viii Refrigerant Oil Safety Precautions

CSR40SL Semi-Hermetic, February 2000

Refrigerant Oil

Observe the following precautions when working with or

around refrigerant oil:

• Do not allow refrigerant oil to contact your eyes.

• Do not allow prolonged or repeated contact with skin or

clothing.

• To prevent irritation, you should wash thoroughly imme-

diately after handling refrigerant oil. Rubber gloves are

recommended when handling Polyol Ester based refriger-

ant oil.

First Aid

• EYES: Immediately flush eyes with large amounts of

water for at least 15 minutes while holding the eyelids

open. Get prompt medical attention.

• SKIN: Remove contaminated clothing. Wash thoroughly

with soap and water. Get medical attention if irritation

persists.

• INHALATION: Move victim to fresh air and restore

breathing if necessary. Stay with victim until arrival of

emergency personnel.

• INGESTION: Do not induce vomiting. Contact a local

poison control center or physician immediately.

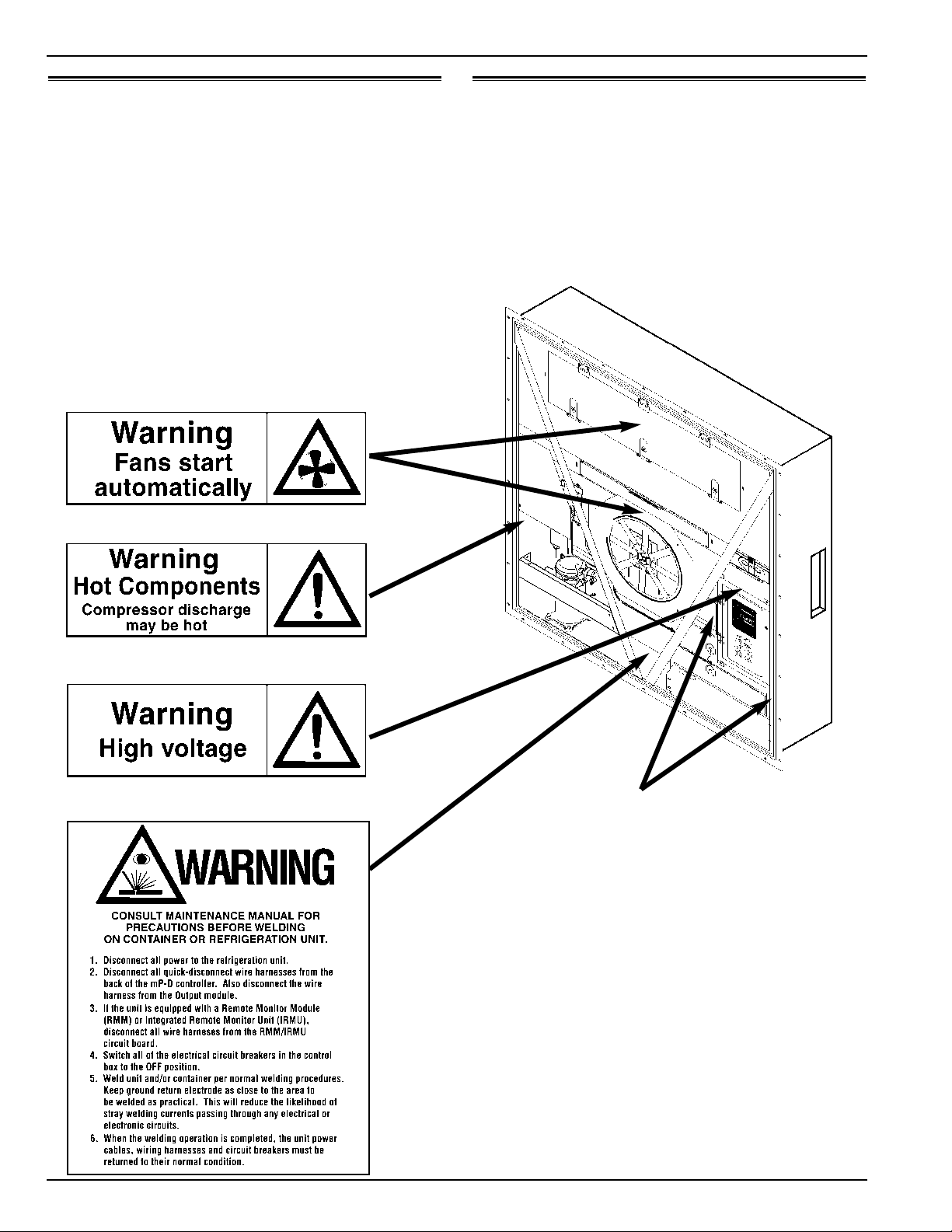

Electrical

High Voltage

When servicing or repairing a refrigeration unit, the possibility

of serious or even fatal injury from electrical shock exists.

Extreme care must be used when working with a refrigeration

unit that is connected to a source of operating power, even if

the unit is not running. Lethal voltage potentials can exist at

the unit power cord, inside the control box, inside any high

voltage junction box, at the motors and within the wiring har-

nesses.

Precautions

1. Be certain the unit On/Off switch is turned OFF before

connecting or disconnecting the unit power plug. Never

attempt to stop the unit by disconnecting the power plug.

2. Be certain the unit power plug is clean and dry before

connecting it to a power source.

3. Use tools with insulated handles that are in good condi-

tion. Never hold metal tools in your hand if exposed,

energized conductors are within reach.

4. Do not make any rapid moves when working on high volt-

age circuits. If a tool or other object falls, do not attempt

to grab it. People do not contact high voltage wires on

purpose. It occurs from an unplanned movement.

5. Treat all wires and connections as high voltage until a

meter and wiring diagram show otherwise.

6. Never work alone on high voltage circuits on the refriger-

ation unit. Another person should always be standing by

in the event of an accident to shut off the refrigeration unit

and to aid a victim.

7. Have electrically insulated gloves, cable cutters and safety

glasses available in the immediate vicinity in the event of

an accident.

First Aid

IMMEDIATE action must be initiated after a person has

received an electrical shock. Obtain immediate medical assis-

tance if available.

The source of shock must be immediately removed by

either shutting down the power or removing the victim from

the source. If it is not possible to shut off the power, the wire

should be cut with either an insulated instrument (e.g., a wood-

en handled axe or cable cutters with heavy insulated handles)

or by a rescuer wearing electrically insulated gloves and safety

glasses. Whichever method is used, do not look at the wire

while it is being cut. The ensuing flash can cause burns and

blindness.

If the victim has to be removed from a live circuit, pull the

victim off with a non-conductive material. Use the victim’s

coat, a rope, wood, or loop your belt around the victim’s leg or

arm and pull the victim off. DO NOT TOUCH the victim.

You can receive a shock from current flowing through the vic-

tim’s body.

After separating the victim from power source, check

immediately for the presence of a pulse and respiration. If a

pulse is not present, start CPR (Cardio Pulmonary

Resuscitation) and call for emergency medical assistance. If a

pulse is present, respiration may be restored by using mouth-

to-mouth resuscitation, but call for emergency medical assis-

tance.

Low Voltage

Control circuits are low voltage (24 Vac and 12 Vdc). This

voltage potential is not considered dangerous, but the large

amount of current available (over 30 amperes) can cause

severe burns if shorted to ground.

Do not wear jewelry, watch or rings. These items can short

out electrical circuits and cause severe burns to the wearer.