Thermo Sphere 12V SE User manual

INSTRUCTION GUIDE

HEATING | WALL

TOWEL BARS

Live well....

ThermoSphere 12V SE Towel

Bar Installation Guide

2+44 (0) 800 019 5899

Warranty terms &

conditions

ThermoSphere covers all its products

with a satisfaction guarantee. In

addition, ThermoSphere will supply a

replacement product where a fault is

shown to be caused by manufacture,

materials or workmanship providing the

goods have been installed correctly and

according to installation instructions.

This guarantee does not include removal,

freight or installation costs.

To use the warranty, repair or service

the customer must provide purchase

invoice/receipt, and completed warranty

registration form.

If the product develops a fault within

the warranty period due to normal wear

and tear, ThermoSphere at its discretion

will recognise whether it‘s a faulty

product or not. If it is impossible or not

economical for the manufacturer to

repair the product, the manufacturer will

replace the faulty product with a new

unit of the same model or if there is no

stock available of the same model as the

product, the manufacturer will replace

the product with a new unit of a similar

size. No responsibility can be taken for

altered dimensions and lining up of

existing holes.

The repair service offered within the

warranty period only covers the faults

and problems as developed from the

manufacturer‘s errors. Any damage

caused by improper use or carelessness

or incorrect wiring is not covered.

ThermoSphere is not responsible for

any monetary loss or injuries caused

by improper use or installation of this

product.

Please Note: Full Terms and Conditions

are available on request.

request your copy or give us a call.

Safety and care

information

ThermoSphere Towel Bars should be

connected to the electrical supply by a

qualied electrician and in accordance

with current local regulations.

We recommend that the towel bar is

installed with the bottom bar at least

600mm from the oor and with a

300mm clearance from permanent

xtures.

Recommended spacing between bars

is 150mm

ThermoSphere Heated Towel Bars can

be xed onto timber stud, steel stud or

masonry (solid or cavity) walls.

Stud walls require noggins at the correct

position for all xings and if the exact

position cannot be determined early in

the job, we recommend using noggins

covered with 18mm construction ply or

OSB covering a larger area.

Fixing to plasterboard or cement

sheeting alone is not recommended and

will not hold long term.

ThermoSphere SE Towel Bars are

designed to be installed BEFORE TILING

and as such it is imperative that the

xing spigot and/or mounting system is

installed perfectly level. We recommend

using a laser level and checking the level

periodically throughout installation.

Towel bars are 12V SELV (safety extra

low voltage) and can be installed in

bathrooms.

Ensure any controls used are installed in

correct zone according to the IP rating

of the control

Ensure that your towel bar is protected

by a suitably rated RCD

Do not use the towel bar to hold

towels or other articles that have been

in contact with oil, petroleum based

products or dry cleaning uids

This appliance is intended to warm and

dry towels not heat spaces

Do not immerse your towel bar in liquid

Ensure the transformer is located no

further than 2m from the ThermoSphere

Towel Bar

Ensure the transformer is accessible and

has adequate ventilation

Care information

The Stainless Steel nish of your

towel bar is hard wearing and easy to

maintain. However any harsh scrubbing,

scratching or acid based cleaning

products will damage the surface of

your towel rail.

Clean with a soft cloth dampened with

warm and warm soapy water only. Dry

immediately for the best nish.

Max weight warning

ThermoSphere SE Towel bars are

designed to hold towels only, and must

not be subjected to excessive forces over

10kg and must not be climbed on or

used as support rails.

This can result in injury and can cause

damage to the towel bars which is not

covered under the guarantee.

Contents

What's in the box? .........................................

Key considerations .........................................

Single bar installation .....................................

Multiple bar installation ..................................

Example wall build up .....................................

Wiring schematics ..........................................

Available models .............................................

4

5

6

9

13

14

15

Watch the installation videos!

Single SE Bar installation

without mounting system

Multiple SE Bar installation

with mounting system

4+44 (0) 800 019 5899

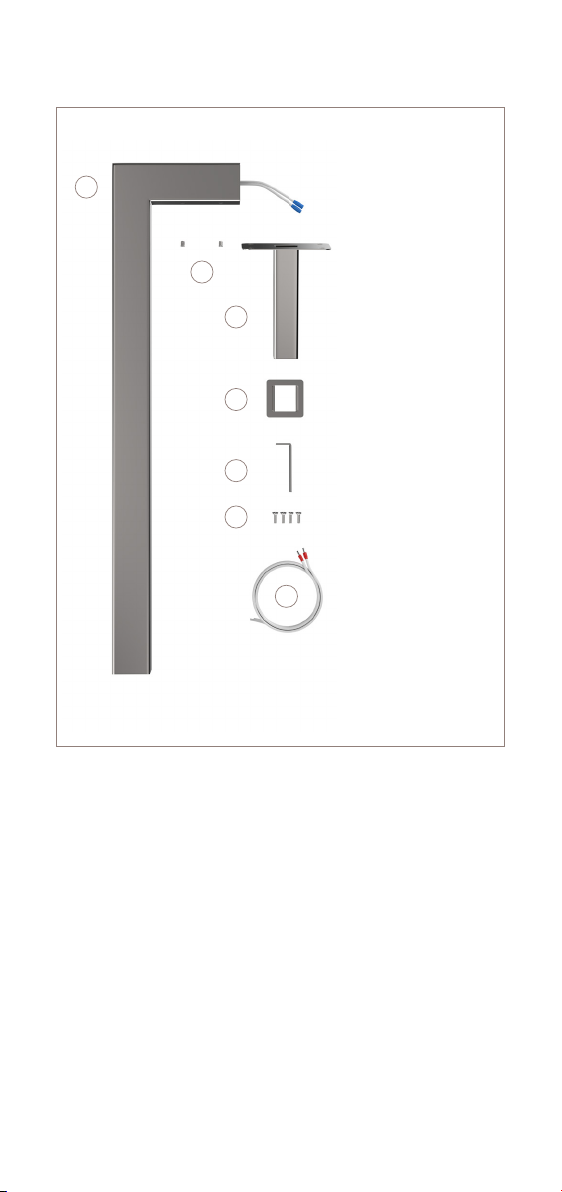

What’s in the box?

You will also need

1. Towel bar body

2. Grub screws

3. Mounting spigot

4. Dress ring

5. Hex key

6. Mounting screws

7. Power lead 2m

• Fixings that are suitable for your wall substrate

• Laser level or spirit level

• Cordless drill or impact driver

• Marker pen or pencil

• 30mm diamond hole cutter bit

• 25mm timber hole cutter bit

• Suitable rated 12V transformer

• 230V electrical supply

• Fibreglass mesh tape

1

2

3

4

5

6

7

Key considerations

Fixing spigots must be installed before tiling!

You MUST make sure xing spigots are level!

Low voltage transformers

Max tiling depth is 35mm

Use the right xings for your wall substrate

SE Towel Bars xing spigots are designed for installation before

tiling. You must install the xings spigots and run cables before

you tile the wall. There is no option to install SE Towel Bars on

top of a tiled wall.

Because the xing spigots are installed behind the tiles, you

have to take extra care to make sure they are installed level. We

recommend using a laser level throughout the process to check

the towel bars are nice and level!

SE Towel Bars are 12V DC and there is no polarity. You must

install a suitably rated 12V transformer between the towel bar

and the 230V supply. You can connect multiple towel bars to

one transformer in parallel, up to the maximum load of the

transformer. The transformer should be somewhere accessible to

facilitate replacement.

The maximum depth of the tiled wall layers that will be situated

over the xing spigot is 35mm. This includes any boards, tile

adhesive and the tiles. Limiting the tiling depth ensures that

there is enough spigot protruding from the wall to achieve a

good, strong xing to the towel bar.

We recommend that you x SE Towel Bars to a solid wall, such

as a brick/block cavity wall, a secure timber noggin within a

cavity wall or a plywood/OSB panel. Use xings that are suitable

for the type of wall you are xing to. We do not recommend

xing directly to plasterboard or tile backer boards as this can

cause the xings to move over time and result in loose towel

bars.

MAX 35MM

Fixing

spigot

plate

Tiling layers Towel bar

chassis

Grub screws

Spigot shaft inside

bar chassis

Table of contents

Other Thermo Sphere Bathroom Fixture manuals

Popular Bathroom Fixture manuals by other brands

Kohler

Kohler Mira Sport Max J03G Installation and user guide

Moen

Moen 186117 Series installation guide

Hans Grohe

Hans Grohe Raindance Showerpipe 27235000 Instructions for use/assembly instructions

Signature Hardware

Signature Hardware ROUND SWIVEL BODY SPRAY 948942 Install

fine fixtures

fine fixtures AC3TH installation manual

LIXIL

LIXIL HP50 Series quick start guide