Thermo King CBci 10 12V User manual

CBci & CB MAX

w/Control Box Thermostat

TK 40738-1-MM (Rev. 1, 1/99)

Copyright©1993 Thermo King Corp., Minneapolis, MN, U.S.A.

Printed in U.S.A.

This manual is published for informational purposes only and the information so provided should not be

considered as all-inclusive or covering all contingencies. If further information is required, Thermo King

Corporation should be consulted.

Sale of product shown in this manual is subject to Thermo King’s terms and conditions including, but not

limited to, the THERMO KING EXPRESS WARRANTY. Such terms and conditions are available upon

request.

Thermo King’s warranty will not apply to any equipment which has been “so repaired or altered outside the

manufacturer’s plants as, in the manufacturer's judgment, to effect its stability.”

No warranties, express or implied, including warranties of fitness for a particular purpose or

merchantability, or warranties arising from course of dealing or usage of trade, are made regarding

the information, recommendations, and descriptions contained herein. Manufacturer is not

responsible and will not be held liable in contract or in tort (including negligence) for any special,

indirect or consequential damages, including injury or damage caused to vehicles, contents or

persons, by reason of the installation of any Thermo King product or its mechanical failure.

The maintenance information in this manual covers unit models:

CBci 10 12V (914725) CB MAX 10 12V (915091)

CBci 10 24V (914724) CB MAX 10 24V (915090)

CBci 20 12V (914729) CB MAX 20 12V (915097)

CBci 20 24V (914728) CB MAX 20 24V (915094)

For further information, refer to…

CBci and CB Parts Manual TK 40097

CBci Operating Manual TK 40170

Diagnosing Thermo King Refrigeration System TK 5984

Tool Catalog TK 5955

The information in this manual is provided to assist owners, operators and service people in the proper

upkeep and maintenance of Thermo King units.

Recover Refrigerant

At Thermo King, we recognize the need to preserve the environ-

ment and limit the potential harm to the ozone layer that can

result from allowing refrigerant to escape into the atmosphere.

We strictly adhere to a policy that promotes the recovery and

limits the loss of refrigerant into the atmosphere.

In addition, service personnel must be aware of Federal regula-

tions concerning the use of refrigerants and the certification of

technicians. For additional information on regulations and tech-

nician certification programs, contact your local THERMO KING

dealer.

R-404A and R-134a

CAUTION: Use ONLY Polyol Ester based refrigeration compressor oil (TK P/N

203-413) in R-404A and R-134a units.

DO NOT use Polyol Ester based oil in standard Thermo King units.

DO NOT mix Polyol Ester and standard synthetic compressor oils.

Keep Polyol Ester compressor oil in tightly sealed containers. If Polyol Ester oil

becomes contaminated with moisture or standard oils, dispose of properly—DO NOT

USE!

CAUTION: When servicing Thermo King R-404A and R-134a units, use only those

service tools certified for and dedicated to R-404A and R-134a refrigerant and

Polyol Ester compressor oils. Residual non-HFC refrigerants and non-HFC refrigerants

or oils will contaminate R-404A and R-134a systems.

Table of Contents

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Maintenance Inspection Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Unit Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Liquid Injection System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Oil Separator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

CBci MAX Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Unit Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Operating Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Unit Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Protection Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Optional Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Serial Number Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

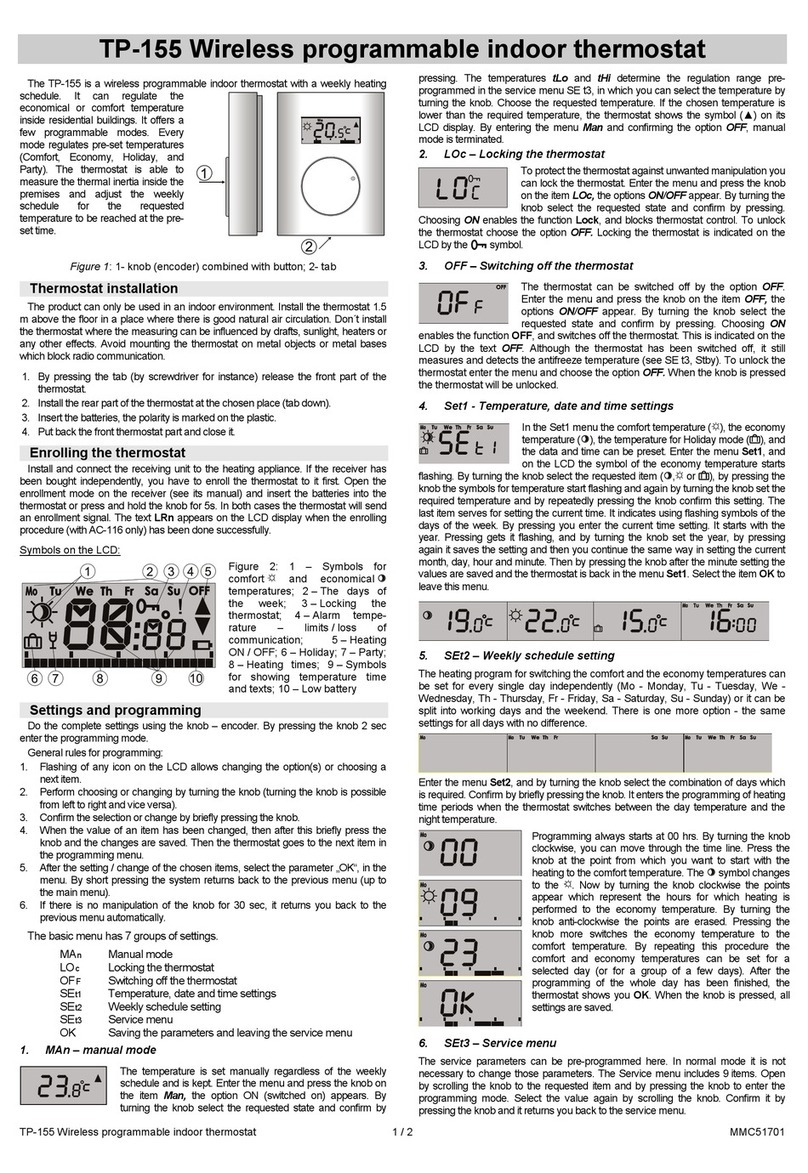

Unit Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Unit Protection Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Unit Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Starting the Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Adjusting the Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

After Start Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Loading Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Post Loading Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Weekly Post Trip Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Electrical Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Unit Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Remote Control Box Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Testing the Thermometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Testing the Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Cab Control Box Components (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Temperature Control Module (TCM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Defrost System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Engine Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Electric Standby Operation (Model 20 Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Defrost Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Testing the Defrost System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Defrost Timer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Circuit Breakers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Condenser Fan Pressure Switch (CFPS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Electric Standby Circuits (Model 20 Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Table of Contents

Refrigeration Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Refrigerant Charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Charging the Refrigeration System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Checking Compressor Oil Charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

High Pressure Cutout Switch (HPCO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

System Cleanup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Refrigerant Hose Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Three-way Valve Condenser Pressure Bypass Check Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Refrigeration Service Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Condenser Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Filter Drier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Evaporator Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Expansion Valve Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Receiver Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Oil Separator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Replacing Refrigerant Hoses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Liquid Injection Solenoid Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Liquid Injection Metering Orifice. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Testing the Liquid Injection Solenoid Valve and Metering Orifice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

High Pressure Cutout And Condenser Fan Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Low Pressure Cutout Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Suction Pressure Regulator Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Discharge Check Valve Repair (Model 20 Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Accumulator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Three-way Valve Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Three-way Valve Condenser Pressure Bypass Check Valve Repair. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Pilot Solenoid. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

In-line Condenser Check Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

In-line Condenser Check Valve Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

O-Ring Seal (ORS) Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Structural Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Unit Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Evaporator Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Fan Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Condenser Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Unit Mounting Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Table of Contents (Continued)

Compressor and Clutch Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Clutch Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Clutch Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Shaft Seal Cover and Shaft Seal: Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Special Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

System Compressor and Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

Checking the Oil Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Electrical Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Clutch Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

Belt Tensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

Engine/Compressor Belt and Pulleys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

Over-the-Road Mechanical Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Electric Standby Mechanical Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

Refrigeration Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Wiring and Schematic Diagrams Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

i

Safety Precautions

GENERAL PRACTICES

1. ALWAYS WEAR GOGGLES OR SAFETY

GLASSES. Refrigerant liquid, refrigeration oil, and

battery acid can permanently damage the eyes (see First

Aid under Refrigeration Oil).

2. Never operate the unit with the compressor discharge

valve closed.

3. Keep your hands, clothing and tools clear of the fans

and belts when the unit is running. This should also be

considered when opening and closing the compressor

service valves.

4. Make sure gauge manifold hoses are in good condition.

Never let them come in contact with a belt, fan motor

pulley, or any hot surface.

5. Never apply heat to a sealed refrigeration system or

container.

6. Fluorocarbon refrigerants, in the presence of an open

flame or electrical short, produce toxic gases that are

severe respiratory irritants capable of causing death.

7. Make sure all mounting bolts are tight and are of cor-

rect length for their particular application.

8. Use extreme caution when drilling holes in the unit.

The holes may weaken structural components, and

holes drilled into electrical wiring can cause fire or

explosion.

9. Use caution when working around exposed coil fins.

The fins can cause painful lacerations.

10. Use caution when working with a refrigerant or refrig-

eration system in any closed or confined area with a

limited air supply (for example, a truck box or garage).

Refrigerant tends to displace air and can cause oxygen

depletion resulting in suffocation and possible death.

11. In the USA, EPA Section 608 Certification is needed to

work on refrigeration systems.

REFRIGERANT

Although fluorocarbon refrigerants are classified as safe

refrigerants, certain precautions must be observed when

handling them or servicing a unit in which they are used.

When exposed to the atmosphere from the liquid state, fluo-

rocarbon refrigerants evaporator rapidly, freezing anything

they contact.

First Aid

In the event of frost bite, the objectives of First Aid are to

protect the frozen area from further injury, to warm the

affected area rapidly and to maintain respiration.

• EYES: For contact with liquid, immediately flush eyes

with large amounts of water and get prompt medical

attention.

• SKIN: Flush area with large amounts of lukewarm

water. Do not apply heat. Remove contaminated cloth-

ing and shoes. Wrap burns with dry, sterile, bulky

dressing to protect from infection/injury. Get medical

attention. Wash contaminated clothing before reuse.

• INHALATION: Move victim to fresh air and use CPR

if necessary. Stay with victim until arrival of emer-

gency medical personnel.

REFRIGERATION OIL

Avoid refrigeration oil contact with the eyes. Avoid pro-

longed or repeated contact of refrigeration oil with skin or

clothing. Wash thoroughly after handling refrigeration oil to

prevent irritation.

First Aid

In case of eye contact, immediately flush with plenty of

water for at least 15 minutes. Wash skin with soap and

water. CALL A PHYSICIAN.

Safety Precautions (Rev. 1/99)

ii

ELECTRICAL HAZARDS

High Voltage

When servicing or repairing a refrigeration unit, the possi-

bility of serious or even fatal injury from electrical shock

exists. Extreme care must be used when working with an

operating refrigeration unit. Lethal voltage potentials can

exist on connections in the high voltage tray of the control

box.

Precautions

1. When working on high voltage circuits on the refrigera-

tion unit, do not make any rapid moves. If a tool drops,

do not grab for it. People do not contact high voltage

wires on purpose. It occurs from an unplanned move-

ment.

2. Use tools with insulated handles that are in good condi-

tion. Never hold metal tools in your hand if exposed,

energized conductors are within reach.

3. Treat all wires and connections as high voltage until a

meter and wiring diagram show otherwise.

4. Never work alone on high voltage circuits on the refrig-

eration unit, another person should always be standing

by in the event of an accident to shut off the refrigera-

tion unit and to aid a victim.

5. Have electrically insulated gloves, cable cutters and

safety glasses available in the immediate vicinity in the

event of an accident.

First Aid

IMMEDIATE action must be initiated after a person has

received an electrical shock. Obtain immediate medical

assistance if available.

The source of shock must be immediately removed by

either shutting down the power or removing the victim from

the source. If it is not possible to shut off the power, the wire

should be cut with either an insulated instrument (e.g., a

wooden handled axe or cable cutters with heavy insulated

handles) or by a rescuer wearing electrically insulated

gloves and safety glasses. Whichever method is used do not

look at the wire while it is being cut. The ensuing flash can

cause burns and blindness.

If the victim has to be removed from a live circuit, pull the

victim off with a non-conductive material. Use the victim’s

coat, a rope, wood, or loop your belt around the victim’s leg

or arm and pull the victim off. DO NOT TOUCH the victim.

You can receive a shock from current flowing through the

victim’s body. After separating the victim from power

source, check immediately for the presence of a pulse and

respiration. If a pulse is not present, start CPR (Cardio Pul-

monary Resuscitation) and call for emergency medical

assistance. If a pulse is present, respiration may be restored

by using mouth-to-mouth resuscitation, but call for emer-

gency medical assistance.

Low Voltage

Control circuits used in the refrigeration unit are low volt-

age (12 volts dc). This voltage potential is not considered

dangerous, but the large amount of current available (over

30 amperes) can cause severe burns if shorted or ground.

Do not wear jewelry, watch or rings. These items can short

out electrical circuits and cause severe burns to the wearer.

1

Specifications

R-134a REFRIGERATION SYSTEM

Compressor Zexel DKS-15CH

Engine Compressor Oil Charge 11.5 oz (339 ml)

Electric Standby Compressor Oil Charge 5.7 oz (168 ml)

Compressor Oil Type Polyol Ester P/N 203-413

Refrigerant Type R-134a

Defrost Method: Truck Engine Operation: CBci210 MAX Hot gas

CBci220 MAX Hot gas

Electric Standby: CBci220 MAX Hot gas and optional electric heaters

Defrost Termination Switch: Opens 52 F (11.1 C)

Closes 42 F (5.6 C)

High Temperature Switch: Opens 200 ± 5 F (39 ± 3 C)

Closes 230 ± 5 F (110 ± 3 C)

High Pressure Cutout Switch:Opens 300 ± 25 psi (2068 ± 68 kPa)

Closes 200 ± 20 psi (3103 ± 138 kPa)

Low Pressure Cutout Switch: Opens 5 to 11 in. Hg vacuum (-17 to -37 kPa)

Closes 4 to 7 psi (28 to 48 kPa)

Condenser Pressure Fan Switch:Opens 130 ± 10 psi (896 ± 69 kPa)

Closes 180 ± 10 psi (1241 ± 69 kPa)

Suction Pressure Regulator Setting 18 psi (124 kPa)

Defrost Timer: Initiation Interval 4 hours

Termination Interval 45 minutes

R-404A REFRIGERATION SYSTEM

Compressor Zexel DKS-15CH

Engine Compressor Oil Charge 11.5 oz (339 ml)

Electric Standby Compressor Oil Charge 5.7 oz (168 ml)

Compressor Oil Type Polyol Ester P/N 203-413

Refrigerant Type R-404A

Defrost Method: Truck Engine Operation: CBci210 Hot gas

CBci220 Hot gas

Electric Standby: CBci220 Hot gas and optional electric heaters

Defrost Termination Switch: Opens 52 F (11.1 C)

Closes 42 F (5.6 C)

High Temperature Switch: Opens 200 ± 5 F (39 ± 3 C)

Closes 230 ± 5 F (110 ± 3 C)

High Pressure Cutout Switch:Opens 470 ± 7 psi (3241 ± 48 kPa)

Closes 375 ± 38 psi (2586 ± 138 kPa)

Low Pressure Cutout Switch: Opens 5 to 11 in. Hg vacuum (-17 to -37 kPa)

Closes 4 to 7 psi (28 to 48 kPa)

Specifications (Rev. 1/99)

2

R-404A REFRIGERATION SYSTEM (continued)

Condenser Pressure Fan Switch:Opens 130 ± 10 psi (896 ± 69 kPa)

Closes 180 ± 10 psi (1241 ± 69 kPa)

Suction Pressure Regulator Setting 18 psi (124 kPa)

Defrost Timer: Intuition Interval 4 hours

Termination Interval 45 minutes

ELECTRICAL SYSTEM

Circuit Breaker Ratings

12 Vdc 40 amp manual reset

24 Vdc 25 amp manual reset

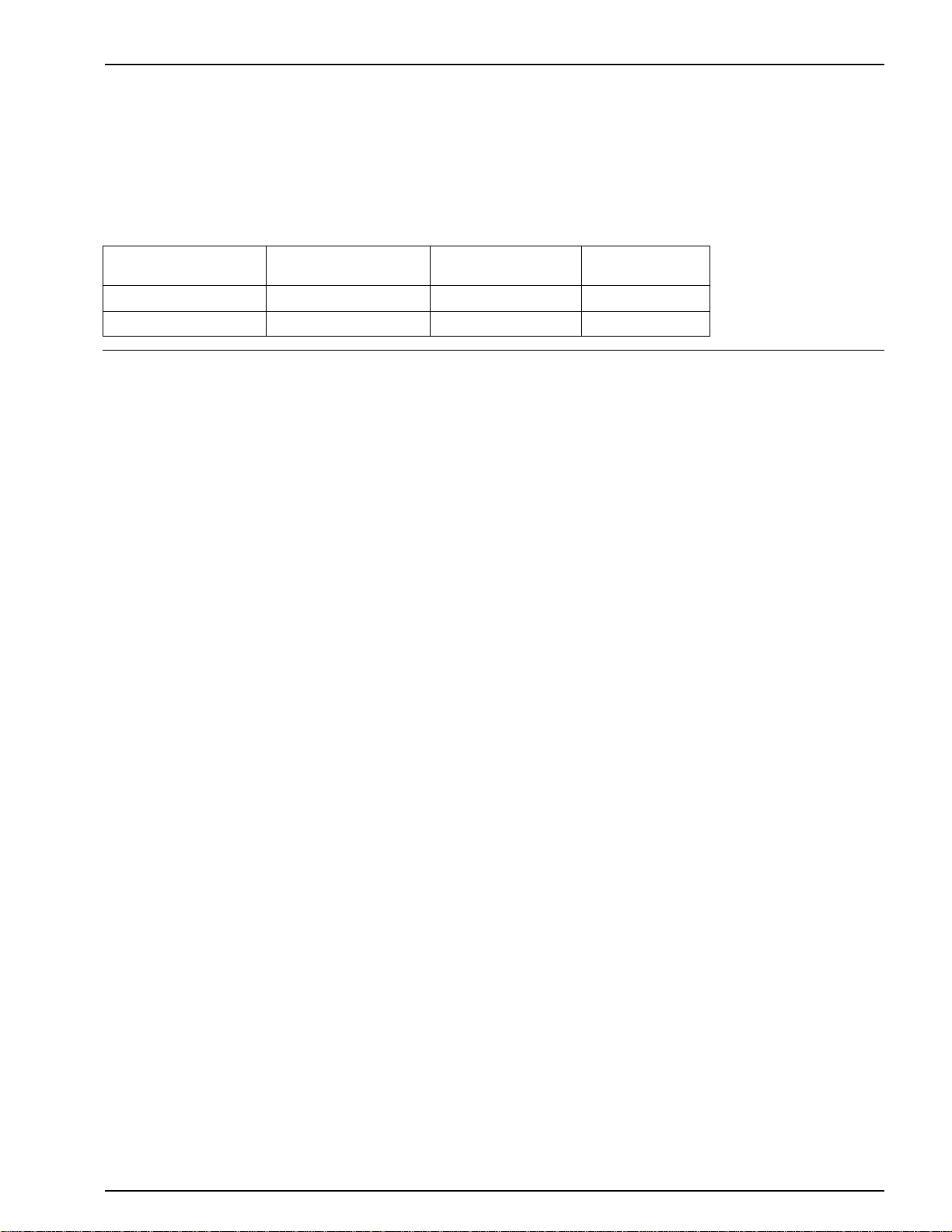

Condenser and Evaporator Fan Motors

Voltage Horsepower Power Rating in

Kilowatts rpm Full Load Current

12 Vdc 0.17 0.12 1850 to 2250 8.0 to 14.5 amps

24 Vdc 0.1 0.12 1850 to 2250 4.2 to 7.8 amps

Pilot Solenoid and Liquid Injection Solenoid Coils

Voltage Current Resistance

12 Vdc 0.6 to 0.8 amps 15 to 19 ohms

24 Vdc 0.3 to 0.4 amps 62 to 72 ohms

Electric Standby Compressor Motors

Voltage Phase Frequency Horsepower Power Rating

in Kilowatts Full Load

rpm Full Load

Current

230 Vac 1 60 Hz 3 2.2 1755 12.4 amps

220 Vac 1 50 Hz 2.5 1.9 1470 11.0 amps

230 Vac* 3 60 Hz 3 2.2 1750 9.8 amps

460 Vac* 3 60 Hz 3 2.2 1750 4.9 amps

380 Vac* 3 50 Hz 2.5 1.9 1420 5.0 amps

380 Vac 3 50 Hz 3 2.2 1420 5.2 amps

415 Vac 3 50 Hz 3 2.2 1420 4.7 amps

*Motor can be wired for all three voltages.

Specifications (Rev. 1/99)

3

Optional Electric Heaters

Voltage Power Rating

Watts Current Resistance

230 Vac 800 3.48 amps 66.1 ohms

380 Vac 800 2.1 amps 180.5 ohms

BELT TENSION (Using Tool P/N 204-427)

Field Reset

Engine/Compressor 35

Electric Motor/Compressor 58

4

5

Maintenance Inspection Schedule

First Week Inspection and Maintenance

After First Week of operation:

•Check the belt tension

•Tighten the unit mounting bolts

•Check the refrigerant level

•Check the compressor oil level

Weekly Monthly Bi-

monthly Annually Inspect/Service These Items

ELECTRICAL

••

Check defrost initiation and termination.

••

Check thermostat cycle sequence.

••

Check operation of protection shutdown circuits.

••

Check thermostat and thermometer calibration in 32 F (0 C)

ice-water bath

••

Inspect wire harness for damaged wires or connections.

•Inspect/replace dc fan motor brushes yearly.

REFRIGERATION

••• •

Check refrigerant level.

•• •

Check compressor oil level.

•Replace dehydrator.

STRUCTURAL

••• •

Visually inspect unit and refrigerant hoses for fluid leaks.

••• •

Visually inspect unit for damaged, loose or broken parts.

••• •

Clean defrost drains.

•• •

Inspect belts (CBci220) for condition and proper tension (belt

tension tool P/N 204-427).

•• •

Clean entire unit including evaporator coil and condenser coil.

••

Check all unit mounting bolts, brackets, lines, hoses, etc.

6

7

Unit Description

The Thermo King CBci truck refrigeration system is a

three-piece system consisting of a condenser, an evaporator,

and a compressor. The assemblies are separate, and the con-

denser section can be installed either in a nosemount or an

undermount position. The evaporator mounts on the inside

of the front wall of the truck body close to the ceiling. The

compressor is mounted on and driven by the truck engine.

Refrigeration hoses or lines are used to connect the con-

denser, the evaporator and the compressor. Model 20 units

have another compressor and an electric motor mounted in

the condenser section for electric standby operation.

The units are designed for low and medium temperature

applications on medium-sized trucks. There are two basic

models:

•Model 10: Cool and defrost on engine-driven compres-

sor operation.

•Model 20: Cool and defrost on both truck engine-

driven and electric standby compressor operation.

The control circuits operate on 12 or 24 Vdc supplied by the

truck batteries for over-the-road operation. On standby

operation, the power is rectified from an AC transformer.

The refrigeration system is protected by a high pressure cut-

out switch and a low pressure cutout switch.

The remote control box is normally mounted on the truck

body. It contains the On-Off switch, manual defrost switch,

thermometer, thermostat, and indicator lights. The remote

control box cover must be opened to access the thermostat.

An optional cab control box is available. It is mounted in the

truck cab and replaces the remote control box. The cab con-

trol box contains the On-Off switch, Manual Defrost switch,

thermometer, thermostat, and indicator lights. The Model 20

cab control box also has a warning light that illuminates if

the driver starts the truck engine while the electric standby

cord is still plugged into the power receptacle.

The electric standby compressor is connected in parallel

with the engine-driven compressor on the Model 20 units.

The engine compressor is driven by a belt from the engine.

The standby compressor is mounted in the condenser sec-

tion and is belt driven by an electric motor. Both compres-

sors use the same refrigeration system circuit. Check valves

isolate one compressor from the other during operation.

Compressor operation is controlled by the thermostat, start-

ing the motor on electric standby or energizing the clutch

during engine operation.

Selection of engine operation or standby operation is auto-

matic on Model 20 units. When the Model 20 unit is

plugged into standby power, engine operation is automati-

cally locked out. If the driver turns the truck on while the

power cord is still plugged into a power receptacle, the

power cord warning light (Model 20 only) comes on to

remind the driver to unplug the cord. The engine driven

compressor cannot be started until the power cord is

unplugged from the unit.

A three-way valve refrigeration system provides defrost in

the unit. An electronic defrost timer can initiate defrost

automatically. Defrost is normally terminated by the defrost

termination switch mounted on the evaporator coil, but the

defrost timer can also terminate defrost.

Liquid Injection System

If the discharge gas leaving the engine driven compressor

reaches a temperature of 230 ± 5 F (110 ± 3 C), the high

temperature switch closes, providing voltage to the liquid

injection solenoid. The solenoid opens a valve, allowing liq-

uid refrigerant to flow from the liquid line near the receiver

outlet valve to the metering orifice attached to the suction

fitting at the compressor. As the refrigerant passes through

the metering orifice it expands and evaporates, cooling the

suction gas entering the compressor. This cooling effect is

transferred to the discharge gas leaving the compressor from

Unit Description (Rev. 1/99)

8

the adjacent cavity in the compressor head. When the dis-

charge gas is cooled to 200 ± 5 F (93 ± 3 C), the high tem-

perature switch opens, the liquid injection solenoid valve

closes and refrigerant no longer flows through the liquid

injection system.

Oil Separator

An oil separator is a standard feature. It separates compres-

sor oil from refrigerant vapor and returns the oil to the com-

pressor through the oil fill hole by using a special adapter.

The oil separator helps provide positive oil return at high

compressor speeds and low operating temperatures. This

feature enhances compressor lubrication and extends com-

pressor life.

CBci MAX Features

The CBci MAX is functionally the same as CBci units, but

it uses R-404A refrigerant. This unit has a redesigned evap-

orator in order to operate more efficiently with R-404A

refrigerant. All other operating features are the same as

CBci units.

UNIT OPERATION

These units shift between cool, null, and heat (optional) to

maintain the box temperature at the thermostat setpoint. The

operating modes are: cool, null, heat (optional), and defrost.

The thermostat controls the operation of the unit by energiz-

ing and de-energizing the cool relay and the heat relay.

When the cool relay is energized, it closes contacts that

energize the fan relay and the compressor clutch (or the

compressor motor contactor on Model 20 units during elec-

tric standby operation).

When the heat relay is energized, it closes contacts that

energize the fan relay.

When the fan relay is energized, it closes contacts that ener-

gize the condenser and evaporator fans. The condenser fan

is also controlled by the condenser fan pressure switch. This

normally open switch monitors the compressor discharge

pressure. When the discharge pressure rises to 180 ± 10 psi

(1241 ± 69 kPa), the switch closes and energizes the con-

denser fan. When the discharge pressure drops to 130 ± 10

psi (896 ± 69 kPa), the switch opens and de-energizes the

condenser fan.

Cool

The thermostat energizes the cool relay at box temperatures

above setpoint when the temperature is dropping. The ther-

mostat energizes the cool relay at box temperatures more

than 2 ± 1 F (1 ± 0.5 C) above setpoint when the tempera-

ture is rising. The cool relay energizes the fan relay and the

compressor clutch (or motor contactor). The fans and the

compressor run and the unit cools.

Null

The thermostat de-energizes the cool relay and the heat

relay at box temperatures between setpoint and 2 ± 1 F (1 ±

0.5 C) below setpoint when the temperature is dropping.

The thermostat de-energizes the cool relay and the heat

relay at box temperatures between setpoint and 2 ± 1 F (1 ±

0.5 C) above setpoint when the temperature is rising. When

the cool relay and the heat relay are both de-energized, the

unit does not operate unless it is in defrost.

Heat (Optional)

NOTE: Heat lockout occurs at setpoints of 15 F (-9.5 C)

and lower. Heat lockout disables Heat and replaces Heat

with Null.

The thermostat energizes the heat relay at box temperatures

more than 2 ± 1 F (1 ± 0.5 C) below setpoint when the tem-

perature is dropping. The thermostat energizes the heat

relay at box temperatures below setpoint when the tempera-

ture is rising. The heat relay energizes the fan relay, but the

compressor clutch (or motor contactor) is not energized.

Therefore, the evaporator fans run but the condenser fan

Unit Description (Rev. 1/99)

9

does not. The heat relay also energizes the optional water

pump and hot water valve, or the optional heater contactor.

Defrost

The defrost cycle can be initiated any time the evaporator

coil temperature is below 42 F (5.6 C). Defrost is initiated

automatically by the defrost timer, or manually by pressing

the Manual Defrost switch.

The defrost relay energizes the compressor clutch (or motor

contactor) and the 26 circuit to route hot refrigerant gas to

the evaporator. The defrost relay also interrupts power to the

fan relay to stop the evaporator and condenser fans during

defrost. The defrost cycle will continue until the evaporator

coil temperature rises to 52 F (11.1 C), causing the defrost

termination switch to open, which terminates the defrost

cycle. If the defrost termination switch does not open in less

than 45 minutes, the defrost timer will terminate the defrost

cycle 45 minutes after is was started.

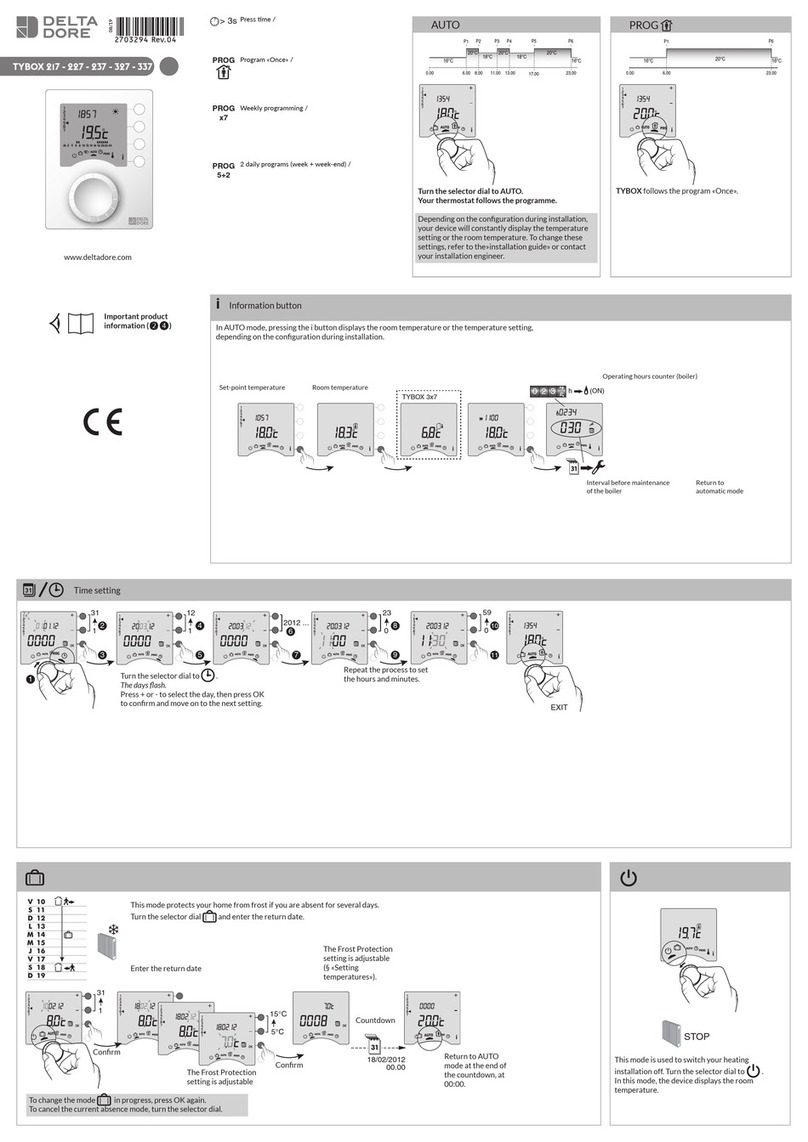

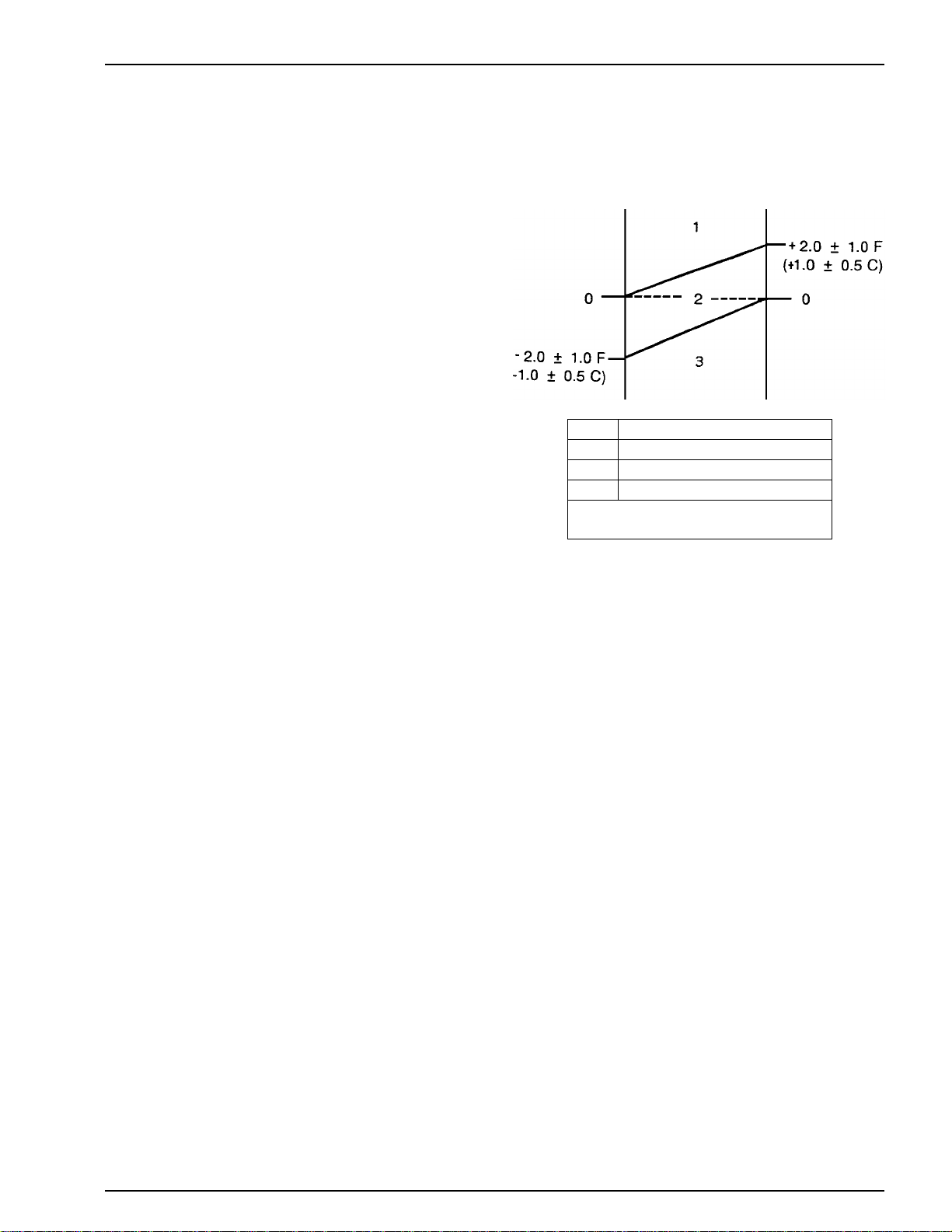

OPERATING MODES

•Cool—Above setpoint when the temperature is drop-

ping. More than 2 ± 1 F (1 ± 0.5 C) above setpoint

when the temperature is rising.

•Null—Between setpoint and 2 ± 1 F (1 ± 0.5 C) below

setpoint when the temperature is dropping. Between

setpoint and 2 ± 1 F (1 ± 0.5 C) above setpoint when

the temperature is rising.

•Heat—More than 2 ± 1 F (1 ± 0.5 C) below setpoint

when the temperature is dropping. Below setpoint when

the temperature is rising (optional).

•Defrost—Initiated manually or automatically at evapo-

rator temperatures below 42 F (5.6 C). Terminated

when the evaporator temperature rises to 52 F (11.1 C),

or 45 minutes after initiated.

0. Setpoint

1. Cool

2. Null

3. Heat* (Optional)

*Heat lockout occurs at setpoints of

15 F (-9.5 C) or lower.

Thermostat Algorithm

AGA301

Unit Description (Rev. 1/99)

10

UNIT FEATURES

•Digital Thermometer

•Electronic Thermostat

•Defrost Timer

•Hot Gas Defrost

•Defrost Termination Switch

•Liquid Injection System

•Manual Defrost Switch

•Receiver Tank with Outlet Service Valve

•Suction Pressure Regulator

•Oil Separator

•Compressor Powered by Truck Engine

•Three-way Valve Refrigeration System

•Accumulator Tank

•Standby Compressor (Model 20 only)

•Refrigerant Flow Controlled by Discharge Check Valve

(Model 20 only)

PROTECTION FEATURES

•Control Circuit Breaker(s):

40 amp auto reset in 12 Vdc system

•Refrigerant High Pressure Cutout

•Refrigerant Low Pressure Cutout

•Refrigerant High Pressure Relief Valve

•Power Cord Warning Light (in Optional Cab Control

Box for Model 20 only)

•Overload Relay Protection for Electric Standby Motor

(Model 20 only)

•Transformer Fuses (Model 20 only)

OPTIONAL FEATURES

•Cab Control Box

•Refrigerant R-134a

•Electric Motors (Model 20 only)

230 Volt/1 Phase/60 Hz

220 Volt/1 Phase/50 Hz

230 Volt/3 Phase/60 Hz

460 Volt/3 Phase/60 Hz

380 Volt/3 Phase/50Hz

415 Volt/3 Phase/50 Hz

•Heat, Truck Engine (Model 10)

•Heat, Truck Engine and Electric Standby Heater Strips

(Model 20)

•Paint, Special Color

SERIAL NUMBER LOCATIONS

Condenser: Roadside, top corner.

Evaporator: Roadside panel.

Compressor: Nameplate on compressor body.

Standby Motor: Nameplate on motor.

This manual suits for next models

14

Table of contents

Other Thermo King Thermostat manuals

Popular Thermostat manuals by other brands

Daikin

Daikin One+ Homeowner's guide

elsner elektronik

elsner elektronik KNX Touch One Style Technical specifications and installation instructions

DELTA DORE

DELTA DORE TYBOX user guide

LK Systems

LK Systems S2 Assembly instructions

Vimar

Vimar 2950 instruction manual

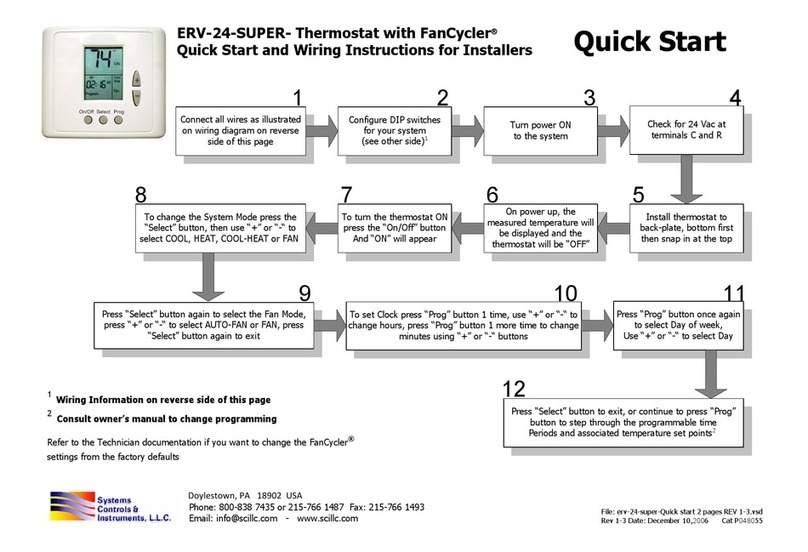

Systems Controls & Instruments

Systems Controls & Instruments ERV-24-Super Quick start and wiring instruction for installers