THERMOSALD UPSCR Series User manual

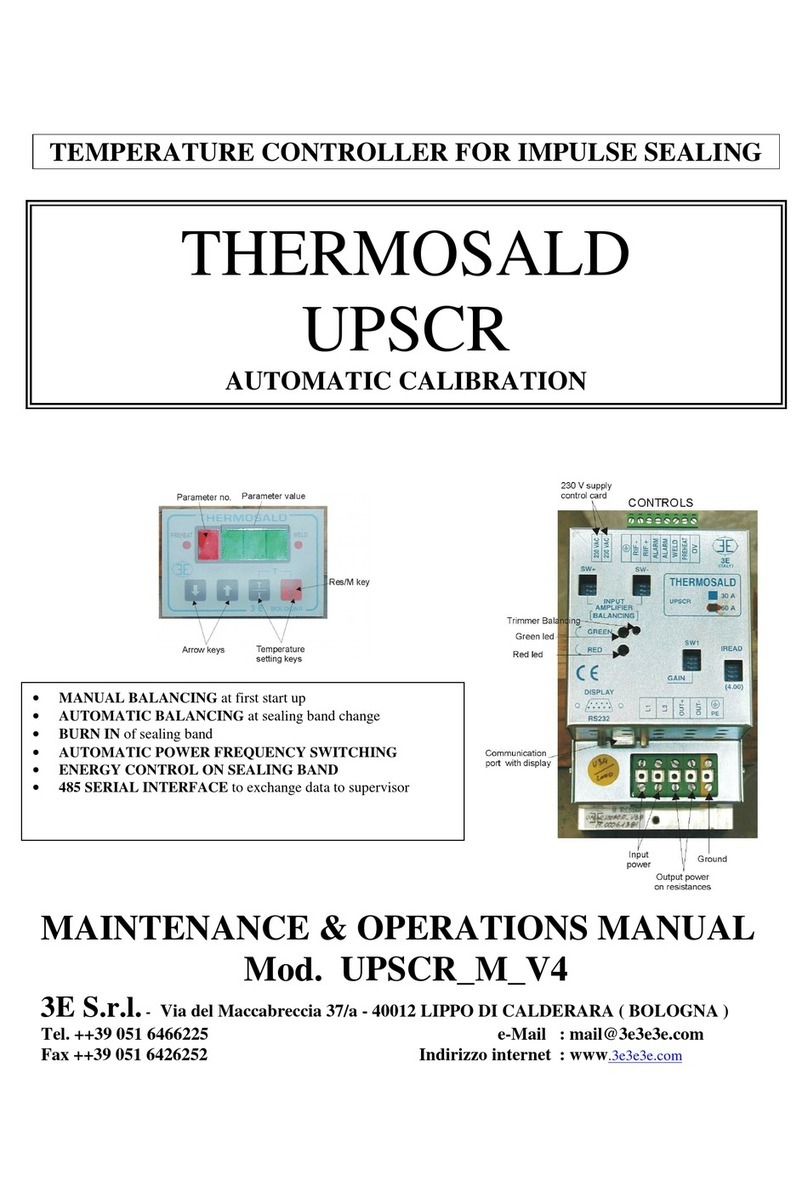

TEMPERATURE CONTROLLER FOR IMPULSE SEALING

THERMOSALD

UPSCR

AUTOMATIC CALIBRATION

OPERATOR MANUAL

Mod. UPSCR_N_V5 (M_V4)

3E S.r.l.

-

Via del Maccabreccia 37/a - 40012 LIPPO DI CALDERARA ( BOLOGNA )

Fax ++39 051 6426252 Indirizzo internet : www

.3e3e3e.com

•MANUAL BALANCING at first start up

•AUTOMATIC BALANCING at sealing band change

•BURN IN of sealing band

•AUTOMATIC POWER FREQUENCY SWITCHING

•ENERGY CONTROL ON SEALING BAND

•485 SERIAL INTERFACE to exchange data to supervisor

THERMOSALD UPSCR_N_V5 - OPERATOR MANUAL - Rev. 2006 / 07

Page N. 2 - Tot: 18

MAINTENANCE & OPERATIONS MANUAL: cod. UPSCR_N_V5_MOP_2001/06

0 WARNINGS

0.1 SAFETY PRECAUTIONS

- Never use the equipment in explosive atmospheres or with explosive materials.

- Never use the equipment with flammable material without first taking the

required safety precautions.

- Never turn on the temperature controller power circuit when the safety guards are

open.

- Do not use the temperature controller for tasks other than those it is designed for

i.e to control the temperature of bands or wires for industrial-grade sealing.

Contact our engineering department for information regarding specific

applications.

- Do not deliver electrical power to the temperature controller if the protective

cover has been removed for special servicing on the electronic system.

- Operate the equipment by following the instructions contained herein.

- Employ qualified and well-trained personnel, familiar with the technology used

to install the equipment and put it into service.

- Use bands or wires having an adequate positive temperature coefficient ( > 1 x

10E-3)

- When the machine is running under normal conditions, make sure the heat sink of

the controller does not exceed 60°C . If this happens, increase heat sink

ventilation or contact our engineering department.

THERMOSALD UPSCR_N_V5 - OPERATOR MANUAL - Rev. 2006 / 07

Page N. 3 - Tot: 18

0.2 COMPLIANCE WITH ELECTRO-MAGNETIC STANDARDS – CE KITE MARKS

Directives which apply :

•Low voltage electrical codes : 73/23 CEE - 9368 CEE (in force since 01/01/97)

•Elecro-magnetic compatibility : 89/336 CEE - 92/31 CEE - 93/68 CEE ( in force since 01/01/96 )

•Machine directive : 89/392 CEE - 91/368 CEE - 93/68 CEE ( in force since 01/01/95 )

NOTE - this directive does not automatically apply to the elecronic equipment; our controllers are designed to conform

with the directive if installed correctly as described in this user's manual.

Electro-magnetic compliance tests :

Test conditions :

•

••

•Mains supply filter Mod. Siemens B84112-B-B60 ( 115 / 250 V - 6A - 50/60 Hz )

•

••

•Temperature controller connecting cable and standard panel 3ESD0035E ( 5 m )

•

••

•Input power cables (3 m long)

•Band output cables (10 m long)

Safety tests :

•

••

•The criteria indicated in the EN50082-2 directive have been followed: general standards regarding safety in industry.

•

••

•IEC 1000-4-2 ( IEC 801-2/1991): STATIC ELECTRICITY DISCHARGE ( ESD )

•

••

•IEC 1000-4-3 ( CEI 801-3 ): RADIATED ELECTRO-MAGNETIC FIELD

•

••

•IEC 1000-4-4 ( CEI 801-4 ): FAST TRANSIENT OSCILLATIONS ( FAST TRANSIENT / BURST )

•

••

•ENV50141: MAINS PICKUP INTERFERENCE

Emissions tests :

•

••

•The criteria specified in the EN50081 -2 directive have been followed: general rules regarding emissions in industry

•

••

•EN55011 ( CEI 110-6 ): LIMITS AND METHODS OF MEASURING RADIO INTERFERENCE PRODUCED BY

INDUSTRIAL, SCIENTIFIC AND MEDICAL EQUIPMENT ( ISM )

Compliance certificate :

•

••

•The temperature controller passed the compliance tests and is considered a class B device.

•

••

•The manufacturer states that the temperature controller fully complies with current council directives as regards electro-

magnetic compatibility, 89/336 CEE standards and following amendments

•The manufacturer states that the temperature controller fully complies with current low voltage electrical codes 73/23

CEE and subsequent amendments.

THERMOSALD UPSCR_N_V5 - OPERATOR MANUAL - Rev. 2006 / 07

Page N. 4 - Tot: 18

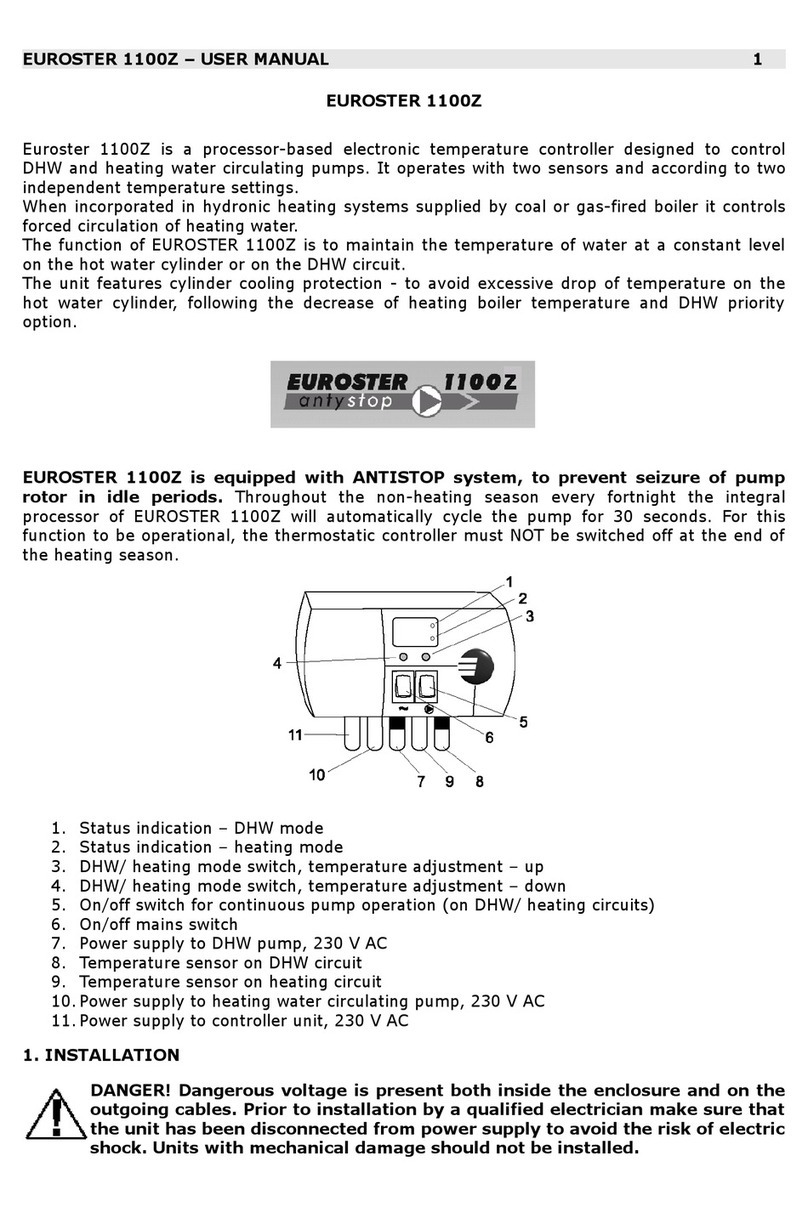

2 WIRING DIAGRAM AND DIMENSIONS

2.1 LIST OF CHANGE-OVER SIGNALS

2.2 WIRING DIAGRAM

CN1 POWER

(Power circuit supply synchronised with control circuit supply )

PIN1 ALTERNATING CURRENT SUPPLY (4 - 6 sq.mm)

PIN2 ALTERNATING CURRENT SUPPLY (4 - 6 sq.mm)

PIN3 BAND + (4 - 6 sq.mm)

PIN4 BAND - (4 - 6 sq.mm)

PIN5 EARTH (4 - 6 sq.mm)

CN2 CONTROL CIRCUIT SUPPLY

(Control circuit supply synchronised with power circuit supply )

PIN 1 230 Vac ( 0.1A absorption, max) (1sq.mm)

PIN 2 230 Vac ( 0.1A absorption, max) (1sq.mm)

CN3 CONTROLS

PIN1 COMMON 0 V PLC (0.5 sq.mm)

PIN2 PRE-HEAT SIGNAL FROM PLC, 24V DC ( 12 mA absorption, max) (0.5 sq.mm)

PIN3 SEALING SIGNAL FROM PLC, 24V DC ( 12 mA absorption, max) (0,5 sq.mm)

PIN4 SEALING FAULT (CONTACT N.C.) cosΦ= 1 250V 8A (0,5 sq.mm)

PIN5 SEALING FAULT (CONTACT N.C.) cosΦ= 0.4 250V 5A (0,5 sq.mm)

PIN6 BAND REFERENCE + (0,5 sq.mm)

PIN7 BAND REFERENCE - (0,5 sq.mm)

PIN8 SIGNAL LEAD SCREEN (do not connect from the machine side) (1 sq.mm)

CN4 DISPLAY CONSOLE

PIN1 Supply, +5V Screened (0,25 sq.mm)

PIN2 Supply, 0 V Screened (0,25 sq.mm)

PIN3 Data Screened (0,25 sq.mm)

PIN4 Clock Screened (0,25 sq.mm)

PIN5 Key Screened (0,25 sq.mm)

PIN6 Key Screened (0,25 sq.mm)

PIN7 Key Screened (0,25 sq.mm)

PIN8 Key Screened (0,25 sq.mm)

CN5 RS485 SERIAL INTERFACE

PIN1

PIN2

PIN3 Channel A- Screened (0,25 sq.mm)

PIN4

PIN5

PIN6

PIN7

PIN8 Channel B+ Screened (0,25 sq.mm)

THERMOSALD UPSCR_N_V5 - OPERATOR MANUAL - Rev. 2006 / 07

Page N. 5 - Tot: 18

- NOTE

The power circuit supply ( CN1/1 and CN1/2 ) MUST BE synchronised with the control circuit

supply ( CN2/1 and CN2/2 ).

CN1/5 should be connected to the EARTH ELECTRODE of the machine by using a yellow-

green wire whose size should be >= that of the power leads.

SEALING FAULT

REF.+ REF.-

EARTH

PRE-HEATING SIGNAL (INPUT FROM PLC)

SEALING SIGNAL (INPUT FROM PLC)

EARTH

BAND

TRANSFORMER 1000VA

EMERGENCY

STOP BUTTON

EMC FILTER

board faulty

THERMOSALD UPSCR_N_V5 - OPERATOR MANUAL - Rev. 2006 / 07

Page N. 6 - Tot: 18

3 - INSTALLATION

•CHAMFERED SPECIAL ALLOY ELEMENTS RESISTANCES CHART

•T-SHAPE SPECIAL ALLOY ELEMENTS RESISTANCES CHART

•BEADED SPECIAL ALLOY ELEMENTS RESISTANCES CHART

•CONCAVE SPECIAL ALLOY ELEMENTS RESISTANCES CHART

Band width

(mm) Band thickness

(mm) Specific resistance R0

Ω

ΩΩ

Ω/ mt

1.5 0.3 1.67

2 0.25 1.59

3 0.1 2.95

3 0.15 1.95

3 0.2 1.50

3 0.25 1.27

4 0.15 1.40

4 0.25 0.96

5 0.2 0.8

5 0.25 0.69

6 0.1 1.6

6 0.2 0.72

8 0.1 1.2

8 0.2 0.51

Band width

(mm) Band thickness

(mm) Specific resistance R0

Ω

ΩΩ

Ω/ mt

2.8 0.3 0.9

4 0.3 0.6

Band width

(mm) Band thickness

(mm) Specific resistance R0

Ω

ΩΩ

Ω/ mt

4 0.15 1.4

4 0.25 0.9

6 0.15 0.99

6 0.25 0.6

Band width

(mm) Band thickness

(mm) Specific resistance R0

Ω

ΩΩ

Ω/ mt

2.8 0.3 0.9

THERMOSALD UPSCR_N_V5 - OPERATOR MANUAL - Rev. 2006 / 07

Page N. 7 - Tot: 18

4 – START UP

4.1 – START UP – START UP WITH GENERAL RESET

1 - The machine must be at ambient temperature.

2 - Pre-heat and seal remote controls must be off.

3 - Set dip switch SW+/SW- according to the rated voltage of the power trasformer; see next CALCULATION

TABLE and DIP SWITCH SW+ / SW- TABLE:

CALCULATION TABLE

Example:

Sealing band = 1 Ω- RATED I = 30 A,

TRASFORMER RATED VOLTAGE = 30 V

TRASFORMER MAXIMUM VOLTAGE = 30 V x 1.5 = 45 V

TRASFORMER SECONDARY VOLTAGE = Compresa fra 30V e 45V

DIP SWITCH SW+ e SW- = OFF OFF ON ON (See DIP SWITCH SW+ / SW- TABLE)

NOTE: SW+ e SW- set depend on

TRASFORMER RATED VOLTAGE = 30V (field 26V - 35 V )

(don’t depend on TRASFORMER SECONDARY VOLTAGE)

DIP SWITCH SW+ / SW- TABLE

Dip 1 Dip 2 Dip3 Dip4 TRASFORMER RATED VOLTAGE

ON ON ON ON 05 - 07 (TO LIGHT GREEN LED)

OFF ON ON ON 08 - 15

ON OFF ON ON 16 - 25

OFF OFF ON ON 26 - 35

ON ON OFF ON 36 - 42

OFF ON OFF ON 43 - 50

ON OFF OFF ON 51 - 57 binary system

OFF OFF OFF ON 58 - 65

ON ON ON OFF 66 - 75

OFF ON ON OFF 76 - 82

ON OFF ON OFF 83 - 92

OFF OFF ON OFF 93 - 97

ON ON OFF OFF 97 - 100

OFF ON OFF OFF -

ON OFF OFF OFF -

OFF OFF OFF OFF - ( TO LIGHT RED LED)

THERMOSALD UPSCR_N_V5 - OPERATOR MANUAL - Rev. 2006 / 07

Page N. 8 - Tot: 18

4 –Press the keys 1 + 4 (down + reset) and, at the same time, power on the thermoregulator

4 - Release the keys 1+4 (down+reset)

5 – Display = “ P H A S ”

On the display appears “ P H A S ” to mean that logic and power supplies phase control is in progress (if logic and power

supplies are not on the same phase, “ F 0 8 3 “ fault signal is sent).

5 – Wait

6 – Display = “ V O L T ”

On the display appears “ V O L T ” to mean that TRASFORMER SECONDARY VOLTAGE control is in progress (this

voltage must be between TRASFORMER RATED VOLTAGE and TRASFORMER MAXIMUM VOLTAGE).

6 – Wait

4– Display = “ V 0. 5 0 ” -> “ V 1. 1 0 ” - USE FACTOR

On the display appears “ V ” followed by a number that informs if thermoregulator is well used or not: the right value are

included in the range V 0.6 – V 1.0; absolute maximum rating V 1.3.

V 1.0 means active current 45A (for model 30A), 90A (for model 60A), 135A (for model 90A)

7 – Wait

8 – Display = “ V D I P ” blinking

On the display blinks “ V D I P ” to remember that SW+ / SW- dip switch must be set (see CALCULATION TABLE and

DIP SWITCH SW+ / SW- TABLE).

8 - Press the RESET key

9 – Display = “ T 0 2 0 ” = 20 DEGREES – Set gripper jaws temperature or wait

(“ T 0 3 0 ” = 30 DEGREES from software release V4.9)

On the display appears the ambient (gripper jaws) temperature set on the thermoregulator.

In applications where a great precision of temperature is necessary, it is possible change this parameter and set it with the

actual gripper jaws temperature, simply pressing keys DOWN / UP.

9 - Wait

- 4 blocks appear on the display; the reset procedure begins; release keys

down + reset (1 + 4).

- Thermoregulators leave our factory in reset state, then at power on 4 blocks

always appear and reset procedure begins.

- Whenever an operator needs to repeat reset procedure, he can keeps keys 1

+ 4 (down + reset) pressed 6 + 8 seconds untill on the display the 4 blocks

appear and the reset procedure begins.

THERMOSALD UPSCR_N_V5 - OPERATOR MANUAL - Rev. 2006 / 07

Page N. 9 - Tot: 18

10 – Display = “ _ B A L ” / “Temperature” – START UP COLD BALANCING BY TRIMMER

(TO TOUCH AND ROTATE ONLY IN THE COURSE OF FIRST START UP)

10 – Press the key RESET (ON DISPLAY DISAPPEAR THE “ B “ OF “ B 0 2 0 “ AFTER SOME SECONDS)

(From software release V4.9 it is possible press also the keys DOWN + UP)

11 – Keep the key RESET pressed for 3 seconds to start the AUTOMATIC BURN-IN CYCLE

THE MACHINE IS READY TO WORK.

NOTE: After the BURN IN cycle, sealing bands modify a little its electric characteristic, but are stable. If pay

attention can observe that temperature of sealing bands is some degree lower then before burn_in cycle. Do not

modify temperature by rotating balancing trimmer (used only in the course of first start up, after a master reset) or

pressing the up/down keys to do an automating balancing (used only after a change of the sealing band)

NOTE: It’s possible to do the machine more hot increasing HOT FACTOR value, parameter 5; From software

release V4.9 it’s possible to change it pressing the keys DOWN+T/I for 3 seconds, parameter nr. 5 appears, change

the value by key DOWN or UP, wait 6 seconds to return to main menu.

(As previous software release, it’s possible to change this parameter entering in the SETTING DATA or HOT

CALIBRATION DATA, pressing key UP+RESET 6 seconds, see ANNEX C)

NOT BALANCED SYSTEM

- On the display appears alternatively “ B A L ” and “temperature value not balanced ” to

remember that green/red led balancing need to do (Note: a red bar down before “ B A L “

means unbalance towards down; a red bar up before “ B A L “ means unbalance towards up;

the wording “ T - - - “ means temperature overflow toward down).

- rotate balancing trimmer clockwise to light green led, rotate anticlockwise to light red led;

update of green/red led is 1 time in a second, so to calibrate fine it is necessary to rotate

balancing trimmer and wait up to aone second to wait update condition.

- When green and red leds are light both, the thermoregulator is balanced; we advise to read

temperature value on the display and rotate trimmer untill having 20 degree, if 20 degree is

the temperature of the gripper jaws: in any case the termoregulator will do next an automatic

perfect balancing.

BALANCED SYSTEM

- On the display appears fixed “ B 0 2 0 “, if 20 degree is temperature of the gripper jaws;

- When green and red leds are light both, the thermoregulator is balanced; we advise to read

temperature value on the display and rotate trimmer untill having 20 degree, if 20 degree is

the temperature of the gripper jaws: in any case the termoregulator will do next an automatic

perfect balancing.

On the display appears “ H100” , to inform that the first heating at 100

degree is in progress; next the writing H160, H100, H160, H100,

H160, H100 will appear to inform that cycles of heating and colding at

160 and 100 degrees are in progress. At the end the termoregulator will

be ready to work.

Burn in cycle can be stopped before end pressing key reset.

THERMOSALD UPSCR_N_V5 - OPERATOR MANUAL - Rev. 2006 / 07

Page N. 10 - Tot: 18

4.2 – SETTING THE PRE-HEATING AND/OR SEALING TEMPERATURES

1 – Press the keys 3+4 (T/I+RESET) for 3 seconds

The PREHEAT led on the panel start flashing and indicate the set pre-heating temperature.

2 – Press the keys UP or DOWN to change the temperature of pre-heating.

3 – Press the key RESET to switch to the temperature of sealing changing.

The WELDING led on the panel start flashing and indicate the set sealing temperature.

4 – Press the keys UP or DOWN to change the temperature of sealing.

5 – Wait 3 seconds to leave temperature setting.

4.3 – WRITING DOWN THE START UP DATA CARD

Write down the START UP DATA CARD – PAG. 1, ANNEX G

If any machine or setting data is modified, write down also START UP DATA CARD – PAG. 2.

That above lets to record start up data in the documentation of the machine; it will be useful for future verify and for starting

up of the next machines, so it will be easer to do and all machine will be equal.

4.4 - SPECIAL FUNCTION ENERGY CONTROL

•CAN BE PERFORMED ON ALL MACHINES HANDLING SLIGHTLY FLAMMABLE MATERIAL; THIS

INCREASE REDUNDANCY AND AUTO-CONTROL THEREBY MAKING THE SYSTEM SAFER TOO

(BEFORE GOING ON, GET IN TOUCH WITH OUR TECHNICAL OFFICE FOR INSTRUCTIONS)

1 - Enter the machine data

F = 1 to Enable the control for the pre-heating procedure

F = 2 to Enable the control for the heat-sealing procedure

F = 3 to Enable the control for the pre-heating + heat-sealing procedure

2 - Pre-heat for 10 seconds

The thermoregulator acquire the power supplied in pre-heating.

3 – Start the machine running with the bags loaded

The thermoregulator acquire the power supplied in sealing.

When acquisition phase is finished, if thermoregulator detects a power on the bag out of tolerance stop in emergency.

In the case of slightly flammable materials, the machine builder must pay much attention to applications and take

right solutions for safety.

NOTE – Each time the pre-heating and sealing temperature or some machine data are changed, an automatic data

acquisition needs to be performed.

4.5 - SPECIAL FUNCTION 485 SERIAL INTERFACE AND FIELD BUS

(IN PROGRESS)

THERMOSALD UPSCR_N_V5 - OPERATOR MANUAL - Rev. 2006 / 07

Page N. 11 - Tot: 18

4.6 – UP-DATE OLD MACHINES

•WOULD YOU LIKE TO UPDATE OLD MACHINES WITH NEW SOFTWARE RELEASE?

For this procedure do not exitate to contact our technical office. From Thermosald Hardware M it is possible update

machine without loose any performance; for older units needs pay attention to. This operation is easy enough, but must be

done only by skilled workers with experience. After update a careful test need to be done. We don’t take any responsibility

on ourself for damage to people or animals or things, if operations are done without our direct control.

Procedure to change the eprom:

Disconnect and detach completely the thermoregulator from electrical panel, to can work on a tooled table, with the power

connector on the left and the 2 connectors + fuse on the right. Unscrew the 4 screws on the bottom heat sink and the 6 self-

tapping screws on the carter; pay much attention to the internal flat, and take off the carter enlarging lightly lateral panel to

unlock the connectors; disconnect internal flat and take off completely the carter.

Inside You can see 3 boards: on the central board, with the components mounted towards inside, the eprom on socket (28

pin) You can see. Pay attention not to stretch some pins, pay attention to the polarity of the eprom; with a right tool pickup

the old eprom and mount the updated eprom (pin 1 and reference mark towards inside like as the other chips).

To close You must: connect the flat, pay much attention to mount the carter enlarging lightly lateral panel and rotating the

carter on the side of the flat; close the lateral panel; screw lightly the 4 screws on the bottom heat sink; screw tight the 6 self-

tapping screws on the carter; screw now tight the 4 screws on the bottom heat sink.

Mount and connect the thermoregulator.

Before power on, set DIP SWITCH in the bottom way:

SW+ / SW- NO CHANGE

SW1 1=ON 2=ON 3=ON 4=ON (ALL = ON )

IREAD 1=ON 2=OFF 3=ON 4=ON (IREAD/2 = OFF)

DO THE START UP WITH GENERAL RESET PROCEDURE – SEE CHAPTER 4.1

THERMOSALD UPSCR_N_V5 - OPERATOR MANUAL - Rev. 2006 / 07

Page N. 12 - Tot: 18

5 – MAINTENANCE

5.1 – CHANGING THE SEALING BANDS WITH MACHINE COLD ( i.e. gripper jaws at ambient temperature )

•HAVE YOU TO CHANGE THE SEALING BANDS WITH THE MACHINE AT AMBIENT TEMPERATURE,

BECAUSE OF A PROGRAMMED MAINTENANCE?

Pre-heat and seal comands are off; the machine is at ambient temperature; The sealing bands have little differences in

measure; for optimum accuracy it is possible to do an automatic cold balance to compensate the differences; it is possible

doing a burn-in cycle after, to become stable electric characteristics.

1 – Switch off power, release pre-heat and seal commands, let the gripper jaws getting cold down.

2 – Install the new sealing bands, switch on power.

3 – Keep the keys 1 + 2 (DOWN + UP) pressed for 6 seconds to make the AUTOMATIC COLD BALANCING

4 - Display = “ T 0 2 0 ” = 20 DEGREES – Set gripper jaws temperature or wait

(“ T 0 3 0 ” = 30 DEGREES from software release V4.9)

On the display appears the ambient (gripper jaws) temperature set on the thermoregulator.

In applications where a great precision of temperature is necessary, it is possible change this parameter and set it with the

actual gripper jaws temperature, simply pressing keys DOWN / UP.

5 – Keep the key RESET pressed for 3 seconds to start the AUTOMATIC BURN-IN CYCLE

THE MACHINE IS READY TO WORK.

NOTE: After the BURN IN cycle, sealing bands modify a little its electric characteristic, but are stable. If pay

attention can observe that temperature of sealing bands is some degree lower then before burn_in cycle. Do not

modify temperature by rotating balancing trimmer (used only in the course of first start up, after a master reset) or

pressing the up/down keys to do an automating balancing (used only after a change of the sealing band)

On the display appears “ H100” , to inform that the first heating at 100

degree is in progress; next the writing H160, H100, H160, H100,

H160, H100 will appear to inform that cycles of heating and colding at

160 and 100 degrees are in progress. At the end the termoregulator will

be ready to work.

Burn in cycle can be stopped before end pressing key reset.

- On the display appears “ B A L “

- Release the key 1 + 2 (DOWN + UP)

THERMOSALD UPSCR_N_V5 - OPERATOR MANUAL - Rev. 2006 / 07

Page N. 13 - Tot: 18

5.2 – CHANGING THE SEALING BANDS WITH MACHINE HOT

( i.e. gripper jaws cooling down , but hot too because of inertia )

•HAVE YOU TO CHANGE THE SEALING BANDS WITH THE MACHINE HOT, WITH THE

PRODUCTION IN PROGRESS, WITHOUT WAITING THAT GRIPPER JAWS TEMPERATURE FALLS

DOWN AT AMBIENT TEMPERATURE?

A sealing bands change, with the machine hot, with the production in progress, is less accurate then a change with the

machine cold, in a programmed mainteinance, because the automatic cold balancing must not be done (an automatic cold

balance is done to compensate the differences in measure of the sealing bands).

If the application needs a very high precision, it is possible doing a quick change of the all gripper jaws with sealing bands,

and go on with the preceding procedure of CHANGING THE SEALING BANDS WITH MACHINE COLD(see par. 5.1).

Another less expensive way to work, but easier to make a mistake, is to set the parameter of ambient temperature at the

gripper jaws temperature and doing an automatic cold balancing (do not exitate to contact our technical office)

1 – Switch off power, release pre-heat and seal commands, let the gripper jaws cooling down.

2 - Install the new sealing bands, switch on power.

- If the machine is hot, must not do the automatic cold balancing.

3 – Keep the key RESET pressed for 3 seconds to start the AUTOMATIC BURN-IN CYCLE.

- Verify if burn-in is necessary in the specific application, looking at the quality of first sealing.

THE MACHINE IS READY TO WORK.

On the display appears “ H100” , to inform that the first heating at 100

degree is in progress; next the writing H160, H100, H160, H100,

H160, H100 will appear to inform that cycles of heating and colding at

160 and 100 degrees are in progress. At the end the termoregulator will

be ready to work.

Burn in cycle can be stopped before end pressing key reset.

THERMOSALD UPSCR_N_V5 - OPERATOR MANUAL - Rev. 2006 / 07

Page N. 14 - Tot: 18

ANNEX D – FAULTS AND WARNINGS LIST (CAUSES – REMEDIES)

NOTA – Press the key RESET / MODE to reset every alarm

WARNINGS CAUSES

REMEDIES

UDIP A GENERAL RESET PROCEDURE HAS BEEN PERFORMED

Set or Verify the DIP SWITCH SW+/SW- and press the key RESET/MODE

FBAL A GENERAL RESET PROCEDURE HAS BEEN PERFORMED

Make cold balancing of led green/red by trimmer and press the key RESET/MODE

FCAL EQUIPMENT NOT CALIBRATED

Make hot automatic calibration (only previous software up to release 4.0)

Fo5o ENTER THE HEATING FACTOR

Keep keys 2+4 (UP+Reset/Mode) Pressed for 6 seconds and set parameter 5 (heat factor)

(only previous software up to release 4.0)

F21/F22/F23/F25/F26 RS485 INTERFACE ERRORS

please wait autoreset and try again

F33 NO CURRENT TO THE BAND

Verify power on the trasformer, Verify Voltage on CN1/1-CN1/2 connector, Verify breaking of power

cables, Verify breaking of bands.

F34 VERIFY DIP SWITCH AND PRESS RESET KEY

Verify DIP and Press RESET/MODE key

F35 DO A BALANCE BY TRIMMER BALANCING

Only at start up after a master reset, it’s necessary to do a trimmer balancing and an electronic balancing

F36 DO AN ELECTRONIC BALANCE BY PRESS DOWN+UP KEY

At start up after a master reset and a trimmer balancing, it’s necessary to do an electronic balancing

F38 THE MACHINE IS WAITING A COOLING DOWN DURING A CALIBRATION PROCEDURE

Wait please

F39 THE MACHINE IS WAITING A COOLING DOWN DURING AN ENERGY ANQUISITION

Wait please (only previous software up to release 4.0)

FAULTS CAUSES

REMEDIES

F41 ENERGY FAULT BY PRE-HEAT CURRENT CONTROL

Verify bands in the machine, repeat energy acquisition

F42 ENERGY FAULT BY PRE-HEAT PHASE CONTROL

Verify bands in the machine, repeat energy acquisition

F43 ENERGY FAULT BY PRE-HEAT CURRENT CONTROL NOT ACQUIRED

Do energy acquisition

F44 ENERGY FAULT BY PRE-HEAT PHASE CONTROL NOT ACQUIRED

Do energy acquisition

F51 ENERGY FAULT BY SEALING CURRENT CONTROL

Verify bands in the machine, repeat energy acquisition

F52 ENERGY FAULT BY SEALING PHASE CONTROL

Verify bands in the machine, repeat energy acquisition

F55 ENERGY FAULT BY CONTINUOS SEALING CURRENT CONTROL

Verify bands in the machine, repeat energy acquisition

F56 ENERGY FAULT BY CONTINUOS SEALING PHASE CONTROL

THERMOSALD UPSCR_N_V5 - OPERATOR MANUAL - Rev. 2006 / 07

Page N. 15 - Tot: 18

Verify bands in the machine, repeat energy acquisition

F61 AUTOMATIC COLD CALIBRATION OVERFLOW TO LOW

Verify bands characteristic, repeat operation, if problem persists contact our technichal office.

F62 AUTOMATIC COLD CALIBRATION OVERFLOW TO HIGH

Verify bands characteristic, leave the machine cooling, repeat operation, if the problem persists do not

exitate to contact our technichal office.

F63 MAINS SUPPLY FREQUENCY OUT OF RANGE

Wait mains supply frequency to stabilize, press key RESET/MODE; if the problem persist set parameter

DATI DI SETTING / BAR CODE 3 = 0.

F69 CURRENT TO GROUND

Verify bands into machine that touch probably ground.

NOTE: the thermoregulator is connected to ground, to verify with an instrument the band problem, it is

necessary disconnect before bands cables from connector CN1/3-CN1/4 and connector CN3/6-CN3/7.

F76 IREAD TOO HIGH

Current circuit saturation.

Verify bands in machine not perfectly isolated.

Verify voltage on secondary of power trasformer.

Contact our technichal office.

F77 50/60 HZ FREQUENCY CHANGE DETECTED

Verify at power on a change in the mains supply frequency 50/60 Hz.

After a master reset or at start up the thermoregulator has recognise 60 Hz mains supply frequency.

Press key RESET/MODE

F78 EQUIPMENT NOT CALIBRATED

Make an automatic calibration

(only previous software up to release 4.0)

F081 CHECK-SUM FAULT – HARDWARE FAILURE

Checked data in the eeprom wrong, pay much attention please.

Press key RESET/MODE, verify MACHINE DATA, SETTING DATA, PRE-HEAT AND SEAL

TEMPERATURE SET, do not exitate to contact our technichal office.

F082 LOGIC SUPPLY(CN2) AND POWER SUPPLY(CN1) HAVE DIFFERENT PHASES

Verify that the supplies have the same phase or out of phase 180 degree.

F083 REFERENCE CABLE OR POWER CABLE WRONG TURNED

Verify connections of reference and power cables:

CN3/6 corresponding to CN1/3

CN3/7 corresponding to CN1/4

F084 POWER TRASFORMER VOLTAGE TOO HIGH

Verify calculation of power trasformer, Verify setting of DIP SWITCH SW+ SW-

F085 SEALING TIME HIGHER THAN MACHINE SET DATA 7.XXX

Verify sealing time set into the PLC, increase MACCHINE DATA 7.XXX

F086 MAINS SUPPLY VOLTAGE DECRESASED BY MORE THEN 10%

Fault do not stop machine and disappear after 10 seconds, Verify mains supply voltage because floating.

F087 MAINS SUPPLY VOLTAGE DECRESASED BY MORE THEN 10% DURING SEALING

Fault do not stop machine and disappear after 10 seconds, Verify main supply voltage because floating.

F088 NO SIGNAL FROM BAND

Verify the band into machine because probably not perfectly isolated.

Fault Hardware on the analog input.

Do not exitate to contact our technichal office.

F089 BAND BROKEN IF THE BANDS ARE PARALLEL CONNECTED

Verify the bands in parallel.

If the problem persist, repeat Burn-in procedure, only few seconds to permit starting of procedure, and press

RESET/MODE to interrupt procedure.

F090 SHORT CIRCUIT BETWEEN THE BANDS OR BETWEEN A BAND AND GROUND IN THE

CASE OF HIGH CURRENT

THERMOSALD UPSCR_N_V5 - OPERATOR MANUAL - Rev. 2006 / 07

Page N. 16 - Tot: 18

Verify bands, Verify power connectios between thermoregulator and bands.

F091 FAULT I2T

Verify currents.

F092 POWER PART FAILURE

Hardware problems, press key RESET/MODE, if the problem persists do not exitate to contact our

technichal office.

F093 BAND BROKEN DURING A SEAL

Verify power on the trasformer, Verify Voltage on CN1/1-CN1/2 connector, Verify breaking of power

cables, Verify breaking of bands.

F094 REFERENCE SIGNAL CABLE FROM BAND IS INTERRUPTED

Verify the connections of reference signal cable from band ( CN3/6 - CN3/7 )

F095 MAINS SUPPLY SYNCRONISM DOES NOT MATCH MACHINE REQUIREMENTES

Internal hardware problem, do not exitate to contact our technichal office.

F096 V-I TOO HIGH

Voltage circuit saturation.

Verify trimmer BALANCING

Verify DIP SWITCH SW1 (only previous software up to release 4.0)

F097 PARTIAL SHORT-CIRCUIT BETWEEN THE BANDS

Verify bands into machine, probably not perfectly isolated.

If the problem persist, repeat Burn-in procedure, only few seconds to permit starting of procedure, and press

RESET/MODE to interrupt procedure.

To reduce the problem increase MACHINE DATA 8.XXX (PARTIAL SHORT CIRCUIT)

F098 NO CURRENT DELIVERED DURING CALIBRATION

Verify power on the trasformer, Verify Voltage on CN1/1-CN1/2 connector, Verify breaking of power

cables, Verify breaking of bands.

F099 FAULT EEPROM

Do not exitate to contact our technichal office.

THERMOSALD UPSCR_N_V5 - OPERATOR MANUAL - Rev. 2006 / 07

Page N. 17 - Tot: 18

ANNEX G – START UP CARD – PAG. 1

COMMERCIAL NOTE

MODEL OF MACHINE:

CUSTOMER:

BAND POSITION:

KIND OF FILM TO SEAL:

THICKNESS OF FILM TO SEAL:

APPLICATION NOTE

Band material = _______________________

Band form profile = _______________________

Width of the band = _______________________ [mm]

Thickness of the band = _______________________ [mm]

Length overall = _______________________ [mm]

Copper/Silver ends = _______________________ [2 x mm]

Copper/Silver in the centre = _______________________ [mm]

Teflon coat in the centre = _______________________ [mm]

Type of connections (Parallel/Serial) = _______________________ [P/S]

TECNICHAL NOTE

RESISTANCE OF THE SEALING = _______________________ [Ω]

RATED CURRENT OF THE THERMOSALD = _______________________ [30/60/90 A]

SECONDARY VOLTAGE OF THE TRANSFORMER = ______________________ [V]

MODEL OF THE THERMOSALD = _______________________ [UPSCR_M_V4_……]

DIP SWITCH TABLE

SW + SW-

1234

ON

OFF

1234

ON

OFF

USE FACTOR = _____________

PRE-HEAT TEMPERATURE = _____________ [°C]

SEALING TEMPERATURE = _____________ [°C]

SEALING TIME (SET INTO THE PLC) = _____________ [Sec.]

ANNEX G – START UP CARD – PAG. 2

MACHINE DATA TABLE Default

Heating incr. degrees/10ms 1. [ 020 ] : 1.

KV proportional gain 2. [ 120 ] : 2.

KINT integral gain 3. [ 50.0 ] : 3.

KINT operating limit 4. [ 030 ] : 4.

00C = °C / 00F = ° F 5. [ 00C ] : 5.

Electr.frequency 50 / 60 Hz 6. [ AUT ] : 6.

Max sealing time 7. [ 00.0 ] : 7.

Partial short circuit factor 8. [ 01.1 ] : 8.

Alarm enable 9. [ 255 ] : 9.

Rated current A. [ 30/60/90] : A.

KD derivative gain B. [ 040 ] : B.

1 = cold system compens. C. [ 000 ] : C.

1 = enable serial printer D. [ 000 ] : D.

sealer number for printer E. [ 000 ] : E.

Energy control enable F. [ 000 ] : F.

Current tol.in pre-heat H. [ 04.0 ] : H.

Phase tol.in pre-heat I. [ 06.0 ] : I.

Current tol.in seal L. [ 04.0 ] : L.

Phase tol.in seal O. [ 06.0 ] : O.

Energy min thresold acquire P. [ 060 ] : P.

Burn-in Temperature C1 [ 160 ] : C1.

Burn-in heating Time C2 [ 030 ] : C2.

Cycle Num. to change freq. C3 [ 000 ] : C3.

Max.err.1/10000 period freq. C4 [ 900 ] : C4.

SETTING DATA TABLE Default

Heating current for test 0. [00.0] : 0.

V-I istantaneus for test 1. [ xxx ] : 1.

I read istantaneus for test 2. [ xxx ] : 2.

Maximum active current 3. [ 45/90/135 ]: 3.

Working active current 4. [ xxx ] : 4.

Heating factor 5. [ 0.9 ] : 5.

V-I 100 degree 6. [ xxx ] : 6.

I-V absolute max. rating 7. [ 3.6 ] : 7.

I-V rated 8. [ xxx ] : 8.

Mains supply frequency 9. [ xxx ] : 9.

Voffset A. [ 400] : A.

Max sealing temperature B. [ 250 ] : B.

Temper.gradient(degree/10sec)C.[ xxx ] : C.

Other manuals for UPSCR Series

1

This manual suits for next models

2

Table of contents

Other THERMOSALD Temperature Controllers manuals