Thermo Forma 8600 Series Operating instructions

8600 Series

Ultra Low Temperature

Upright Freezers

Operating and Maintenance Manual

Manual No: 7008602 Rev. 0

Model 8600 Series _______________________________________________________________________________

i

Read This Instruction Manual.

Failure to read, understand and follow the instructions in

this manual may result in damage to the unit, injury to operat-

ing personnel, and poor equipment performance.

CAUTION! All internal adjustments and maintenance must

be performed by qualified service personnel.

Refer to the serial tag on the back of this manual.

The material in this manual is for information purposes only.

The contents and the product it describes are subject to change

without notice. Thermo Forma makes no representations or war-

ranties with respect to this manual. In no event shall Thermo

Forma be held liable for any damages, direct or incidental, aris-

ing out of or related to the use of this manual.

MANUAL NUMBER 7008602

0 -- 1/10/03 Original Manual aks

REV ECR/ECN DATE DESCRIPTION By

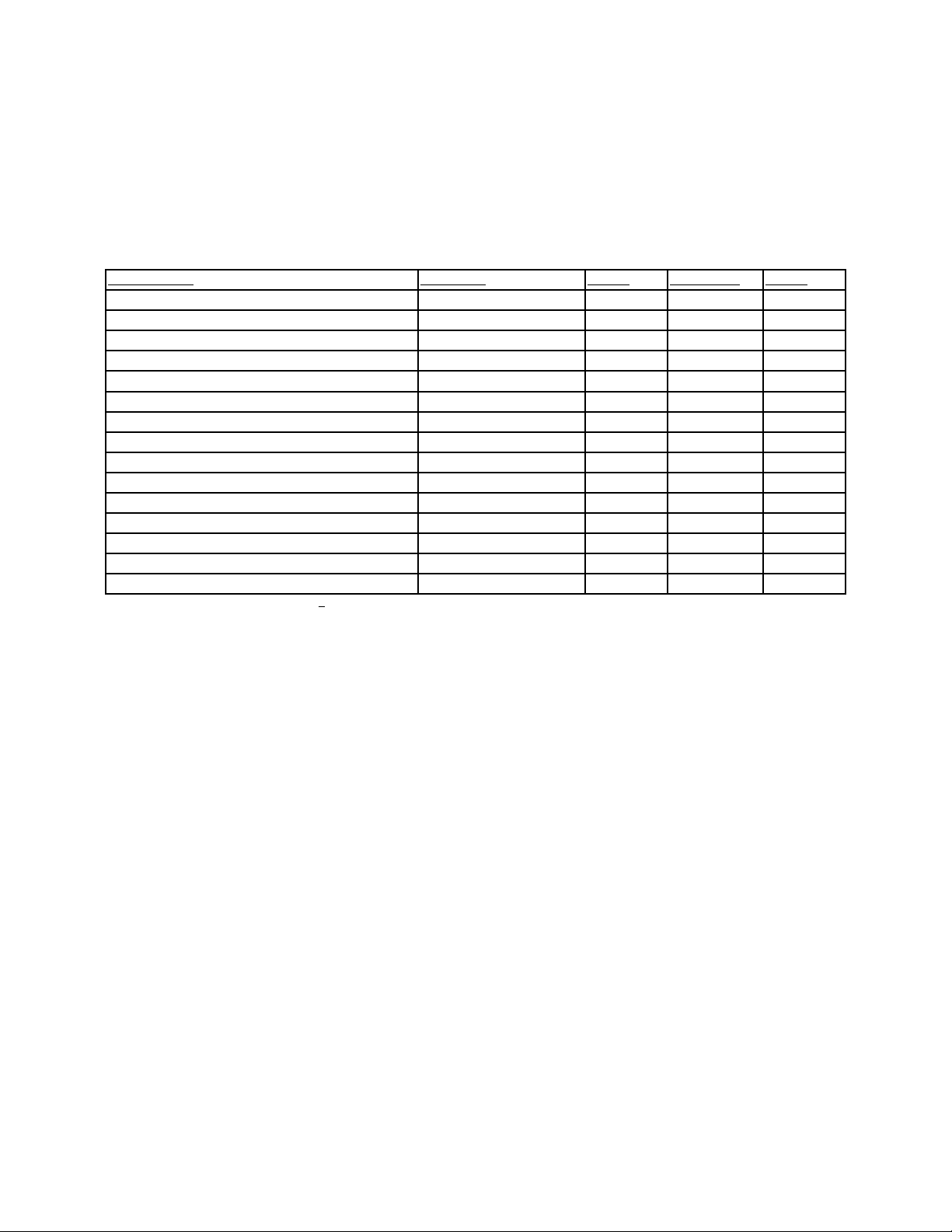

Models Capacity in

Cubic Feet

Voltage

8602 13 230

8603 13 120

8604 17 120

8605 17 230

8606 23 230

8607 28 230

Double Door Units

8691 13 230

8692 13 120

8693 17 120

8694 17 230

8695 23 230

Red Cell Storage

8627 13 230

Model 8600 Series _________________________________________________________________________Warnings

ii

Important operating and/or maintenance instructions. Read the accompanying text carefully.

Potential electrical hazards. Only qualified persons should perform procedures associated with this symbol.

Hot surface(s) present which may cause burns to unprotected skin or to materials which may be damaged by elevated

temperatures

Extreme temperature hazards, hot or cold. Use special handling equipment or wear special, protective clothing.

√ Always use the proper protective equipment (clothing, gloves, goggles, etc.)

√ Always dissipate extreme cold or heat and wear protective clothing.

√ Always follow good hygiene practices.

√ Each individual is responsible for his or her own safety.

Model 8600 Series ___________________________________________________________________________Service

iii

Model 8600 Series __________________________________________________________________Table of Contents

iv

Table of Contents

Section 1 - Installation and Start-up . . . . . . . . . . . . . . .1 - 1

1.1 Freezer Components . . . . . . . . . . . . . . . . . . . . . . . . .1 - 1

1.2 Control Panel Keys, Displays and Indicators . . . . . .1 - 2

1.3 Operation of the Keypad . . . . . . . . . . . . . . . . . . . . . .1 - 3

1.4 Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 3

1.5 Installing the Freezer . . . . . . . . . . . . . . . . . . . . . . . . .1 - 3

a. Choosing the Location . . . . . . . . . . . . . . . . . . . . .1 - 4

b. Installing the Wall Bumpers . . . . . . . . . . . . . . . . .1 - 4

c. Installing the Shelves . . . . . . . . . . . . . . . . . . . . . .1 - 4

d. RS-232 Communications . . . . . . . . . . . . . . . . . . . .1 - 4

e. Remote Alarm Contacts and Analog Output . . . . .1 - 5

f. Attaching the Power Cord . . . . . . . . . . . . . . . . . . .1 - 5

g. Connecting the Unit to Electrical Power . . . . . . . .1 - 5

1.6 Freezer Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 5

a. Setting the Operating Temperature . . . . . . . . . . . .1 - 5

b. Setting the High Temperature Alarm . . . . . . . . . . .1 - 6

c. Setting the Low Temperature Alarm . . . . . . . . . . .1 - 6

e. Access Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 6

1.7 Run Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 6

Chart 1-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 7

Section 2 - Calibrate . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 1

2.1 Calibrate Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 1

a. Calibrating the Control Probe . . . . . . . . . . . . . . . .2 - 1

b. Calibrating The Optional Sample Probe . . . . . . . .2 - 1

Chart 2-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 2

Section 3 - Configuration . . . . . . . . . . . . . . . . . . . . . . . .3 - 1

3.1 Configuration Mode . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 1

a. High Alarm Test . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 1

b. Low Alarm Test . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 1

c. System Battery Test . . . . . . . . . . . . . . . . . . . . . . .3 - 1

d. BUS Battery Test . . . . . . . . . . . . . . . . . . . . . . . . .3 - 1

e. Display Temperature . . . . . . . . . . . . . . . . . . . . . . .3 - 1

f. Clear High Stage Alarm . . . . . . . . . . . . . . . . . . . . .3 - 1

g. Setting an Access Code . . . . . . . . . . . . . . . . . . . . .3 - 2

h. RS-485 Address . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 2

i. Back Up System Type . . . . . . . . . . . . . . . . . . . . . .3 - 2

3.2 The RS-232 Configuration . . . . . . . . . . . . . . . . . . . . . .3 - 2

Section 4 - Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 1

4.1 Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 1

a. Wrong Power Alarm . . . . . . . . . . . . . . . . . . . . . . . .4 - 1

b. High Stage System Failure Alarm . . . . . . . . . . . . .4 - 1

c. Multiple Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 1

4.2 Probe Failure Alarms . . . . . . . . . . . . . . . . . . . . . . . . .4 - 1

Section 5 - Maintenance . . . . . . . . . . . . . . . . . . . . . . . . .5 - 1

5.1 Cleaning the Cabinet Exterior . . . . . . . . . . . . . . . . . .5 - 1

5.2 Cleaning the Air Filter . . . . . . . . . . . . . . . . . . . . . . . .5 - 1

5.3 Cleaning the Condenser . . . . . . . . . . . . . . . . . . . . . . .5 - 1

a. Cleaning the Water-cooled Condenser . . . . . . . . . .5 - 1

5.4 Defrosting the Chamber . . . . . . . . . . . . . . . . . . . . . . .5 - 1

5.5 Cleaning the Door Gasket . . . . . . . . . . . . . . . . . . . . .5 - 2

5.6 Cleaning the Vacuum Relief Port . . . . . . . . . . . . . . . .5 - 2

5.7 Replacing the Battery(s) . . . . . . . . . . . . . . . . . . . . . .5 - 2

5.8 Preparing the Unit for Storage . . . . . . . . . . . . . . . . . .5 - 2

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 3

Section 6 - Factory Options . . . . . . . . . . . . . . . . . . . . . .6 - 1

6.1 BUS (Back Up System) . . . . . . . . . . . . . . . . . . . . . . .6 - 1

a. Installing the vent stack, solenoid and injection

assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 1

b. Installing the Temperature Probe . . . . . . . . . . . . . .6 - 2

c. Connecting the probe/solenoid harness . . . . . . . . .6 - 2

d. BUS Control Panel . . . . . . . . . . . . . . . . . . . . . . . .6 - 3

e. Setting the Optional BUS Set Point . . . . . . . . . . . .6 - 3

f. System Operation Check . . . . . . . . . . . . . . . . . . . .6 - 3

g. Cleaning the Vent Stack . . . . . . . . . . . . . . . . . . . . .6 - 3

h. Disconnecting the fitting assembly and

transfer hose . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 3

6.2 Chart Recorder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 4

a. Installing the chart paper . . . . . . . . . . . . . . . . . . .6 - 4

c. Recorder Calibration . . . . . . . . . . . . . . . . . . . . . . .6 - 4

6.3 Datalogger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 5

6.4 Water-Cooled condenser . . . . . . . . . . . . . . . . . . . . . . .6 - 5

6.5 Five Inner Door Option . . . . . . . . . . . . . . . . . . . . . . .6 - 5

Section 7 - Specifications . . . . . . . . . . . . . . . . . . . . . . . . .7 -1

Section 8 - Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . .8 - 1

Section 9 - Refrigeration Schematics . . . . . . . . . . . . . .9 - 1

Section 10 - Electrical Schematics . . . . . . . . . . . . . . .10 - 1

Section 11 - Warranty . . . . . . . . . . . . . . . . . . . . . . . . .11 - 1

Appendix A - Handling Liquid Nitrogen . . . . . . . . . . . .A - 1

Appendix B - Handling Liquid CO2. . . . . . . . . . . . . . .B - 1

First Aid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C - 1

Section 1 - Installation and Start-up

Model 8600 Series ___________________________________________________________________Installation and Start-Up

1 - 1

Figure 1-1

Model 8600 Series Front

Figure 1-2

Model 8600 Series Rear

1.1 Freezer Components

Figure 1-1

• Control Panel - keypad, displays and indicators.

• BUS (Optional Back Up System) panel.

• Optional temperature recorder - 7 day, one pen or datalog-

ger.

• Documentation compartment - storage of user’s manual

and other documentation.

Figure 1-2

• Remote alarm contacts and selectable analog output con-

nection - 0-1V, 4-20mA (default), 0-5V).

• Power inlet for power cord connection.

• Optional BUS connections for probe and solenoid.

• RS-232 (default) or RS-485 interface.

• Power Switch (mains disconnect).

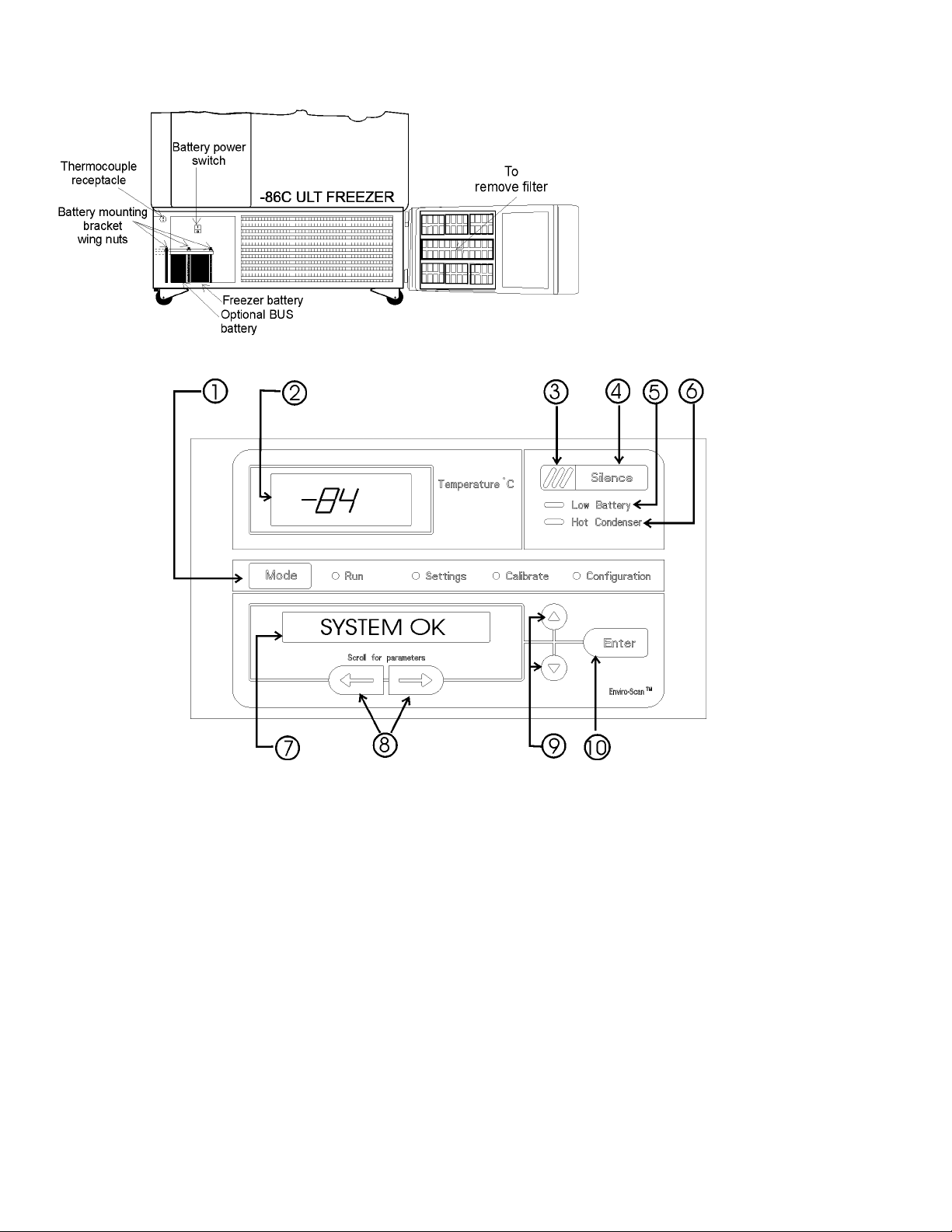

Figures 1-3 and 1-4

• Vacuum relief port - pressure equalization port.

• Probe cover - houses control, optional recorder or datalog-

ger and 1535 alarm (optional) probes.

Figure 1-4

Vacuum Relief and Probe Cover Location

Figure 1-3

Vacuum Relief Port and Probe Cover

1.2 Control Panel Keys, Displays and Indicators

(See Figure 1-6)

1. Mode Select Switch - Used to select Run, Settings,

Calibrate and System Configuration Modes.

Mode Select Indicators -

Run: Run Menu

Settings: Set Points Menu

Calibrate: Calibrate Menu

Configuration: Configuration Menu

2. Temperature Display - Displays temperature in degrees

Celsius.

3. Alarm Indicator - Light pulses on/off during an alarm

condition of the cabinet.

4. Silence - Silences the audible alarm.

5. Low Battery - indicates a low battery condition of the

freezer battery.

6. Hot Condenser - indicates a hot condenser condition.

7. Message Center - displays system status and alarms.

8. Scroll for Parameters Arrows - moves the operator

through the choices of the selected mode.

9. Up and Down Arrows - Increases or decreases values,

toggles between choices.

10. Enter - Stores the value into computer memory.

Figure 1-6, Control Panel

1 - 2

Model 8600 Series ____________________________________________________________Installation and Start-Up

Figure 1-5

Battery(s) location and Switch

Figure 1-5

• Battery mounting bracket wing nuts

(three).

• Battery power switch (freezer and BUS).

• Freezer battery.

• Optional BUS battery.

• Freezer filter location.

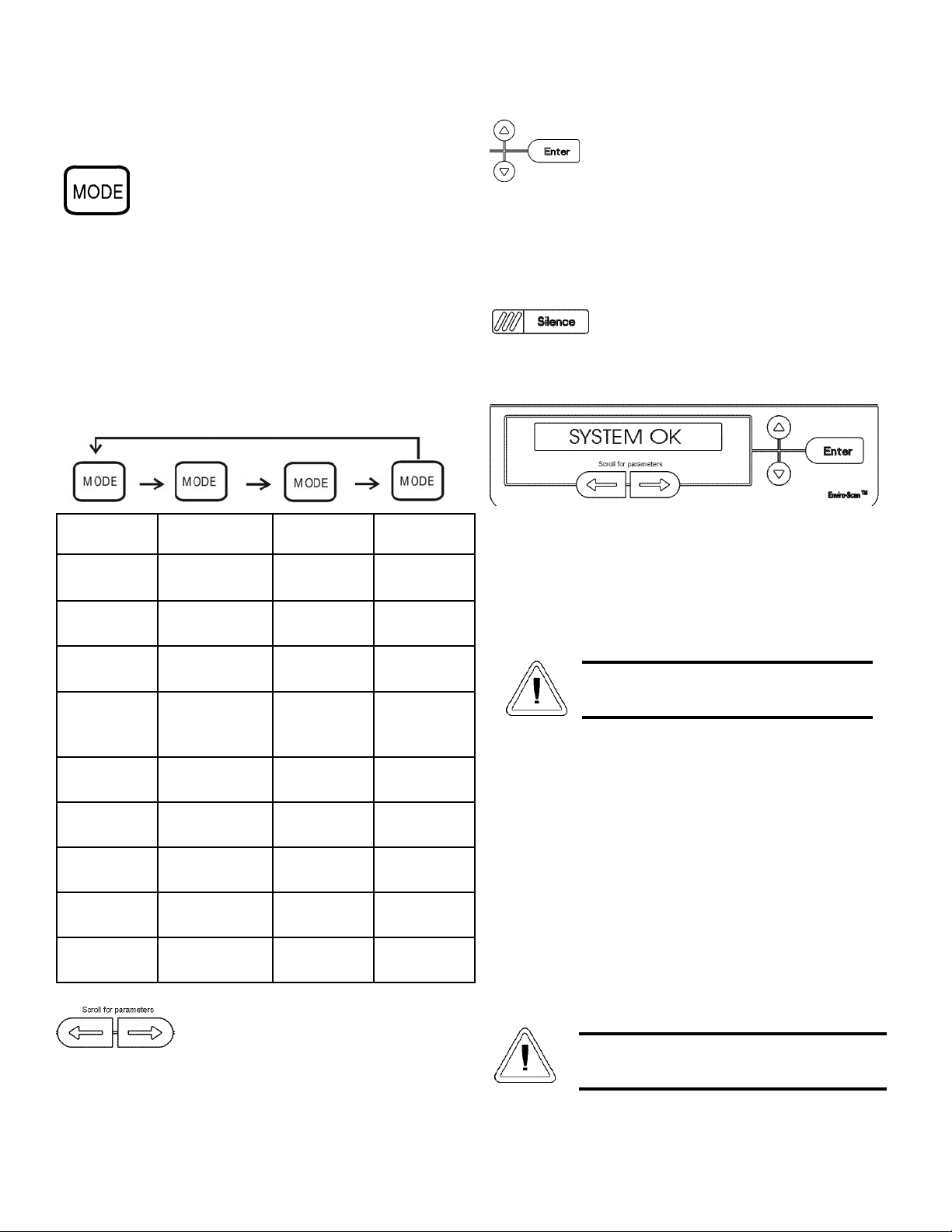

1.3 Operation of the Keypad

The 8600 Series freezer has four basic modes

which allow freezer setup: Run, Settings,

Calibrate and Configuration.

Run is the default mode which the freezer will normally be

in during operation.

Settings is used to enter system set points for freezer oper-

ation.

Calibrate is used to calibrate various system parameters.

Configuration allows for custom setup of various options.

The chart below shows the selections under each of the

modes.

Scroll for Parameters Arrows: Steps the

operator through the parameters of SET-

TINGS, CALIBRATE and CONFIGURA-

TION Modes. The right arrow goes to the

next parameter, the left arrow returns to the

previous parameter.

Up Arrow: Increases or toggles the parameter

value that has been selected in the SETTINGS,

CALIBRATE, and CONFIGURATION Modes.

Enter: Must press Enter key to save to memo-

ry all changed values.

Down Arrow: Decreases or toggles the param-

eter values that have been selected in the SET-

TINGS, CALIBRATE and CONFIGURATION

Modes.

Silence Key: Press to silence the audible

alarm. See Section 4 for alarm ringback times.

1.4 Displays

Message Center: Displays the system status (Mode) at all

times. Displays SYSTEM OK during normal operation,

or alarm messages if the system detects an alarm condi-

tion. See Section 4.1- Alarms.

1.5 Installing the Freezer

To remove the freezer from the pallet, use

the 7/16" wrench to remove all the bolts securing the shipping

bracket to the pallet.

Remove the shipping bracket. Remove the ramp

boards from the pallet and place the slotted end over the ramp

brackets on the pallet. The support blocks on the ramps will be

facing down. Before moving the freezer, make sure the casters

are unlocked and moving freely. Align the caster with the ramp

boards. Use adequate personnel to roll the freezer off the pallet.

The freezer can be easily pushed to the desired

approved location, described in Section 1.5.a. If necessary, the

doors and lower front panel may be opened to move the unit

through tight openings. When the freezer is in position, set the

front caster brakes.

Model 8600 Series ___________________________________________________________________Installation and Start-Up

1 - 3

If tipped more than 45°, allow the unit to set

upright for 24 hours before start up.

The freezer must not be moved with the prod-

uct load inside.

RUN SETTINGS CALIBRATE CONFIGU-

RATION

Default Mode

SYSTEM OK

Control Set Point Control Probe High Alarm

Test

LINE VOLT-

AGE

High Alarm Set

Point

Optional

Sample Probe

Low Alarm

Test

COMPENSAT-

ED VOLTAGE

Low Alarm Set

Point

System Battery

Test

HSHX TEM-

PERATURE

Optional Back

Up System Set

Point

BUS Battery

Test

Display

Temperature

Clear High

Stage Alarm

Set Access

Code

RS485

Address

BUS type CO2

or LN2

a. Choosing the Location

Locate the freezer on a firm, level surface in an area with

an ambient temperature between 18°C and 32°C. Provide ample

room to reach the mains disconnect switch (power switch)

located on the rear of the freezer.

b. Installing the Wall Bumpers

The parts bag, located inside the cabinet, contains the fol-

lowing parts.

Install the bolts into the pre-tapped holes on the back of the

compressor section. Install a neoprene cap on each bolt. Refer

to Figure 1-2 for the locations of the pre-tapped holes.

c. Installing the Shelves

Install the shelf clips into the shelf pilasters (front and

back) at the desired shelf level. Install the shelves in the cabinet

onto the clips.

NOTE: On units having the optional 5 inner door option, refer

to the instructions accompanying the inner door kit.

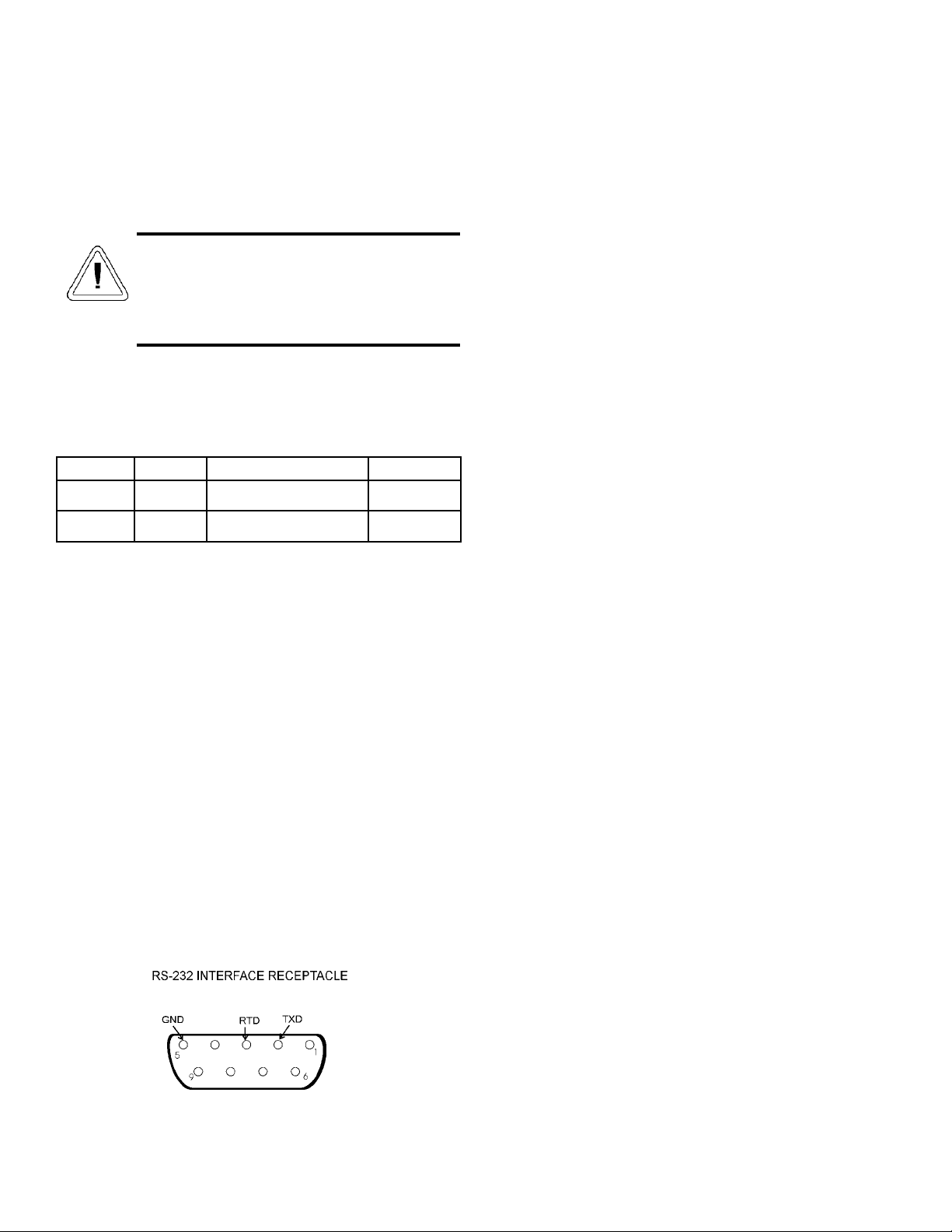

d. RS-232 Communications

The 8600 series freezer has a data communications interface.

The factory default setting is RS-232.

The wiring identification for the interface is shown in

Figure 1-7. One nine pin, sub "D" style connector is located on

the back of the freezer. See Figure 1-2 for the location of the

connector on the freezer.

The freezer transmits temperature information one

minute after power is first applied to the unit, then every 60

minutes thereafter.

Data format:

Baud 1200

Data bits 8 (7 bit ASCII with leading zero)

Start bits 1

Stop bits 2

Parity none

The data transfer sequence is transmitted in the follow-

ing format. X refers to numerical temperature data.

(NUL) (-) XXX (SP) C (SP) (OVERTEMP) (SP) (LF) (CR)

(EOT) (SP) (UNDER TEMP)

The words "OVER TEMP" or "UNDER TEMP" are

transmitted when an alarm condition exists along with the tem-

perature. If no alarm condition exists, spaces will be sent. A

total of 20 characters will be sent.

SP - Space LF - Line feed

CR - Carriage return EOT - End of text (4)

NUL - Null character (00)

Model 8600 Series ___________________________________________________________________Installation and Start-Up

1 - 4

Quantity Stock # Description Purpose

2510016 1/4-20 x 5-1/2” Bolt Wall Bumper

2 380520 Neoprene Cap Cap Protector

Figure 1-7

For proper ventilation and airflow, a minimum

clearance of 5” at the rear and top and a clear-

ance of 8” on the side of the freezer is required.

Allow adequate space in the front of the freezer

for door opening.

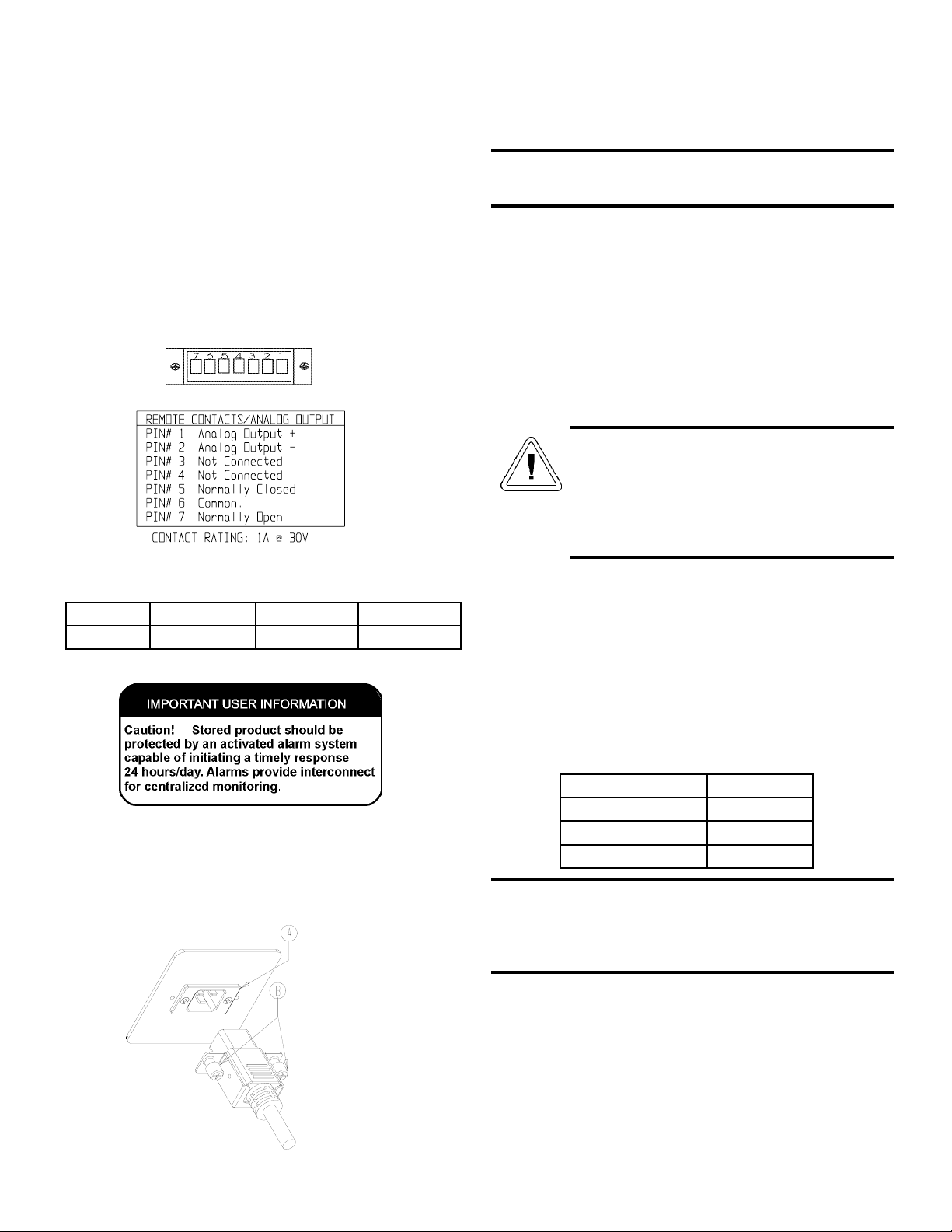

e. Remote Alarm Contacts and Analog Output

The 8600 series freezer has remote alarm contacts and ana-

log output. The remote alarm provides a NO (normally open)

output, a NC (normally closed) output and COM (common).

The contacts will trip on a power outage, high temperature

alarm or low temperature alarm.

The pin configuration for the remote contacts/analog output

is shown below (in alarm state). The analog output function

allows the freezer to output signals representing the temperature

of the freezer cabinet. The factory default setting is 4-20 mA.

Refer to figure 1-9 for output specifications.

f. Attaching the Power Cord

Insert the power cord into the power outlet module (A).

Tighten screws (B) on the power cord retainer.

g. Connecting the Unit to Electrical Power

See the serial tag on the side of the unit for electrical specifi-

cations or refer to the electrical schematics in this manual.

The freezer should be operated on a dedicated grounded

service. Check the voltage rating on the serial tag of the unit

and compare it with the outlet voltage. Then, with the power

switch turned off, plug the line cord into the wall outlet.

First turn on the freezer power switch. Then open the lower

front door by grasping the bottom left corner. Locate the battery

switch and turn it on. See Figure 1-5. During initial freezer

start-up, the system battery may require charging and the Low

Battery message may appear in the message center.

1.6 Freezer Start-Up

With the freezer properly installed and connected to power,

system set points can be entered. The following set points can

be entered in Settings mode: Control temperature, high temper-

ature alarm set point, low temperature alarm set point, and

(optional) BUS set point. Default settings are shown in the table

below. See Chart 1-1 for more detail.

a. Setting the Operating Temperature

All 8600 Series freezers have an operating temperature

range of -50°C to -86°C, depending on ambient temperature.

The freezer is shipped from the factory with a temperature set

point of -80°C. To change the operating temperature set point:

1. Press the Mode key until the Settings indicator lights.

Model 8600 Series ____________________________________________________________Installation and Start-Up

Figure 1-10

1 - 5

If the set point is changed and the low temperature and high

temperature alarms are set 10° from the set point, the alarm

set points will be adjusted automatically to maintain a dis-

tance of at least 10° from set point.

Control Set Point -80°C

High Temperature Alarm -70°C

Low temperature alarm -90°C

Optional BUS Set Point -60°C

4-20 mA 0-1V 0-5V

Temperature -100 to +50°C -100 to +50°C -100 to +50°C

Figure 1-9

Assure the battery switch is turned on. The

rechargeable batteries require 36 hours to charge

at initial start-up. A “Low Battery” alarm may

occur until the batteries are fully charged. Should

a power failure occur during the initial start-up

period, the electronics will have limited operation.

Figure 1-8

1 - 6

Model 8600 Series ____________________________________________________________Installation and Start-Up

2. Press the right arrow until “SET PT = -XX” is displayed

in the message center.

3. Press the up/down arrow key until the desired tempera-

ture set point is displayed.

4. Press Enter to save the set point.

5. Press the Mode key until the Run indicator lights for

Run mode or press the right/left arrow keys to go to

next/previous parameter.

If no control keys are pressed, the freezer will automatical-

ly return to RUN mode after 5 minutes.

b. Setting the High Temperature Alarm

The high temperature alarm will activate an audible/visual

warning when the freezer chamber temperature has reached or

exceeded the high temperature alarm set point.

To set the high temperature alarm set point:

1. Press the Mode key until the Set indicator lights.

2. Press the right arrow until “HI ALM = -XX” is dis-

played in the message center.

3. Press the up or down arrow key until the desired high

temperature alarm set point is displayed.

4. Press Enter to save the setting.

5. Press the Mode key until the Run indicator lights or

press the right or left arrow to go to the next or previous

parameter.

If no control keys are pressed, the freezer will automatical-

ly return to RUN mode after 5 minutes.

Note: The high alarm set point must be set at least 10°C from

the control set point.

c. Setting the Low Temperature Alarm

The low temperature alarm will activate an audible/visual

warning when the freezer chamber temperature has reached or

decrease below the low temperature alarm set point.

To set the low temperature alarm set point:

1. Press the Mode key until the Settings indicator lights.

2. Press the right arrow until “LO ALM = -XX” is dis-

played in the message center.

3. Press the up or down arrow key until the desired low

temperature alarm set point is displayed.

4. Press Enter to save the setting.

5. Press the Mode key until the Run indicator lights or

press the right or left arrow to go to the next or previous

parameter.

If no control keys are pressed, the freezer will automatical-

ly return to RUN mode after 5 minutes.

Note: The low alarm set point must be set at least 10°C from

the control set point.

d. Access Code

An access code of 000 is required to access the Settings,

Calibrate or Configuration modes. If the access code is not at

the default 000, you can not leave RUN mode without entering

a code. See section 3.1.d for instructions on modifying the

access code.

1.7 Run Mode

The Run mode is the default mode for the freezer. The run

mode will display the cabinet temperature on the temperature

display and ‘SYSTEM OK’ on the message center under nor-

mal operating conditions. In addition, the Run mode allows dis-

play of the following information:

LINE VOLTAGE

COMPENSATED VOLTAGE

HSHX TEMPERATURE (heat exchanger temperature)

This information is scrolled individually by pressing the

right arrow key. In each case, the message center returns to

SYSTEM OK in 10 seconds if no keys are pressed.

Model 8600 Series ____________________________________________________________Installation and Start-Up

1 - 7

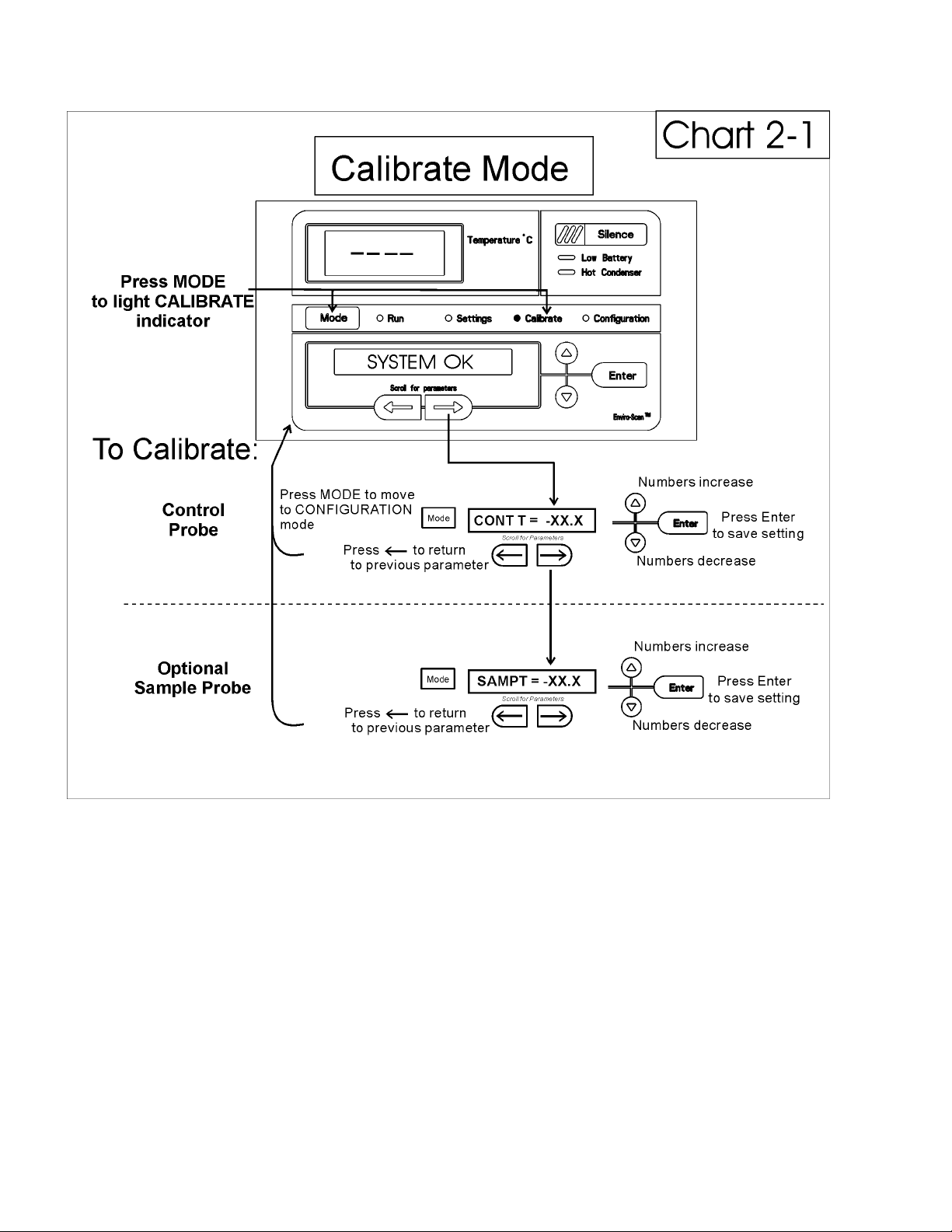

Section 2 - Calibrate

2.1 Calibrate Mode

Once the freezer has stabilized, the control or sample probe

may need to be calibrated. Calibration frequency is dependent

on use, ambient conditions and accuracy required. A good labo-

ratory practice would require at least an annual calibration

check. On new installations, all parameters should be checked

after the stabilization period.

Before making any calibration or adjustments to

the unit, it is imperative that all reference instru-

ments be properly calibrated.

a. Calibrating the Control Probe

Plug a type T thermocouple reader into the receptacle

located inside the lower door (see Figure 1-5). Compare the

control temperature set point to the temperature of the measur-

ing device. See Chart 2-1 at the end of this section for more

detail.

1. Press the Mode key until the Calibrate indicator lights.

2. Press the right arrow until “CONT T = -XX.X” appears

in the message center.

3. Press up/down arrow to match the display to calibrated

instrument.

4. Press Enter to store calibration.

5. Press the Mode key to return to Run or the right/left

arrow to go to next/previous parameter.

b. Calibrating the Optional Sample Probe

For freezers with the optional sample probe, place the cali-

brated instrument in the center of the sample bottle. The bottle

should contain an appropriate medium and the measuring

instrument should be centered in the bottle.

1. Press the Mode key until the Calibrate indicator lights.

2. Press the right arrow until “SAMP T = -XX.X” appears

in the message center.

3. Press up/down arrow to match display to calibrated

instrument.

4. Press Enter to store calibration.

5. Press the Mode key to return to Run or the right/left

arrow to go to next/previous parameter.

See Chart 2-1 for calibration process functions.

Temperature Stabilization Periods

Startup - Allow 12 hours for the temperature in the cabinet to

stabilize before proceeding.

Already Operating - Allow at least 2 hours after the display

reaches set point for temperature to stabilize before proceeding.

During calibration, the temperature display will not be avail-

able.

If no keys are pressed for approximately five minutes while

in calibration mode, the system will reset to Run mode.

Model 8600 Series _________________________________________________________________________Calibration

2 - 1

Model 8600 Series ________________________________________________________________________Calibration

2 - 2

cator will light. Press the Silence key and the alarm indicator

will go off. The Low Battery light will stay on until a future

battery test is performed and passed.

d. BUS Battery Test

To test the charge of the BUS battery:

1. Press the Mode key until the Configuration indicator

lights.

2. Press the right arrow until BUS BAT TEST is displayed

in the message center.

3. Press Enter to initiate the test.

TESTING BATT will display during the testing period.

Upon completion of the test the message center will display

BBAT GOOD or BBAT FAIL When a test is failed, the audible

alarm will sound, the alarm indicator and the Low Battery indi-

cator will light. Press the Silence key and the alarm indicator

will go off. The Low Battery light will stay on until a future

battery test is performed and passed.

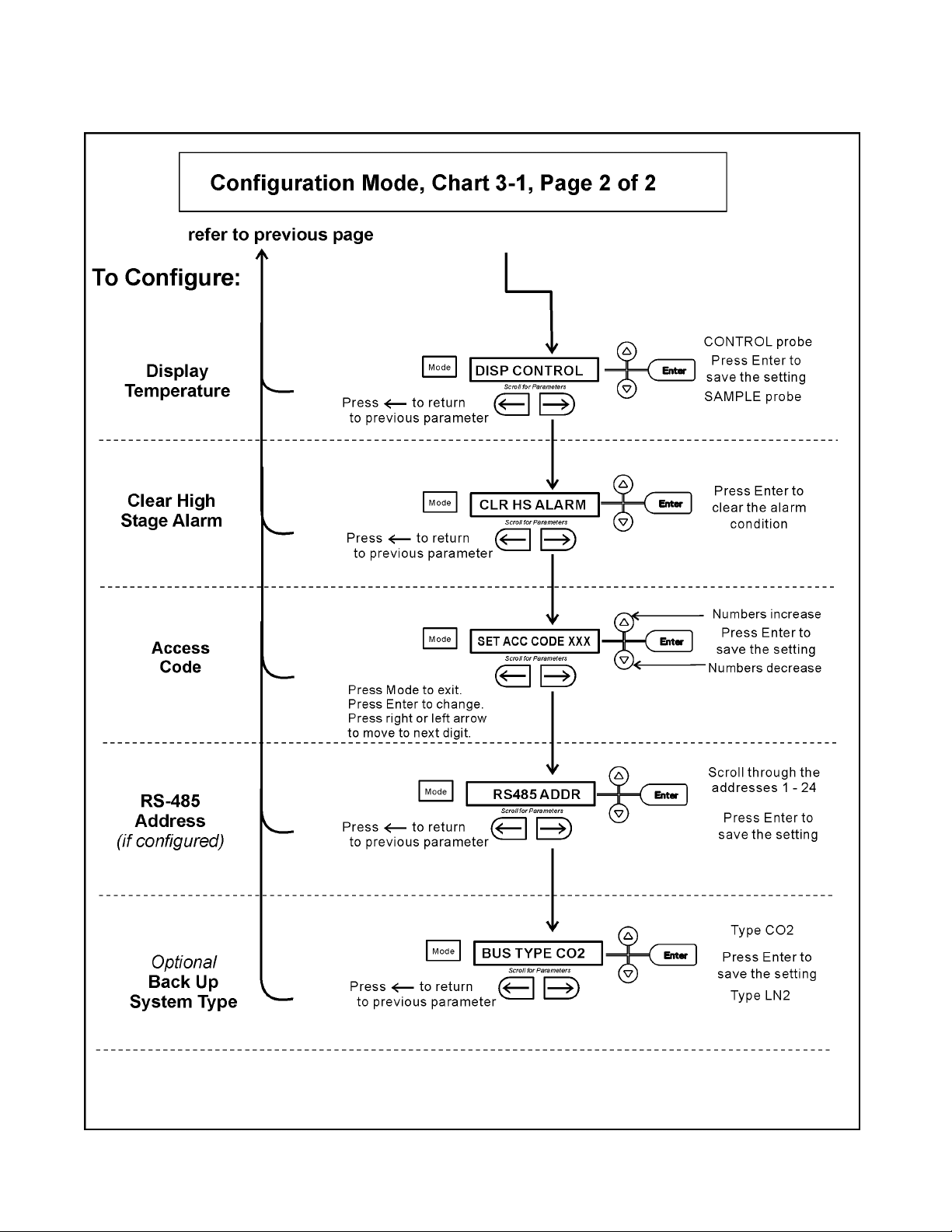

e. Display Temperature

This function, only available on freezers with the

optional sample probe, allows the user to select which tempera-

ture is displayed in the temperature display window. The

options are CONTROL or SAMPLE.

1. Press the Mode key until the Configuration indicator

lights.

2. Press the right arrow until DISP CONTROL or DISP

SAMPLE is displayed in the message center.

3. Press up/down arrow to toggle between the two display

selections.

4. Press Enter to save.

If control probe is selected, the temperature display

will be on continuously. If sample probe is selected, the temper-

ature display will be preceded with a letter ‘S’.

f. Clear High Stage Alarm

Should a high stage alarm occurred, it may become neces-

sary to the clear the alarm condition after the condition has

been corrected.

1. Press the Mode key until the Configuration indicator

lights.

2. Press the right arrow until CLR HS ALARM is dis-

played in the message center.

3. Press Enter to clear the alarm.

Model 8600 Series ______________________________________________________________________Configuration

3 - 1

Section 3 - Configuration

3.1 Configuration Mode

The Configuration Mode is used for testing and custom

setup of the freezer. The configuration functions listed and

described below may not be necessary in all applications, but

are available if needed. See Chart 3-1 for more detail.

a. High Alarm Test

The high alarm test is used to verify the high alarm will

activate, should the freezer temperature equal or exceed the

high alarm set point.

1. Press the Mode key until the Configuration indicator

lights.

2. Press the right arrow until HI ALRM TEST is displayed

in the message center.

3. Press Enter to initiate the test.

The temperature on the display will begin to increase until

the high alarm set point has been reached. The audible alarm

will sound and the alarm indicator will flash. Press the Silence

key to silence the alarm.

b. Low Alarm Test

The low alarm test is used to verify the low alarm will acti-

vate, should the freezer temperature equal or become less than

the low alarm set point.

1. Press the Mode key until the Configuration indicator

lights.

2. Press the right arrow until LO ALRM TEST is dis-

played in the message center.

3. Press Enter to initiate the test.

The temperature on the display will begin to decrease until

the low alarm set point has been reached. The audible alarm

will sound and the alarm indicator will flash. Press the Silence

key to silence the alarm.

c. System Battery Test

To test the charge of the freezer battery:

1. Press the Mode key until the Configuration indicator

lights.

2. Press the right arrow until SYS BAT TEST is displayed

in the message center.

3. Press Enter to initiate the test.

TESTING BATT will display during the testing period.

Upon completion of the test the message center will display

BATT GOOD or BATT FAIL When a test is failed, the audible

alarm will sound, the alarm indicator and the Low Battery indi-

i. Back Up System Type

This function, which is only available on freezers with the

optional BUS (back up system), allows the user to select which

type of gas is injected into the freezer chamber. The options are

CO2 and LN2.

1. Press the Mode key until the Configuration indicator

lights.

2. Press the right arrow until BUS TYPE CO2 or BUS

TYPE LN2 is displayed in the message center.

3. Press up/down arrow to toggle between the two display

selections.

4. Press Enter to save.

g. Setting an Access Code

To set the Access Code:

1. Press the Mode key until the Configuration indicator

lights.

2. Press the right arrow until “SET ACC CODE” is dis-

played in the message center.

3. Press Enter.

4. The message center will display ACC CODE = 000.

Press the up or down arrow key until the desired access

code is displayed (000 - 999). Press the left or right

arrow key to select digit 1, 2, 3.

The left and right arrow keys are used to move from the first

through the third digits within the access code.

5. Press Enter to save the setting

6. Press the Mode key until the Run indicator lights.A 3-

digit Access Code can be entered to avoid unauthorized

personnel from changing the set points, calibration, or

configuration. A setting of 000 will bypass the access

code. The factory setting is 000.

h. RS485 Address

If the freezer is configured for RS-485 communications, it

will need to have a unique identification address. This address

is set through the Configuration mode.

1. Press the Mode key until the Configuration indicator

lights.

2. Press the right arrow until RS485ADDR is displayed in

the message center.

3. Press Enter. The message center will display

485 ADDR XX.

4. Press up/down arrow to select the appropriate address

for the freezer (1 - 24).

4. Press Enter to save.

Model 8600 Series ______________________________________________________________________Configuration

3 - 2

Model 8600 Series _______________________________________________________________________Configuration

3 - 3

3 - 4

Model 8600 Series _______________________________________________________________________Configuration

Section 4 - Alarms

4.1 Alarms

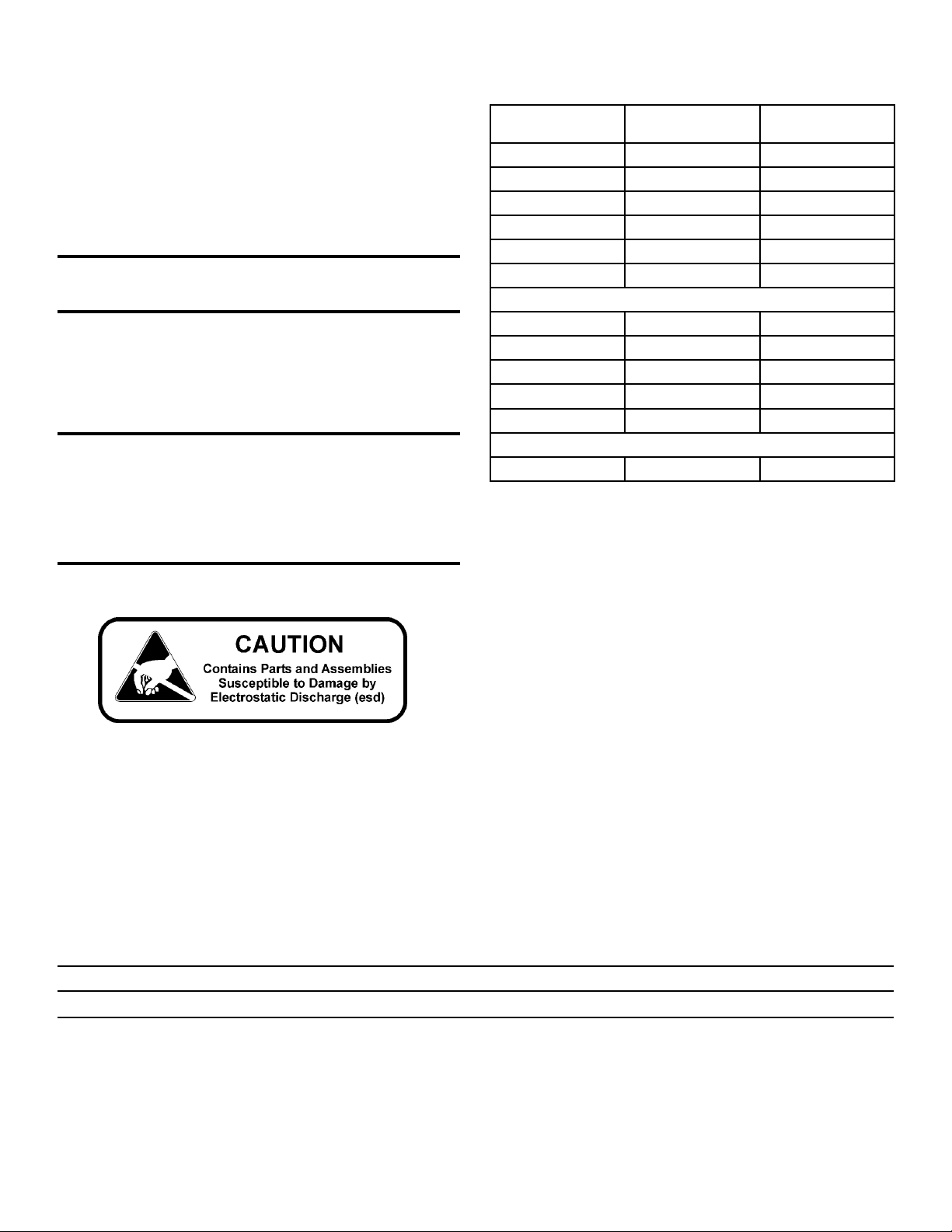

The Model 8600 Series freezer alarm system is shown in the table below. When an alarm is active, the message appears in the

LED message center. Press the Silence key to disable the audible alarm for the ringback period. The visual alarm will continue until

the freezer returns to a normal condition. The alarms are momentary alarms only. When an alarm condition occurs and then returns

to normal, the freezer automatically clears the alarm condition and the message center.

Model 8600 Series ___________________________________________________________________________Alarms

4 - 1

a. Wrong Power Alarm

If a 230 V freezer is connected to a 120 V power source or a

120 V freezer is connected to a 230 V power source, the elec-

tronics will detect that an incorrect power source has been con-

nected to the freezer. Under this condition, the fans and com-

pressors will not turn on and an audible and visual alarm will

occur along with the "WRONG POWER" message in the LED

message center. The audible and visual alarms will remain until

the freezer is connected to the correct power source.

b. High Stage System Failure Alarm

This condition is created when the high stage compressor

and fans run for 30 minutes and are not capable of cooling the

interstage heat exchanger to the proper temperature. Under this

condition, the high stage compressor and fans will turn off after

30 minutes and an audible and visual alarm will occur along

with the "HS SYST FAIL" message in the LED message center.

c. Multiple Alarms

When multiple alarm conditions occur, active messages are

displayed in the message center one at a time, updating at 5 sec-

ond intervals. Pressing Silence during multiple alarms causes all

active alarms to be silenced and to ring back in 15 minutes.

4.2 Probe Failure Alarms

The microprocessor in 8600 series freezers continually

scans all probes including the control probe, heat exchanger

probe, condenser probe and optional sample probe to ensure that

they are operating properly. Should an error be detected, the

"PROBE # FAIL" alarm will occur as described in 4.1 above. If

an error is detected with the control probe (PROBE 1 FAIL), the

high and low stage compressors will run continuously. As a

result, the cabinet temperature will decrease until it reaches the

lowest temperature that the refrigeration system can maintain. If

an error is detected with the heat exchanger probe (PROBE 2

FAIL), the freezer will cycle properly at its temperature set point

using a 5 minute step start between the high and low stage com-

pressors. If an error is detected with the condenser probe

(PROBE 3 FAIL) or optional sample probe (PROBE 4 FAIL),

there is no impact on the performance of the freezer. However,

the hot condenser alarm may also occur when the condenser

probe fails. Contact the Thermo Forma Service Department (1-

888-213-1790) or your local distributor.

Description Message Delay Ringback Relay

No alarm condition exists SYSTEM OK ---- ---- ----

Power Failure POWER FAIL 1 min. 15 min. Yes

High Temperature Alarm TEMP IS HIGH 1 min. 15 min. Yes

Low Temperature Alarm TEMP IS LOW 1 min. 15 min. Yes

Door Ajar DOOR IS OPEN 1 min. 15 min. No

Low Battery LOW BATTERY 1 min. 12 hours No

Control Probe Failure - see 4.2 PROBE 1 FAIL 1 min. 15 min. No

Heat Exchanger Probe Failure - see 4.2 PROBE 2 FAIL 1 min. 15 min. No

Condenser Probe - see 4.2 PROBE 3 FAIL 1 min. 15 min. No

Sample Probe Failure (optional) - see 4.2 PROBE 4 FAIL 1 min. 15 min. No

High Stage System Failure HS SYST FAIL 1 min. 15 min. No

Condenser Hot Condition HOT CONDENSR 1 min. none No

Wrong Power WRONG POWER 0 min. none No

Filter Needs Cleaning CLEAN FILTER 0 min. 3 months No

Gasket Needs Cleaning CLEAN GASKET 0 min. 3 months No

All alarm delays and ringback times are +30 seconds.

Section 5 - Maintenance

5.1 Cleaning the Cabinet Exterior

Wipe down the freezer exterior using soap and water and

a general use laboratory disinfectant. Rinse thoroughly with

clean water and dry with a soft cloth.

5.2 Cleaning the Air Filter (minimum four times a

year*)

1. Open the front lower door by grasping the bottom left

corner.

2. Locate the grille on the door. See Figure 1-5. Grasp the

middle of the grille material and gently pull out to

remove.

3. Wash the filter material using water and a mild deter-

gent.

4. Dry by pressing between two towels.

5. Install the filter back into the grille and attach the grille.

* The clean filter alarm occurs every three months as a

reminder to clean the air filter. Depending upon environmental

conditions, the filter may need to be cleaned or replaced more

frequently. If the filter becomes torn or excessively dirty, a

replacement can be purchased from Thermo Forma. Order part

number 760203.

5.3 Cleaning the Condenser (minimum of twice a

year*)

1. Open the front lower door by grasping the bottom left

corner. See Figure 1-5.

2. Using a vacuum cleaner, exercising care to not damage

the condenser fins, clean the condenser.

* Depending upon environmental conditions, the condenser

may need to be cleaned more frequently.

a. Cleaning the Water-cooled Condenser

The water-cooled condenser can be cleaned-in-place by

using the CIP procedure. Cleaning solutions can be used,

depending on type of deposits or build-up to be removed.

Do not use liquids that are corrosive to stainless

steel or the brazing material (copper or nickel).

CIP (Clean-In-Place) Procedure

1. Disconnect the unit from the water supply.

2. Drain the unit.

3 . Rinse with fresh water and drain the unit again.

4. Fill with fresh water.

5. Add cleaning agent (solution and concentration depend-

ent on deposits or build-up).

6. Circulate cleaning solution (if feasible).

7. Drain the cleaning solution.

8. Add and circulate a passivating liquid for corrosion inhi-

bition of plate surfaces.

9. Drain this liquid.

10. Rinse with fresh water and drain.

11. Reconnect the water supply and fill the unit.

12 . Return to service.

5.4 Defrosting the Chamber

1. Remove all product and place it in another freezer.

2. Turn the unit off and disconnect it from the power

source.

3. Turn off the power switch (see figure 5-1) to the bat-

tery(s).

4. Open all of the doors and place towels on the chamber

floor.

5. Allow the frost to melt and become loose.

6. Remove the frost with a soft cloth.

7. After defrosting is complete, clean the interior with a

non-chloride detergent. Rinse thoroughly with clean

water and dry with a soft cloth.

8. Plug unit in and turn power switch on.

9. Turn the battery power switch to the on position.

10. Allow the freezer to operate empty overnight before

reloading the product.

Model 8600 Series ______________________________________________________________________Maintenance

5 - 1

Avoid the excessive use of water

around the control area due to the risk

of electrical shock. Damage to the con-

trols may also result.

This manual suits for next models

12

Table of contents

Other Thermo Forma Freezer manuals

Thermo Forma

Thermo Forma 3795 Operating instructions

Thermo Forma

Thermo Forma 8097 Operating instructions

Thermo Forma

Thermo Forma 8523 Operating instructions

Thermo Forma

Thermo Forma Power Plus 8500 Series Operating instructions

Thermo Forma

Thermo Forma 916 Operating instructions

Thermo Forma

Thermo Forma 900 Series Operating instructions