ThermoKey EPS User manual

MT TC R EPS GEN 03 2018

Technical Manual – TC

Manuel Technique – TC

Manuale tecnico – TC

EPS

Adiabatic Evaporative Panel System

EPS

Système adiabatique

« Evaporative Panel System »

EPS

Sistema adiabatico a pannelli per V-Type

THE ORIGINAL VERSION OF THESE

INSTRUCTIONS IS IN ITALIAN

EN

IT

FR

EN TECHNICAL MANUAL – TC

IT MANUALE TECNICO – TC

FR MANUEL TECHNIQUE – TC

LANGUAGES SUMMARY

04

31

58

03MT TC A DF GEN 04 2017

Technical Manual TC

EPS

Adiabatic Evaporative Panel System

THE ORIGINAL VERSION OF THESE

INSTRUCTIONS IS IN ITALIAN

EN

MT TC R EPS ENG 03 2018

MC TC R EPS ENG 03 2018 MC TC R EPS ENG 03 2018

Technical Manual TC Instruction and technical data

CAREFULLY READ AND ENSURE YOU HAVE FULLY UNDERSTOOD ALL

OF THE INFORMATION CONTAINED IN THIS MANUAL PRIOR TO

THE DESIGN, AND IN ANY CASE PRIOR TO CARRYING OUT ANY

OPERATIONS OF HANDLING, UNPACKING, MOUNTING, POSITIONING,

AND COMMISSIONING OF THE MODULE. THE MANUFACTURER ACCEPTS

NO RESPONSIBILITY FOR DAMAGE TO PERSONS OR PROPERTY RESULTING

FROM THE FAILURE TO FOLLOW THE INSTRUCTIONS CONTAINED HEREIN.

The original version of this manual is in Italian, and it is available on the website:

www.thermokey.com.

The English translation is a true copy of the original document and it is available on the website:

www.thermokey.com.

Translations in other languages may contain errors; if in any doubt, always refer to the original

version in Italian or to its translation in English.

The Quality Management System of Thermokey, in compliance with ISO 9001, is certified

by TÜV, while the Environmental Management System, in compliance with ISO 14001,

and the Safety Management System, in compliance with OHSAS 18001, are certified by IMQ.

EN

Heat Exchange Solutions

MC TC R EPS ENG 03 2018 MC TC R EPS ENG 03 2018

ThermoKey Technical Manual TC Instruction and technical data

08

EN

TC 1. Regulatory references

The product described in this manual is compliant with:

MACHINERY DIRECTIVE 2006/42/EC

LOW VOLTAGE DIRECTIVE 2014/35/EU

ELECTROMAGNETIC COMPATIBILITY DIRECTIVE 2014/30/EU

PED DIRECTIVE 2014/68/EU

ERP DIRECTIVE 2009/125/EC

Danger of electrocution. e product is in contact with models equipped with electric fans and control panels and may be

equipped with electrical components with a three-phase or single-phase operational nominal low-voltage. e power supply

lines must be tted with protection systems against electric shock and equipment earthing devices as required by law.

Risk of burns. e evaporative module is an accessory of a product with unprotected headers. e surfaces of the collectors can

reach high temperatures.

Risk of cutting. In addition to the heat exchanger, an integral part of the model, which consists of metallic fins with

unprotected sharp edges, the shell casing of the evaporative module is made of sheet metal components that may in some

points present unprotected sharp edges.

Danger of moving parts. The evaporative module is an accessory to a product equipped with electric fans fitted with a

protective grid, as provided by law. For some products it could be possible to deliberately access moving parts (motor fan

blades) from unprotected areas. Before any access, ensure that moving parts do not constitute a hazard to operators.

Danger of crushing limbs or persons. During all the phases of handling, transportation, installation, operation, and

maintenance, pay maximum attention to the indicated weight of each product to avoid them tipping over or falling

dangerously onto operators.

Danger of falling objects. e products are supplied with doors, tanks, or sheet metal linings that may be dismounted during

installation or maintenance operations by removing the fastening screws supplied, taking the appropriate safety precautions.

TC 2. Hazards

TC 3. Instruction

TC 3.1

Contents of the Technical Manual of the Product:

GENERAL INSTRUCTIONS FOR SAFE USE (I.G.)

INSTRUCTIONS FOR HANDLING AND UNPACKING (I.M.)

INSTRUCTIONS AND TECHNICAL DATA (T.C.)

SPECIFIC INSTRUCTIONS FOR USE AND MAINTENANCE (I.S.)

TC 3.2

This manual constitutes the TC section, denominated as INSTRUCTIONS AND TECHNICAL DATA, of the Technical

Manual of the product. For any information not covered in this manual refer to the other sections (IG-IM-IS), and if

in doubt contact the Manufacturer.

TC 3.3

is manual is an integral part of models equipped with the EPS evaporative panel system, and as such must be retained

throughout the operational life of the product.

TC 1. REGULATORY REFERENCES

TC 2. HAZARDS

TC 3. INSTRUCTIONS

TC 4. INTENDED USE

TC 5. INSPECTION, HANDLING, AND TRANSPORT

TC 6. INSTALLATION AND COMMISSIONING

TC 7. EPS SYSTEM BASE EQUIPMENT (STANDARD OPTION)

TC 8. GENERAL MAINTENANCE AND CONTROL

TC 9. EPS EQUIPMENT WATER SUPPLY CHARACTERISTICS

TC 10. MOUNTING THE LOWER CASING PANELS OF THE PLENUM

(IF SUPPLIED SEPARATELY)

TC 11. MOUNTING OF SUPPORTS FOR EPS MODULES

TC 12. MOUNTING OF EPS MODULES

TC 13. MOUNTING OF PIPING (IF SUPPLIED AS A KIT)

TC 14. WATER PANEL DISTRIBUTOR (STANDARD OPTION)

TC 15. DIMENSIONS OF EPS EVAPORATIVE MODULE

TC 16. RECIRCULATION TANK KIT (SPECIAL OPTION)

TC 17. OPERATIONAL GUIDELINES

TC 18. DISPOSAL AND RECYCLING

SUMMARY

07

08

08

09

09

11

13

16

18

19

21

22

24

27

28

29

31

32

07

Heat Exchange Solutions

MC TC R EPS ENG 03 2018 MC TC R EPS ENG 03 2018

ThermoKey Technical Manual TC Instruction and technical data

10

EN

09

TC 3.4

Any additional technical documentation relating to non-standard products is attached to this manual, becoming an

integral part of it, and is identified with a specific code indicated on the shipping documents.

TC 3.5

The product described in this manual is considered an accessory. It is therefore not usable as supplied but as a

component for air conditioning and refrigeration systems, and must be installed and commissioned only by qualified

operators (see chapter on installation and commissioning).

TC 3.6

Every component is CE marked, where required by the relative legislation.

TC 3.7

Further documentation relating to the product, consisting of catalogues, guide, and technical bulletins, is

provided directly by ThermoKey, available on the website www.thermokey.com.

CATALOGUES – http://www.thermokey.com/Cataloghi.aspx

MANUALS – http://www.thermokey.com/Manuali.aspx

TC 4. Intended use

TC 4.1

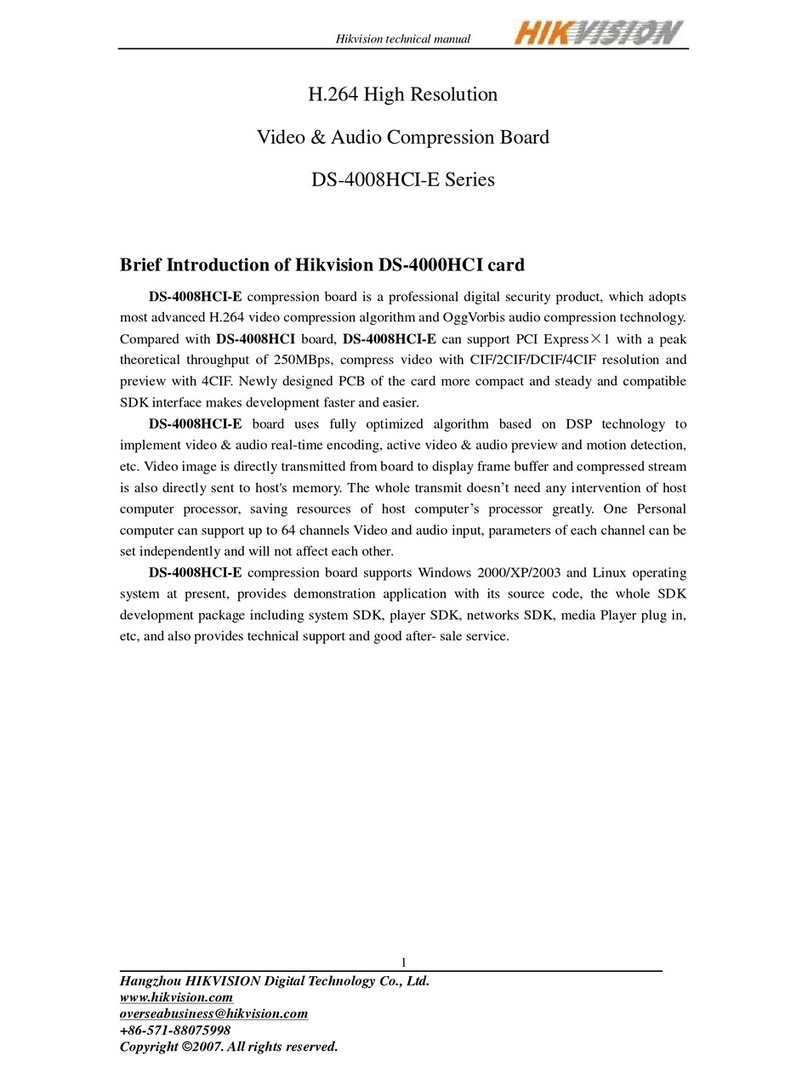

The adiabatic evaporative panel modules (EPS) must be used exclusively for the purpose indicated below. Any other

use is considered improper and exempts the Manufacturer from any and all liability.

TC 4.2

The EPS system is designed to be used as an accessory on coolers, condensers, and gas coolers of the V-type series,

in all refrigeration and air conditioning applications. The system is composed of evaporative panels that, using water,

enable an increase in the specific capacity of the process heat exchangers.

TC 4.3

If in any doubt regarding the intended use of the product, contact the Manufacturer.

TC 5. Inspection, handling and transport

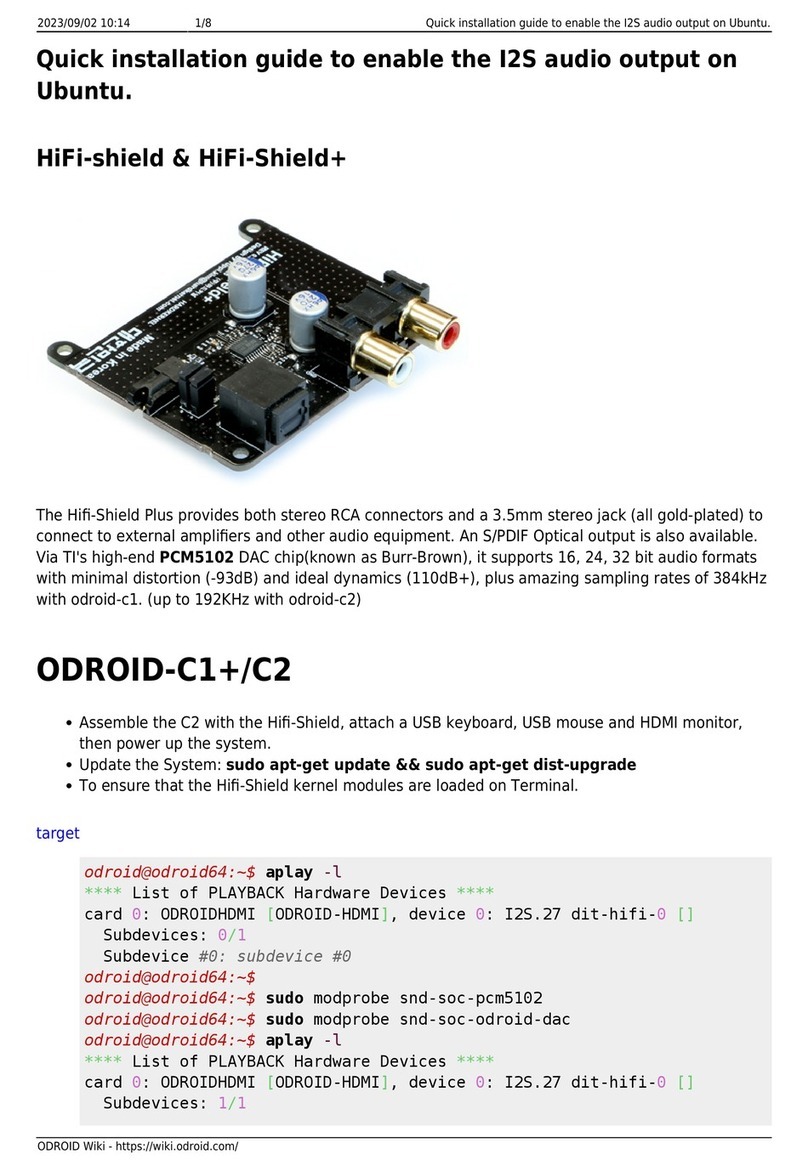

TC 5.1

The components of the EPS system are shipped in a mounting kit. The modules of adiabatic evaporative panels come

already pre-assembled (see fig.1).

TC 5.2

Upon receipt of the kit, check the integrity of the packaging and of the product, immediately notifying the transporter

of any damage that occurred. The packaging is made in accordance with the model and the appropriate means of its

transportation and handling.

TC 5.3

During the transportation and handling of the packed product, take care to avoid any excessive and improper stress on

the packaging, and follow all the indications given on the packaging, always keeping the model in the prescribed position.

TC 5.4

During the transportation and handling of the packed product, use appropriate means of protection to avoid any

injury from the parts of the packaging, such as nails, boards, or cardboard, or from any component parts of the model

itself, such as the metal casing (see DPI Technical Manual, section I chapter IG.6).

TC 5.5

Unpack the kit in a location as close as possible to the installation site (see also the chapter on installation and commissioning).

In general, the product should not be transported or handled without its original packaging.

TC 5.6

During the handling of the unpacked modules and components for installation, use appropriate means of protection to avoid

any injury from sharp edges, such as the metal casing (see DPI Technical Manual section I chapter IG.6).

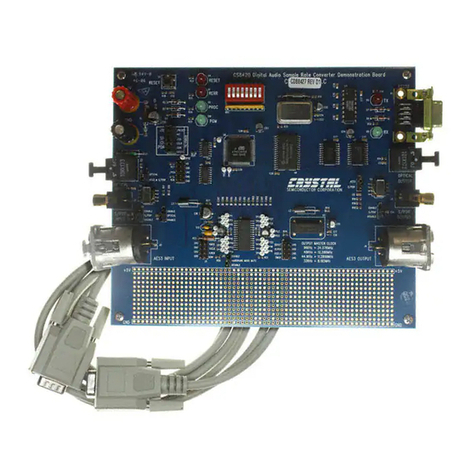

Fig.1 Pre-assembled adiabatic evaporative panel module

Heat Exchange Solutions

MC TC R EPS ENG 03 2018 MC TC R EPS ENG 03 2018

ThermoKey Technical Manual TC Instruction and technical data

1211

EN

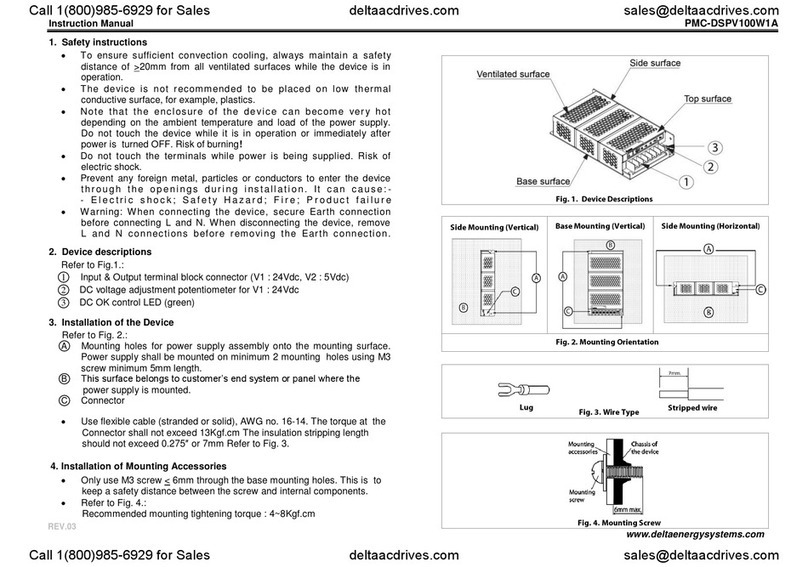

TC 6.1

The installation and commissioning of the modules and the piping of the EPS system must be performed by qualified

and experienced personnel. Follow the diagrams and instructions for assembly (see fig. 2, 3).

TC 6.2

Fasten the components to all the points provided for using the screws supplied in the kit (see the chapter on mounting

instructions).

TC 6.3

e modules determine an additional static pressure to the ventilation of the model on which they are installed. For

proper air circulation, verify that there is an adequate guaranteed volume and passage of air in the area of installation

that conforms to the airow characteristics of the model. If this is not the case, the declared performances cannot be

guaranteed, and operating defects may arise. Be careful not to obstruct either the air intake or the discharge of the fan

motors and the heat exchanger.

TC 6.4

The modules are not designed to support additional loads. The water distribution piping to the modules is protected

with metal casing. It is not permitted to walk on the upper metal casing of the modules or the piping protection. Care

must be taken during any maintenance operations that require workers to walk on the model (e.g. for the replacement

of fan motors).

TC 6.5

Check that the water supply network is adequate to meet the flow rate and pressure required.

The EPS system is designed for connection to the public water supply network.

TC 6.6

Before connecting the components, verify the presence of shut-off and sectioning devices on the power supply line,

protection against electric shock, protection of the equipment, and anything else required by current legislation.

The modules are mounted on models fitted with electric fans and possibly electrical control panels, and may be

equipped with low-voltage electrical components such as solenoid valves.

TC 6.7

Access to the installed model, for any type of intervention, must be reserved to personnel who are qualified and

experienced to run the system, according to current regulations.

TC 6. Installation and commissioning

Fig.3 General diagram for connection of the water supply to the EPS system

Fig.2 General diagram for mounting of EPS modules

Heat Exchange Solutions

MC TC R EPS ENG 03 2018 MC TC R EPS ENG 03 2018

ThermoKey Technical Manual TC Instruction and technical data

1413

EN

TC 7. General maintenance and control

TC 7.1

EPS module assembly kit

Stainless steel removable modular frame, treated cellulose evaporative panels, water distributor with full cone

nozzles, modular drip tray and drain pipes with fittings type Geberit Silent-PP, drain pipes resistant to low and

high temperatures, drain pipes resistant to ultraviolet rays and resistant to aggressive substances with EPDM

lamellar seals pre-assembled. Openable top covers for nozzles cleaning. Easy fit nozzles (see fig.es 4 and 6).

TC 7.2

EPS model covering panels

FeZn vertical panels painted RAL7035, FeZn plenum closing panels (preassembled, see fig.5), FeZn modules supports

and FEZN mounting brackets painted RAL7035. Stainless steel screws.

TC 7.3

EPS water distribution piping

HD polyethylene pipe, brass fittings, flexible stailess steel connection pipe, FeZn pipe fixing brackets painted RAL7035

(preassembled, see fig.5). FeZn pipe cover protection panels painted RAL7035. Stainless steel screws.

TC 7.4

Water supply connection

HD polyethylene pipe, brass fittings, ramp manual balancing valves type DANFOSS, solenoid main valve type

DANFOSS, solenoid drain valve type CASTEL (preassembled, see fig.5). Mounting brackets. Stainless steel screws.

Fig.4 Detailed view of discharge side and internal side

of the xing strip

g.5.1 - Factory pre-assembling JV MODELS

g.6.1 - Assembling by the installer JV MODELS

Heat Exchange Solutions

MC TC R EPS ENG 03 2018 MC TC R EPS ENG 03 2018

ThermoKey Technical Manual TC Instruction and technical data

1615

EN

g.5.2 - Factory

pre-assembling SJ MODELS

g.6.2 - Assembling

by the installer SJ MODELS

(VERTICAL SYSTEM)

g.6.3 - Assembling

by the installer SJ MODELS

(SLANTED SYSTEM)

TC 8 . General maintenance and control

TC 8.1

Before performing any maintenance work ensure that the power supply of the model has been sectioned: the

electrical parts may be connected to automatic controls. All maintenance work should be performed by qualified

and experienced personnel.

TC 8.2

The EPS system principally consists of: the evaporative modules, composed of a supporting frame in stainless steel,

a treated cellulose panel, a cross connection water distribution, high density polyethylene piping for connection to the

water supply, high density polyethylene piping for connection to the wastewater network, and a discharge pipeing UV

resistant polypropylene.

TC 8.3

Periodically check the fixing points of the module, the water supply and wastewater connections, and the electrical

connections that are found in the required equipment configuration.

TC 8.4

The modules of the EPS system are removable for possible winter storage. Consider, in line with climatic conditions,

storing modules during prolonged periods when the adiabatic system is not in use, in order to increase the operative

lifetime of the panels. During storage, keep modules in a dry place, protected from dust and direct sunlight, possibly

by reusing the original packaging.

TC 8.5

The module frame can be completely disassembled for the programmed replacement of the evaporative panel.

The efficiency and lifecycle of the panel material is determined by the mineral characteristics of the water used, the

air intake, and the amount of use and possible storage.

TC 8.6

To obtain an optimal operation, the flow of air must be as uniform as possible across all areas of the panel. This has an

influence on both the effectiveness of the panel and on the operation of the machine (the vertically mounted panels

make the most of this condition). It is advisable to make periodic checks to prevent or remove obstructions to the

passage of air.

TC 8.7

Provide for the inspection and periodic cleaning of the evaporative panel. The correct passage of air and the wettability

of the panels must always be ensured. Not doing so may compromise the operative efficiency of the adiabatic system,

with a consequent reduction of the performance expected when selecting the product. Perform at least one daily

water-wash cycle and one drying cycle of the panels (see chapter on practical conditions of use). Replace the panels

when there is an obvious deterioration or when cleaning is no longer effective (5% of the front surface of the panel).

The performance of the heat exchanger is guaranteed only with panels supplied by ThermoKey.

TC 8.8

Clean the evaporative panels with a soft bristle brush, and then run a cleaning cycle using fresh water.

Heat Exchange Solutions

MC TC R EPS ENG 03 2018 MC TC R EPS ENG 03 2018

ThermoKey Technical Manual TC Instruction and technical data

1817

EN

TC 8.9

Provide for the periodic inspection and cleaning of the water distribution system. Do not use aggressive detergents,

solvents, acid or alkaline solutions containing chlorine or ammonia, or abrasives in general. If sanitising agents must be

used, check their compatibility with the materials first. The nozzles are removable for programmed cleaning, and can

be washed with substances suitable for removing the deposited limescale. If in any doubt, contact the Manufacturer.

TC 8.10

The frequency of inspection and maintenance operations is dependent on the environmental characteristics and on

the specific characteristics of the feed water and any treatments used, and therefore must be defined on an individual

basis.

TC 8.11

To guarantee the maximum efficacy of the EPS system, check that the operating parameters, namely the measurements

of relative humidity, ambient temperature, and air output temperature from the panel conform to the expected

characteristics of the product selected.

TC 8.12

If proceeding with the replacement of worn panels, contact the Manufacturer for replacement materials.

TC 8.13

Provide for the checking of the chemical and microbiological parameters of the water used in the EPS system

before every period of operation, and programme the frequency of inspections so as to maintain the characteristics

required (see chapter on characteristics of the water).

TC 8.14

For any operation on the product not described in this manual, contact the Manufacturer.

TC 8.15

For the cleaning of the heat exchangers see the technical manual IS.

TC 9. Practical conditions of use

TC 9.1

The water used for the adiabatic system with evaporative EPS panel does not require specific treatments. However,

for a longer lifespan and more efficient operation of the evaporator panel and reduction of maintenance work, it is

suggested to use water with the characteristics indicated in the table.

REFERENCE WATER PARAMETERS FOR EPS SYSTEM

pH (@25°C) 6.5 ... 8.0

Total hardness 3.5 ... 4.0 °d (1°d = 17,85 ppm CaCO3, 1°f = 10mg/l = 10 ppm

CaCO3)

El. Conductivity (@25°C) < 1500 mS/cm

Chlorides < 50.0 mg/l

Sulfates < 90.0 mg/l

Nitrates < 50.0 mg/l

Silicon < 20.0 mg/l

Iron dissolved < 0.1 mg/l

To avoid spontaneous corrosion and/or incrustation, the Langelier saturation index (IL) and the

Ryznar stability index (IR) should be within the following range: IL -1 ... +1 / IR 5.5 ... 6.6

TC 9.2

Water shared by the common water network or water derived from other water resources can be used, possibly to

be treated appropriately with the expectations of material durability and cost of treatment, but measures must be

taken for all chemical and microbiological parameters directly related to health in compliance with the current

legislation and Directive 98/83 / EC. In accordance with what is stated in the use and maintenance manual, the

Thermokey Adiabatic Evaporative System is in compliance with the requirements of VDI 2047-2.

TC 9.3

The feed water should never get down below the minimum level of pH 5 and overcome the maximum level of pH 9,

in order to avoid problems of chemical aggression to the panels. Water hardness should never exceeding 250 ppm

CaCO3. In the event that the system is configured to recirculate the water, purging cycles should be performed in

order to prevent the salinity level exceeding the acceptable limits.

TC 9.4

The installer must ensure that the treatments and chemical substances added, in order to respect the parameters

indicated, are compatible and do not cause any corrosion and damage to the materials used in the module. If necessary,

the water used must be conditioned by the addition of suitable inhibitors of corrosion and incrustation

TC 9.5

Do not routinely add oxidising agents to the feed water as this can create problems for the cellulose sheet of

the panel. If necessary, endeavour to use them only in minimal quantities: max 1 ppm in the case of continued

treatment, or max 5 ppm in the case of a one-time treatment.

Heat Exchange Solutions

MC TC R EPS ENG 03 2018 MC TC R EPS ENG 03 2018

ThermoKey Technical Manual TC Instruction and technical data

2019

EN

TC 10. Mounting the lower casing panels

of the plenum

TC 10.1

Preliminary operations. Position and fix the base of the model to the relative support structure or floor, and proceed

with the disassembly of the longitudinal handling and transportation spars (see fig.7), to allow the positioning of the

respective lower casing panels. The spars are all the same, and are fastened with M10 bolts. After having positioned

and fastened the lower casing panels, reassemble the spars (the longitudinal spars are provided for the handling and

transport of the model).

TC 9.6

Warning! Do not use hot water for feeding or for cleaning, but water at ambient temperature (T max <20°C).

TC 9.7

The values of the water must be tested during the commissioning of the adiabatic system by qualified personnel,

and subsequently verified in accordance with the standards in force and the frequency scheduled for the specific

application and also of measured values. The results must be documented and recorded. If during the monitoring,

the values of the water are found to be non-compliant with the requirements, spraying must be stopped for all the

chemical and microbiological parameters directly related to health and appropriate remedial actions undertaken.

The evaporative panels are the consumable material of the adiabatic system, ThermoKey reserves its warranty

intervention.

g.7 - Longitudinal handling and transportation spars

TC 10.3

Positioning the lower panel. Position all of the panels in their respective plenum, resting them between the base crossbeams,

see g.9. e panels are all the same.

TC 10.4

Fixing the lower panel. Fixing all of the panels in their respective plenum, using the screws supplied (2 x M6 screws

with rosette for each panel). The panels are all the same.

TC 10.2

Preparing the lower casing panel of the plenum. Apply approximately 1m of polyurethane strip (roll supplied) on

each panel, see fig.8.

g.8 - Polyurethane strip positioning

g.9 - Lower panel positioning

g.10 - Panel xing

Heat Exchange Solutions

MC TC R EPS ENG 03 2018 MC TC R EPS ENG 03 2018

ThermoKey Technical Manual TC Instruction and technical data

2221

EN

TC 11.2

Positioning and fastening the vertical headboard panels. Two vertical panels must be fixed to each headboard panel

(one on the right and the other on the left), to enclose the EPS modules. Fasten the panels with the screws supplied (3

nos. M8 screws with rosette for each panel).

TC 11. Mounting of supports for EPS module

TC 11.1

Positioning and fastening the base supports of the EPS module. Position and fasten each bearing support of the EPS

module, as shown in the two photos. The supports are all the same, and are fixed to the headboard panels of the base

crossbeams. Fasten them with the screws supplied (4 nos. M6 screws with washer for each support), first on one side

and then the other.

g.11 - Pre-xing the rst side g.12 - Pre-xing the second side

g.13 - Vertical panel g.14 - Fastening internal screws

Proceed with the positioning of all the EPS modules and the fastening of the respective rear fixing bars.

The EPS modules are all the same. It is advisable to tighten the mounting screws last to recover backlash.

TC 12. Mounting of EPS module

TC 12.1

Positioning and fastening of EPS modules. Position the modules on the base supports, also making sure that its rear

fixing bar is resting on the upper part of the model. Fasten the rear bar to the model using the screws supplied (2 nos.

M6 screws with rosette for each module). Each bar is fixed to its module with screws, and is therefore adjustable for

the recovery of backlash. Start the positioning sequence from the headboard panel of the model.

g.15 - Placement on the lower supports

g.17 - Mounting sequence

g.16 - Upper xing bar

Heat Exchange Solutions

MC TC R EPS ENG 03 2018 MC TC R EPS ENG 03 2018

ThermoKey Technical Manual TC Instruction and technical data

2423

EN

TC 12.2

Mounting the lower platelets. Proceed with the mounting of the lower fixing platelets of the EPS module to the base

crossbeams using the screws supplied (4 nos. M6 screws with rosette for each plate). The lower platelets are all the same.

TC 12.3

Mounting the upper platelets. Proceed with the mounting of the upper platelets of the EPS between the EPS modules

and between the modules and the vertical headboard panels, using the screws supplied (4 nos. M6 screws with rosette

for each plate). The upper platelets are all the same.

TC 13. Mounting of piping

(If supplied as a kit)

TC 13.1

Positioning and fastening of piping brackets. Proceed with the mounting of the brackets for fastening the vertical

pipes of the water supply piping on the vertical headboard panels using the screws supplied (2 nos. M6 screws with

washer for each bracket). The brackets for the left and right vertical panels are the same.

Proceed with the mounting of the brackets for the fastening of the horizontal distribution piping to the EPS

modules on the upper casing of the module, using the screws supplied (2 x M6 screws with washer for each bracket).

The brackets for the upper covers for the right and left cylinder bank are the same.

Brackets position view

Heat Exchange Solutions

MC TC R EPS ENG 03 2018 MC TC R EPS ENG 03 2018

ThermoKey Technical Manual TC Instruction and technical data

2625

EN

TC 13.2

Water distribution piping to the EPS modules. Connect the intermediate sections of the polyethylene tube with a

TEE fitting and the final ones of the two ramps to the elbow fitting, supplied. Each fitting has a threaded 1” 1/4 GAS

diameter outlet for feeding each module using the reducer and the flexible stainless steel 1/4” GAS fitting for the

connection to the distribution cross connection of the EPS module, also supplied.

Fasten the pipes thus prepared to the respective upper fixing brackets using the U-bolts supplied.

For the sealing of the threaded fittings (excluding the removable ones equipped with their own seals) it is recommended

to use a sealant such as LOCTITE 577, or equivalent.

TC 13.3

Piping connection to the water supply network/tank. Fit the manual or automatic balancing valves to the distribution

ramps (right bank and left bank). The valves are supplied in the kit. Complete the connection piping using the pipe

sections and the elbow fittings supplied. Fix the pipes with the U-bolts.

Water distributor module/ramp connection view

Ramp piping view

U-bolt pipe xing view

Ending ramp view

Mount the support brackets of the connection group. The connection group of the feed piping coming from the

water supply network is designed with a reducer fitting for polyethylene 40mm diameter pipe, or a threaded 1” 1/4

connection for attachment directly to the input filter. A solenoid valve with 1/2” threaded attachment is supplied in

the kit to use for the possible piping discharge command.

Ramp piping view

Water supply connection group view

Ending ramp view

Heat Exchange Solutions

MC TC R EPS ENG 03 2018 MC TC R EPS ENG 03 2018

ThermoKey Technical Manual TC Instruction and technical data

2827

EN

TC 13.4

Upper protection covers. Havingcompletedtheinstallation

of the piping, fasten the upper pipe protection covers, using

the screws supplied (2 x M6 screws with rosette for each

cover). Te protective cover is provided to protect the pipes

and for the safety of operators during possible maintenance

operations to the upper part of the model.

TC 13.5

Discharge pipes. The modular discharge system consists

of Geberit Silent-PP pipes and couplings, resistant to low

and high temperatures, resistant to ultraviolet rays, and

resistant to aggressive substances, and pre-assembled

lamellar seals in EPDM. Connect the discharge pipes and

the couplings supplied in the kit.

TC 14. Cross connection of water distribution

(Standard option)

TC 14.1

The water distribution system of each module consists of a cross connection in copper piping with brass attachments

complete with Lechler full cone nozzles, for an adjustable flow rate pressure of between 0.5 and 2 bars. In practical

terms, the flow rate can be varied from a minimum of 2 /min up to a maximum of 6 /min for each evaporative panel,

if a water flow regulating system is used. The nozzles can be quickly disassembled for cleaning operations.

Cross connection of the module with ramp of nozzles Full cone nozzle

TC 15. Dimensions of EPS

evaporative module

Proprieta' riservata - Riproduzione

vietata a termine di legge - Copyrig

ht

THERMO KEY

HEAT EXCHANGER TECHNOLOGY

Rev.

Data

Descrizione

Description

TITOLO:

DISEGNO N.

Visto

Data

Diseg.

Scala

Vol.Int.

Peso

TITLE:

Date

Scale

Date

Check

Draft.

Int.Vol.

Weight

dm3

Diseg.

Draft.

Visto

Check.

kg

DRAWING N.

Proprieta' riservata - Riproduzione

vietata a termine di legge - Copyrig

ht

Rev.

TOLLERANZE

SECONDO NORME

UNI ISO 2768 m

Sost. il:

Replace:

Rif.cliente:

Cust. ref.:

A2

Per costruzione vedere

SC010000

- -

MODULO ADIABATICO

EPS x VJV/G

2:15 0 0.000

MB MR 21/10/16

00P1600770 00

PARTE POSTERIORE

PARTE ANTERIORE

A

B

(1:5)ADETTAGLIO

(1:5)

BDETTAGLIO

ATTACCO 1/2"

1200 PANNELLO

1800 PANNELLO

2090

1980

40 1168 40

114 1020 114

1248

1250

50 575 575 50

115 1020 115

150 PANNELLO

208

29 29

25

99100

44

60

22

42

72

110

245

39

210

40

40

110

15°

15°

20

92

130

Heat Exchange Solutions

MC TC R EPS ENG 03 2018 MC TC R EPS ENG 03 2018

ThermoKey Technical Manual TC Instruction and technical data

3029

EN

TC 16. Recirculation tank kit (Special option)

TC 16.1

The EPS system is an open system, in which the water collected in the tanks of the modules is fed into the wastewater

network. A kit is available for the transformation of the EPS system to recirculate it instead.

The recirculation kit consists of a double tank in AISI type 316L stainless steel to contain the water and the recirculation

pump. The GRUNDFOS or equivalent (non-immersed) type electronic pump and inverter, located in the pump

compartment, draws water from the water chamber to send it to the piping of the EPS system. Appropriate level gauges

regulate the filling of the tank through a solenoid valve connected to the water supply network.

Double compartment tank Side xing points for discharge solenoid valve and 1/2” oat

valve

Water intake group. Solenoid valve and oat valve for

manual lling. Water supply 1” 1/4 GAS female outlet.

Electronic recirculation pump

Electrode type level indicators Overow pipe and discharge plug for cleaning the tank

Heat Exchange Solutions

MC TC R EPS ENG 03 2018 MC TC R EPS ENG 03 2018

ThermoKey Technical Manual TC Instruction and technical data

3231

EN

TC 17. Operational guidelines

TC 17.1

The EPS system is not suitable for operation at ambient temperatures below 3°C. The system is therefore provided

with solenoid valves for the discharge of the piping and possibly of the recirculation tank when present. If the

ambient temperature falls below the limit specified the operating command is blocked.

TC 17.2

The environmental characteristics of temperature and relative humidity determine the cooling capacity of the

evaporative panels. Preset the detection of these parameters for monitoring as provided for by the design.

TC 17.3

Operation for assisting the motorised fan (or water saving): the main parameter that must determine the start up of the

EPS system, or the opening of the discharge solenoid valve, or the signal to the recirculation pump in systems with a tank,

is the reaching of a programmable temperature or process pressure that the ambient air can no longer control. Shutdown

will occur if the detected value falls below of a range that can be programmed to optimise and reduce uctuations in

operation. A control panel must manage the operation of the EPS system (e.g. the consent to the intake and discharge

valves, the possible regulation of the water ow rate, the washing cycles, the sanitisation cycles, the reading of the sensors,

the ranges of intervention, etc.). If the model is equipped with regulated motorised fans (electronic or inverter) from a

dedicated control panel, the fan motor control logic will pilot the control panel of the EPS system.

TC 17.4

Combined operation for the motorised fans (or energy saving): the EPS system can be put into operation to reduce

the temperature of the air intake in combination with the operation of the motorised fan for choking the airflow. This

function can be used on models equipped with regulated motorised fans. The main parameter that must determine

the start up of the EPS system, or the opening of the discharge solenoid valve, or the signal to the recirculation pump

in systems with a tank, is the reaching of a programmable speed of the motorised fan. Shutdown will occur if the

detected value falls below a range that can be programmed to optimise and reduce fluctuations in operation. A control

panel must manage the operation of the EPS system (e.g. the consent to the intake and discharge valves, the possible

regulation of the water flow rate, the washing cycles, the sanitisation cycles, the reading of the sensors, the ranges of

intervention, etc.) that is piloted by the control panel dedicated to the motorised fan.

TC 17.5

For the setting of the operating parameters, refer to the manual of the electric control panel of the EPS system.

TC 17.6

For the water consumption of the adiabatic system, the following parameters were defined:

MIN = theoretical water consumption referring to technical data

MID = practical working water flow (about 4 l/min of water per panel)

MAX = cleaning water flow (discretionary, about 6 l/min of water per panel)

TC 18. Disposal and recycling

TC 18.1

Disposal must be carried out by qualified and qualified personnel in accordance with the environment as prescribed

by current legislation.

FAC SIMILE

Manuale Tecnico TC

EPS

Sistema adiabatico a pannelli per V-Type

THE ORIGINAL VERSION OF THESE

INSTRUCTIONS IS IN ITALIAN

MT TC R EPS ITA 03 2018

IT

Heat Exchange SolutionsThermoKey Manuale tecnico TC Istruzioni e dati tecnici

3534 MC TC R EPS ITA 03 2018 MC TC R EPS ITA 03 2018

IT

LEGGERE ATTENTAMENTE E COMPRENDERE COMPLETAMENTE TUTTE

LE INFORMAZIONI CONTENUTE IN QUESTE ISTRUZIONI PRIMA DELLA

PROGETTAZIONE ED IN OGNI CASO PRIMA DI EFFETTUARE QUALUNQUE

OPERAZIONE DI MOVIMENTAZIONE, DISIMBALLAGGIO, MONTAGGIO,

POSIZIONAMENTO E MESSA IN ESERCIZIO DELL’APPARECCHIO.

IL COSTRUTTORE DECLINA OGNI RESPONSABILITÀ PER DANNI A PERSONE

O COSE DERIVANTI DALLA MANCATA OSSERVANZA DELLE INDICAZIONI

CONTENUTE NEL PRESENTE DOCUMENTO.

L’originale del presente manuale è in italiano, ed è reperibile sul sito internet: www.thermokey.com.

La traduzione in inglese è conforme all’originale ed è reperibile sul sito internet: www.thermokey.com.

Le traduzioni in altre lingue possono contenere errori; in caso di dubbio fare sempre riferimento

alla versione originale in italiano od alla sua traduzione in inglese.

Il sistema di gestione Qualità della ThermoKey è certificato dal TÜV in conformità alla norma

ISO 9001 mentre i sistemi di gestione Ambiente, in conformità alla norma ISO 14001, e Sicurezza,

in conformità alla norma OHSAS 18001, sono certificati da IMQ.

Heat Exchange SolutionsThermoKey Manuale tecnico TC Istruzioni e dati tecnici

3736 MC TC R EPS ITA 03 2018 MC TC R EPS ITA 03 2018

IT

TC 1. Riferimenti normativi

Il prodotto descritto in questo manuale risulta conforme alla:

DIRETTIVA MACCHINE 2006/42/EC

DIRETTIVA BASSA TENSIONE 2014/35/EU

DIRETTIVA COMPATIBILITA’ ELETTROMAGNETICA 2014/30/EU

DIRETTIVA PED 2014/68/EU

DIRETTIVA ERP 2009/125/EC

Pericolo di elettrocuzione. Il prodotto è a contatto con modelli allestiti con elettroventilatori ed eventuali quadri elettrici

e può essere corredato di componenti elettrici in bassa tensione nominale di funzionamento, trifase o monofase. Le linee di

alimentazione elettrica dovranno utilizzare i sistemi di protezione contro la scossa elettrica e di protezione dell’equipaggiamento

previsti dalla normativa vigente.

Pericolo di ustione. Il modulo evaporativo è accessorio di un prodotto provvisto di collettori non protetti, le temperature

superciali dei collettori possono raggiungere temperature elevate.

Pericolo di taglio. Oltre allo scambiatore di calore, parte integrante del modello, che è costituito da alette metalliche con

bordi taglienti, non protette, la carrozzeria del modulo evaporativo è costituita da componenti in lamiera che in alcuni

punti possono presentare bordi taglienti non protetti.

Pericolo parti in movimento. Il modulo evaporativo è accessorio di un prodotto allestito con elettroventilatori dotati

di griglia di protezione secondo quanto previsto dalla normativa vigente. Per alcuni prodotti potrebbe essere possibile

accedere volutamente alle parti in movimento (pale dei motoventilatori) da zone non protette. Prima di qualsiasi accesso

assicurarsi che le parti in movimento non possano costituire pericolo agli operatori.

Pericolo di schiacciamento degli arti o della persona. Durante le fasi di movimentazione, trasporto ed installazione,

funzionamento e manutenzione, porre la massima attenzione al peso indicato di ogni prodotto per evitare ribaltamenti

o cadute pericolose verso gli operatori.

Pericolo di caduta oggetti. I prodotti sono provvisti di porte, vaschette o lamierati di tamponamento che in fase di

installazione o di manutenzione possono essere smontate rimuovendo le viti di fissaggio previste, prendere le opportune

precauzioni.

TC 2. Pericoli

TC 3. Avvertenze

TC 3.1

Contenuto del Manuale Tecnico di prodotto:

ISTRUZIONI GENERALI PER UN USO SICURO (IG)

ISTRUZIONI PER LA MOVIMENTAZIONE ED IL DISIMBALLO (IM)

ISTRUZIONI E DATI TECNICI (TC)

ISTRUZIONI SPECIFICHE D’USO E MANUTENZIONE (IS)

TC 3.2

Questo manuale è la sezione TC denominata ISTRUZIONI E DATI TECNICI del Manuale Tecnico di prodotto.

Per qualsiasi informazione non contemplata nel presente manuale fare riferimento alle altre sezioni (IG–IM–IS) e in

caso di dubbio contattare il Costruttore.

TC 1. RIFERIMENTI NORMATIVI

TC 2. PERICOLI

TC 3. AVVERTENZE

TC 4. DESTINAZIONE D’USO

TC 5. ISPEZIONE, MOVIMENTAZIONE E TRASPORTO

TC 6. INSTALLAZIONE E MESSA IN OPERA

TC 7. ALLESTIMENTO BASE SISTEMA EPS (OPZIONE STANDARD)

TC 8. MANUTENZIONE GENERALE E CONTROLLO

TC 9. CARATTERISTICHE ACQUA DI ALIMENTAZIONE SISTEMA EPS

TC 10. MONTAGGIO PANNELLI INFERIORI DI CHIUSURA PLENUM

(SE FORNITI A CORREDO)

TC 11. MONTAGGIO SUPPORTI MODULI EPS

TC 12. MONTAGGIO MODULI EPS

TC 13. MONTAGGIO PIPING (SE FORNITO A CORREDO)

TC 14. CROCERA DI DISTRIBUZIONE ACQUA (OPZIONE STANDARD)

TC 15. CARATTERISTICHE DIMENSIONALI MODULO EVAPORATIVO EPS

TC 16. KIT VASCA DI RICIRCOLO (OPZIONE SPECIALE)

TC 17. LINEE GUIDA DI FUNZIONAMENTO

TC 18. SMALTIMENTO E RICICLAGGIO

INDICE

36

37

37

38

39

40

42

45

47

48

50

51

53

56

57

58

60

61

36

Table of contents

Languages: