Thermo Neslab CryoCool Series Manual

-~

ARTISAN

®

~I

TECHNOLOGY

GROUP

Your definitive source

for

quality

pre-owned

equipment.

Artisan Technology

Group

Full-service,

independent

repair

center

with

experienced

engineers

and

technicians

on staff.

We

buy

your

excess,

underutilized,

and

idle

equipment

along

with

credit

for

buybacks

and

trade-ins

.

Custom

engineering

so

your

equipment

works

exactly as

you

specify.

•

Critical

and

expedited

services

•

Leasing

/

Rentals/

Demos

• In

stock/

Ready-to-ship

•

!TAR-certified

secure

asset

solutions

Expert

team

ITrust

guarantee

I

100%

satisfaction

All

tr

ademarks,

br

a

nd

names, a

nd

br

a

nd

s a

pp

earing here

in

are

th

e property of

th

e

ir

r

es

pecti

ve

ow

ner

s.

Find the Thermo / Neslab Cryocool CC-65 at our website: Click HERE

CC-65/CC-100

CFC-Free

Immersion Coolers

Instruction and Operation Manual

ThermoNESLABManualP/N002782

Rev.04/05/99

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

- 1 -

CrCr

CrCr

Cryy

yy

yoCool Series ImmeroCool Series Immer

oCool Series ImmeroCool Series Immer

oCool Series Immersion Coolersion Cooler

sion Coolersion Cooler

sion Coolerss

ss

s

Instruction and Operation ManInstruction and Operation Man

Instruction and Operation ManInstruction and Operation Man

Instruction and Operation Manualual

ualual

ual

TT

TT

Tabab

abab

able of Contentsle of Contents

le of Contentsle of Contents

le of Contents

PREFACEPREFACE

PREFACEPREFACE

PREFACE Compliance ............................................................................................ 2

Unpacking .............................................................................................. 2

Warranty ................................................................................................ 2

NES-care ............................................................................................... 2

After-sale Support .................................................................................. 2

SECTION ISECTION I

SECTION ISECTION I

SECTION I

SafetySafety

SafetySafety

Safety Warnings................................................................................................ 3

SECTION IISECTION II

SECTION IISECTION II

SECTION II

General InformationGeneral Information

General InformationGeneral Information

General Information Description............................................................................................. 4

Specifications......................................................................................... 4

SECTION IIISECTION III

SECTION IIISECTION III

SECTION III

InstallationInstallation

InstallationInstallation

Installation Site......................................................................................................... 6

Electrical Requirements ......................................................................... 6

Fluids ..................................................................................................... 7

Cooling Probes ...................................................................................... 7

SECTION IVSECTION IV

SECTION IVSECTION IV

SECTION IV

OperationOperation

OperationOperation

Operation Operation ............................................................................................... 8

Temperature Adjustment ....................................................................... 8

SECTION VSECTION V

SECTION VSECTION V

SECTION V

MaintenanceMaintenance

MaintenanceMaintenance

Maintenance Service Contracts .................................................................................. 9

Cleaning................................................................................................. 9

Cooling Fluid .......................................................................................... 9

SECTION VISECTION VI

SECTION VISECTION VI

SECTION VI

TroubleshootingTroubleshooting

TroubleshootingTroubleshooting

Troubleshooting Checklist ................................................................................................ 10

Service Assistance ................................................................................ 10

Technical Support .................................................................................. 10

SECTION VIISECTION VII

SECTION VIISECTION VII

SECTION VII

WarrantyWarranty

WarrantyWarranty

Warranty ............................................................................................................... 11

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

- 2 -

PrefacePreface

PrefacePreface

Preface

Products tested and found to be in compliance with the requirements defined in the

EMC standards defined by 89/336/EEC as well as Low Voltage Directive (LVD)

73/23/EEC can be identified by the CE label on the rear of the unit. The testing has

demonstrated compliance with the following directives:

LVD, 73/23/EEC Complies with UL 3101-1:93

EMC, 89/336/EEC EN 55011, Class A Verification

EN 50082-1:1992

IEC 1000-4-2:1995

IEC 1000-4-3:1994

IEC 1000-4-4:1995

For any additional information refer to the Letter of Compliance that shipped with the

unit (Declaration of Conformity).

Retain all cartons and packing material until the unit is operated and found to be in

good condition. If the unit shows external or internal damage, or does not operate

properly, contact the transportation company and file a damage claim. Under ICC

regulations, this is your responsibility.

Units have a warranty against defective parts and workmanship for one full year from

date of shipment. See back page for more details.

• Extend parts and labor coverage for an additional year.

• Worry-free operation.

• Control service costs.

• Eliminate the need to generate repair orders.

• No unexpected repair costs.

Other contract options are available. Please contact Thermo

NESLAB for more information.

Thermo NESLAB is committed to customer service both during and after the sale. If

you have questions concerning the operation of your unit or the information in this

manual, contact our Sales Department. If your unit fails to operate properly or if you

have questions concerning spare parts or Service Contracts, contact our Service

Department.

Before calling,

please

refer to the serial number label on the rear of the case top to

obtain the following information:

- BOM number _________________________

- Serial number _________________________

ComplianceCompliance

ComplianceCompliance

Compliance

UnpackingUnpacking

UnpackingUnpacking

Unpacking

WarrantyWarranty

WarrantyWarranty

Warranty

NES-careNES-care

NES-careNES-care

NES-care

ExtendedExtended

ExtendedExtended

Extended

Warranty ContractWarranty Contract

Warranty ContractWarranty Contract

Warranty Contract

After-saleAfter-sale

After-saleAfter-sale

After-sale

SupportSupport

SupportSupport

Support

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

- 3 -

Section I SafSection I Saf

Section I SafSection I Saf

Section I Safetyety

etyety

ety

WarningsWarnings

WarningsWarnings

Warnings Make sure you read and understand all instructions and safety precautions

listed in this manual before installing or operating your unit. If you have any

questions concerning the operation of your unit or the information in this

manual, contact our Sales Department (see After-sale Support).

Performance of installation, operation, or maintenance proceduresPerformance of installation, operation, or maintenance procedures

Performance of installation, operation, or maintenance proceduresPerformance of installation, operation, or maintenance procedures

Performance of installation, operation, or maintenance procedures

other than those described in this manual may result in a hazardousother than those described in this manual may result in a hazardous

other than those described in this manual may result in a hazardousother than those described in this manual may result in a hazardous

other than those described in this manual may result in a hazardous

situation and may void the manufacturer's warranty.situation and may void the manufacturer's warranty.

situation and may void the manufacturer's warranty.situation and may void the manufacturer's warranty.

situation and may void the manufacturer's warranty.

Transport the unit with care. Sudden jolts or drops can damage theTransport the unit with care. Sudden jolts or drops can damage the

Transport the unit with care. Sudden jolts or drops can damage theTransport the unit with care. Sudden jolts or drops can damage the

Transport the unit with care. Sudden jolts or drops can damage the

refrigeration lines.refrigeration lines.

refrigeration lines.refrigeration lines.

refrigeration lines.

Observe all warning labels.Observe all warning labels.

Observe all warning labels.Observe all warning labels.

Observe all warning labels.

Never remove warning labels.Never remove warning labels.

Never remove warning labels.Never remove warning labels.

Never remove warning labels.

Never operate damaged equipment.Never operate damaged equipment.

Never operate damaged equipment.Never operate damaged equipment.

Never operate damaged equipment.

Always turn off the unit and disconnect the line cord from the powerAlways turn off the unit and disconnect the line cord from the power

Always turn off the unit and disconnect the line cord from the powerAlways turn off the unit and disconnect the line cord from the power

Always turn off the unit and disconnect the line cord from the power

source before performing any service or maintenance procedures, orsource before performing any service or maintenance procedures, or

source before performing any service or maintenance procedures, orsource before performing any service or maintenance procedures, or

source before performing any service or maintenance procedures, or

before moving the unit.before moving the unit.

before moving the unit.before moving the unit.

before moving the unit.

Never operate equipment with damaged line cords.Never operate equipment with damaged line cords.

Never operate equipment with damaged line cords.Never operate equipment with damaged line cords.

Never operate equipment with damaged line cords.

Refer service and repairs to a qualified technician.Refer service and repairs to a qualified technician.

Refer service and repairs to a qualified technician.Refer service and repairs to a qualified technician.

Refer service and repairs to a qualified technician.

In addition to the safety warnings listed above, warnings are posted

throughout the manual. These warnings are designated by an exclamation

mark inside an equilateral triangle with text highlighted in bold print. Read

and follow these important instructions. Failure to observe these instructions

can result in permanent damage to the unit, significant property damage, or

personal injury or death.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

- 4 -

Section II General InfSection II General Inf

Section II General InfSection II General Inf

Section II General Informationormation

ormationormation

ormation

DescriptionDescription

DescriptionDescription

Description The CryoCool Series of immersion coolers is designed as a refrigeration

source for sub-ambient work in liquid baths.

CryoCools employ mechanical refrigeration systems constructed with full-

hermetic refrigeration compressors. The CC-65 employs a single stage

refrigeration system with one compressor. The CC-100 has a dual stage

refrigeration system using two compressors in cascade configuration. An

insulated coaxial hose assembly carries refrigerant to the cooling probe.

SpecificationsSpecifications

SpecificationsSpecifications

Specifications

Temperature RangeTemperature Range

Temperature RangeTemperature Range

Temperature Range11

11

1

Temperature StabilityTemperature Stability

Temperature StabilityTemperature Stability

Temperature Stability

Evaporator HeadEvaporator Head

Evaporator HeadEvaporator Head

Evaporator Head

DimensionsDimensions

DimensionsDimensions

Dimensions22

22

2

(Length x Diameter)

F-head

Inches

Centimeters

FV-head

Inches

Centimeters

R-head

Inches

Centimeters

Minimum Bend RadiusMinimum Bend Radius

Minimum Bend RadiusMinimum Bend Radius

Minimum Bend Radius33

33

3

F-head

Inches

Centimeters

FV-head

Inches

Centimeters

R-head

Inches

Centimeters

N/A

N/A

1

2.5

N/A

N/A

1 1/2

3.8

1

2.5

N/A

N/A

CC-65CC-65

CC-65CC-65

CC-65 CC-100CC-100

CC-100CC-100

CC-100

-25°C to -90°C

±0.5°C

N/A

N/A

25 x 1/2

63.5 x 1.3

7 ¼x 1 1/4

18.4 x 3.2

18 x 5/8

45.7 x 1.6

25 x 1/2

63.5 x 1.3

7 ¼x 1 1/4

18.4 x 3.2

1. Low end specifications listed for "no load" conditions.

2. SeeSection III,CoolingProbes foradescription oftheevaporator heads.

3. Theminimum bend radiusis the smallestradiusthat the cooling probe canbe bent

withoutsuffering damage at roomtemperature.Never bend theprobewhen it is cold.

-20°C to -55°C

±0.5°C

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

- 5 -

Evaporator HoseEvaporator Hose

Evaporator HoseEvaporator Hose

Evaporator Hose

DimensionsDimensions

DimensionsDimensions

Dimensions

(Length x Diameter)

Inches

Centimeters

Unit DimensionsUnit Dimensions

Unit DimensionsUnit Dimensions

Unit Dimensions

(H x W x D)

Inches

Centimeters

WeightWeight

WeightWeight

Weight

Pounds

Kilograms

15 1/4x 7 1/2x 10 1/4

38.7 x 19.1 x 26.0 20 1/2x 14 1/2x 17 3/4

52.1 x 36.8 x 45.1

CC-65CC-65

CC-65CC-65

CC-65 CC-100CC-100

CC-100CC-100

CC-100

41.0

18.6 130.0

59.0

44 x 1 1/4

111.8 x 3.2 65 x 1 ½

165.1 x 3.8

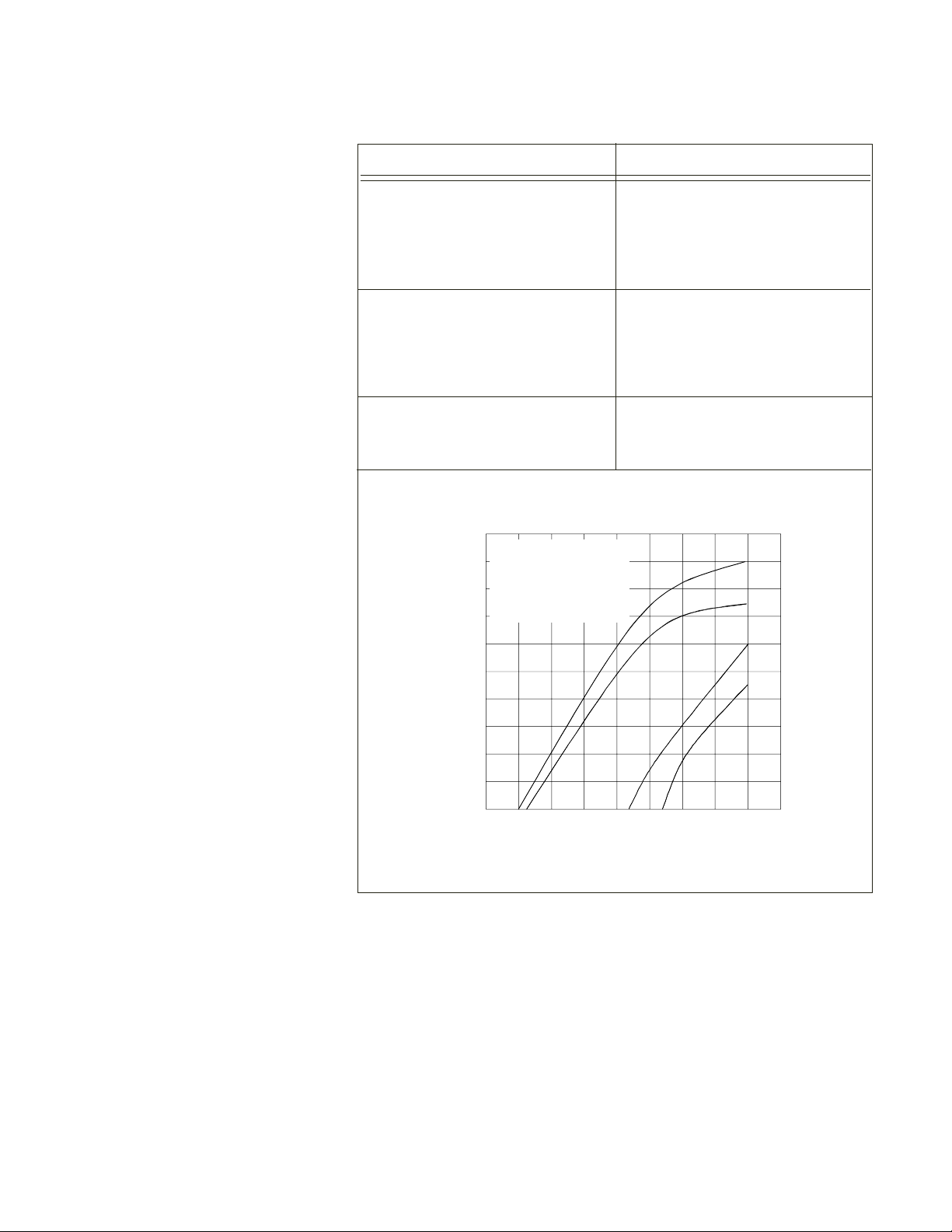

Cooling CapacityCooling Capacity

Cooling CapacityCooling Capacity

Cooling Capacity44

44

4

HeatRemoval (Watts)

4. Specificationsobtained in a2litercontainer at +20°C ambientwithcooling fluid specific

heatof0.5.

A=CC-100,60Hz

B=CC100,50Hz

C=CC65,60HzR-Probe

D=CC65,50HzR-Probe

200

180

160

140

120

100

80

60

40

20

A

-90 -80 -70 -60 -50 -40 -30 -20

Temperature(°C)

B

D

C

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

- 6 -

Section III InstallationSection III Installation

Section III InstallationSection III Installation

Section III Installation

SiteSite

SiteSite

Site The unit should be located in a laboratory or clean industrial environment

where ambient temperatures are inside the range of +55°F to +95°F (+13°C

to +35°C).

Never place the unit in a location where excessive heat, moisture, orNever place the unit in a location where excessive heat, moisture, or

Never place the unit in a location where excessive heat, moisture, orNever place the unit in a location where excessive heat, moisture, or

Never place the unit in a location where excessive heat, moisture, or

corrosive materials are present.corrosive materials are present.

corrosive materials are present.corrosive materials are present.

corrosive materials are present.

The unit has an air-cooled refrigeration system. On the CC-65 air is drawn

through the top of the unit and discharged through the sides and bottom of

the unit. On the CC-100 air is drawn through the front of the unit and dis-

charged through the rear. The unit must be positioned so the intake and

discharge are not impeded. A minimum clearance of 12 inches (30 centi-

meters) on all vented sides is necessary for adequate ventilation.

Inadequate ventilation will cause a reduction in cooling capacity and, in

extreme cases, compressor failure.

Excessively dusty areas should be avoided and a periodic cleaning schedule

should be instituted (see Section V, Cleaning).

The unit will retain its full rated capacity in ambient temperatures up to

approximately +75°F (+24°C). Above +75°F, reduce the cooling capacity 1%

for every 1°F above +75°F, up to a maximum ambient temperature of +95°F.

In terms of Celsius, reduce the cooling capacity 1% for every 0.5°C above

+24°C, up to a maximum ambient temperature of +35°C.

ElectricalElectrical

ElectricalElectrical

Electrical

RequirementsRequirements

RequirementsRequirements

Requirements Refer to the serial number label on the rear of the unit for the specific

electrical requirements of your unit.

Make sure the voltage of the power source meets the specified voltage, ±10%.

Make sure an adequate ground connection is provided.Make sure an adequate ground connection is provided.

Make sure an adequate ground connection is provided.Make sure an adequate ground connection is provided.

Make sure an adequate ground connection is provided.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

- 7 -

FluidsFluids

FluidsFluids

Fluids The selected fluid must have a viscosity of 50 centistokes or less at the

lowest operating temperature.

Never use flammable or corrosive fluids with this unit.Never use flammable or corrosive fluids with this unit.

Never use flammable or corrosive fluids with this unit.Never use flammable or corrosive fluids with this unit.

Never use flammable or corrosive fluids with this unit.

Cooling ProbesCooling Probes

Cooling ProbesCooling Probes

Cooling Probes Three cooling probes (or evaporator heads) are available with CryoCool

units: F (flexible), FV (flexible, very), and R (rigid). Refer to Section II,

Specifications to determine the specific cooling probe on your unit.

Place the cooling probe in the work area. For maximum cooling efficiency,

the probe should be fully immersed in the fluid and should be located as

close as possible to the agitator or stirrer motor (if so equipped).

Care should be taken not to stretch or bend the probe beyond it limitsCare should be taken not to stretch or bend the probe beyond it limits

Care should be taken not to stretch or bend the probe beyond it limitsCare should be taken not to stretch or bend the probe beyond it limits

Care should be taken not to stretch or bend the probe beyond it limits

or exceed its minimum bend radius. Bend the probe only at roomor exceed its minimum bend radius. Bend the probe only at room

or exceed its minimum bend radius. Bend the probe only at roomor exceed its minimum bend radius. Bend the probe only at room

or exceed its minimum bend radius. Bend the probe only at room

temperatures, never bend it when it is cold.temperatures, never bend it when it is cold.

temperatures, never bend it when it is cold.temperatures, never bend it when it is cold.

temperatures, never bend it when it is cold.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

- 8 -

Section IV OperationSection IV Operation

Section IV OperationSection IV Operation

Section IV Operation

OperationOperation

OperationOperation

Operation Before starting the unit, double check all electrical connections and make

sure the cooling probe is properly immersed in the work area.

All CryoCools are operated by a single power switch.

The CC-100 has three lights: one indicates the unit is operating, a second

indicates the high stage compressor is operating, and a third indicates the

low stage compressor is operating.

Once the unit is turned on, the refrigeration system will reduce the tempera-

ture of the cooling fluid in the work area to the lowest achievable temperature

under the existing heat load conditions.

For best results, stirring or agitation in the work area is recommended.

When not stirred, cooling capacities will be reduced and the work area will

show temperature layering, with the coldest, most dense zone at the bottom.

When the unit is shut off, wait approximately five minutes before restarting.

This allows time for the refrigeration pressures to equalize. If the pressures

are not allowed to equalize, the compressor will short-cycle (clicking sound)

and no cooling will occur.

TemperatureTemperature

TemperatureTemperature

Temperature

AdjustmentAdjustment

AdjustmentAdjustment

Adjustment If temperature control is desired, a Thermo NESLAB Cryotrol Temperature

Controller is required. Refer to the Cryotrol Temperature Controller Instruc-

tion and Operation Manual for installation and operation instructions.

Never operate any CryoCool unit above -25°C.Never operate any CryoCool unit above -25°C.

Never operate any CryoCool unit above -25°C.Never operate any CryoCool unit above -25°C.

Never operate any CryoCool unit above -25°C.

Older Cryotrols are equipped with a round 8 pin connector. If you wish to

connect your older Cryotrol unit to the CryoCool, an adapter cable is avail-

able from Thermo NESLAB. Contact our Service Department for more

information (see Preface, After-Sale Support).

A Thermo NESLAB Exatrol Digital Temperature controller may also be used

to control temperature. The Exatrol is designed for more precise temperature

control and offers tighter temperature stability than the Cryotrol.

Refer to the Exatrol manual for additional information.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

- 9 -

SectionSection

SectionSection

SectionV MaintenanceV Maintenance

V MaintenanceV Maintenance

V Maintenance

Service ContractsService Contracts

Service ContractsService Contracts

Service Contracts Thermo NESLAB offers on-site Service Contracts that are designed to

provide extended life and minimal down-time for your unit. For more informa-

tion, contact our Service Department (see Preface, After-sale Support).

CleaningCleaning

CleaningCleaning

Cleaning For proper operation, the unit needs to pull substantial amounts of air

through the condenser. A build up of dust or debris on the fins of the

condenser will lead to a loss of cooling capacity.

Periodic vacuuming of the condenser fins is necessary. The frequency of

cleaning depends on the operating environment. We recommend making a

monthly visual inspection of the condenser after initial installation. After

several months, the cleaning frequency will be established.

Cooling FluidCooling Fluid

Cooling FluidCooling Fluid

Cooling Fluid The cooling fluid in the work area should be periodically replaced when

operating at low temperatures. At low temperatures, the cooling fluid may

collect water vapor from the air. As the concentration of water in the cooling

fluid increases, performance is adversely affected.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

- 10 -

SectionSection

SectionSection

SectionVIVI

VIVI

VITT

TT

Trr

rr

rouboub

ouboub

oubleshootingleshooting

leshootingleshooting

leshooting

ChecklistChecklist

ChecklistChecklist

Checklist Unit will not start.Unit will not start.

Unit will not start.Unit will not start.

Unit will not start.

Make sure the voltage of the power source meets the specified voltage,

±10%. Refer to the serial number label on the rear of the unit for the specific

electrical requirements of your unit.

Loss of cooling capacity.Loss of cooling capacity.

Loss of cooling capacity.Loss of cooling capacity.

Loss of cooling capacity.

Make sure the heat load in the work area is not greater than the cooling

capacity of the unit. Refer to Section II, Specifications to review the cooling

capacity specifications.

Check for ice build up on the cooling probe. A layer of ice will act as

insulation and reduce the cooling capacity. Ice build up is often an indication

that the cooling fluid needs replacing. Defrost the cooling probe and change

the cooling fluid.

When the unit is shut off, wait approximately five minutes before restarting.

This allows time for the refrigeration pressures to equalize. If the pressures

are not allowed to equalize, the compressor will short-cycle.

Service AssistanceService Assistance

Service AssistanceService Assistance

Service Assistance If, after following these troubleshooting steps, your unit fails to operate

properly, contact our Service Department for assistance (see Preface,

After-sale Support). Before calling,

please

obtain the following information:

Part number

Serial number

Voltage of unit

Voltage of power source

Technical SupportTechnical Support

Technical SupportTechnical Support

Technical Support Our Service Department can provide you with a complete list of spare parts

for your unit (see Preface, After-sale Support). Before calling,

please

obtain

the following information:

Part number

Serial number

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

- 11 -

WARRANTY

Thermo NESLAB Instruments, Inc. warrants for 12 months from date of shipment any Thermo NESLAB unit

according to the following terms.

Any part of the unit manufactured or supplied by Thermo NESLAB and found in the reasonable judgment of

Thermo NESLAB to be defective in material or workmanship will be repaired at an authorized Thermo NESLAB

Repair Depot without charge for parts or labor. The unit, including any defective part must be returned to an

authorized Thermo NESLAB Repair Depot within the warranty period. The expense of returning the unit to the

authorized Thermo NESLAB Repair Depot for warranty service will be paid for by the buyer. Thermo NESLAB’s

responsibility in respect to warranty claims is limited to performing the required repairs or replacements, and no

claim of breach of warranty shall be cause for cancellation or recision of the contract of sales of any unit.With

respect to units that qualify for field service repairs, Thermo NESLAB’s responsibility is limited to the component

parts necessary for the repair and the labor that is required on site to perform the repair. Any travel labor or

mileage charges are the financial responsibility of the buyer.

The buyer shall be responsible for any evaluation or warranty service call (including labor charges) if no defects

are found with the Thermo NESLAB product.

This warranty does not cover any unit that has been subject to misuse, neglect, or accident. This warranty does

not apply to any damage to the unit that is the result of improper installation or maintenance, or to any unit that

has been operated or maintained in any way contrary to the operating or maintenance instructions specified in

Thermo NESLAB’s Instruction and Operation Manual. This warranty does not cover any unit that has been altered

or modified so as to change its intended use.

In addition, this warranty does not extend to repairs made by the use of parts, accessories, or fluids which are

either incompatible with the unit or adversely affect its operation, performance, or durability.

Thermo NESLAB reserves the right to change or improve the design of any unit without assuming any obligation

to modify any unit previously manufactured.

THE FOREGOING EXPRESS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR

IMPLIED, INCLUDING BUT NOT LIMITED TO WARRANTIES OR MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE.

Thermo NESLAB’S OBLIGATION UNDER THIS WARRANTY IS STRICTLY AND EXCLUSIVELY LIMITED TO

THE REPAIR OR REPLACEMENT OF DEFECTIVE COMPONENT PARTS AND Thermo NESLAB DOES NOT

ASSUME OR AUTHORIZE ANYONE TO ASSUME FOR IT ANY OTHER OBLIGATION.

Thermo NESLAB ASSUMES NO RESPONSIBILITY FOR INCIDENTAL, CONSEQUENTIAL, OR OTHER

DAMAGES INCLUDING, BUT NOT LIMITED TO LOSS OR DAMAGE TO PROPERTY, LOSS OF PROFITS OR

REVENUE, LOSS OF THE UNIT, LOSS OF TIME, OR INCONVENIENCE.

This warranty applies to units sold in the United States. Any units sold elsewhere are warranted by the affiliated

marketing company of Thermo NESLAB Instruments, Inc. This warranty and all matters arising pursuant to it shall

be governed by the law of the State of New Hampshire, United States. All legal actions brought in relation hereto

shall be filed in the appropriate state or federal courts in New Hampshire, unless waived by Thermo NESLAB.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Artisan

Technology

Group

is

an independent supplier

of

quality pre-owned equipment

Gold-standard

solutions

Extend the life

of

your

critical industrial,

commercial, and military systems

with

our

superior service and support.

We

buy

equipment

Planning to

upgrade

your current

equipment? Have surplus equipment taking

up shelf space? We'll give it a

new

home.

Learn

more!

Visit us at artisantg.com for more info

on price quotes, drivers, technical

specifications, manuals, and documentation.

Artisan Scientific

Corporation

dba

Artisan

Technology

Group

is

not

an affiliate,

representative,

or

authorized

distributor

for

any

manufacturer

listed herein.

We're here to make your life easier.

How

can

we

help you today?

(217)

352-9330

Isales@artisantg.com Iartisantg.com

This manual suits for next models

2

Table of contents