off.

To change the CO2setpoint:

1. Press the Mode key until the Set indicator lights.

2. Press the right arrow until CO2 XX.X is displayed in the

message center.

3. Press the up/down arrow until the desired CO2setpoint

is displayed.

4. Press Enter to save the setpoint.

5. Press the Mode key until the Run Indicator lights to go

to run mode or right/left to go to next/previous parame-

ter.

d. Setting the O2Setpoint

Models 3130, 3131, 3140, and 3141 of the incubator have

a built-in O2control system. The O2setpoint range is 1.0% to

21.0%. The incubator is shipped from the factory with a O2set-

point of 21.0%. At this setting, all O2control and alarms are

turned off. The gas sample port must be capped when running

controlled O2levels.

To change the O2setpoint:

1. Press the Mode key until the Set indicator lights.

2. Press the right arrow until O2 XX.X is displayed in the

message center.

3. Press the up/down arrow until the desired O2setpoint is

displayed.

4. Press Enter to save the setpoint.

5. Press the Mode key until the Run Indicator lights to go

to run mode or right/left to go to next/previous parame-

ter.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Model 3110/3210 Series ________________________________________________________Installation and Start-Up

1 - 10

Press MODE to light SET

Silence Mode

Mode

Mode

Mode

SET POINTS

TEMP XX.X C

CO2 XX.X%

O2 XX.X%

36.9

4.9

Enter

Enter

Enter

Enter

Numbers increase

Numbers increase

Numbers increase

Numbers increase

Press MODE to move

to CALIBRATE

mode

Numbers decrease

Numbers decrease

Numbers decrease

Numbers decrease

MODES-A2.CDR

Press Enter

to save setting

Press Enter

to save setting

Press Enter

to save setting

Press Enter

to save setting

Run Set Cal Config Heat Temp

Inject % CO2

Scro ll for Parameters

Scro ll for Parameters

Scro ll for Parameters

Scro ll for Parameters

Mode OTEMP XX.X C Enter

Scro ll for Parameters

Press to return

to previous parameter

Press to return

to previous parameter

Press to return

to previous parameter

Press to return

to previous parameter

Percent O2

Percent CO2

Over

Temperature

Operating

Temperature

To Set:

(with O option only)2

Set Mode

Chart 1-1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Model 3110/3210 Series ___________________________________________________________________Calibration

2 - 1

Section 2 - Calibration

2.1 Calibration Mode

After the unit has stabilized, several different systems can

be calibrated. In the Calibration Mode, the air temperature, CO2

reading, O2reading, and RH reading can all be calibrated to ref-

erence instruments. To enter Calibration Mode, press the Mode

key until the CAL indicator lights. Press the right and/or left

arrow until the proper parameter appears in the message center.

See Chart 3-1 for more detail.

Calibration frequency is dependent on use, ambient condi-

tions, and accuracy required. Good laboratory practice would

require at least an annual calibration check. On new installa-

tions, all parameters should be checked after the stabilization

period. When using O2controls, all parameters should be

checked before each test experiment, or at least every 6 months.

Prior to calibration, the user should be aware of the follow-

ing system functions. While the unit is in Calibration Mode, all

system control functions will be stopped so that the unit

remains stable. Readout of the system being calibrated will

appear as “—-” on the readout displays. If no keys are pressed

for approximately five minutes while in Calibration Mode, the

system will reset to Run Mode so that control functions can be

reactivated.

Before making an calibration or adjustments to

the unit, it is imperative that all reference instru-

ments be properly calibrated.

a. Calibrating the Temperature

Place the calibrated instrument in the center of the cham-

ber. The instrument should be in the airflow, not against the

shelf. Before calibration, allow the cabinet temperature to sta-

bilize.

Temperature Stabilization Periods

Start-Up - Allow 12 hours for the temperature in the cabinet to

stabilize before proceeding.

Operating Unit -Allow at least two hours after the display

reaches setpoint for the temperature to stabilize before proceed-

ing.

1. Press the Mode key until the CAL indicator lights.

2. Press the right arrow until TEMPCAL XX.X appears in

the message center.

3. Press the up/down arrow to match the display to a cali-

brated instrument.

4. Press Enter to store the calibration into memory.

5. Press the Mode key to return to Run, or the right/left

arrow to go to the next/previous parameter.

b. Calibrating Thermal Conductivity CO2System

Models 3110, 3111, 3130 and 3131 have a thermal conduc-

tivity (T/C) CO2sensor. Thermal conductivity of the incubator

atmosphere is not only effected by the quantity of CO2present,

but also by the air temperature and the water vapor present in

the incubator atmosphere. In monitoring the effects of CO2, air

temperature and absolute humidity must be held constant so

any change in thermal conductivity is caused only by a change

in CO2concentration.

Changing temperature or changing from elevated humidity

levels to room ambient humidity levels would necessitate a

recalibration of the CO2control.

T/C CO2Sensor Stabilization Periods

Start-up - The CO2sensor has been calibrated at the factory for

37°. Allow temperature, humidity, and CO2levels in the cham-

ber to stabilize at least 12 hours before checking the CO2con-

centration with an independent instrument.

Presently operating - Make sure the chamber doors are closed.

Allow at least 2 hours after the temperature and CO2displays

reach their setpoints for chamber atmosphere stabilization.

1. Make sure stabilization periods outlined above are fol-

lowed.

2. Sample the chamber atmosphere through the sample port

with an independent instrument. Sample the atmosphere

at least 3 times to ensure the accuracy of the instrument.

2. Press the Mode key until the CAL indicator lights.

3. Press the right arrow until CO2 CAL XX.X is displayed

in the message center.

4. Press the up/down arrow to change the display to match

the independent instrument.

5. Press Enter to store calibration.

6. Press the Mode key to return to Run Mode, or the right

or left arrow keys to go to the next/previous parameter.

c. Calibrating the Infra-Red CO2System.

Models 3120, 3121, 3140 and 3141 have an infra-red CO2

sensor. Infra-red CO2sensors are not effected by chamber

atmosphere temperature or humidity. However, the light detec-

tor in the sensor is effected by wide temperature changes.

Therefore, changing temperature setpoints could necessitate a

recalibration of the CO2. Chamber temperature should be

allowed to stabilize before checking CO2concentrations with an

independent instrument, especially on start-up.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Model 3110/3210 Series ___________________________________________________________________Calibration

All models equipped with an IR/CO2sensor have an auto-

matic calibration that occurs every 24 hours, and lasts for 5 to 6

minutes. During automatic calibration, the CO2display is

blanked out and HEPA filtered room air is pumped through the

CO2sensor. A new CO2calibration value is stored in memory

for use as the 0.0% CO2reference point. The keypad/ control

panel is locked during calibration, with the message center

reading CO2 AUTO CAL.

IR CO2Sensor Stabilization Times

Startup- Allow the temperature and the CO2of the cabinet to

stabilize at least 12 hours before proceeding.

Operating Unit - Allow CO2to stabilize at least 2 hours at set-

point before proceeding.

1. Measure the CO2concentration in the chamber through

the gas sample port with a Fyrite or other independent

instrument. Several readings should be taken to ensure

accuracy.

2. Press the Mode key until the CAL indicator lights.

3. Press the right arrow until IR CAL XX.X appears in the

message center.

4. Press the up/down arrow to adjust the display to match

the independent instrument reading.

5. Press Enter to store calibration.

6. After Enter is pressed, the unit will go into a calibration

cycle that will last 5 to 6 minutes. The control panel is

locked during this calibration cycle.

7. Press the Mode key to return to Run Mode.

d. Calibrating the O2System

Models 3130, 3131, 3140 and 3141 have an O2control sen-

sor. The sensor is a fuel cell that puts out a linear millivolt sig-

nal based on O2content of the chamber. The fuel cell depletes

over time depending on required O2levels, therefore the system

should be calibrated before each test experiment, or at least

every 6 months.

There are two methods available to calibrate the O2system.

• The preferred method calibrates the system to the known

ambient O2value of 20.7% and checks the life of the sen-

sor. This method should be used whenever a new sensor is

installed.

• The second method available allows the system to be cali-

brated to an independent reference instrument by entering

an offset.

O2Calibration at 20.7%

1. Press the Mode key until the CAL indicator lights.

2. Press the right arrow until the display reads O2

3. Press Enter.

4. OPEN DOOR appears on the display. Open the outer

and inner doors.

5. The display reads CALIBRATING.

6. When calibration is complete, approximately 2 minutes,

an audible tone will sound and the display returns to O2

7. The O2display will change to 20.7.

8. Press the Mode key to return to Run.

A new O2span value is stored in memory for use as the

20.7% O2reference point. The keypad/control panel is "locked-

up" during calibration.

If using an O2Fyrite, the accuracy of the instru-

ment will be greatly affected by the concentration

of CO2in the cabinet. Refer to the Fyrite operating

manual.

O2Offset Calibration

Startup - Allow the cabinet to stabilize at least 12 hours before

proceeding.

Operating Unit - Allow O2to stabilize at least 2 hours at set

point before proceeding.

Measure the O2concentration in the chamber through the

gas sample port with an independent instrument. Several read-

ings should be taken to ensure accuracy.

1. Press the Mode key until the CAL indicator lights.

2. Press the right arrow until O2 OFFS XX.X appears in

the message center.

3. Press the up/down arrow to adjust display to independ-

ent instrument reading.

4. Press Enter to store calibration.

5. Press the Mode key to return to Run Mode.

2 - 2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Model 3110/3210 Series ___________________________________________________________________Calibration

2 - 3

e. Calibrating Relative Humidity

All 3110 Series incubators can be equipped with an option-

al direct readout relative humidity sensor. This is a readout only

of the chamber relative humidity. It does not provide any con-

trol of the relative humidity in the cabinet.

Relative Humidity Stabilization Times

Startup - Allow 12 hours for the relative humidity and temper-

ature in the chamber to stabilize before proceeding.

Operating Unit - Allow at least 2 hours after temperature dis-

play reaches setpoint for relative humidity to stabilize before

proceeding.

1. Place an accurate independent instrument in the center

of the chamber. Allow at least 30 minutes for RH to sta-

bilize.

2. Press the Mode key until the CAL indicator lights.

3. Press the right arrow key until RH CAL XX appears in

the message center.

4. Press the up/down arrow to match the display to the

independent instrument.

5. Press Enter to store the calibration.

6. Press the Mode key to return to Run Mode.

If a reliable RH measuring device is not available, you may

calibrate the display to a typical level.

1. Follow the RH stabilization periods outlined above.

2. With a full humidity pan and stable temperature, the rel-

ative humidity in the chamber will be 95%.

3. Using Steps 3-5 of the relative humidity sensor adjust-

ment, adjust the display to 95%.

4. This calibration method should be accurate to within

5%.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Model 3110/3210 Series ___________________________________________________________________Calibration

2 - 4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

This manual suits for next models

8

Table of contents

Other Thermo Forma Accessories manuals

Popular Accessories manuals by other brands

Alpina

Alpina 871125226552 quick start guide

Milesight

Milesight LoRaWAN EM320-TH quick start guide

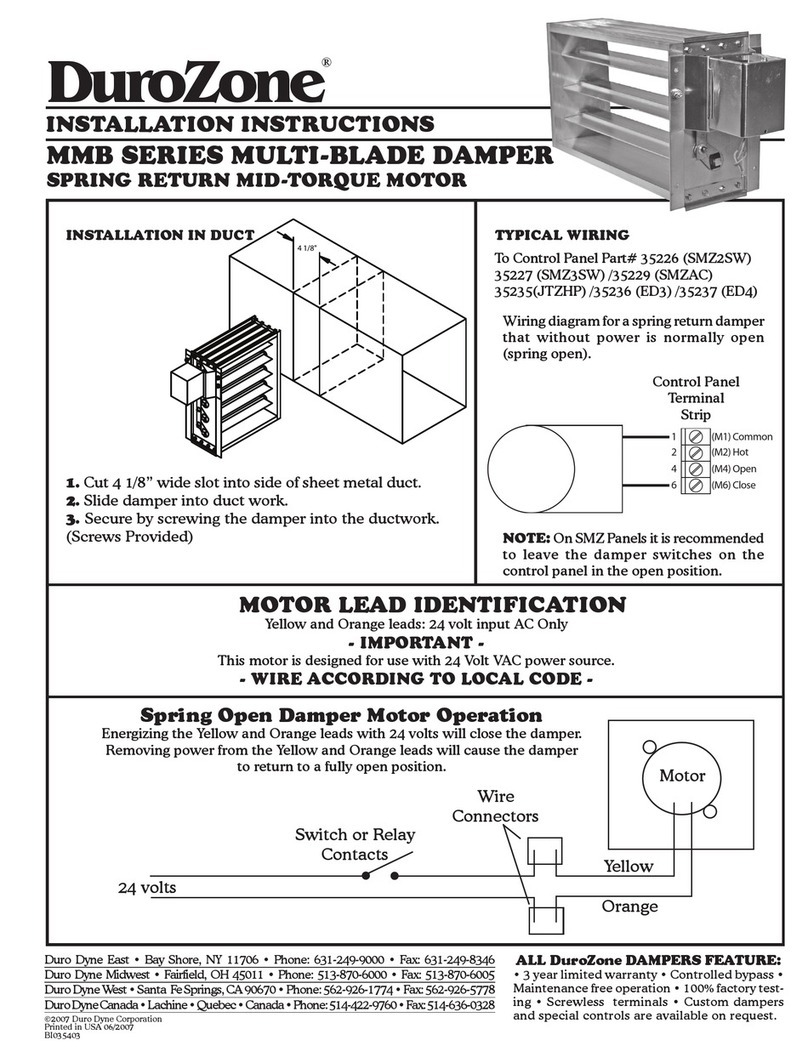

DuroZone

DuroZone MB Series Multi-Blade Damper installation instructions

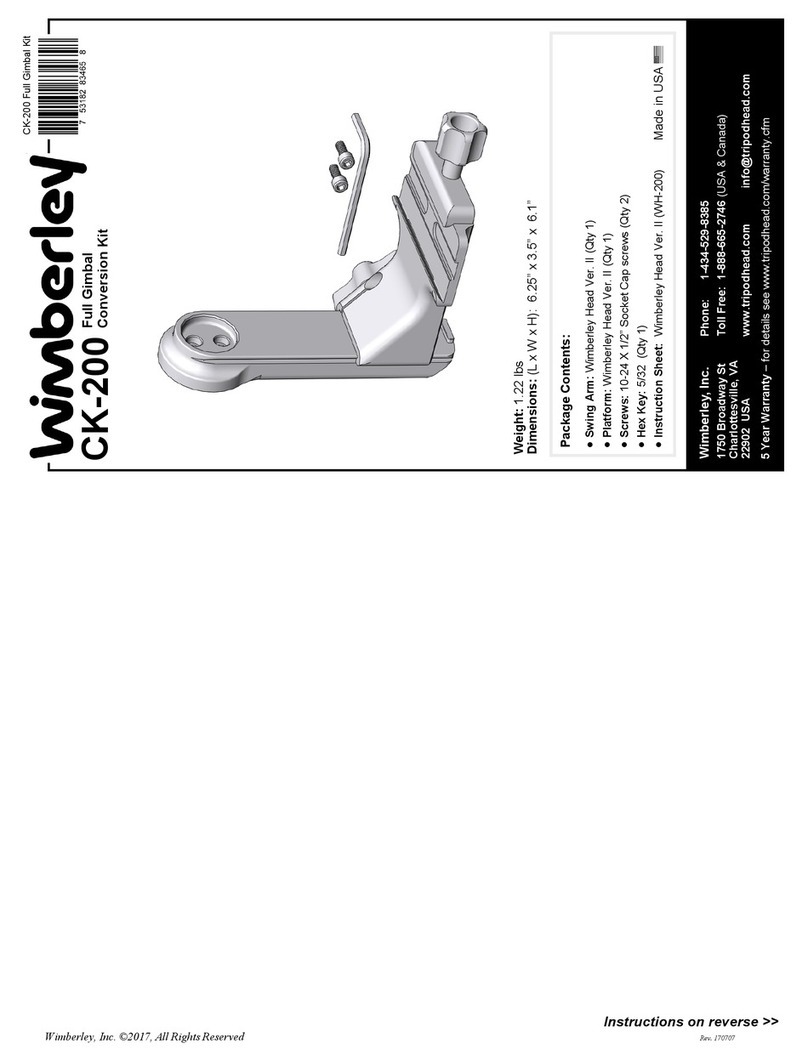

Wimberley

Wimberley CK-200 instructions

Cover Pools

Cover Pools Save-T Cover II owner's manual

Mee-go

Mee-go Ladybird Sit & Ride instruction manual