Sofraser MIVI 8001 User manual

Quality system certified

instruments

Manuel Technique

Technical Manual

MIVI 8001

Re

f

: 128-41/5

Technical Manual MIVI 8001

Ref. 128-41/5 2

IMPORTANT

BEFORE STARTING THE PROCESS, PROCEED TO

THE OFFSET IN AIR ADJUSTMENT.

IT MEANS THAT THE ROUGH SIGNAL WILL BE

SHIFTED TO THE REFERENCE "900" :

1. CLEAN AND DRY THE SENSOR ROD.

2. BE SURE THE PROCESS IS EMPTY.

3. INSTALL THE SENSOR ON THE PROCESS AND FIX IT WITH ITS 4 SCREWS.

4. ON VIEW #1, PRESS SIMULTANEOUSLY + R/L + KEYS DURING

APPROXIMATELY 3 SECONDS.

"900" MUST BE INDICATED ON THE RED DISPLAY UNTIL THE THREE KEYS ARE

PRESSED.

5. CHECK THE RED DISPLAY INDICATES "0" AS VISCOSITY VALUE.

6. PRESS CONTINEOUSLY R/L KEY AND CHECK THAT THE RED DISPLAY INDICATES

900 ±0.5.

OTHERWISE, REPEAT STEP #4.

Technical Manual MIVI 8001

Ref. 128-41/5 3

TABLE OF CONTENT

1. GENERAL PRESENTATION ...........................................................................................5

1.1. The sensor ................................................................................................................5

1.2. The processor............................................................................................................5

1.3. Checking the equipment at the receipt ...................................................................... 6

1.4. Checking the equipment when placed at the process ............................................... 6

1.5. Periodic checking ......................................................................................................6

1.5.1. Adjusting the mounting offset in air.........................................................................6

1.5.2. Modification of the previous calibration...................................................................7

1.6. Directives and standards ...........................................................................................7

1.6.1. European Directive ATEX.......................................................................................7

1.6.2. Installation in hazardous area.................................................................................7

1.6.3. European Pressure Equipment Directive................................................................ 8

1.6.4. EMC and low voltage directive................................................................................8

2. THE MIVI SENSOR .......................................................................................................... 9

2.1. Various models..........................................................................................................9

2.2. Sensor installation .....................................................................................................9

2.2.1. Elbow mounting ....................................................................................................10

2.2.2. Plane side mounting .............................................................................................10

2.2.3. On pot mounting, for small flow rates, or pilot plant .............................................. 10

2.2.4. Special mountings ................................................................................................ 10

2.2.5. Replacement cap..................................................................................................10

2.3. Practical advices...................................................................................................... 10

2.4. Checking ................................................................................................................. 11

2.5. Sensors wiring .........................................................................................................11

2.6. Models and dimensions...........................................................................................13

2.7. Tightness.................................................................................................................14

3. THE PROCESSOR......................................................................................................... 15

3.1. Mechanical characteristics ...................................................................................... 15

3.2. Power supply ...........................................................................................................15

3.3. Display.....................................................................................................................15

3.4. Universal analog inputs ........................................................................................... 16

3.5. Logic inputs .............................................................................................................16

3.6. Standard outputs (Relays 1 and 2) .......................................................................... 16

3.7. Viscosity current output (slot n°4)............................................................................16

3.8. Supervisor digital RS ...............................................................................................16

3.9. Watchdog ................................................................................................................17

3.10. Option outputs (slots N° 1 to 3)............................................................................17

3.10.1. 1 relay output board............................................................................................17

3.10.2. 2-relay output board............................................................................................17

3.10.3. 2- safety relay output board ................................................................................17

3.10.4. Current output board...........................................................................................17

3.10.5. Voltage output board .......................................................................................... 17

3.10.6. RS485/422 or RS232 board ............................................................................... 17

3.11. Connections ......................................................................................................... 18

3.12. General information ............................................................................................. 20

4. MATERIAL CONFIGURATION...................................................................................... 21

5. USER MODE..................................................................................................................22

5.1. Restoration of the configuration from the MEMOCARD ..........................................23

5.2. Adjustment of the brightness of the front panel .......................................................23

6. CONFIGURATION MODE..............................................................................................24

Technical Manual MIVI 8001

Ref. 128-41/5 4

6.1. Access to the configuration ..................................................................................... 24

6.2. Configuration type "TYPE".......................................................................................24

6.3. Inputs N° 1 to 6 "Entr.n"...........................................................................................25

6.4. Software alarm N° 1 to 4 "ALRM.n" .........................................................................25

6.5. Relays outputs 1 and 2 "REL.n" .............................................................................. 25

6.6. Outputs (slots 1 to 4) ............................................................................................... 26

6.6.1. Current or voltage board "OUT.n".........................................................................26

6.6.2. Relay board "REL.n".............................................................................................26

6.6.3. RS Link "RS.n"...................................................................................................... 26

6.6.4. Slave address "Adr"..............................................................................................27

6.7. Display.....................................................................................................................27

6.7.1. Display 1 block "AFFI.1" .......................................................................................27

6.7.2. Display 2 block "AFFI.2" .......................................................................................27

6.8. Change to User mode "UTIL" .................................................................................. 27

7. ADAPTATION MODE ....................................................................................................28

7.1. Access to the ADAPTATION mode .........................................................................28

7.2. ADAPTATION blocks diagrams...............................................................................29

7.3. Alarm Block "ALARME" ........................................................................................... 30

7.4. Filter block "FILTRE" ...............................................................................................30

7.5. Cycle information block "INFO" ...............................................................................31

7.6. Memocard block "MCARD"...................................................................................... 31

7.6.1. Save : From the device to the Memocard .............................................................31

7.6.2. Load : from the Memocard to the device .............................................................. 31

7.7. Security block "SECUR" ..........................................................................................31

7.7.1. Global locking "GLOBAL" .....................................................................................31

7.7.2. Adaptation blocks locking "REGU"…"PLG.HOR" .................................................31

7.8. Linearization block "LINEAR" .................................................................................. 32

7.9. Timer block "TIMER" ...............................................................................................32

7.10. Constants block "CONST" ...................................................................................32

7.11. Parameters block "PARAM".................................................................................33

7.12. Program block "PRGRAM"................................................................................... 33

8. DIGITAL COMMUNICATION .........................................................................................34

8.1. MODBUS slave and addressing .............................................................................. 34

8.2. Slicing of the bit memory that can be addressed.....................................................34

8.3. Slicing of the word memory (16 bits) ....................................................................... 34

9. SPECIFIC NOTES AND MANUFACTURING PARAMETERS ...................................... 37

9.1. Configuration Mode .................................................................................................37

9.2. Adaptation Mode .....................................................................................................38

10. ERROR MESSAGES .....................................................................................................41

Technical Manual MIVI 8001

Ref. 128-41/5 5

1. General presentation

1.1. The sensor

Each sensor is matched with its own electronics. Before switching on, be sure that serial numbers at

the sensor and the electronics identification plates are corresponding.

The operation principle of the equipment makes that the provided viscosity information is relative: in

the same fluid, at the same conditions the information is the same. But for 2 rheologically different

fluids the response can be different (despite it is perfectly repeatable).

The sensor active part is protected by an stainless tube which must not be removed.

The sensor is fixed upon its mounting flange by means of the provided 4 long screws.

See the detailed leaflet, § 2.

1.2. The processor

Its functions:

− Powers the sensor;

− Processes the sensor’s information;

− Displays and transmits the process information : viscosity, temperature, sensor’s frequency,

outputs states …

It is composed of three software modes:

• « USER» Mode :

Used for the working mode, it allows:

− Visualizing viscosity, temperature and outputs states (relays, digital link,…);

− Adjusting the offset in air;

− Accessing to ADAPTATION and CONFIGURATION modes;

See detailed leaflet, § 5.

• « ADAPTATION » Mode:

Allows adjusting the functioning parameters as:

− The table of linearization (Re-calibration and thermal drift compensation);

− Hysteresis and thresholds alarms values;

− Scale of bargraphs;

− Filtering parameters of inputs and outputs;

See detailed leaflet, § 7.

• « CONFIGURATION » Mode:

Allows defining:

− The inputs parameters ;

− The alarm types;

− The outputs parameters (relays, analogs, digital);

See detailed leaflet, § 6.

Technical Manual MIVI 8001

Ref. 128-41/5 6

1.3. Checking the equipment at the receipt

a- At first, check the supply conformity with the ordered equipment, mainly the presence of the parts

necessary for the equipment mounting. Those to be used at the process will be given to the

concerned department, for the installation preparation.

b- Place the sensor on a soft foam plate, connect it to the 8001 module (see § 3.11), and then switch

on. The vibration appears at the rod, and the indication (display and output) is close to the minimal

required values. When touching the rod, the information has to increase.

In case of subnormal operation, check as follows :

− The power supply, the connections, and the cables.

− The good condition of the vibrating rod (no bending on knock damages).

Consult your Distributor.

1.4. Checking the equipment when placed at the process

Before filling the network check that the viscosity information is stable (vibrating rod in air). If not,

check the strength of the sensor fitting, then rotate the sensor of 90° (4 possible positions). Choose

the position where the information is the most stable.

Locate this position, in order to restore it when the sensor is removed – put in place.

Adjust the offset in air, at room temperature. When possible, note the viscosity information when a

cleaning or rinsing solution is flowing.

If the original calibration is convenient, one of the 2 above mentioned values can be taken as

reference for periodic control of the equipment operation each time that the same conditions will occur

(rod in air, or in the cleaning solution). Such an operation can be assimilated to a self-checking.

If the original calibration has been modified the reference values will be of course those obtained with

the new calibration.

1.5. Periodic checking

Conformity to regulations relative to Quality Insurance implicates a periodic control of the measuring

equipment used in the manufacturing operations, taking in consideration (or correcting) their drift in

time.

It is proved that this equipment drift is negligible. However, it is good to check their aspect and their

response once a year, at the same time as the other process equipment.

A fast test is many times available, when the sensor active part is in air, or immersed in a cleaning or

rinsing solution. As long as these values stay similar, we can say that the sensor operation is right

among its whole range (if no intermediate re-programming occurred).

1.5.1. Adjusting the mounting offset in air

The sensor active part must be clean and dry.

Press simultaneously the following keys of the device’s front panel :

+ R/L +

Be sure before you stop pushing the keys that the red display indicates "900".

The upper display (red one) must indicate “0” when you stop pushing the keys.

Technical Manual MIVI 8001

Ref. 128-41/5 7

1.5.2. Modification of the previous calibration

The device has been programmed in order to answer to your needs. These features programming

steps are noticed on the features specification pages at the end of this document.

At first, be sure that the modification is necessary, and not consecutive of a non coherent

comparative information (different measuring conditions, bad standards, inaccurate or wrong

laboratory measurements,…).

To re-calibrate the viscometer, measure several viscosities of standard oils and then, transfer the

values in the table n°2 of the electronic processor. Refer to the User Manual 8001 to know each steps

of a re-calibration.

1.6. Directives and standards

1.6.1. European Directive ATEX

MIVI sensors are in agreement with 94/9/EC directive (ATEX) for equipments installed in explosive

gas atmospheres or in presence of combustible dust :

II 2G (gas)

II 2D (dust)

Ex d IIC T1 to T6 : gas

Ex tD A21 IP67 T75°C, T90°C, T125°C, T190°C, T290°C, T300°C : dust

Be sure the sensor’s certification is in accordance with the security level required on your process

location : Area classification, equipments group, protection method, gas type, temperature codes…

Area classification and equipments installation rules are detailed into IEC 7910 and EN 60079

standards for gas or EN 61241 standards for dust.

To always keep the maximum security level of the viscometer, don’t open it. Furthermore, we advice

to install the sensor with the cable gland orientated to the floor.

Check periodically information indicated on the sensor’s identification plate are still visible.

1.6.2. Installation in hazardous area

Here are the possible ways to install MIVI sensors in hazardous area.

SAFE AREA

HAZARDOUS AREA SAFE AREAHAZARDOUS AREA

(1)

(2)

(3)

(1) : non-exproof connectors

(2) : exproof box (3) : exproof connection box

Ex

Ex

IMPORTANT : Always connect the sensor's body (screw on the top of the body) to the ground.

Technical Manual MIVI 8001

Ref. 128-41/5 8

1.6.3. European Pressure Equipment Directive

Up to 60 bars, MIVI sensors are in agreement with the article 3.3 of the PED 97/23/EC. In case of

higher pressure, sensors are certified one by one.

The mounting flange is an accessory to be welded on the process line. It means it can not be

individually certified but with the whole process line.

1.6.4. EMC and low voltage directive

MIVI 8001 is in agreement with EMC specifications detailed into 89/336/EEC (modified by 92/31/EEC

and 93/68/EEC).

8001 processor is also in agreement with the low voltage directive 73/23/EEC (modified by

93/68/EEC).

MIVI sensors have been designed and manufactured according to the electrical safety rules.

Technical Manual MIVI 8001

Ref. 128-41/5 9

2. The MIVI sensor

2.1. Various models

• General purpose sensors

• Sanitary sensors (special design for no retention areas).

• Ex-proof sensors (ATEX, FM or JIS approvals).

• High-pressure sensors up to 150 bars (reinforced fitting).

• Special models, according to the requirements (in design and material).

• When required, a temperature probe can be incorporated to the MIVI sensor.

2.2. Sensor installation

It operates at any position, even upside down. Its active part has to be permanently immersed in the

fluid (low part of the network or reactor). If the fluid temperature varies widely and fast, choose the

upside down or horizontal position, in order to allow a convenient air convection among the sensor

body.

It is screwed to its mounting flange by means of 4 screws M6X100 (or 8 screws M8 for high

pressures). The mounting flange has to be welded close to the device generating the viscosity

variations (heater, mixer, reactor, etc…). Retention, high flow velocities, strong vibrations and high

magnetic fields have to be avoided.

According to the application the mounting flange material can be :

Stainless steel Z3CND 17/11-02 (316L).

Carbon steel XC38

Other materials, according to the requirement.

Technical Manual MIVI 8001

Ref. 128-41/5 10

2.2.1. Elbow mounting

2.2.2. Plane side mounting

2.2.3. On pot mounting, for small flow rates, or pilot plant

See fig.3.

2.2.4. Special mountings

2.2.5. Replacement cap

2.3. Practical advices

The flange is welded on a right angle tee as indicated in

fig.1.

• The minimal pipe diameter is of 32 mm.

• The flange and the pipe axes have to be superjacent.

• The flow direction is as indicated on fig.1 (unless for

fibrous fluids where the flow is inverted and the rod

protector removed.

A free area of at least 150 mm length is necessary.

• The flange is welded as indicated on fig.2.

• The free area around the vibrating rod has to be at

least ∅40, 150 mm length.

• In order to avoid parasitic vibrations, the plate where

the flange is welded must be thicker than 5 mm.

The small sensor size allows numerous personalization

of its fitting according to the user's requirements.

Consult

y

our Distributor.

Each mounting flange is provided with the

corresponding cap and its accessories (screws and

gaskets). It allows the installation working when the

sensor has to be removed.

Torque at the mounting screws: 9 N.m ±1 at the M6×100

screws, or 22 N.m ±1 at the M8 screws (for the high

pressure design).

Notes:

Each sensor is equipped with a guard tube in order to

protect the vibrating rod. In most cases, it is designed

according to the application, and has not to be removed,

unless when it disturbs the sensor operation: on pot

mounting, sanitary use, very viscous and fibrous fluids,

where a replacement ring is used.

Mounting flange,

welded

150 mm

5 mm

int.

∅

32 mm mini

Fig. 1

∅

40 mm mini

150 mm

17

Mounting flange,

welded

Fig. 2

¼

g

as

Fig.3

On circulation pot

Weight : 5,6 kg

Earth terminal

Technical Manual MIVI 8001

Ref. 128-41/5 11

WARNING ! In this case, the mounting / removing of the sensor must be made with precaution, in

order to avoid to bend the vibrating rod.

A ring, with the same dimensions of the protector’s base must be placed on the head of the sensor in

order to maintain the O-ring.

IMPORTANT :

• As soon as the sensor is removed, screw immediately its guard tube.

• IP 67 rightness is only obtained when firmly screwing either the cable connectors, their replacing

caps, and the cable glands.

• The minimal bending radius at the flexible pipe (electric outlet) is of 100 mm. Less radius can

generate leakage, then failure.

2.4. Checking

In case of subnormal operation, check the following points:

• Electrical connections (connectors, cables, power supply…)

• Remove the sensor from the process and clean it

• Check that the vibrating rod is not bent.

When powered, check with the finger that the vibration is existing at the rod end. At this moment,

the viscosity information has to increase.

2.5. Sensors wiring

Wire Color

1 Blue

3 Brown

3 Transparent

4 Black

26 Green

25 Yellow

24 Red

Technical Manual MIVI 8001

Ref. 128-41/5 12

General purpose sensors Exproof sensors

Figure 5

1 3 3 4 26 25 24

5

4

3

2

1

6

7

1

2

3

4

5

6

7

7

6

5

4

3

2

1

1

2

3

4 5 6

7

Figure 4

1 3 3 4 26 25 24

Sensor socket

(female)

Cable plug

(male)

Earth terminal

Earth terminal

Cable

Cable

Screen

Motor

coil

Pick up

coil

Motor

coil

Optional

temperature

p

robe

Optional

temperature

p

robe

Earth

Earth

Screen

Pick up

coil

Technical Manual MIVI 8001

Ref. 128-41/5 13

2.6. Models and dimensions

GENERAL PURPOSE

Ex-proof 200°C

Std 200°C

135 mm

120 mm

100 mm

17 mm

30 mm

Guard tube short slits

Pot ¼ gas

156 mm

156 mm

HIGH PRESSURE

HP 200°C

HP ex-proof 200°C

Pot ¼ gas

Guard tube lon

g

slits

Low pressure Hi

g

h pressure

∅ 76

∅ 60

Mountin

g

flan

g

e

∅ 99

1 o’rin

g

Sanitary low pressure Sanitary high pressure

Mounting flange

3 o’rings

∅ 70

Replacement ring

Usual

Sanitary

Fig. 6

Technical Manual MIVI 8001

Ref. 128-41/5 14

2.7. Tightness

Material : Viton, PTFE, EPDM, Silicone, etc. … on request.

∅76 or 99

17

1

15

4

∅

70 or 99

3

2

: Gasket ∅29.82×1.78

: Gasket ∅21.95

×

1.78

: Gasket ∅30.00 ×2.00

: Gasket ∅30.00 ×2.50

Technical Manual MIVI 8001

Ref. 128-41/5 15

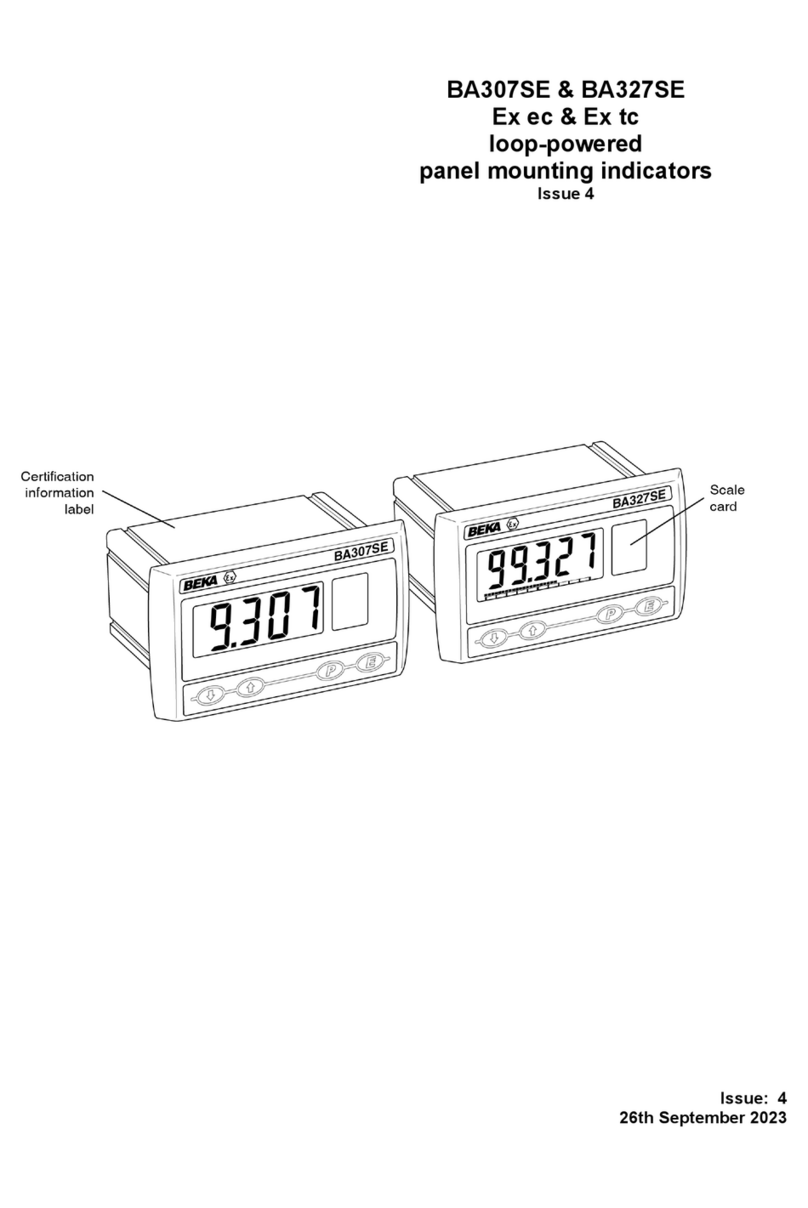

3. The processor

3.1. Mechanical characteristics

Dimensions : 72 x 144 x 203 mm behind the collar.

Cut-out : 68 x 138 mm.

Weight : 1,8 Kg environ.

Metallic casing.

Removable drawer.

Protection IP 54 on front panel. IP20 on rear panel.

Screw terminals : 2,5 mm2max.

68 +1

-0

138

+1

-0

144

72

30 203

3.2. Power supply

Standard power supply : 80..265 Vac - 100..380 Vdc C / 50-60 Hz

Optional power supply : 21-60 Vac-dc / 50-60 Hz

Consumption lower than 25 VA.

3.3. Display

Cyclic display on 2 channels :

View n°1 View n°2

Viscosity Temperature

− 7-segment display :

• 4 digits, height 10 mm, red for the process variables.

• 6 digits, height 7,6 mm, green for the rod’s frequency display, the physical units, etc.

• 1 digit, height 7,6 mm, green for the view number.

− Bargraph : red, 50 points, for the measurements.

− 4 red LED (programmable alarms lights).

− 1 green LED (transmission of digital data).

Technical Manual MIVI 8001

Ref. 128-41/5 16

3.4. Universal analog inputs

They are all referenced to the same potential and isolated at 500 Veff from all the other signals.

Temperature Sensor Pt 100 Ω

3-wire mode

-50 à 300°C

Rligne = 20 Ωmax, 0,5.10-4/Ω

Viscosity/Thermal Drift

Compensation

Voltage 0-1 V

Accuracy 0,1% of the scale on the linear

0,12% of the scale on the RTD and the resistance

Temperature drift All the inputs 100 ppm/°C

Sampling 100 ms

Rejection Common Mode 120 dB to 250 Vac; serial mode 50 dB

We advise you to connect the logic inputs with shielded cables.

3.5. Logic inputs

3 physical logic inputs are available El3 to El5.

They can be driven by contact free from potential or by an open collector. The polarization voltage

24V is internal, the polarization current is 5mA.

1 ⇒Closed contact

Voltage between –0,6V and 10V

0 ⇒Open contact (impedance ≥3.3 kΩ)

Voltage between 16V and 30V

The logic inputs are referenced to the same potential and galvanically isolated from all the

other potentials at 500 Veff.

We advise you to connect the logic inputs with shielded cables.

3.6. Standard outputs (Relays 1 and 2)

The units has in standard 2 relays (250 Vac or 30 Vdc, 1 A). The internal protection networks allows a

leakage current of 1 mA for 250 Vac.

If these relays are used to commute some inductive charge, we advise you to add some RC networks

to the charge terminals (preferably) or to the contacts terminals. They will then lessen the electro-

magnetical phenomena.

3.7. Viscosity current output (slot n°4)

It is a 4-20 mA or a 0-20 mA current output. The output resolution is 12 bits. The maximum load

resistance is 750 Ω.

It is isolated from the rest of the device up to 500 Vac. Accuracy : ±0,1%. See § 3.11 for the

connections.

WARNING : The current output must not be connected to any external power supply. In this

case, the current output will be damaged.

3.8. Supervisor digital RS

MODBUS SLAVE Protocol RS485/422 (2 or 4 wires) Baud rate from 300 to 19200 bauds.

Technical Manual MIVI 8001

Ref. 128-41/5 17

3.9. Watchdog

The device owns a system that controls the functioning of the microprocessor board. When it is

wrong, the corresponding output is de-energized (contact opening) and the “watchdog” light on the

front panel is on. When everything is OK, this output is energized (the contact is present).

The watchdog output is a relay type one (250 Vac, 1 A). The internal protection networks allow a

leakage current of 1 mA for 250 Vac.

3.10. Option outputs (slots N° 1 to 3)

3 option slots are available and accept all the boards described below :

3.10.1. 1 relay output board

The output relay is a changeover one.

Power cut-out : 1 A, 250 Vac or 30 Vdc.

3.10.2. 2-relay output board

The output relays are normally open at rest with a common point.

Power cut-out : 1 A, 250 Vac or 30 Vdc.

3.10.3. 2- safety relay output board

Identical to the 2-relay output board, but a security avoids the two contacts to be simultaneously

activated, even the two relays are driven this way.

3.10.4. Current output board

It is a 4-20 mA or a 0-20 mA current output. The output resolution is 12 bits. The maximum load

resistance is 750 Ω.

It is isolated from the rest of the device up to 500 Vac.

Accuracy : ±0,1%.

WARNING : The current output must not be connected to any external power supply. In this

case, the current output will be damaged.

3.10.5. Voltage output board

It is a 0-5 V, 1-5 V, 0-10 V or 2-10 V voltage output. The output resolution is of 12 bits. The output is

protected against the short-circuits, 35 mA max.

It is isolated from the rest of the device up to 500 Vac.

Accuracy : ±0,1%.

3.10.6. RS485/422 or RS232 board

− MODBUS SLAVE Protocol RS485/422 (2 or 4 wires) Baud rate from 300 to 19200 bauds.

− MODBUS SLAVE Protocol RS232 (3 wires) Baud rate from 300 to 19200 bauds.

Don't use RS232 and RS485 simultaneously (see § 6.6.3)

Technical Manual MIVI 8001

Ref. 128-41/5 18

3.11. Connections

Inputs wiring

Slots wiring : Example SLOT1

Volt , mV

mA DC

50

0.1%

P

Pt100 ohms

P

U < 5V

P

Resistance

integrated to

the connection

Digital RS 485

mA / V

+

-

0

RTX-RTX+

RELAY 4

RELAY 3

C

R

T

C

T

T

RELAY 4

43

42

41

1 relay board 2 relays board Voltage board

Current board RS485 board

P

P

P

V5

V2

V1

P

Watch dog

21-60Vac dc

1

2

3

4

5

6

7

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

8

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

V6

Relay 1

Relay 2

REL.3

REL.4

SLOT 1

+

-

REL.5

REL.6

SLOT 2

+

-

REL.7

REL.8 SLOT 3

+

-

Relays 1 and 2 Common

EL3

EL4

EL5

24 Volts 100mA

4 sensors power supply

RX-

RX+

0

RS485 2/4 wires

TX-

TX+

49 50 51 52

Neutral / V-

80..264Vac

2 wires wiring :

Connect Tx+ to Rx+

Connect Tx- to Rx-

P

P

P

V5

V2

V1

P

optional

1

2

3

4

5

6

7

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

8

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

V6

REL.3

REL.4

+

-

REL.5

REL.6

+

-

REL.7

REL.8

+

-

EL4

EL5

24 Volts 100mA

RX-

RX+

0

TX-

TX+

49 50 51 52

CIVI

MIVI

Standard current

output (viscosity)

SLOT 4

Galvanic insulation

V1 and V2 in option

Optional current

output (temperature)

Technical Manual MIVI 8001

Ref. 128-41/5 19

RS422/485 Wiring

The braid of the shielded cable can be connected to the earth of each network is correctly meshed.

To improve the site equipotentiality, you may have to connect each device with a 2,5 mm² cable.

The polarizations are performed with 5 kΩresistances (at 5 Volts for the + and at 0 for the -).

Then, you have to set the jumpers as shown above. On delivery, the polarizations are not performed.

ST6 :Polarization RX-

ST5 :Polarization TX+

ST7 :Polarization RX+

SLOT3SLOT1

ST4 :Polarization TX-

SLOT 2

MASTER

SLAVE

FIRST

BUS RS485 5 WIRES

MASTER

SLAVE

FIRST

BUS RS485 3 WIRES

Tx+ Tx-

SLAVE

LAST

Tx+ Tx-Rx+ Rx- 0V

120

120

120

SLAVE

LAST

0V

5v 0V

5K 5K

0V

5K

5V

5K

0V

5K

5V

5K

shielded cable shielded cable

shielded cable

120

Equipotential connection

Equipotential connection

120

Rx+ Rx+ Rx+

Tx+ Tx- 0V

Rx+ Rx+

Tx+ Tx- 0V

Rx+

Tx+ Tx-Rx+ Rx- 0V

120

Tx+ Tx- Rx+

Rx-

0V

Technical Manual MIVI 8001

Ref. 128-41/5 20

Connection advises :

The casing earth and the neighbor grounds must be connected between each other through short

links and strong sections (big cables).

To secure a good on site equi-potentiality, you have to multiply the interconnections (ground

meshing).

Separate if possible the relay zones from the signals processing zones.

All the analog and logic signals must be connected with a standard leaked cable (twisted internal

wires and leakage with metallic braid).

3.12. General information

List of the device generic standards :

Security EN 61010-1 Insulation zones : 250 Vac

CEM Immunity

EN 50082-2 Electro-statical discharge

Radio-frequency

Burst quick transients

CEM Emission EN 50081-1 Radio-frequency

Process variable CEI 584

CEI 751

Thermocouples

RTD

MODBUS digital RS CNOMO E04.80.130.N

April 1995

Communication with supervisor

Control CNOMO E04.81.125.N

July 1995

Controller of physical variable cascade

or dual-loop

Protection CEI 529 IP 54 on front panel and IP 20 on the

rear panel

Size CEI 473 Front panel : 72 * 144 mm

Cut-out : 68 * 138 mm

Mechanical sturdiness EN 60068-2-32 Fall : 0.5 m

Climatic conditions Storage -20 to 70°C

5 to 95% HR without condensation

Work 0 to 50°C

5 to 90% HR without condensation

Table of contents

Other Sofraser Measuring Instrument manuals