Thermoline Scientific TD Series User manual

Ovens

User Manual & Setup Guide

Thermoline Scientic Equipment Pty. Ltd.

ABN 80 000 859 129

10-12 Ross Place

Wetherill Park, NSW 2164. Australia.

Phone: +61 2 9604 3911

email: [email protected]

www.thermoline.com.au

TD & TD-FM RANGE

Omron E5CC

1

Contents

General Information

4

Product Specications

5

Operating Environment

10

Drying Oven Operating Environment

10

Bench Top Location

10

Electrical Connections

11

Operating Environment Warnings

12

Setup

13

Unpacking

13

Moving

13

Castors

14

Drying Oven Location

15

Shelves

16

Inlet and Exhaust

17

Cleaning

18

Door Gasket

18

Port Hole

19

Start Up Procedure

20

Start Up Procedure

20

Loading

21

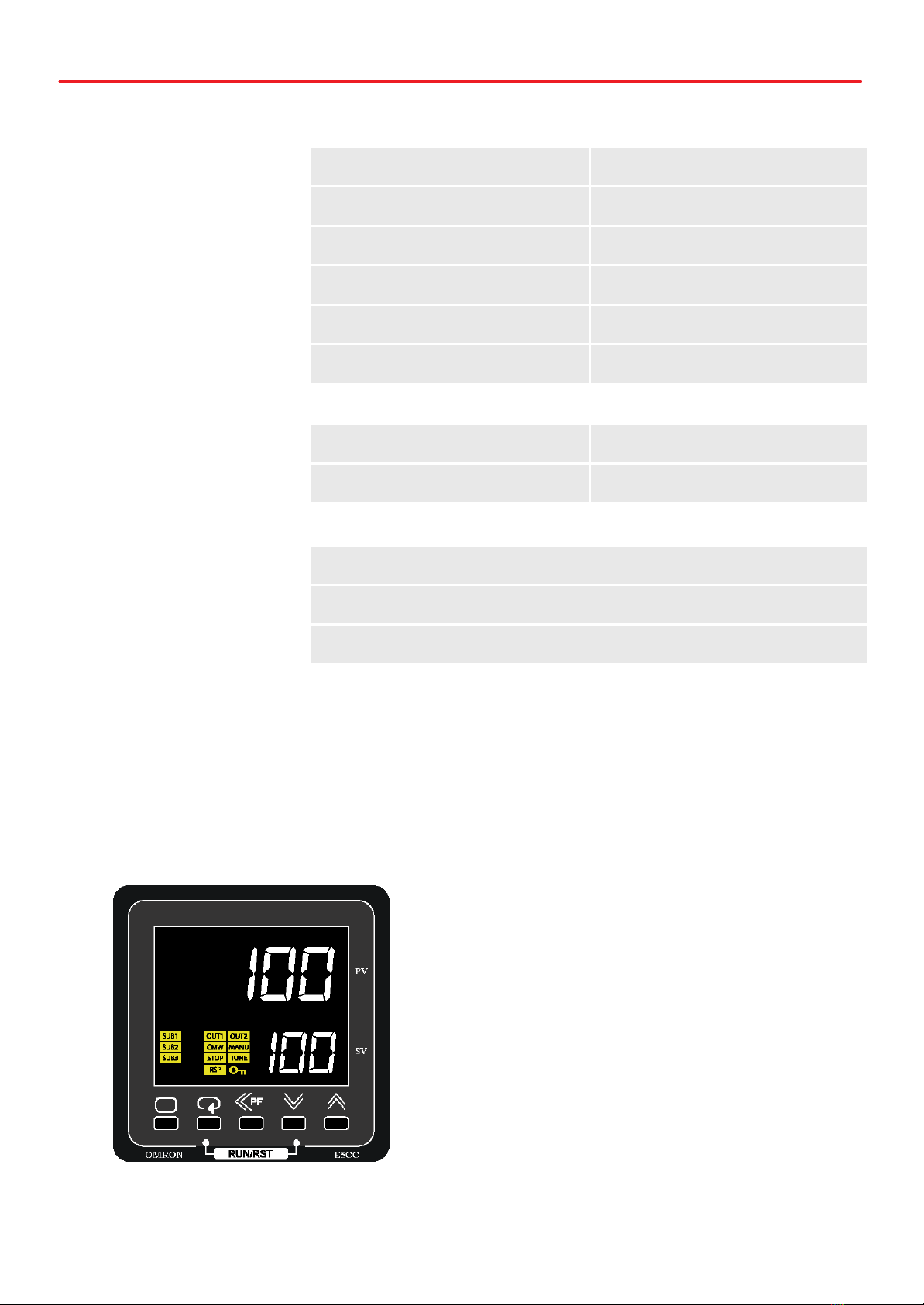

Omron User Guide

22

Display Symbols

22

Temperature Control

23

Sensor Calibration

23

BMS Output

24

Manual Reset Safety Thermostat

25

Troubleshooting

26

Technical and Repair Support

27

Warranty

28

2

Symbols Drying Oven User Manual By Thermoline Scientific

General

Warning Sign

Warning sign: signies a general warning, and indicates a risk to people specied by the supplementary sign

that if not avoided, may result in death or serious injury.

Flammable

Warning; Flammable: signies a ammable warning, and indicates a risk of ammable content as specied

by the supplementary sign that if not avoided, may result in a re by igniting ammable material.

Warning;

Electricity

Warning; Electricity: signies a electricity warning, and indicates a risk of contact with electricity as specied

by the supplementary sign that if not avoided, could result in injury.

Warning; Hot

Surface

Warning; Hot Surface: signies hot surface warning, and indicates a risk to people specied by the

supplementary sign that if not avoided, will result in contact with hot surface.

General

Prohibition Sign

General Prohibition: signies a prohibited action, indicates a risk to people specied by the supplementary

sign that if not avoided, will result in death or serious injury.

Do Not Expose

Outside

Do Not Expose Outside: signies prohibiting the exposure to direct sunlight, and indicates a raised

temperature due to sunlight or placement on hot surface can cause harmful damage to cabinet.

3

General Information Drying Oven User Manual By Thermoline Scientific

This user manual is intended for Thermoline's drying oven range. We recommend that you read this user manual the whole

way through before you start using the cabinet. Consider this manual as a part of the cabinet and an integral part to its

function. We recommend keeping it close and within easy access.

The Thermoline drying ovens 80F, 150F, 250F, 500F, 630F and

700F models are designed and manufactured to remove large

quantities of moisture from products and samples. Designed

to operate between ambient +10°C and 200°C, the Thermoline

drying oven offers an industry-standard in moisture removal.

Thermoline also offers specic macadamia models with a

reduced maximum temperature, a programmable controller

and extra shelves.

• Operating Temperature of Ambient +10°C to 200°C

• Operating Temperature of Ambient +10°C to 70°C for

macadamia models

The Thermoline range of ovens are set to function with specic

operating ranges. The optimum operating conditions will be

explained further in this manual.

4

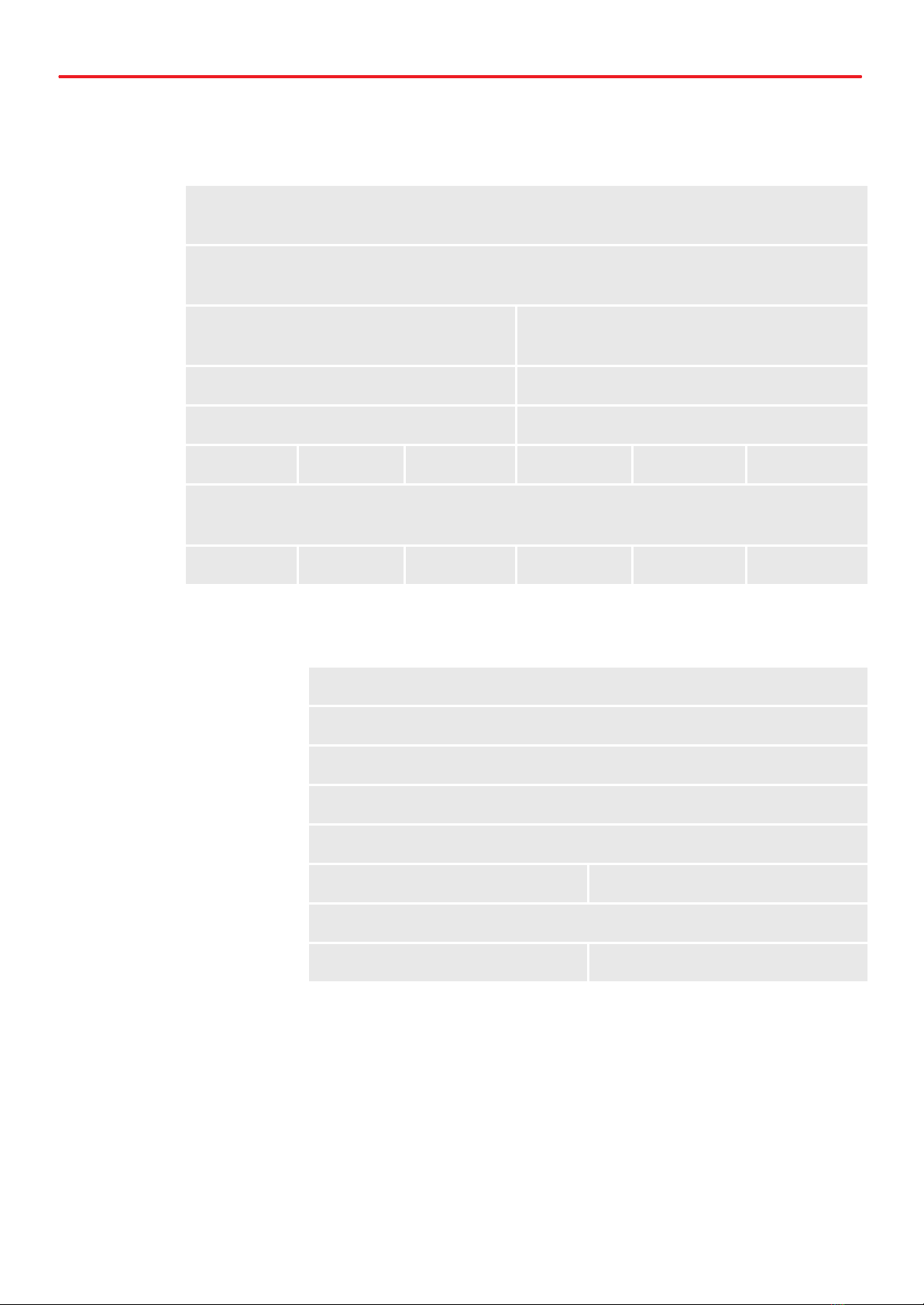

Product Specifications Drying Oven User Manual By Thermoline Scientific

Dimensions

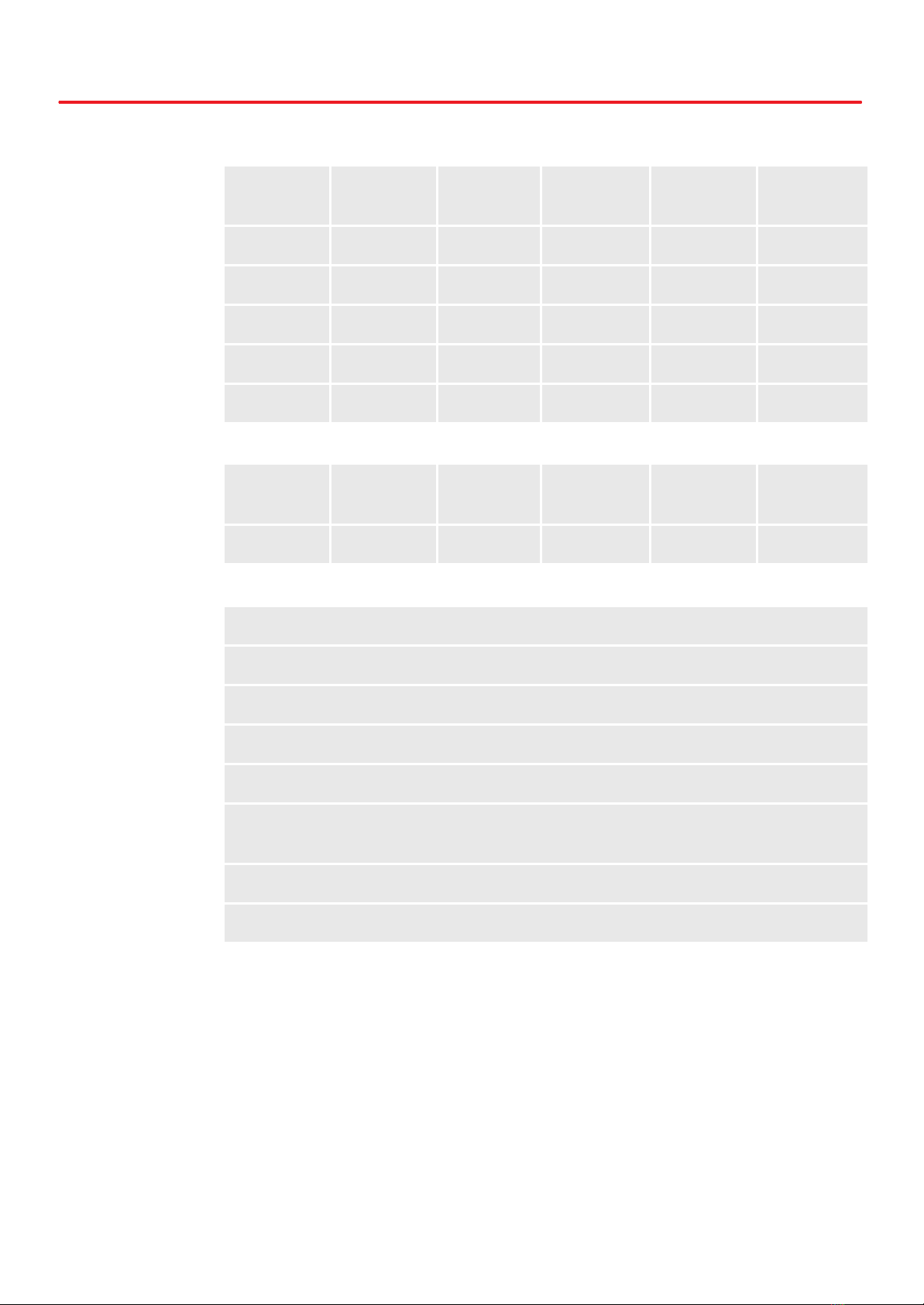

External TD-80F TD-150F TD-250F TD-500F TD-700F TD-630F

WxDxH (mm) 520x560x800 630x660x1010 630x660x1360 780x810x1680 780x810x1980 1450x860x1100

Note: Inlet and Exhaust ports extend the overall height of the ovens by approximately 40mm.

Internal

WxDxH (mm) 390x400x400 500x510x600 500x510x950 650x650x1200 650x650x1500 1300x690x650

Clearance TD-80F TD-150F TD-250F TD-500F TD-700F TD-630F

Front (mm) 520 630 780 725

Back (mm) 100

Sides (mm) 100

5

Technical Specifications

Dimensions

External TD-500FM TD-700FM

WxDxH (mm) 780x810x1680 780x810x1980

Note: Inlet and Exhaust ports extend the overall height of the ovens by approximately 40mm.

Internal

WxDxH (mm) 650x650x1200 650x650x1500

Clearance TD-500FM TD-700FM

Front (mm) 780

Back (mm) 100

Sides (mm) 100

6

Technical Specifications

Technical

Specification

TD-80F TD-150F TD-250F TD-500F TD-700F TD-630F

Temperature

Range

Ambient +10°C to 200°C

Temperature

Control Stability

+/- 0.1°C

Temperature

Uniformity

+/-2°C @ 100°C +/-4°C @ 100°C

Heater Power 1500 watts 3000 watts

Electrical 7A/230V 13A/230V (requires 15A supply)

Nominal Capacity 80L 150L 250L 500L 700L 630L

Porthole

Diameter

13mm

Weight 60kg 100kg 110kg 170kg 190kg 190kg

Technical Specification TD-500FM TD-700FM

Temperature Range Ambient +10°C to 70°C

Temperature Control Stability +/- 0.1°C

Temperature Uniformity +/-2°C @ 70°C (unloaded and vents closed)

Heater Power 1500W

Electrical Requirement 10A/230V

Nominal Capacity 500L 700L

Porthole Diameter 13mm

Weight 170kg 190kg

7

Technical Specifications

Features TD-80F TD-150F TD-250F TD-500F TD-700F TD-630F

Shelves (max @100mm

spacing)

2 (max 3) 3 (max 4) 4 (max 6) 5 (max 9) 6 (max 11) 3 levels

(max 4)

Lockable Castors Optional

✔ ✔ ✔ ✔ ✔

Internal Fan

✔ ✔ ✔ ✔ ✔ ✔

Omron E5CC

✔ ✔ ✔ ✔ ✔ ✔

Solid Door

✔ ✔ ✔ ✔ ✔ ✔

Fibreglass Insulation

✔ ✔ ✔ ✔ ✔ ✔

Safety

Over Temperature

Safety

✔ ✔ ✔ ✔ ✔ ✔

Over Current Protection

✔ ✔ ✔ ✔ ✔ ✔

Options

BMS Plug No volt contact closure plug and socket connection to a Building Management System

Additional Shelves Additional Stainless Steel shelves to suit

Heavy Duty Shelves Update to allow for higher loads on shelves (limits total number of shelves possible for use)

Door Locks Key lockable door locks

Customisable Port Hole Add additional stainless steel 13mm port holes or choose 50mm port holes

Programmable

Controller (MSP)

(E5CC-MSP) Upgraded Omron Controller features 256 ramp and/or dwell segments

Glassware Drying See TGD-range for oven models specic to drying of laboratory glassware

Natural Convection See TO-range for oven models without fan forced circulation

8

Technical Specifications

Features TD-500FM TD-700FM

Shelves 10 12

Lockable Castors

✔ ✔

Internal Fan

✔ ✔

Omron E5CC-T

✔ ✔

Solid Door

✔ ✔

Fibreglass Insulation

✔ ✔

Safety

Over Temperature Safety

✔ ✔

Over Current Protection

✔ ✔

Options

BMS Plug No volt contact closure plug and socket connection to a Building Management System

Door Locks Key lockable door locks

Customisable Port Hole Add additional stainless steel 13mm port holes or choose 50mm port holes

The controller is preset with the following program using the Ormon E5CC-T

48 hrs. at 38˚C

48 hrs. at 45˚C

48 hrs. at 52˚C

“As per the Recommended Standards for Sampling Nut-In-Shell and Kernel Recovery Evaluation”

9

Operating Environment Drying Oven User Manual By Thermoline Scientific

Drying Oven Operating Environment Bench Top Location

Ensure that the drying oven is placed in the correct

environment, away from direct sunlight or direct heat sources

such as heaters (Fig 1). The product shouldn’t be placed in a

room where the ambient temperature exceeds that of which it

was designed to operate.

Drying ovens should be stored inside at all times. Failure to

adhere to this could cause signicant drops in cabinet

performance and damage to items stored inside.

Extreme Operating Environment:

• Temperature: 10°C to 32°C (+/-2.0°C)

• Humidy: Up to 85%RH

Optimal Environment: (Fig 2)

• Temperature: 23°C (+/-2.0°C)

• Humidy: 50%RH (+/-5%RH)

Fig 1. Suitable Environment

Bench Top Requirements:

• Under no circumstances should any ovens be stacked

on top of each other (Fig 2).

• Thermoline 150 litre ovens have removable castors for

benchtop storage. To safely remove castors, simply tip

the cabinet over gently onto it's back or side and

unscrew the castors from the bottom the cabinet (Fig

3). This is a two person job so please get assistance.

Fig 2.

Fig 3.

10

Operating Environment

Electrical Connections

Depending on the model the drying ovens either require a

require a 15amp, 230V, 50hz power supply or a 10amp 230V

50hz power supply. Requirements are shown in the below

table.

A dedicated outlet should be used for all ovens. Do not use

power boards or the like. A 3-pin moulded plug is supplied as

standard.

Electrical requirements

TD-80F

TD-150F

TD-500FM

TD-700FM

10A/230V

TD-500F

TD-630F

TD-700F

15A/230V

Electrical Conditions:

• All drying ovens include a 2.5m removable mains

power lead with a three pin plug and right angle female

IEC plug (straight plug for 15A). Ensure the product is

reasonably distanced from the power supply. (Fig 1)

• On the oven itself is a male IEC socket (Fig 2) and (Fig

3).

Fig 1. Suitable distance from power supply (2m)

Fig 2. 15amp IEC socket Fig 3. 10amp IEC socket

Fig 4. Location of of the IEC socket.

11

Operating Environment Warnings

Do not store items on top of the cabinet as this will also affect ventilation! CAUTION: When installing

more than one cabinet in the same location ensure that they are positioned in such a way that warm air

exhausted from one cabinet, is not drawn directly into the other cabinet.

Drying ovens should be stored inside at all times. Failure to adhere to this could cause signicant drops

in cabinet performance and damage to items stored inside.

Drying ovens are not suitable for use with ammable solvents! They are tted with components that may

be the source of ignition.

The drying ovens are designed for large capacity drying, and hot moist air will be discharged.

12

Setup Drying Oven User Manual By Thermoline Scientific

Unpacking

Unpacking process for foam wrapped or boxed

• The drying oven will be delivered foam wrapped and

on its castors via sensitive freight (Fig 1) or in a box on

a skid (Fig 2).

• If the drying oven is delivered on a skid, a forklift may

be required to lift it off the skid.

• Please don't dispose of the packaging until the oven is

inspected. If damage is present upon opening your

package, notify your supplier or Thermoline Scientic

without delay on +61 2 9604 3911 or email at

Fig 1. Unpacking Process (foam wrapped)

Fig 2. Unpacking Process (Box)

Moving

Moving the drying oven:

• Ensure that the oven is rolled on an even and at

surface. Uneven surfaces can cause the oven to fall

over.

NOTE: Drying ovens are 'Top Heavy'. Do not move the cabinet

too quickly. (Fig 3 & 4)

Fig 3. Safe moving of cabinet.

Fig 4.

13

Setup

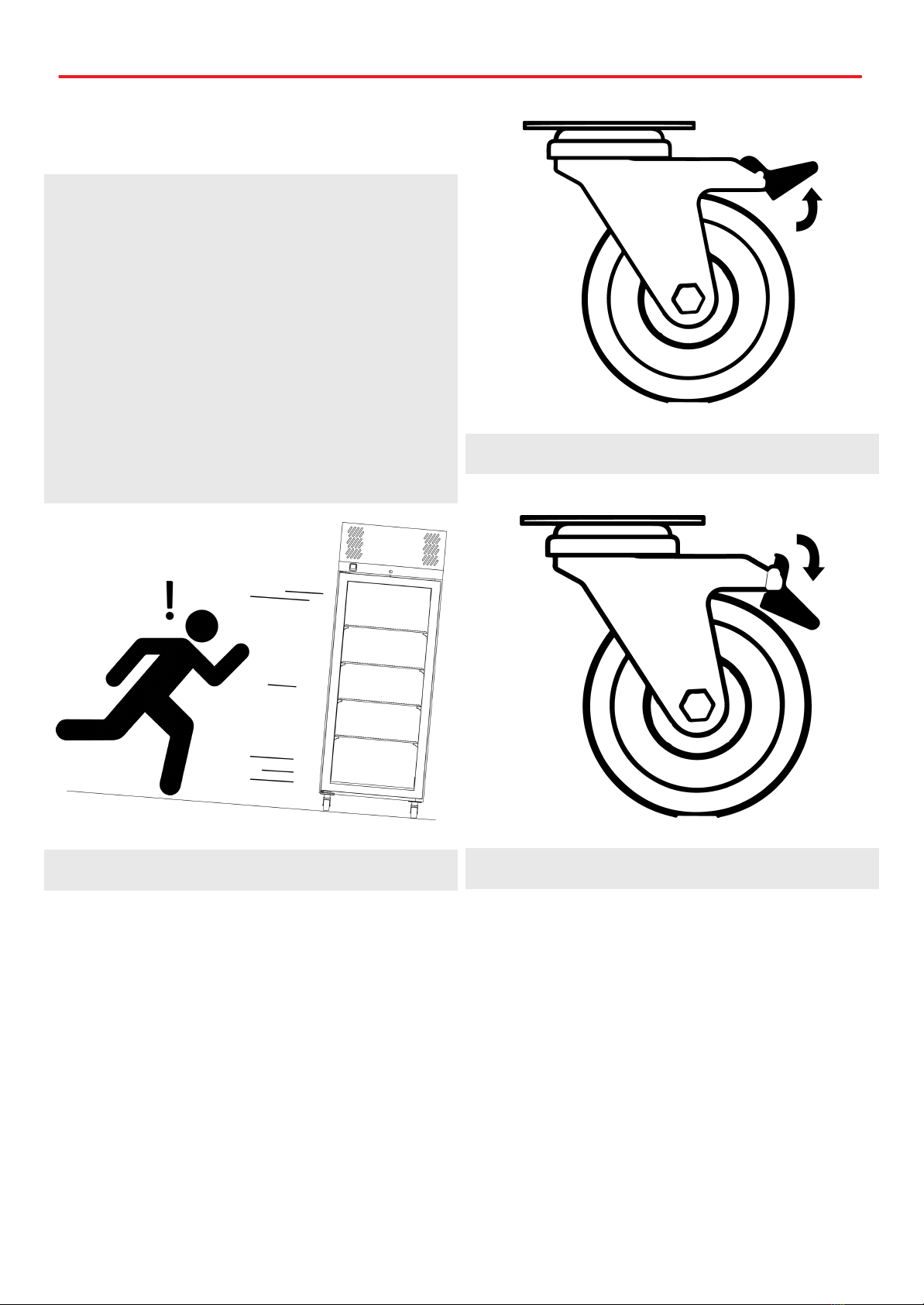

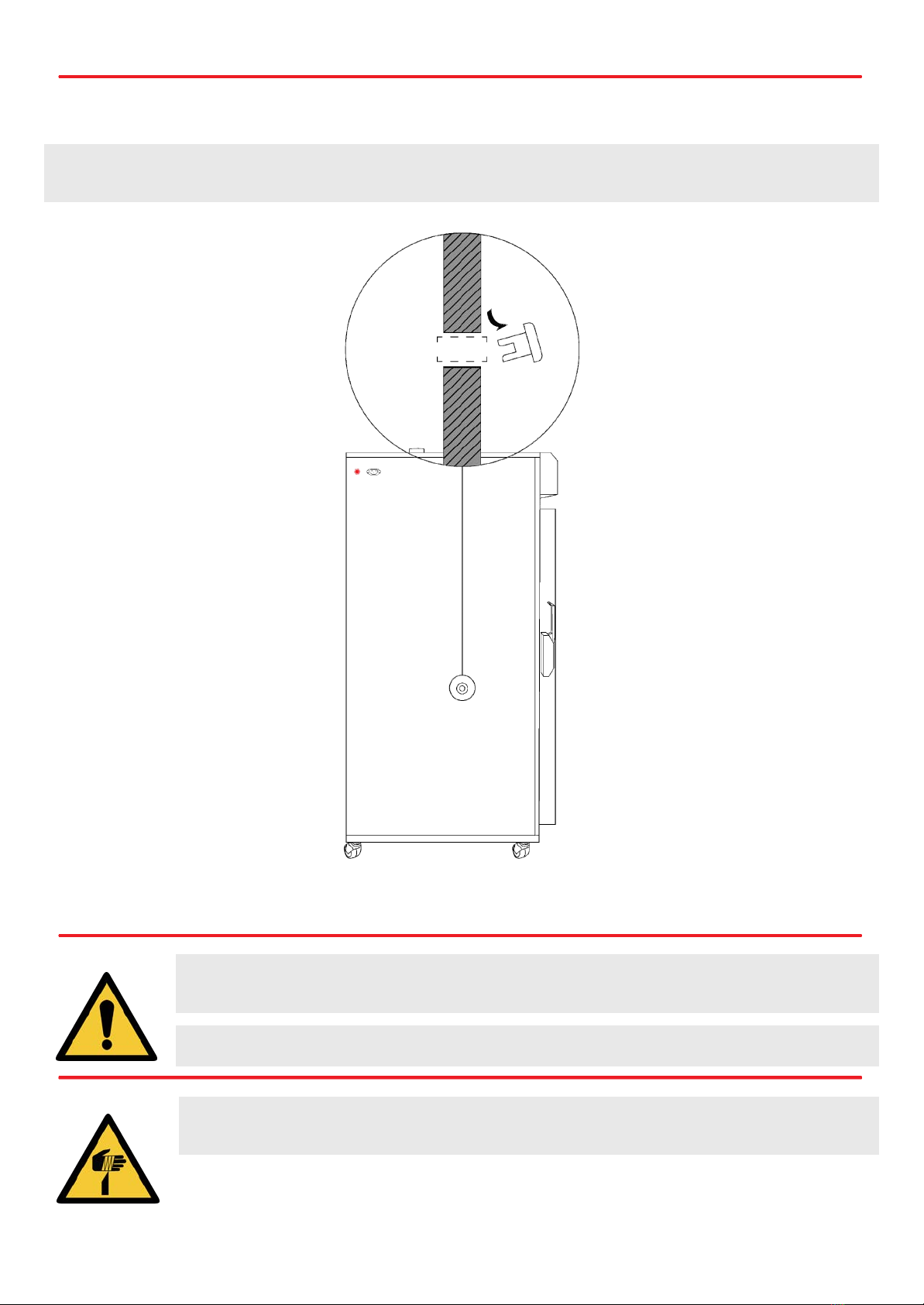

Castors

The drying ovens are equipped with lockable castors to prevent

cabinet movement.

Castor Setup:

• Ensure that the drying oven is placed on an even and

at surface. Uneven surfaces can cause issues within

the cabinet. Uneven surfaces can cause the cabinet to

fall over or roll away with unlocked castors.

• Castors can be xed in place by pushing down on the

brake lever. Ensure the castors are locked to prevent

unwanted movement from the drying oven (Fig 1).

• Ensure when placing the drying oven into place that

the castors can be accessed so they can be locked

(Fig 3) and unlocked (Fig 2). Please contact your

supplier or Thermoline should there be any damage to

the castors.

Fig 1.

Fig 2. Castor Unlocked

Fig 3. Castor Locked

14

Setup

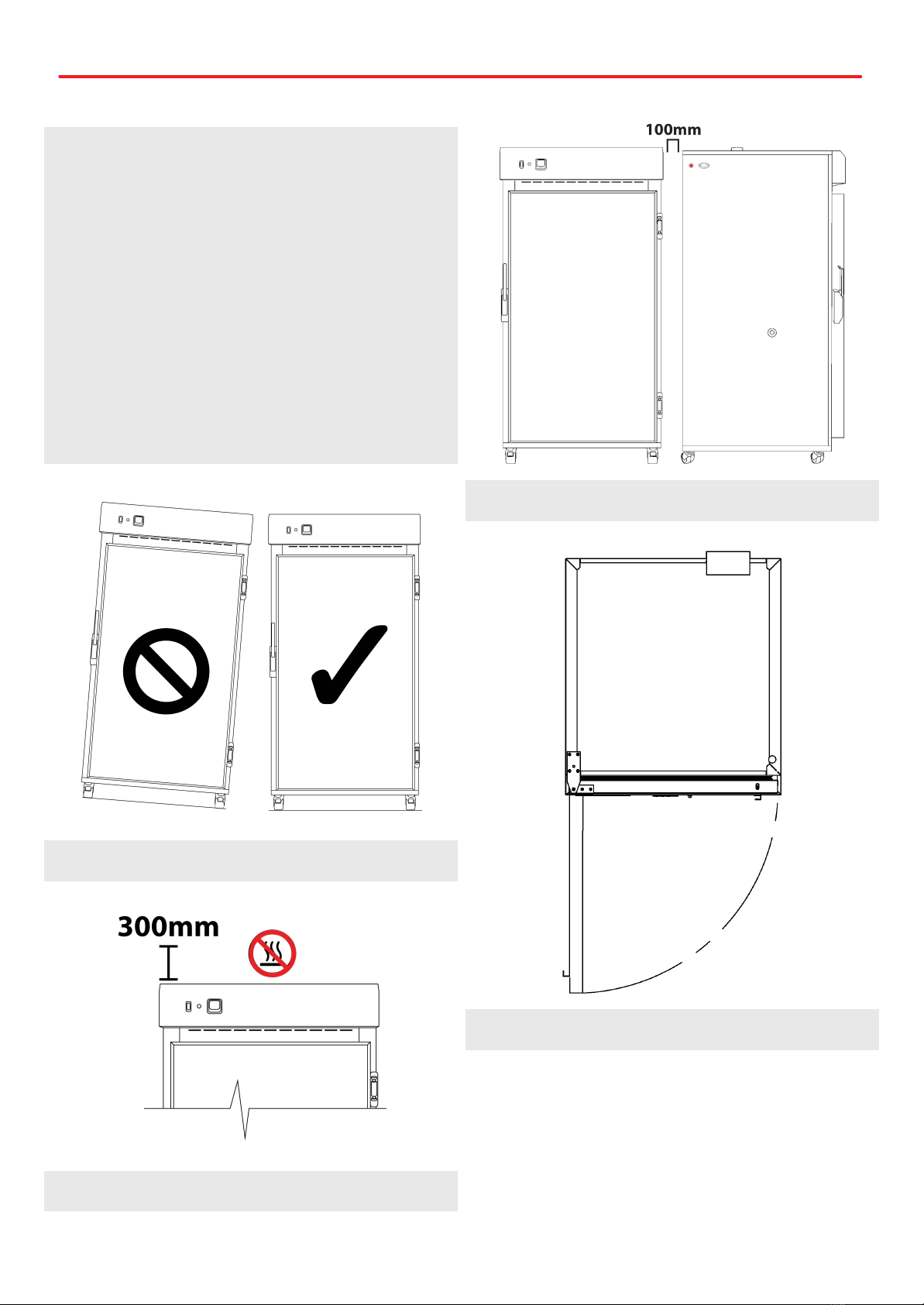

Drying Oven Location

Location Requirements:

• The drying oven requires a level surface to operate

correctly. (Fig 1)

• Do not store items on top of the drying oven (Fig 2).

Space is required to accommodate the inlet and outlet

vents.

• The drying oven requires ventilation. Thermoline still

suggests 100mm on the sides and back that also aids

with accessibility (Fig 3). 300mm at the top to ensure

the inlet and outlet vent is not obstructed in any way.

• The drying oven door should also be allowed to open

and close at full range. (Fig 4)

Fig 1. Correct Levelling

Fig 2.

Fig 3.

Fig 4.

15

Setup

Shelves

All ovens comes equipped with shelves used for holding items while the oven is in operation. They allow for more than one item to

be conditioned at a time. The shelves can be adjusted to different heights to accommodate different size items.

To adjust the shelf clips you must:

• Hook the top of the clip into the slot seen below.

• Pinch and squeeze the base of the clip

• Push base of clip into slot and release.

• To remove, repeat process.

SAFETY NOTE:

• The edges of the clips can be sharp. Thermoline

recommends using protective gloves while adjusting

or moving the clips (e.g. leather gloves).

Shelving:

• All ovens are supplied with adjustable shelf clips to

accommodate different size items within the cabinet,

The amount of shelf clips supplied changes depending

on the size of the cabinet ordered.

Model Shelvex Length (mm)

TD-80F 304

TD-150F 455

TD/-250F 455

TD-500F TD-500FM 915

TD-700F TD-700FM 1219

TD-630F 455

16

Setup

Inlet and Exhaust

All drying ovens feature an inlet and an exhaust port on top of

the cabinet. The inlet regulates the amount of fresh (dry air)

that enters the cabinet and the outlet regulates the amount of

exhaust air that can exit the cabinet. In combination, this

regulates the rate of drying.

Exhaust Requirements:

• The top covers of the inlet and exhaust can be rotated

either way to open up the exhaust and allow airow

(Fig 2). The air vents are located on the top of the

cabinet. (Fig 1)

• On all drying ovens covered in this manual the exhaust

is on the left and in the inlet is on the right as you look

at the oven. Due to the location and number of fans in

the different models the location may differ slightly,

but they are still in this conguration. (Fig 3).

• The drying oven's vents can also be connected to a

ventilation system whether it is exhaust only or both

inlet and exhaust. To do so, you must rst remove the

vent covers (Fig 4).

• To prevent a potential pressure drop, please ensure

that the pipe is no smaller than 75mm in diameter for

proper ventilation (Fig 4).

Fig 1.

Fig 2.

Fig 3.

Fig 4. Recommended minimum diameter 75mm

17

Setup

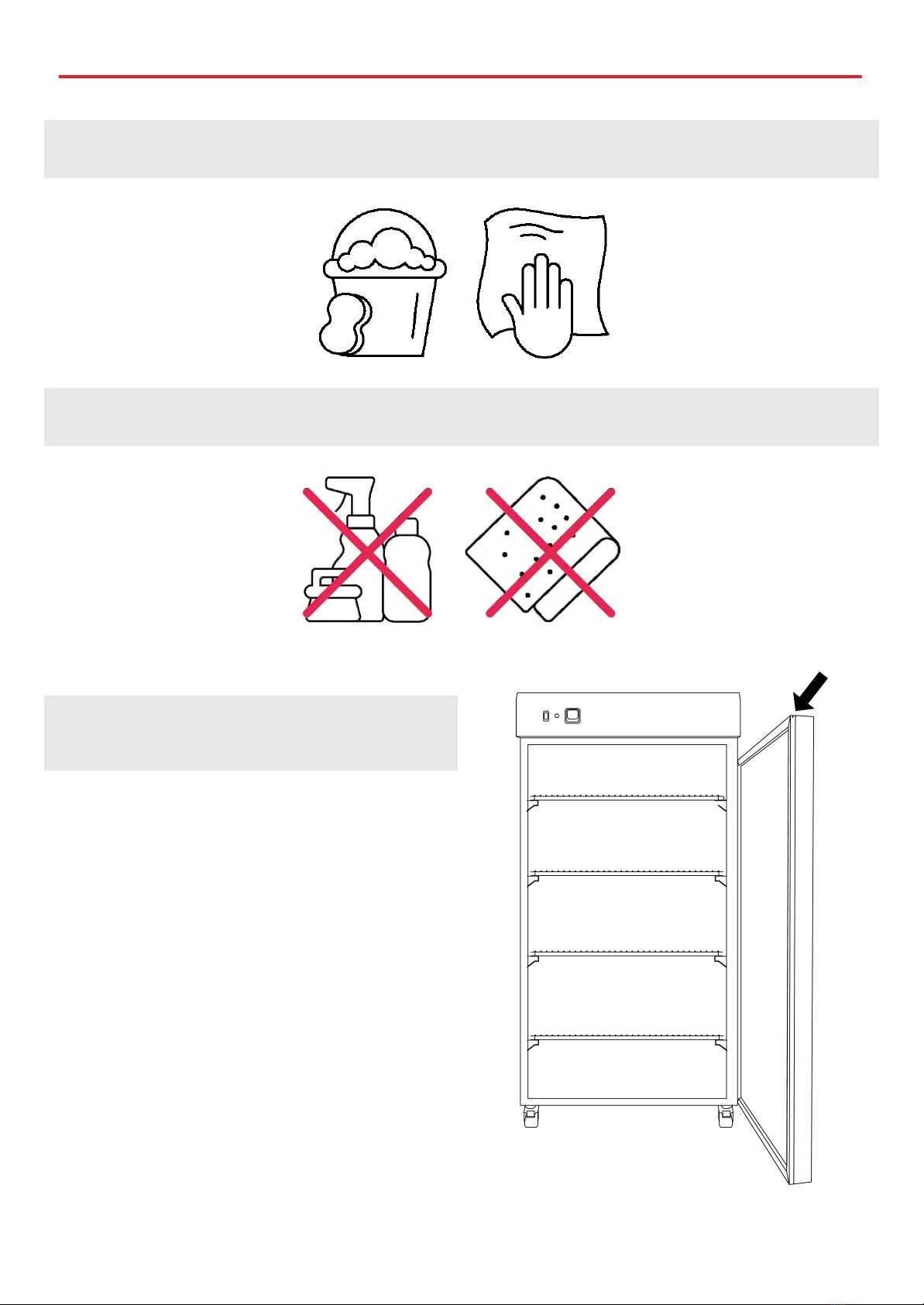

Cleaning

The interior, exterior, and door gasket can be cleaned as often as required using a soft cloth and soapy water. Never use abrasive

cleaners or scouring pads as these will scratch the surface and may result in corrosion. Never use caustic type cleaning agents.

All cabinets have electrical components. Power should be turned off prior to cleaning. These items should not be subjected to any

levels of moisture.

Door Gasket

The door gasket should be cleaned regularly with a mild soap

solution. If a gasket is to be replaced, please contact

Thermoline Scientic. Regular inspection is recommended.

18

Setup

Port Hole

The port hole can be found on the left side of the drying oven. The cabinet comes equipped with a plug that may be removed by

simply pulling it out. Keep the plug safe in case the port hole needs to be closed again.

Setup Warnings

Ensure when placing the cabinet into place that the castors can be accessed so they can be locked and

unlocked. Any damage to the castors must be noted to the supplier or manufacturer

Ensure there are no blockages around or on top of the exhaust as this will effect proper ventilation.

Caution must be taken when removing the packaging particularly when using knives to cut tape and

cardboard.

19

Start Up Procedure Drying Oven User Manual By Thermoline Scientific

Start Up Procedure

Start Up process:

• Before proceeding, please make sure that all internal

and external packaging has been removed from the

appliance and that all tape, plastic bags and foam

pieces have been removed.

• Take the supplied lead and plug it into the male IEC

socket on the side of the oven. Next, plug the 3 pin

plug into a 10amp or 15amp General Purpose Outlet

depending on which is required.

• Turn the main switch adjacent to the temperature

control to 'ON' to start the Oven.

• The controller will go through a warm up period where

all segments of the display will be on, before indicating

the set temperature (SV) on the lower display and oven

actual temperature (PV) on the top display.

• For '-FM' models and those with the MSP option,

please see TM-009-UM Omron MSP manual for

instructions on this controller.

20

This manual suits for next models

9

Table of contents

Popular Oven manuals by other brands

Blomberg

Blomberg GGN61Z user manual

Middleby Marshall

Middleby Marshall PS640G Owner's operating and installation manual

Hotpoint Ariston

Hotpoint Ariston SA2540HWH Use and care guide

Atag

Atag OX4592C Instructions for use

Buffalo

Buffalo Y067 instruction manual

Electrolux

Electrolux air-o-convect Natural Gas Hybrid Convection Oven... Short form specification