MAX/Wall®Technical Wall System

4

Section 1 – Introduction

Tools Required:

3/8" Drive socket set, including the following:

Extension (2" or 3")

Universal joint

Hex bits (4" long min.) - 3/16", 5/16".

Combination wrenches - 3/8", 3/16", 1/2", 9/16".

Phillips screwdrivers - (#2 and #3 tips)

1/2" drill motor (Hammer drill preferable)

1/2" masonry drill bit

Torque wrench

Rubber mallet

Jigsaw with metal cutting blade

Chalk line

Carpenter’s level (4' min.)

Facing insert removal tool

Flat blade screwdriver

Hammer

Knife

Measuring tape

Optional Tools to speed installation:

Drill motor or cordless drill including: set of drill bits

(specifically #12 or 3/16")

1/2" hex shank (2-1/2" long)

2 C-clamps (4" min. throat depth)

Masking tape

This manual is intended as a procedural tool for the

installation and assembly of Fisher Hamilton furni-

ture. It also serves as an aid to designers and plan-

ners during layout and cost analysis, and to facility

managers to carry out periodic modifications.

Disclaimer and Warning:

Fisher Hamilton disclaims liability for installations

(including re-arrangements and additions) not in

strict conformity with the instructions contained here-

in or with other written instruction of Fisher Hamilton.

Fisher Hamilton further disclaims liability if its

products are modified, altered, abused or misused.

1.1 Preparation for Installation

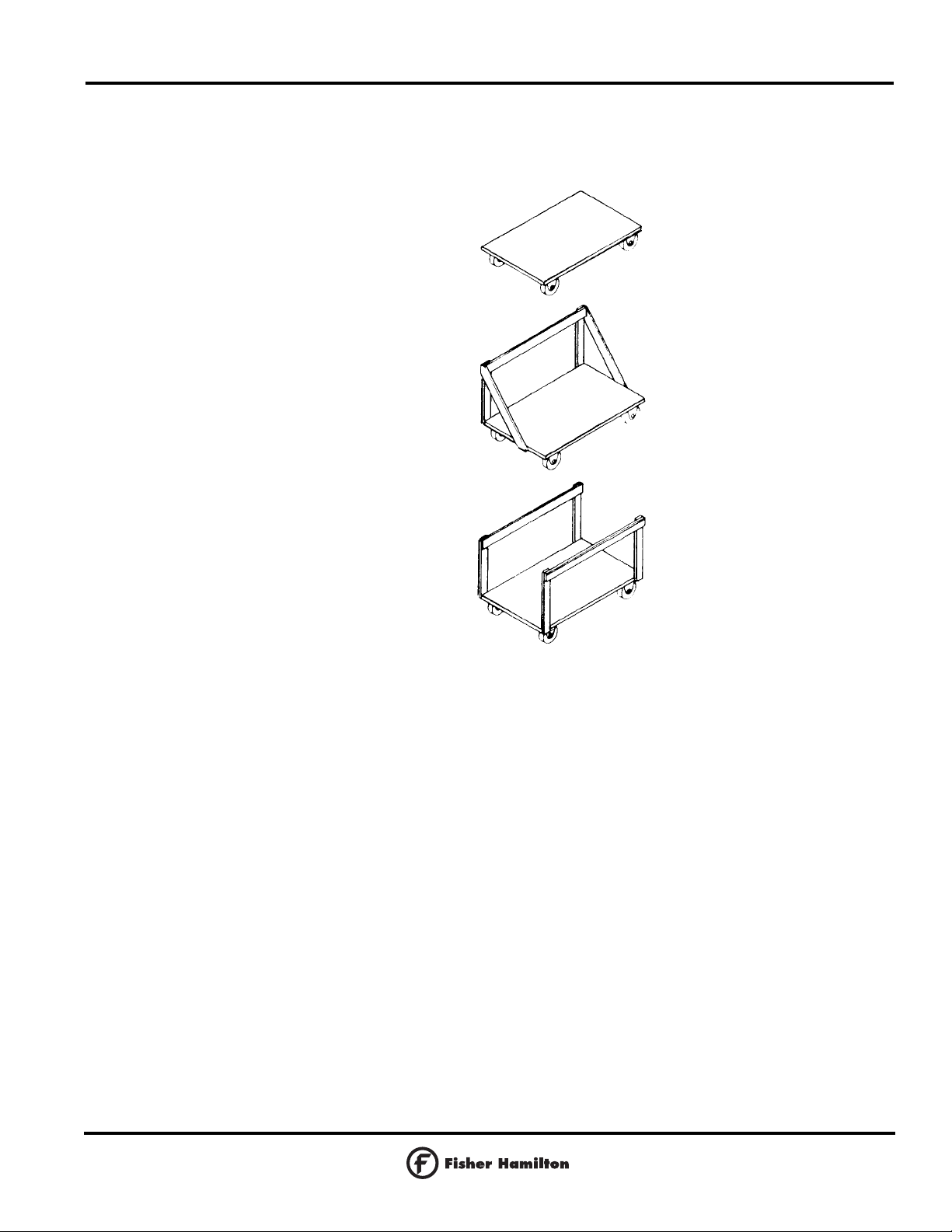

1. Select a staging area as close to the installation

as possible. If more than one floor is involved,

provide a staging area for each floor.

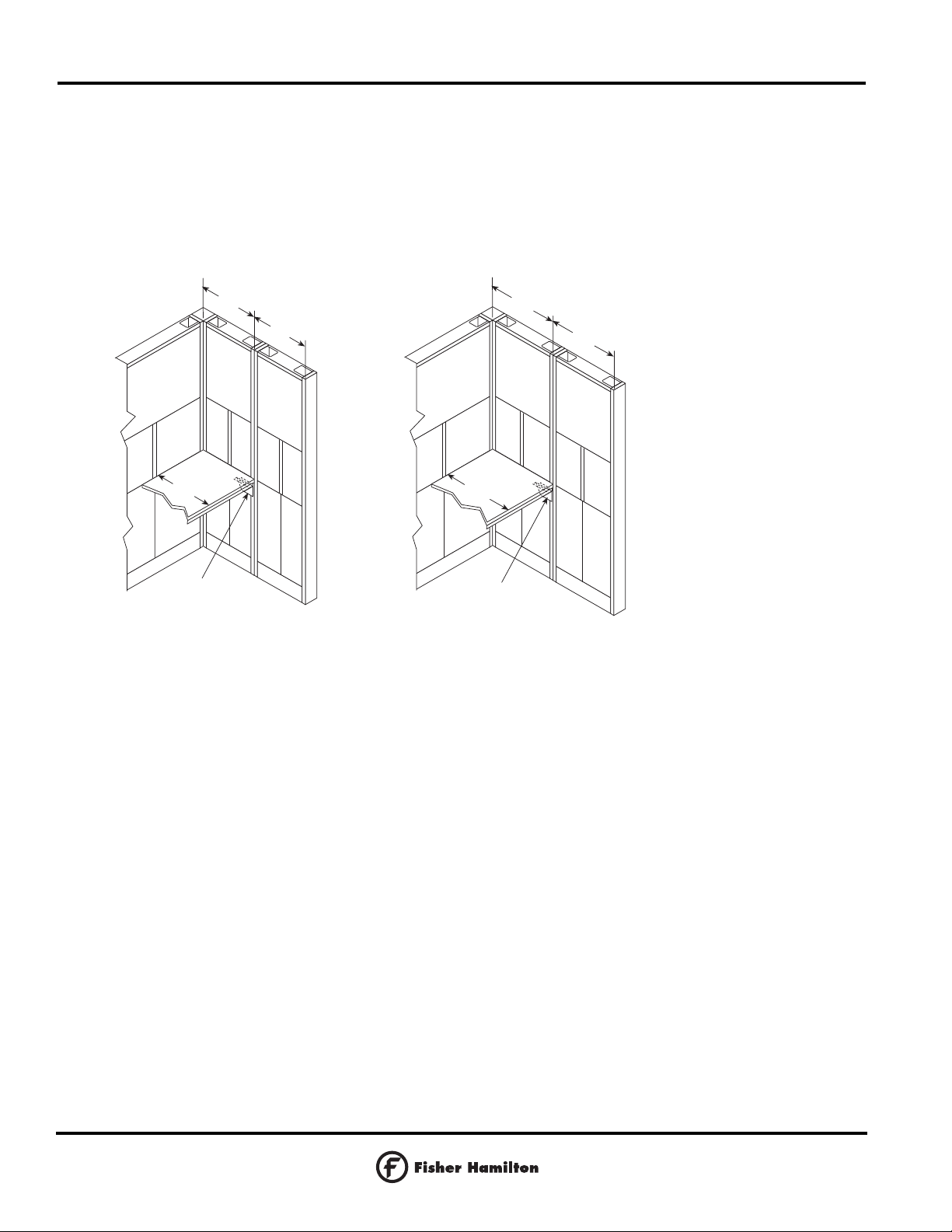

2. Check actual floor dimensions against the layout

print for possible un-planned obstructions. These

could include walls, columns, service entrances,

or changes in floor elevation such as slopes or

steps.

3. Mark the proposed layout on the floor with mask-

ing or a chalk line. Find and mark the high spot on

the floor by sliding a four foot carpenter’s level

across the floor.

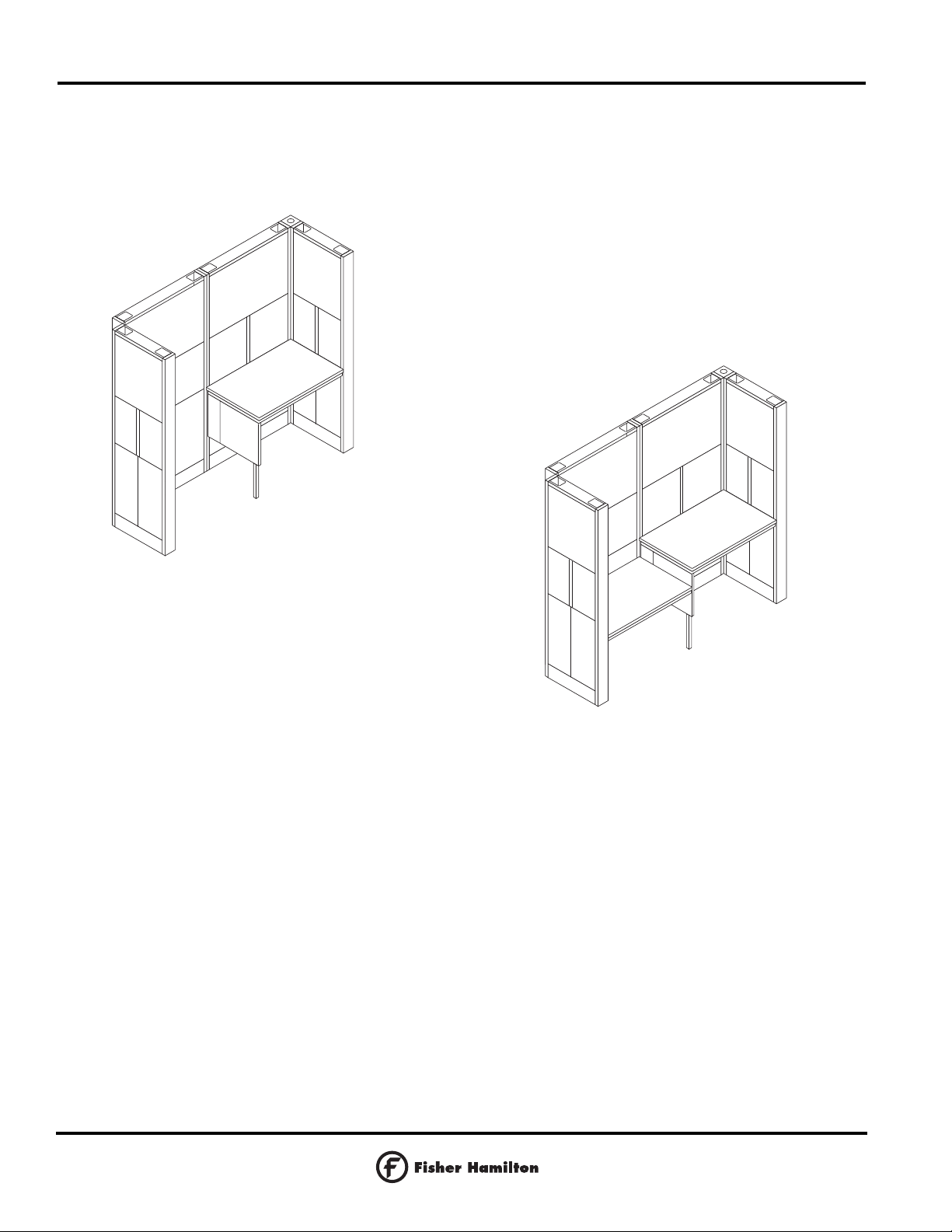

4. Start the installation of each run at a corner near-

est the high point and adjust the leveler out 1-1/4"

at that point. Caution: Support structures must be

1-1/4" minimum off the floor to provide adequate

clearance for power cables and installation of

supported structural table.

Caution: Support structures must be 1-1/4" mini-

mum off the floor to provide adequate clearance

for power cables and installation of supported

structural table.

5. If possible, start the installation at the farthest

point from the staging area to avoid hauling prod-

ucts through areas already installed.

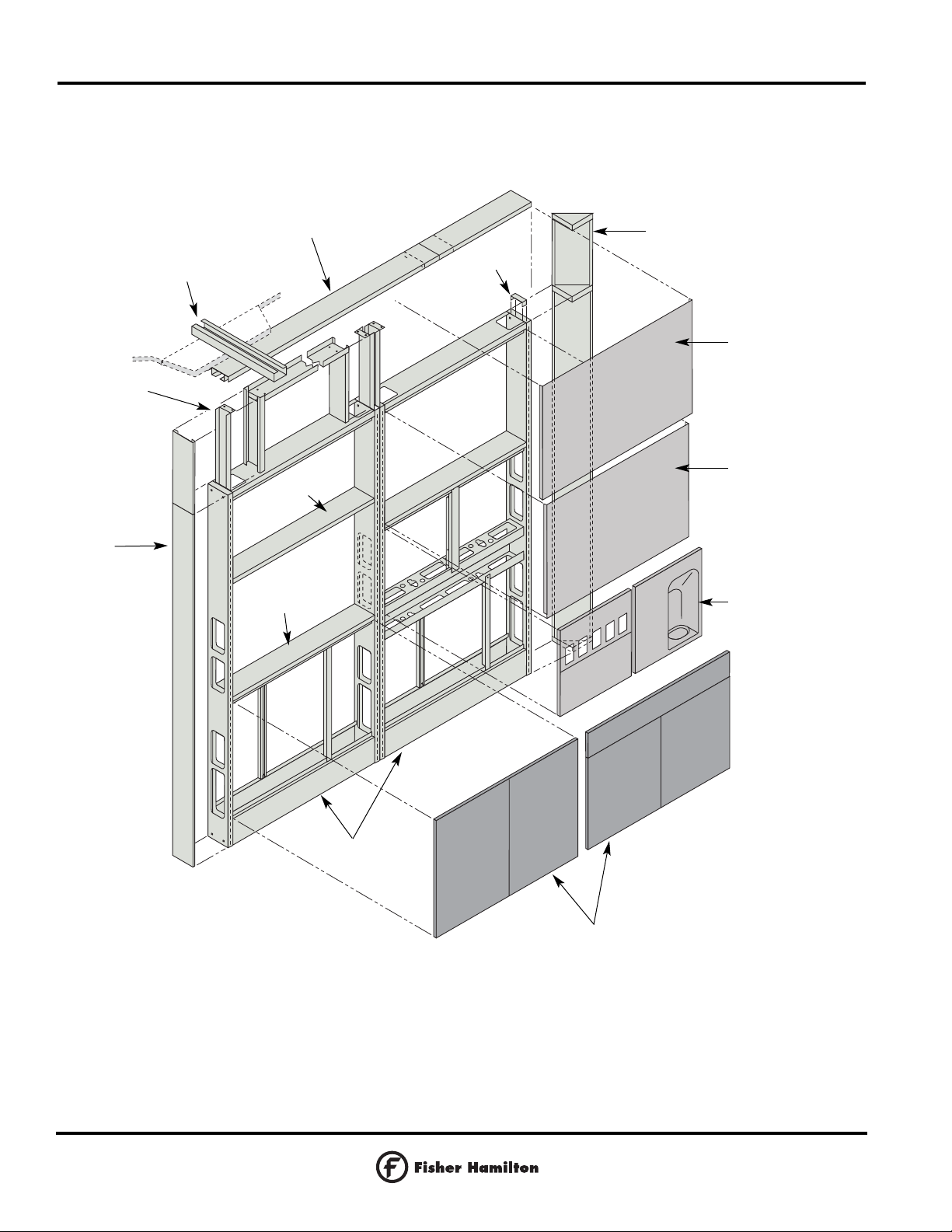

6. Installation sequence:

a. Assemble the panels and cores per to floor

plan,

making sure adequate support is provided to

stabilize the configuration.

If structural tables are to be installed, they

should, whenever possible, be attached to

individual panels before assembling panels into

runs.

b. Install the appropriate wiring, and plumbing.

c. Attach the base covers and facing inserts.

d. Install cantilevered work surfaces, upper and

lower storage, and other accessories.

e. Move primary tables and any other free-

standing furniture into place.

7. To avoid soiling the fabric on fabric covered

facing inserts, handling them with white cotton

gloves is recommended.

8. When installation of the Max Furniture System is

complete, extra hardware and components may

have accumulated. It is recommended that all

”extra parts” be saved for future additions or re-

arrangements to the system.