Thermocable ProH2O User guide

Document 520/001 Rev 2.2 Dec 2013 Page 1 of 10

Web: www.waterleakdetection.com Email: info@thermocable.com

Tel: +44 (0)1274 882359 Fax: +44 (0)1274 882229

ProH2O Water Leak Detection Application Guide

IMPORTANT GUIDELINES

The ProH2O Water Leak Detection Systems are ideally suited for early warning of water leaks in a wide variety

of applications. Planning and correct placement of the ProH2O sensor cable will maximize the effectiveness of

the system to detect water leaks and trigger an alarm. Before starting the installation identify all areas where a

water leak is likely to occur and make a note of these areas in order to plan placement of the cable.

In all applications of water leak detection it should be noted that the ProH2O sensor cable

MUST come into contact with sufficient amount of water in order to trigger an alarm. Therefore

before installing the sensor cable check either visually or by experiment to ensure water will

flow to where you intend to lay the cable.

• Ensure the product is installed, commissioned and maintained by persons according to good

engineering practices and authorities having jurisdiction.

• It is important at all times to keep the detection cable clean and free from dust, debris and other

contaminants that may soil the cable, especially during installation.

• Ensure any major construction work has been completed and signed off before installing the detection cable

• Periodically inspect the detection cable. The cable should be clean and free of dust or other contamination.

The inspection interval should be no greater than 12 months.

• Ensure the detection cable is thoroughly dried out after a leak has occurred.

• A selfadhesive or screwtype Uclip should be used to secure the detection cable to the mounting surface

without lifting it or creating an air gap between the surface and cable.

• Do not cut and reterminate the detection cable.

The connections have been factory fitted and are unservicable.

• Do not paint the detection cable.

• Do not put the detection cable under excessive tension.

Maintain some slack in the detection cable when laying it out on surfaces.

• Do not bend the detection cable less than the minimum bend radius of 25mm (1")

• Avoid laying the detection cable in areas where heavy taffic may result in damage.

• Do not solder or weld around the detection cable. Flux or other conductive contaminants will prevent the

detection cable from operating correctly.

• Do not crush the detection cable.

Document 520/001 Rev 2.2 Dec 2013 Page 2 of 10

Web: www.waterleakdetection.com Email: info@thermocable.com

Tel: +44 (0)1274 882359 Fax: +44 (0)1274 882229

ProH2O Water Leak Detection Application Guide

Typical Applications for Water Leak Detection

• Data Centres/Computer rooms

Detect leaks underneath raised flooring

• Fire Sprinkler systems

Ensure the integrity of pipework/tanks

• Vacant property

Prevent leaks from causing extensive damage in property which may not be visited for several days

or weeks.

• Air conditioning systems (HVAC)

Early warning of leaks from HVAC pipes, drip pans and other fittings.

• High value property e.g. Historical/Period buildings, libraries, museums

Detect water leaks where a small amount of water may cause very high value damage.

• Commercial/Office Buildings

Detect leaks near plumbing which may cause damage to the floors below.

• Multioccupancy Buildings

Prevent water leaks causing widespread damage

• Roofs & Basements

Early warning of leaks which may go unnoticed

• Water cooled equipment

Detection of leaks which may cause costly downtime

Other Applications

• Areas of the world where water is scarce

Preventing excess loss of water which is considered a valuable commodity

Document 520/001 Rev 2.2 Dec 2013 Page 3 of 10

Web: www.waterleakdetection.com Email: info@thermocable.com

Tel: +44 (0)1274 882359 Fax: +44 (0)1274 882229

ProH2O Water Leak Detection Application Guide

SENSOR CABLE OVERVIEW

ProH2O Sensor Cable is a linear sensor for

the detection of water leaks. When water

comes into contact with the detection cable a

controller can detect changes in the electrical

characteristics of the cable and signal an

alarm or other action. The sensor cable is

available in preterminated lengths for simple

assembley and extension. Nonsensing pre

terminated lengths are also available when

the cable is to pass through areas which do

not require protection.

Technical Data

Overall Diameter: 6.05mm (0.238in)

Approvals: CE Marked, RoHS Compliant

Ambient Temperature Range: 20˚C to +70˚C (4˚F to +158˚F)

Construction: 4core twisted sensor cable

with insulating polymer braid

Standard Lengths: 3.75m (12ft)

7.5m (25ft)

15m (50ft)

30m (100ft)

50m (164ft)

100m (328ft)

Custom lengths on request

Document 520/001 Rev 2.2 Dec 2013 Page 4 of 10

Web: www.waterleakdetection.com Email: info@thermocable.com

Tel: +44 (0)1274 882359 Fax: +44 (0)1274 882229

ProH2O Water Leak Detection Application Guide

SENSOR CABLE INSTALLATION

Area Protection Standard application

ProH2O sensor cable is ideally suited to detecting leaks over a wide area such as underneath a raised floor or

similar applications. The sensor cable should be laid around the perimeter of the room and then spaced equally

across the remaining floor space as shown below. The required cable length can be approximately calculated

using the following formula:

Floor area (m2) + 10 ≈ Minimum Cable Length (m)

Figure 1 shows the layout of ProH2O Sensor Cable when protecting an area of approximately 10m2. Here the

sensor cable has first been laid around the perimeter of the room, no more than 0.5m away from the walls. The

sensor cable is then laid in the middle of the room at a 0.5m spacing between runs. Using standard ProH2O

sensor cable lengths, a 15m and 3.75m cable provide the required coverage. Depending upon the risk increase

the coverage by reducing the spacing between cable runs and installing additional lengths of detection cable.

Figure 1. ProH2O Sensor Cable layout for Area Protection

Document 520/001 Rev 2.2 Dec 2013 Page 5 of 10

Web: www.waterleakdetection.com Email: info@thermocable.com

Tel: +44 (0)1274 882359 Fax: +44 (0)1274 882229

ProH2O Water Leak Detection Application Guide

SENSOR CABLE INSTALLATION

Leak detection around pipes

ProH2O detection cable can be used to provide early warning of leaks from pipework, valves and similar

equipment. It is important to maintain the surface contact between the pipe and detection cable. A

maximum spacing of 150mm (6") is recommended between cable ties when the detection cable is

attached to a pipe. Adding lagging around the pipe over the detection cable further improves the chance of

detecting a leak. The effectiveness of the detection cable when attached underneath a pipe is dependant on

many variables however the most important differerence between leak detection on a pipe and laying the cable

on a surface is that a continuous flow of water must be present on the pipe to trigger an alarm.

Figure 2. ProH2O Sensor Cable used to protecting piping

Document 520/001 Rev 2.2 Dec 2013 Page 6 of 10

Web: www.waterleakdetection.com Email: info@thermocable.com

Tel: +44 (0)1274 882359 Fax: +44 (0)1274 882229

ProH2O Water Leak Detection Application Guide

SENSOR CABLE INSTALLATION

Water Tanks Protection

ProH2O Sensor cable can be used to protect water tanks in a roof space where there is a possibility of leaks

going unnoticed for extended periods. Typical examples include header tanks or expansion tanks in the loft of a

house or in the roof space of an office building. ProH2O sensor cable should be laid around the tank no more

than 15cm (6") away from the tank. It is good practice to lay excess cable (in a sine wave pattern) around areas

which have a higher risk of leaking, such as pipe entrances/exits to the tank.

Figure 3. ProH2O Sensor Cable used to protect tanks

Document 520/001 Rev 2.2 Dec 2013 Page 7 of 10

Web: www.waterleakdetection.com Email: info@thermocable.com

Tel: +44 (0)1274 882359 Fax: +44 (0)1274 882229

ProH2O Water Leak Detection Application Guide

SENSOR CABLE INSTALLATION

Air Conditioning (or HVAC) Units (Indoor use)

ProH2O Sensor cable can be laid around air conditioning units and the associated drip trays to provide an early

warning of a malfunction or damage to the connecting equipment. It is important to ensure the sensor cable will

remain dry during normal operation of the air condition unit. Regular maintenance and servicing is required to

verify the sensor cable is clean and to confirm the system is functioning correctly.

Figure 4. ProH2O Sensor Cable used to monitor air conditioning equipment

Document 520/001 Rev 2.2 Dec 2013 Page 8 of 10

Web: www.waterleakdetection.com Email: info@thermocable.com

Tel: +44 (0)1274 882359 Fax: +44 (0)1274 882229

ProH2O Water Leak Detection Application Guide

SENSOR CABLE INSTALLATION

Securing the sensor cable

It is important to correctly secure the ProH2O detection cable in order to maximize the possibility of water

coming into contact with the water sensitive cores within the cable. Figure 5 below shows the recommended

mounting clips used to secure the sensor cable. The clips shown hold the cable to the floor without any material

between the floor and the cable. Any clip which lifts the cable off the floor will reduce the effectiveness of the

sensor cable. The clips also allow some sideways movement which aids servicing and maintenance.

It is important not to crush the cable when securing it to a surface or a pipe with a clip or cable tie.

Figure 5. ProH2O Sensor Cable recommended mounting clips

Document 520/001 Rev 2.2 Dec 2013 Page 9 of 10

Web: www.waterleakdetection.com Email: info@thermocable.com

Tel: +44 (0)1274 882359 Fax: +44 (0)1274 882229

ProH2O Water Leak Detection Application Guide

Frequently Asked Questions

1. What is the best way to secure the detection cable to a surface?

The leak detection cable should be firmly attached using selfadhesive Uclips or similar. These can be screwed

through to the floor to ensure the clip does not become loose. When using the detection cable on the floor it is

preferable to keep the detection cable in contact with the surface as much as possible. Any gaps between the

surface and the cable decreases the response time and increases the required amount of water needed to

trigger an alarm.

2. What is the best way to secure the detection cable to a pipe?

If the detection cable is run alongside a pipe it should be placed underneath the pipe and cable ties placed at a

maximum spacing of 150mm (6"). Ensure the surface contact between the pipe and detection cable is

maintained as much as possible along the cable length. Lagging further aids the ability of the cable to detect a

leak. Refer to page 4 for examples.

3. How can I check the integrity of the cable?

Each ProH2O System continuously monitors the cable for a fault anywhere along its length and emits a trouble

signal if a fault occurs. However the cable may be checked using a multimeter. Measuring the resistance

between the two outermost connectors at either end of the detection cable without an endofline plug attached

should read greater than 20Mohms. Dipping the cable in water should result in the resistance decreasing to less

than 5Mohms.

4. Can ProH2O leak detection cable be laid on metal surfaces?

Yes, the ProH2O detection cable is designed to maintain a gap between any metallic or conductive surface and

the sensor cores within the detection cable. Ensure no conductive parts can protrude through the braid and

touch a sensor core.

5. What is the best way to clean the detection cable?

The detection cable can be cleaned with a damp cloth or by washing the cable in water. Once cleaned the cable

will need to be dried before the ProH2O system can be used. Do not use solvent based cleaners on the cable.

6. How often should I check the detection cable?

The detection cable should be examined and tested at regular intervals and no greater than 12 months apart. At

each inspection the function of the cable should be check (see question 3 above) and clean if necessary.

Document 520/001 Rev 2.2 Dec 2013 Page 10 of 10

Web: www.waterleakdetection.com Email: info@thermocable.com

Tel: +44 (0)1274 882359 Fax: +44 (0)1274 882229

ProH2O Water Leak Detection Application Guide

Frequently Asked Questions

7. How much water is required to trigger an alarm?

The amount of water required to trigger an alarm varies depending on which ProH2O controller the sensor cable

is connected to. Please refer to the ProH2O Module documentation (Document No. 550/001) or ProH2O

Professional documentation (Document 500/001) for more information. It is worth noting that the ProH2O

system has the ability to detect very small amounts of water or even a saturated environment (R.H. >98%)

however this would increase the frequency of alarms for situations which pose no serious problem. The

sensitivity of all ProH2O controllers have been set to provide an optimum level of protection against leaks which

are a signficant problem and have the potential to cause major damage.

Table of contents

Popular Measuring Instrument manuals by other brands

Franklin Fueling Systems

Franklin Fueling Systems EVO 200 Programming guide

Panasonic

Panasonic K-NL316G quick start guide

SMC Networks

SMC Networks PME-500-TR quick start guide

PROSPORT

PROSPORT EVO SERIES installation instructions

Shodex

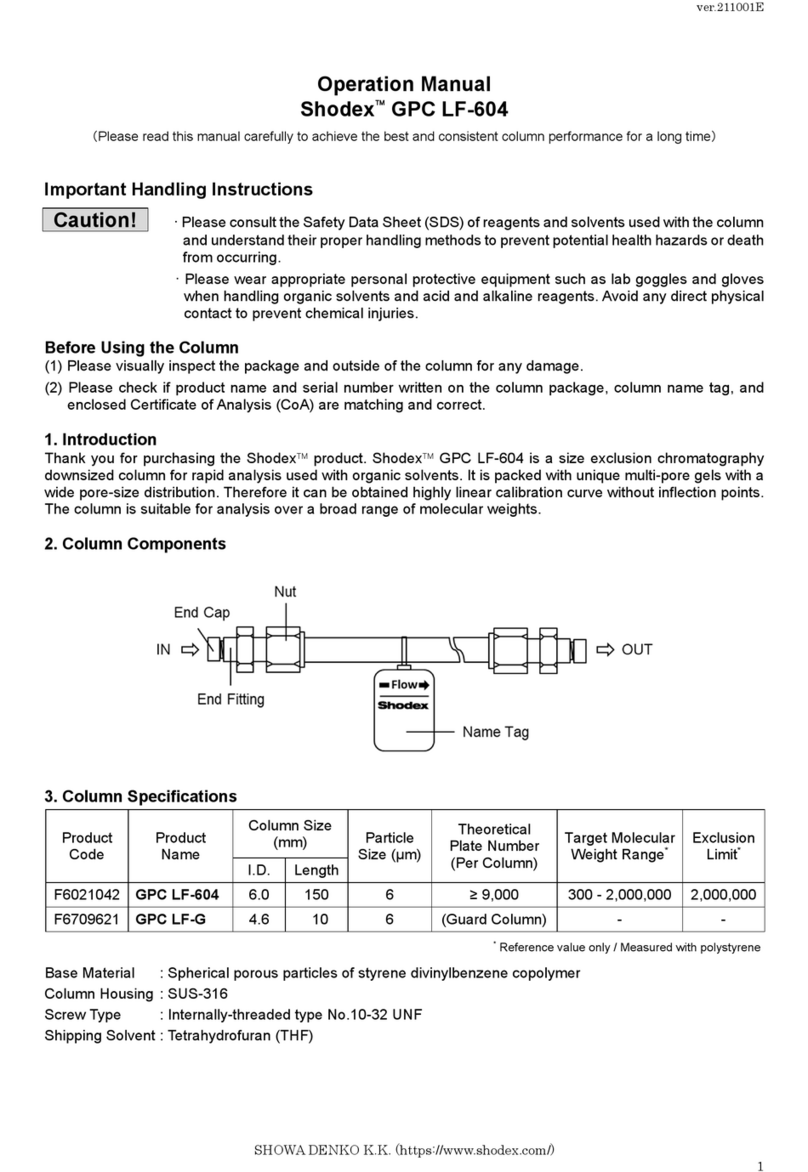

Shodex GPC LF-604 Operation manual

Endress+Hauser

Endress+Hauser LT5 operating instructions