Thermomax SM QUATTRO User manual

THERMOMAX

SM QUATTRO

4 - CHANNEL DATALOGGERANDALARM

ENGLISH

THERMOMAX

3

4

www.Thermomax-Group.com

CONTENTS

SECTION 1 - INTRODUCTION.................................................……..................... 2

SECTION 2 - INSTALLATION ............................................................….........……. 3

2.1 - SMQUATTROUnit ........................................................................... 4

2.2 - Sensors ............................................................................................. 4

2.3 - AlarmRelay ......................................................................…............. 5

2.4 - PowerConnections andWiringDiagram ..........................…...... 5

2.5 - Battery .....................................................................................….….. 5

SECTION 3 - OPERATION ..................................................................................…. 6

3.1 - DESCRIPTION ...........................................................................…... 6

3.2 - MAIN SCREENS:

3.2.1 MAIN SCREEN 1: Bar Graph Temperature / Humidity

Display ……........................................................................... 8

3.2.2 MAIN SCREEN 2: Digital Temperature / Humidity

Display .……….....................................…...………….......... 9

3.3 - SET SCREENS:

3.3.1 SETSCREEN 1:Clock/ Calendar ..................….............. 10

3.3.2 SETSCREEN 2:System Presets1 ...............................… 11

3.3.3 SET SCREEN 3: System Presets 2………………............ 13

3.3.4 SET SCREEN 4: Sensor Input Type Selection ……........ 14

3.4 - SYSTEM DIAGNOSTICS:

3.4.1 DATABANKDIAGNOSTICS SCREEN .........……….......... 15

3.4.2 CHANNELDIAGNOSTICS SCREEN ..............….............. 16

3.4.3 CALIBRATIONTRIMMINGSCREEN ................................. 17

3.5 - CHANNEL SCREENS: ……

3.5.1 CHANNELDISPLAY SCREENS ........................................ 18

3.5.2 CHANNELSETSCREEN - TEMPERATURE ..……........ 19

3.5.3 CHANNELSETSCREEN – HUMIDITY ………....……... 20

3.6 - CURRENT DAY PLOT: ………………………................……. 21

3.7 - PLOT HISTORY: Data log of previous days: ...................…... 22

3.8 - DATATRANSFER: ….................................…..................….….. 24

3.8.1 Transferring Data Using the Masterlink software ......... 24

3.8.2 Transferring Data to the Masterlink Hardware .............. 24

3.8.3 Printing Data to the Thermomax Serial Printer ............. 26

3.9 - DATATRANSFER -Panelmountunits Only ................................ 27

SECTION 4 - FAULTFINDING …........................................................................... 31

SECTION 5 - SPECIFICATIONS …..................................................…….............. 32

KEYPADLOCK …………………………………………………..………............… 33

SMQUATTROPANELMOUNT ............................................................................... 34

DEUTSCHE BEDIENUNGSANLEITUNG …………………………………....... 36

1

SECTION 1 INTRODUCTION

The SM QUATTRO microprocessor-based datalogger uses the novel approach of a

paperless logging and filing system, which allows the data of any day in its history to

be read and examined with a few key presses.

The large graphics LCD display communicates the information to the user with clarity,

making programming and setting up friendly and uncomplicated, without

compromising its sophistication and digital accuracy.

SUMMARYOFFEATURES

DATALOGGER

•Paperless datalogger with automatic filing by date

•50-year clock/calendar for datalogger filing.

•The temperature from each Channel is sampled every 15 minutes and stored

to an internal databank.

•‘Percentage of internal databank used’ indication in bargraph and digital form.

•Power Supply 220 – 240V AC Mains.

•Contents of internal databank can be transferred directly to the PC using the

MASTERLINK Software or via a MASTERLINK Hardware module to a PC at a

remote site.

ALARM

•2-Stage high and low level alarms with mute and reset facilities,

•Stage 1 temperature threshold with trigger delay.

•Stage 2 limit temperature with immediate trigger.

•Status window for system fault indication.

•Diagnostics screen revealing system parameters.

•Alarm history record for low alarm, high alarm and power fail.

•Battery back-up for power-fail operation.

Note: The information supplied in this manual is for guidance only – no part of this

may be used for any agreement, whether express or implied, or to form any contract.

2

SECTION 2 INSTALLATION

Note: This installation procedure is for guidance only, and its suitability

should be verified by the installer.

SAFETY PRECAUTIONS

The following safety precautions are strongly recommended:

1Before attempting to install and operate the unit, read this instruction manual

carefully.

2Installation and any maintenance required should only be carried out by

suitably qualified personnel.

3It is recommended that the unit be connected to the mains supply via a

suitably rated isolating switch.

4WARNING: When the unit is connected to the mains supply and the

cover is opened, the circuits at mains voltage will be exposed. Therefore

when installing the unit, ensure all required connections (including battery

connection, if included), are made and covers replaced before turning on the

mains supply. Ensure that all the connections made are secure. If any

maintenance work e.g. installing a new battery, is required ensure that the

unit is isolated from the mains supply before removing the cover. Never

leave the unit unattended if the cover has been removed and the mains

supply is connected.

5Do not exceed unit ratings as shown on the ratings label.

6It is advisable to route mains cables away from low voltage or sensor cables.

3

2.1 SMQUATTRO UNIT

NOTE: For viewing comfort, the SM QUATTRO unit should be positioned at

eye level. It is always good practice to keep electronic equipment away from

cold, heat and electrical plant, as extremes of temperature may reduce the

lifetime of the device, and heavy electrical loads, switches, relays or

contactors too close to the device may cause electrical and electro-magnetic

interference when switched on or off.

2.1.1 Knock out the entries into the moulding to be used for connection, either

behind or under the moulding, whichever is suitable for the particular

installation.

2.1.2 Fasten the screw corresponding to the top centre lug on the back of the SM

QUATTRO moulding, into the wall or panel on which the unit is to be

mounted. Leave a gap of approximately 3mm between the screw head and

the wall. Position the moulding and slot in the lug over the screw.

2.1.3 Level the SM QUATTRO moulding and, if using rear entry, mark the entry

holes in the panel behind the appropriate knock-out entries, as well as the

two lower mounting holes. Remove the moulding, drill the necessary holes in

the panel, assemble any grommets or conduit adapters if used, replace the

moulding and fasten using the two lower screws.

2.2 SENSORS

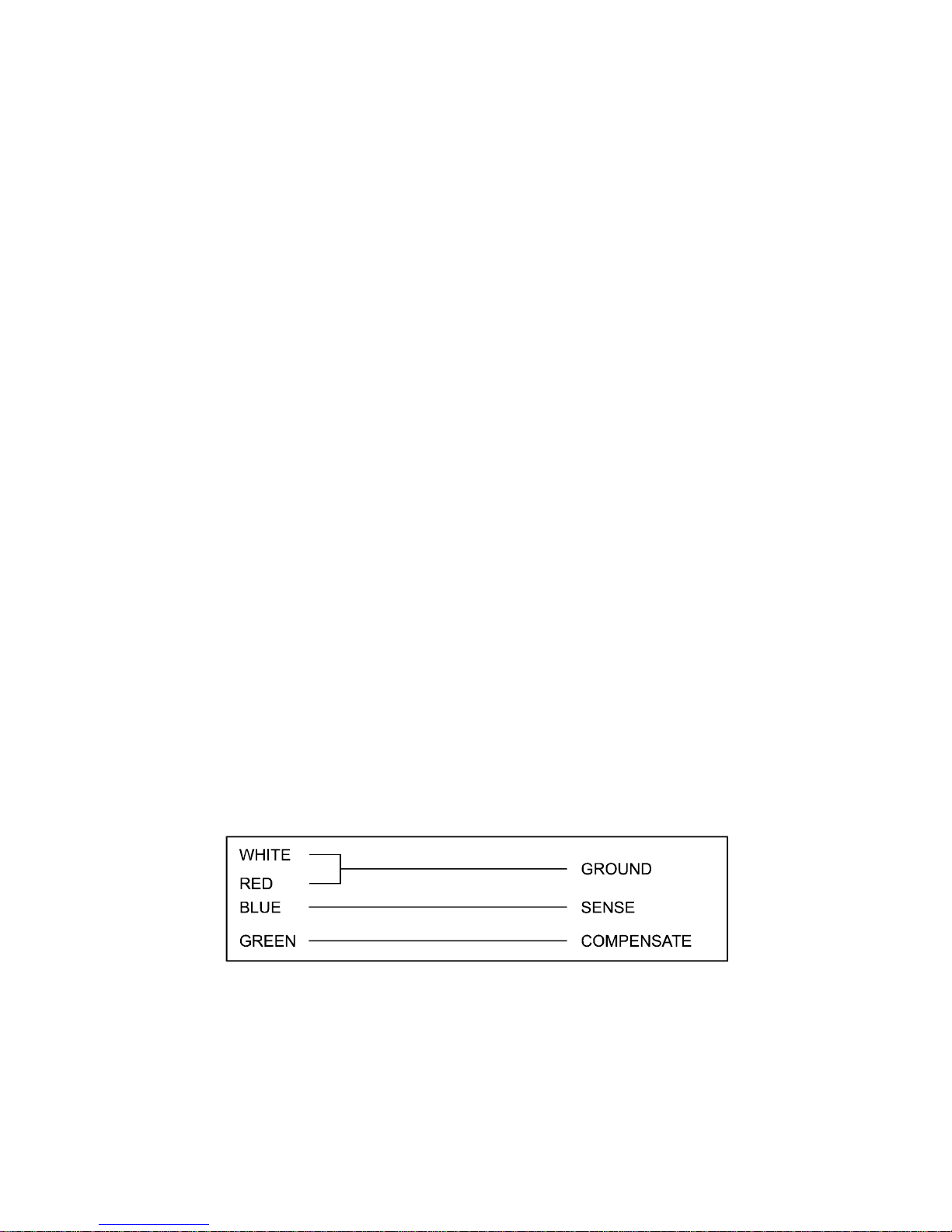

The SM QUATTRO may be used with a variety of sensors of different cable

lengths. If required, sensors are available with extended cable lengths or

alternatively, sensor extenders are available, also in a variety of lengths. If the

sensors need to be extended, but factory-made extenders are not available,

they can be extended using a suitable 4 core or 3 core cable, according to

the diagram shown below.

Please note however, that as with all PT100 sensor applications, a good

connection is vital. It is therefore recommended that wherever there is any

doubt, a factory- extended sensor or sensor extender should be used.

4

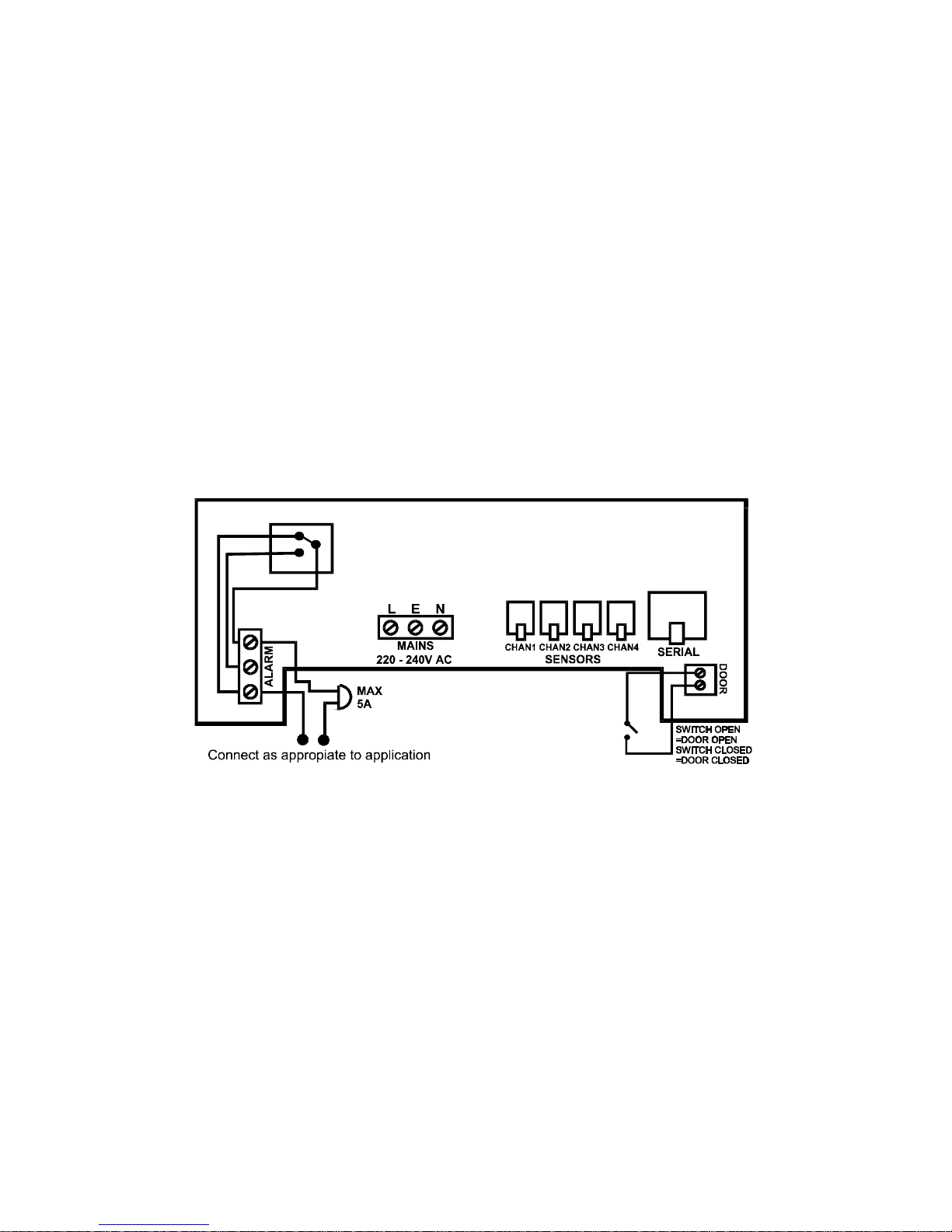

2.3 ALARMRELAY

NOTE: The alarm relay is a 3 contact changeover arrangement which is

isolated (volt-free). This relay is normally energised, and switches off when

the alarm is triggered, or in the case of power failure. It may be used to

trigger an external bell, warning lamp, or digital communicator (telephone

dialler).

If an external device is used, connect the alarm as appropriate, according to

the diagram in the next section.

2.4 POWERCONNECTIONSAND WIRING DIAGRAM

NOTE: This device should be properly earthed. Flexible wires simplify

connection to the terminals. All connections should be secure and adequately

tightened. It is good practice to keep mains cables away from sensor cables

and other low voltage signal cables.

Connect the supply to the unit, as per diagram below, using the appropriate

input voltage according to the application.

2.5 BATTERY

The battery supplied is a 9V PP3 nickel metal hydride rechargeable battery

and is attached to the lid of the terminal compartment, but not plugged in.

This should be plugged in after installation. This battery is not essential for

the system operation, but is used in the case of power failure, thereby

continuing to log the four input temperatures for 3 – 4 hours, and maintaining

the system clock.

If the power cut takes longer and the battery is discharged, the clock must

be set when the power supply is re-established. The system parameters

remain intact.

It is recommended that the battery is changed every 12 months, in order to

maintain good power failure operation. When replacing, ensure that the type

of battery used is as specified.

5

SECTION 3 SM QUATTRO OPERATION

In order to fully understand the operation of the SM QUATTRO, this section should

be read carefully.

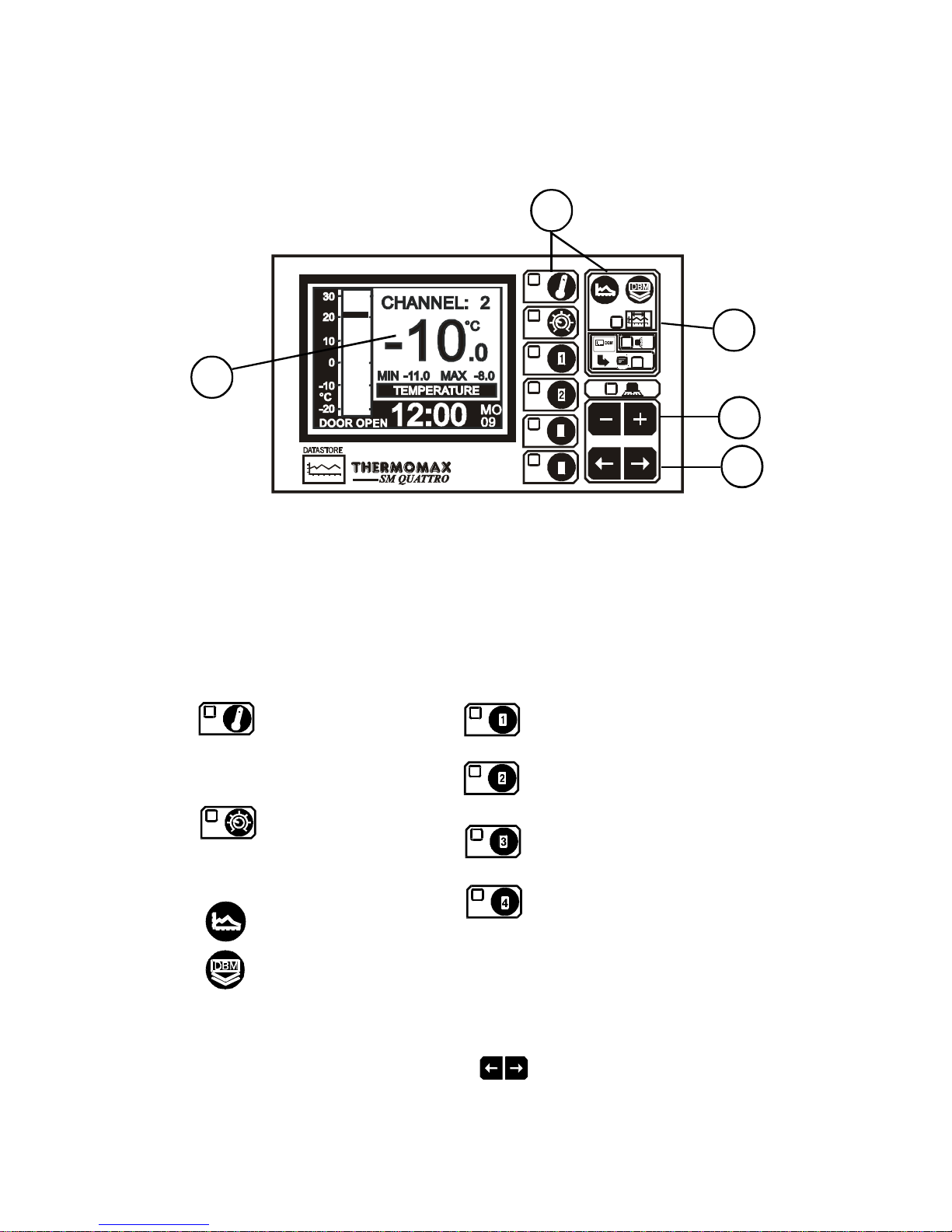

3.1 DESCRIPTION

THERMOMAX

3

4

1GRAPHICSLCDDISPLAY

Displays all the information. The contrast is adjustable to suit the user. (See

3.2.1 Main Screen 1).

2FUNCTION KEYS

There are eight function keys on the SM QUATTRO datalogger:

- Main Screen 1 - Channel 1 Display Screen

- Main Screen 2 - Channel 1 Set Screen

- Channel 2 Display Screen

- Channel 2 Set Screen

- Set Screen 1

- Set Screen 2 - Channel 3 Display Screen

- Set Screen 3 - Channel 3 Set Screen

- Set Screen 4 - Channel 4 Display Screen

- Current Day Plot - Channel 4 Set Screen

- Plot History Screen

- Data Transfer Key

3SELECT KEYS

Within each function, there are some parameters that can be selected for

setting or displaying purposes. The keys allow the required parameter

to be chosen, without changing any of its properties.

6

4

2

1

5

3

7

4SET KEYS

The and keys are used to set the value of any selected parameter, by

increasing and decreasing the value respectively.

In most of the functions, described later in the manual, the and keys

have an auto-repeat facility: press and hold the key in order to advance

quickly.

Note: The and keys are the only keys which can alter the value of a

selected parameter. Other keys may be pressed to view or select these

parameters without effecting any change in the system.

5INDICATORS

The System Alarm can be triggered by the high temperature alarm, low

temperature alarm, or by a sensor fault.

INTERNAL DATABANK

DATA TRANSFER IN PROGRESS

SYSTEM ALARM

8

3.2 MAINSCREENS

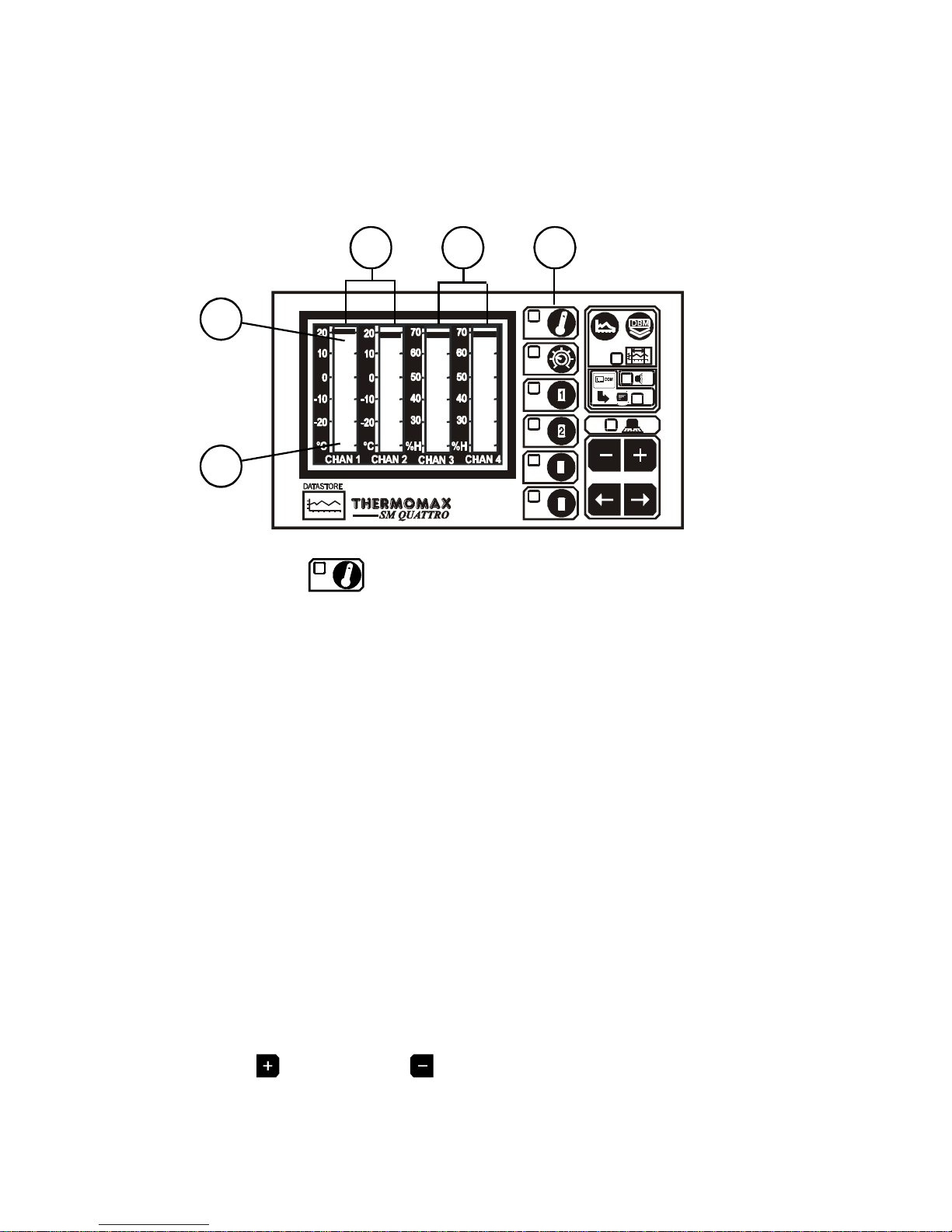

3.2.1 MAIN SCREEN 1: BAR GRAPH TEMPERATURE / HUMIDITY DISPLAY

This screen allows the user to view the information for each channel in

bargraph form and is shown below. The high and low Temperature / Humidity

limits are shown on these bargraphs and are represented by the shaded

areas.

THERMOMAX

3

4

Pressing the key the first time will display the MAIN SCREEN which

shows a four channel bargraph display as shown above.

2Channels 1 & 2 in this example display temperature.

3Channels 3 & 4 display relative humidity in this example.

4This shaded area shows the High Alarm Limits (Stage 2 Alarm).

5This shaded area shows the Low Alarm Limits (Stage 2 Alarm).

Note 1:

In this example configuration, channels 1 & 2 are connected to temperature

sensors and channels 3 & 4 are connected to humidity sensors, therefore the

bargraph for channels 3 & 4 displays relative humidty (%H). (See section

3.3.4).

Note 2:

See Section 3.5.2 “Channel Set Screens” for more information on

temperature Alarms, and section 3.5.3 for information on Humidity Alarms.

Note 3:

The display contrast may be adjusted in this screen.

Press to increase and to decrease the contrast.

To adjust quickly, press and hold for auto-repeat.

4

5

231

9

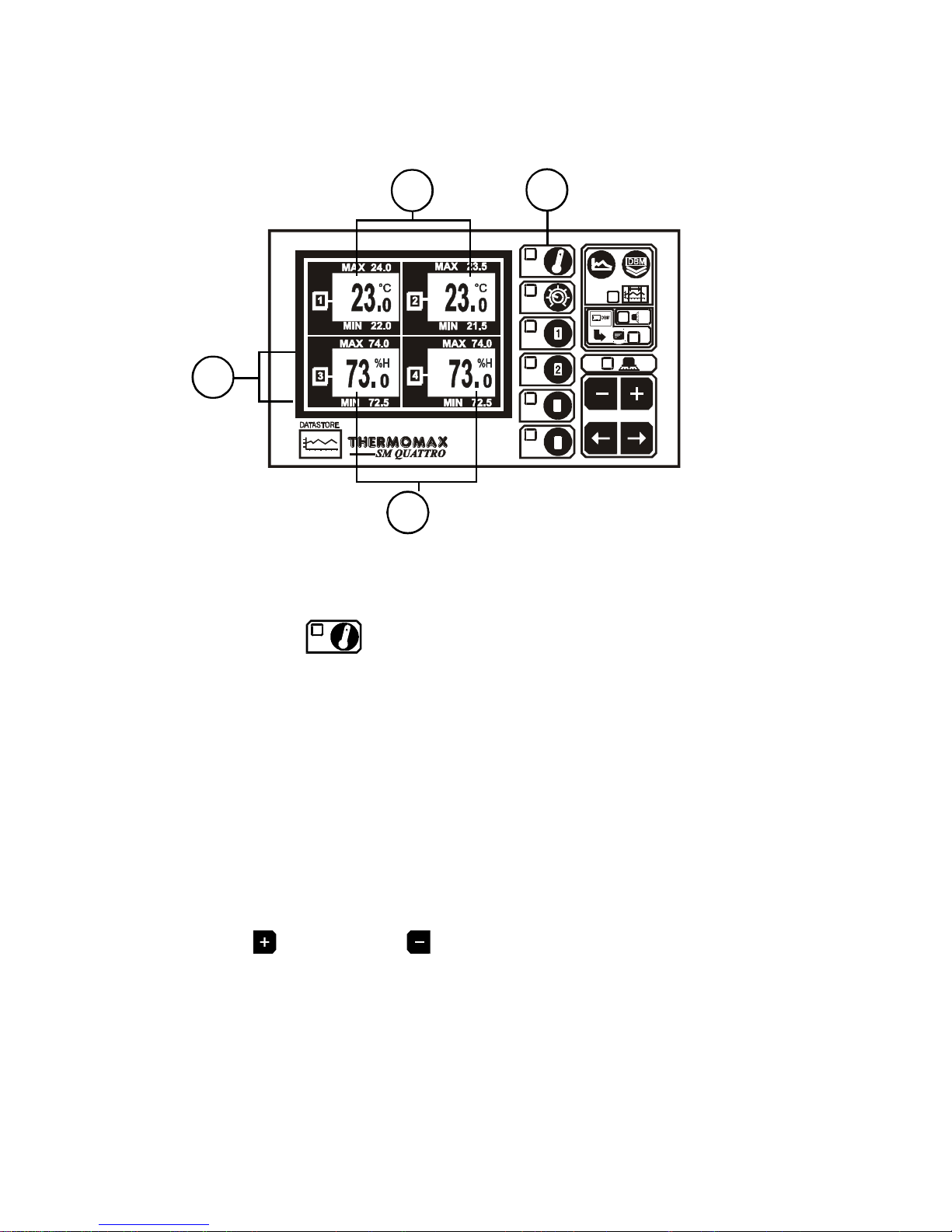

3.2.2 MAINSCREEN2:DIGITALTEMPERATURE/HUMIDITYDISPLAY

1MAIN SCREEN function selector.

Pressing the key a second time reveals the screen above.

2Current temperature for channels 1 & 2.

3Current humidity reading for channels 3 & 4.

4Maximum and minimum daily temperature / humidity readings for each

channel.

Note: The display contrast may be adjusted in this screen.

Press to increase and to decrease the contrast.

To adjust quickly, press and hold for auto-repeat.

4

3

21

10

3.3 SETSCREENS

3.3.1 SET SCREEN 1 : CLOCK / CALENDAR

THERMOMAX

3

4

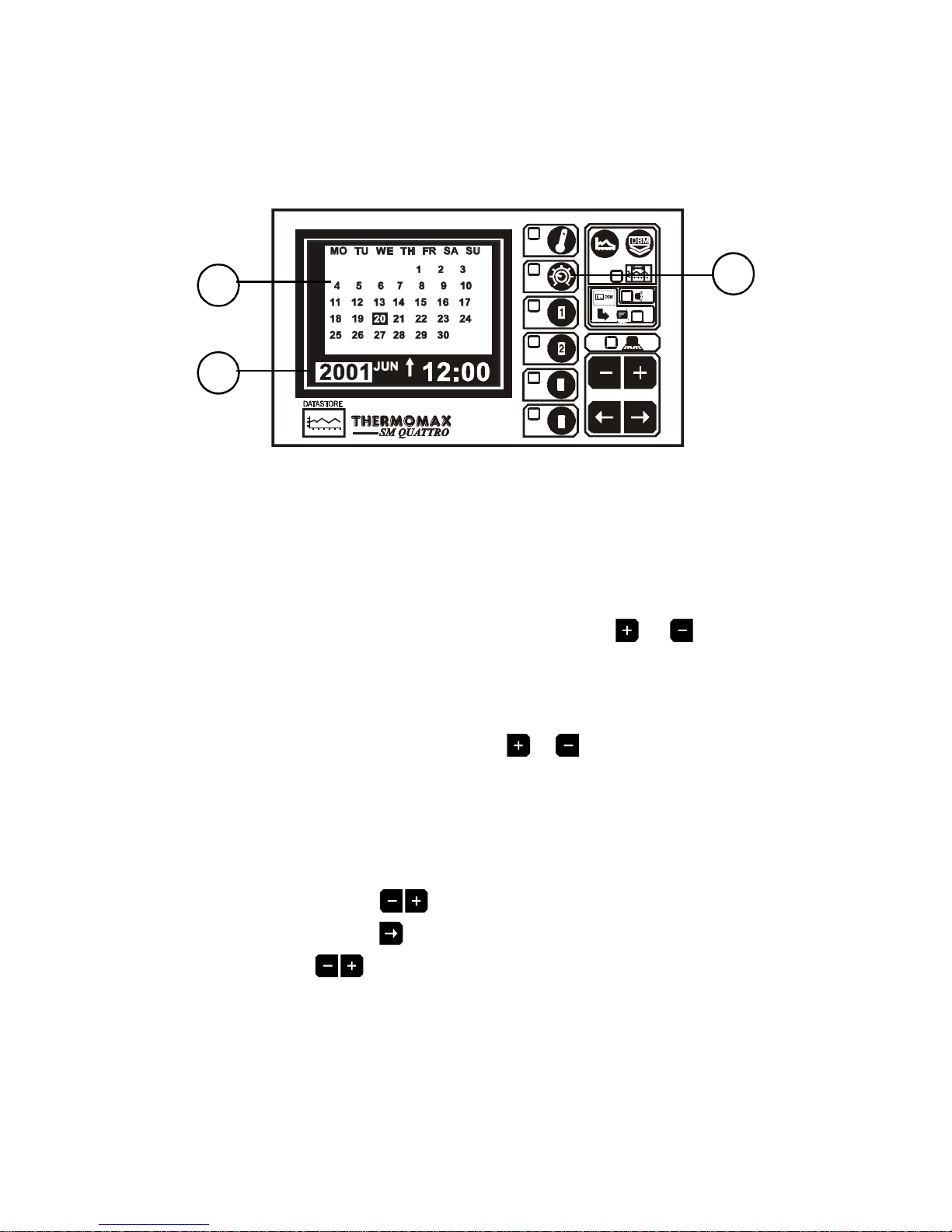

1SET SCREEN function selector

The datalogging system uses the calendar to file the logged data.

2Selection indicator

The highlighted parameter is adjusted by pressing the or key..

(The selections are: ‘year’, ‘month’, ‘day’, ‘↑’, ‘hour’ and ‘minutes’.)

The ‘↑’ indicates that the day on the calendar above is being set.

The clock is in 24-hour format.

To advance quickly, press and hold the or key for auto repeat.

3Calendar

This is the calendar of the month selected, with day of the week indication.

SETTINGTHEDATEANDTIME:

Step 1 : Use the keys to set the current ‘Year’.

Step 2: Use the key to move to the ‘Month’ option and then use the

keys to set the current month.

Step 3: Repeat step 2 to set the current ‘date’ and ‘time’ (‘minutes’

and ‘hours’) in turn.

2

31

11

3.3.2 SETSCREEN2:SYSTEM PRESETS 1

THERMOMAX

3

4

1SET SCREEN function selector

Pressing this key a second time reveals Set Screen 2.

2Alarm Mute

To mute the SM QUATTRO’s internal audible alarm, press the key when

the MUTE window is selected. When the alarm system is reset, either

manually or by the temperatures dropping within pre-set limits, the alarm

mute will be cancelled automatically.

3Alarm Reset

Any current activities, delays or counters are reset by pressing the key

when the RESET window is selected.

4Alarm Relay Status

The output status of the alarm relay may be either viewed or altered by

pressing the or key when the RELAY window is selected.

0 = Relay Manually disabled (ALARM ON)

AUTO = For normal operation:

1= Relay Manually activated (ALARM OFF)

6 7 8 9

2 3 4 5

1

12

5Keypad Lock

The keypad may be locked or unlocked when this window is selected.

See page 27 at the end of this manual.

6Piezo and Indicator test

By pressing the key when the TEST window is selected, the SM

QUATTRO’s internal audible alarm will ‘sound’ and all indicators will

illuminate.

7Door Switch Selection

The SM QUATTRO provides the option to connect a door switch for

monitoring purposes (the status of the door is displayed and logged in

graphical form, see section 3.6). This option may be enabled or disabled by

pressing the or respectively..

Note: See section 2.4 for wiring diagram.

8Diagnostics

By pressing the key when the DIAG window is selected, the SM

QUATTRO DIAGNOSTICS screen is activated. (see next section 3.4).

9Language Selection

The language used by the system to communicate the information may be

selected here. Use the and keys to make your English, French or

German selection.

13

3.3.3 SETSCREEN3:SYSTEM PRESETS 2

THERMOMAX

3

4

1SET SCREEN function selector

Pressing this key a third time reveals Set Screen 3.

2Alarm Mute

Alarm mute period for Channel 1 (from 0 to 95 Minutes). If any key is

pressed during an Alarm situation for this channel, the buzzer will be muted

(silenced) for this period.

3-5 Alarm Mute period for Channel 2 to Channel 4(from 0 to 95 Minutes).

Same as above.

6Channel select for Channel 1. Each sensor input can be “switched” on or off

by pressing the or keys for 5 seconds respectively. When the sensor

input is switched “ON”, the unit will operate in normal mode and the actual

sensor temperature will be monitored and logged to the databank every 15

minutes. If the sensor input is switched “OFF”, the unit will display 0°C

continuously. This value will also be logged to the databank. Hence it is

therefore only necessary to connect sensors to the required number of

inputs.

Note: If a channel is switched off, the Alarm parameters will automatically

revert back to the default factory settings to prevent an alarm occurrence.

These parameters cannot be changed until the sensor input is switched on

again.

7-9 Channel Select for channel 2 to channel 4.

6 7 8 9

2 3 4 5

1

14

3.3.4 SETSCREEN4:SENSORINPUT TYPE SELECTION

The new SM Quattro now has the ability to measure, display and record

Relative Humidity (as a percentage %H) on any of its 4 sensor inputs using

the Thermomax Humidity Sensor (CO429). The 4 sensor inputs can be

configured to read either Temperature or Relative Humidity. As a factory

default, all 4 sensor inputs are configured to accept temperature sensors.

The following paragraph describes how to change the configuration for each

sensor input if required.

1In order to change the sensor input configuration, press the key four

times to reveal the new INPUT SELECTION screen as displayed below. This

screen gives you the option to choose the sensor type to be used with each

of the four input channels. This can be either the standard PT100

temperature sensor or the Humidity Sensor.

THERMOMAX

3

4

2By using the keys, you can move to the required channel

selection window.

3Pressing the key, allows you to select the input channel for

connection with a humidity sensor for measurement of relative humidity

percentage.

4Pressing the key selects an input for connection with a standard

PT100 temperature sensor.

For example, the diagram above shows channels 1 and 2 configured as

Temperature inputs and 3 and 4 configured as Humidity inputs.

Note: The information displayed on various screens will vary,

depending on the sensor type input as selected above (humidity /

temperature).

15

3.4 SYSTEM DIAGNOSTICS

3.4.1 DATABANK DIAGNOSTICS SCREEN

THERMOMAX

3

4

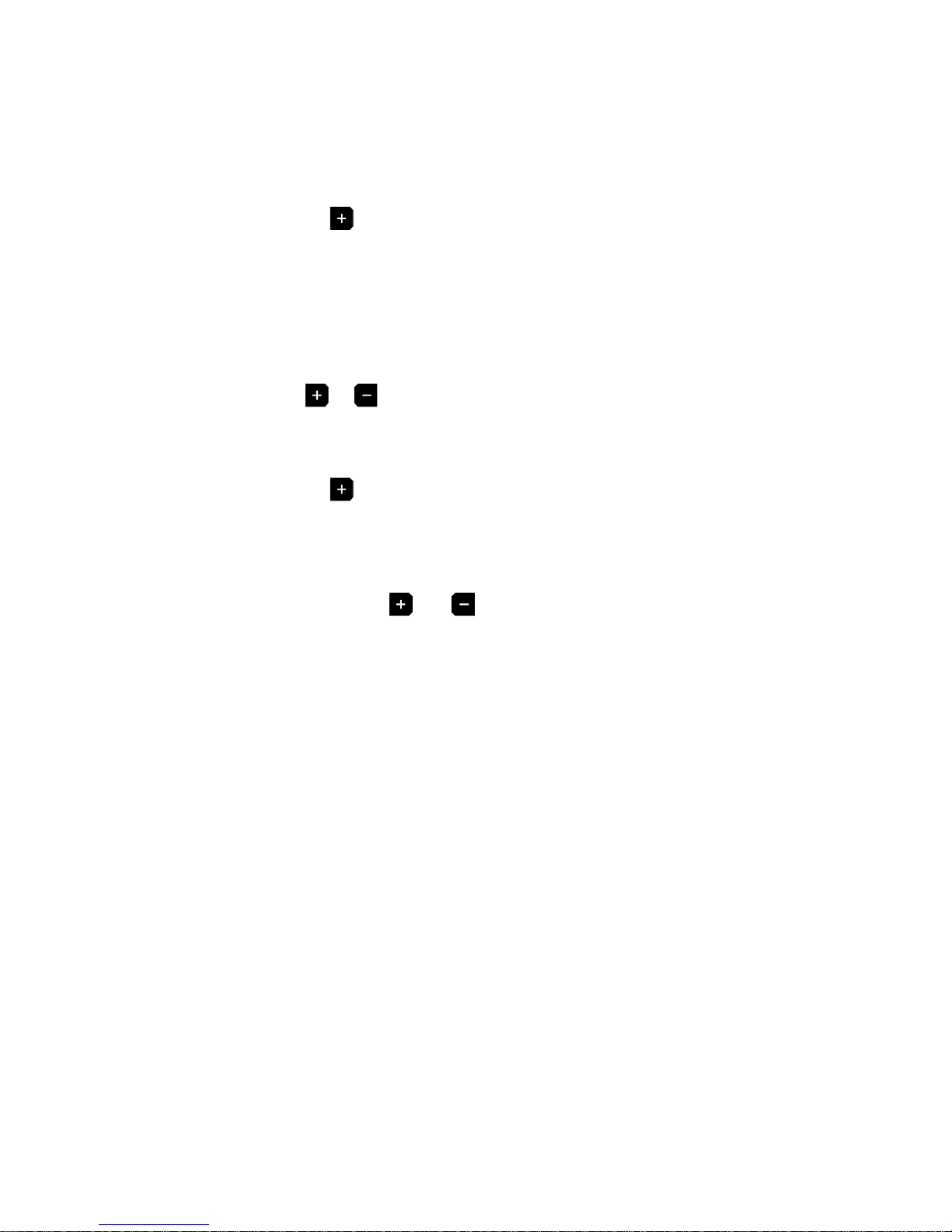

1This is the unique electronic signature of the SM QUATTRO.

2The DATABANK window shows the capacity of the internal databank.

3The DAYS FREE window shows the number of days which have not yet been

used.

4The PERC FREE window shows the percentage of the databank which has

yet not been used.

5The LAST ALRM window shows the last date on which an alarm condition

occurred.

6The TRANSF ON window shows the date on which the contents of the

internal databank need to be transferred.

7The MAINS FL window shows the last date on which the powerfailed. During

a power fail situation this window will display the duration, in minutes, of the

power failure.

8Diagnostics Screen Selection.

Use the keys to move between one of four diagnostic screens:

-DBM : Databank Diagnostics Screen (Ref. 3.4.1 above)

- CH1 : Channel 1 Diagnostics Screen (Ref. 3.4.2)

- CH4 : Channel 4 Diagnostics Screen (Ref. 3.4.2)

- CAL : Calibration Trimming Screen (Ref. 3.4.3)

8

1

7

6

5

4

3

2

16

3.4.2 CHANNELDIAGNOSTICSSCREEN

THERMOMAX

3

4

1The CHANNEL window shows the number of the currently selected channel.

2The INPUT TYPE window shows which type of sensor is being used. (PT100

in this case – this is the only type used by the SM QUATTRO at present).

3The CALIB DATA window shows calibration values, for factory use only, and

the current temperature reading.

4The LAST CALIB window shows the date when the SM QUATTRO was

calibrated.

5The AL HIGH window shows the date when the last high alarm condition

occurred for this channel.

6The AL LOW window shows the date when the last low alarm condition

occurred for this channel.

1

2

3

4

5

6

17

3.4.3 CALIBRATIONTRIMMINGSCREEN

Calibration trimming allows qualified personnel to adjust the SM

QUATTRO’s calibration by ±2oC.

Note: A known reference temperature should be used.

THERMOMAX

3

4

To enter the CALIBRATION TRIMMING Screen, press and hold the key

for 5 seconds.

THERMOMAX

3

4

Use the keys to move to the channel which requires calibration

trimming. Then use the or keys to adjust the current temperature

reading.

Current

Readings

3.5 CHANNELSCREENS

3.5.1 CHANNELDISPLAY SCREENS

THERMOMAX

3

4

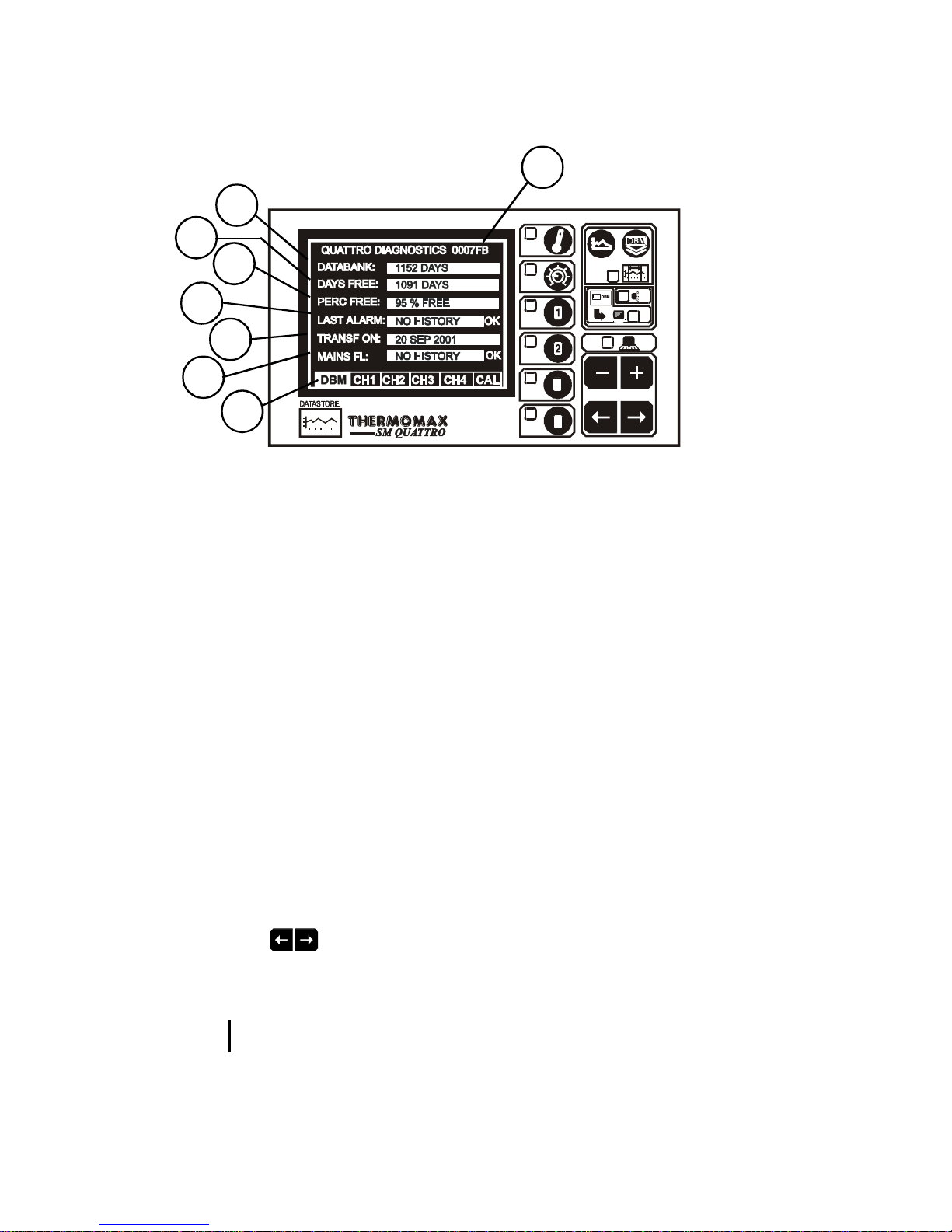

1 to 4 CHANNEL 1 to 4 function selector

Pressing any key of these keys a second time will display the “Channel Set

Screen” for that channel.

5Clock display : 24-hour format with day of week abbreviation.

6Temperature bargraph : High and low alarm limits are shown as

shaded areas.

7If any channel has been set up to read humidity, will

be displayed in this area, and all values will be displayed as % relative

humidity.

8Digital display of Channel temperature / humidity, with minimum / maximum

indication. The minimum and maximum values are daily values, and are

reset at midnight.

9When the door switch facility is activated (see 3.3.2) this area will show the

status as ‘door open’ or ‘door closed’. Note that if there is no switch

connected, the unit will display ‘door open’.

Note: The display contrast may also be adjusted from any of these

screens by pressing the or keys.

18

8

5

6

7

94

3

2

1

19

3.5.2 CHANNELSET SCREENS–TEMPERATURE

THERMOMAX

3

4

1 to 4 Channel 1 to 4 function selector

Pressing any of these keys a second time will display the “Channel Set

Screen” for that channel.

5 Bargraph Display Scale

By pressing the or key, the bargraph display scale may be adjusted to

show the temperature range best suited to the particular installation. This

scale is also used for the “Plot display” (Ref. 3.6 Current Day Plot and 3.7

Plot History).

6 High Alarm Stage 1 temperature (-50°C to +50°C)

The Stage 1 alarm is a time / temperature related alarm. If the

maximum threshold is exceeded, a timer is initiated, and no further action is

taken at this time.

7 High Alarm Stage 1 Delay (1 – 99 min.)

After the maximum threshold has been exceeded (Ref. 4 above), the alarm

will not be triggered until the timer exceeds the time delay set here. If the

temperature drops below the threshold before the expiry of this delay, the

timer is reset. If following this the temperature rises above the threshold

again, the timer restarts from zero.

8 High Alarm Limit Stage 2 temperature (-50°C to +50°C)

If at any time this limit is exceeded the time delays will be overridden and the

alarm will trigger immediately.

9 Low Alarm

All the functions described in 6-8 above also apply to the low alarm.

76 8

5

9

4

3

2

1

Table of contents

Other Thermomax Data Logger manuals