v

Preface

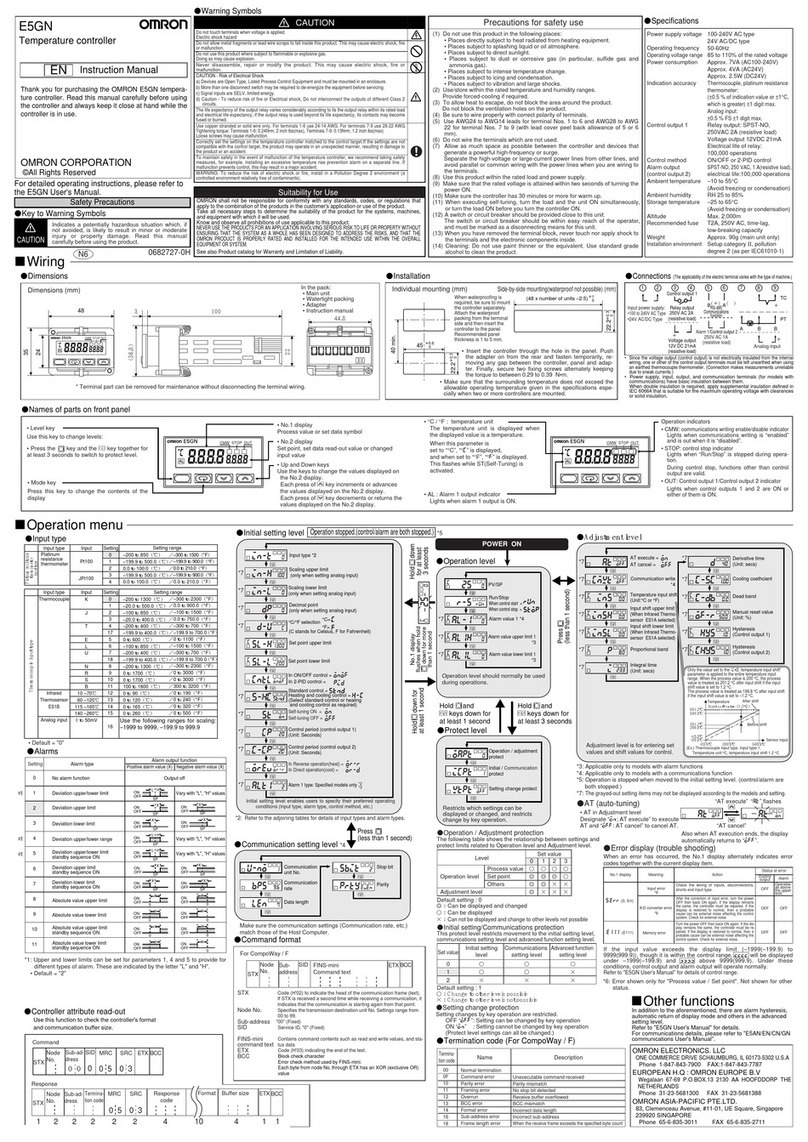

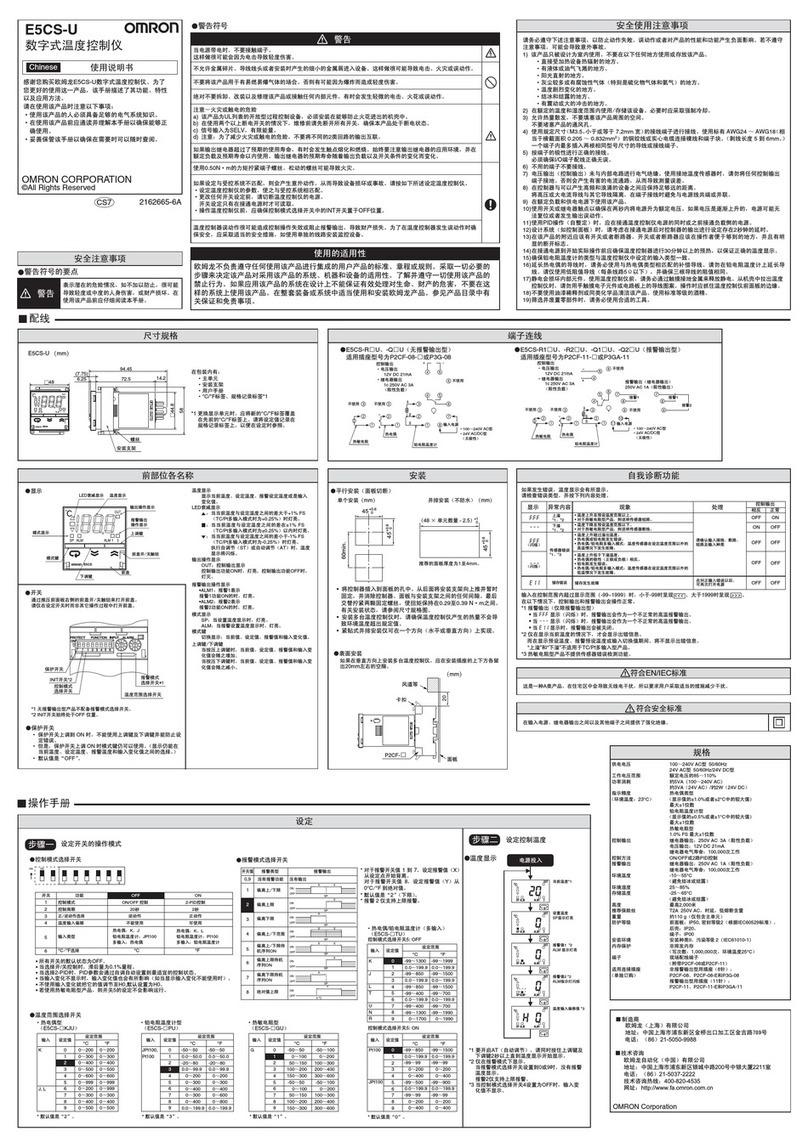

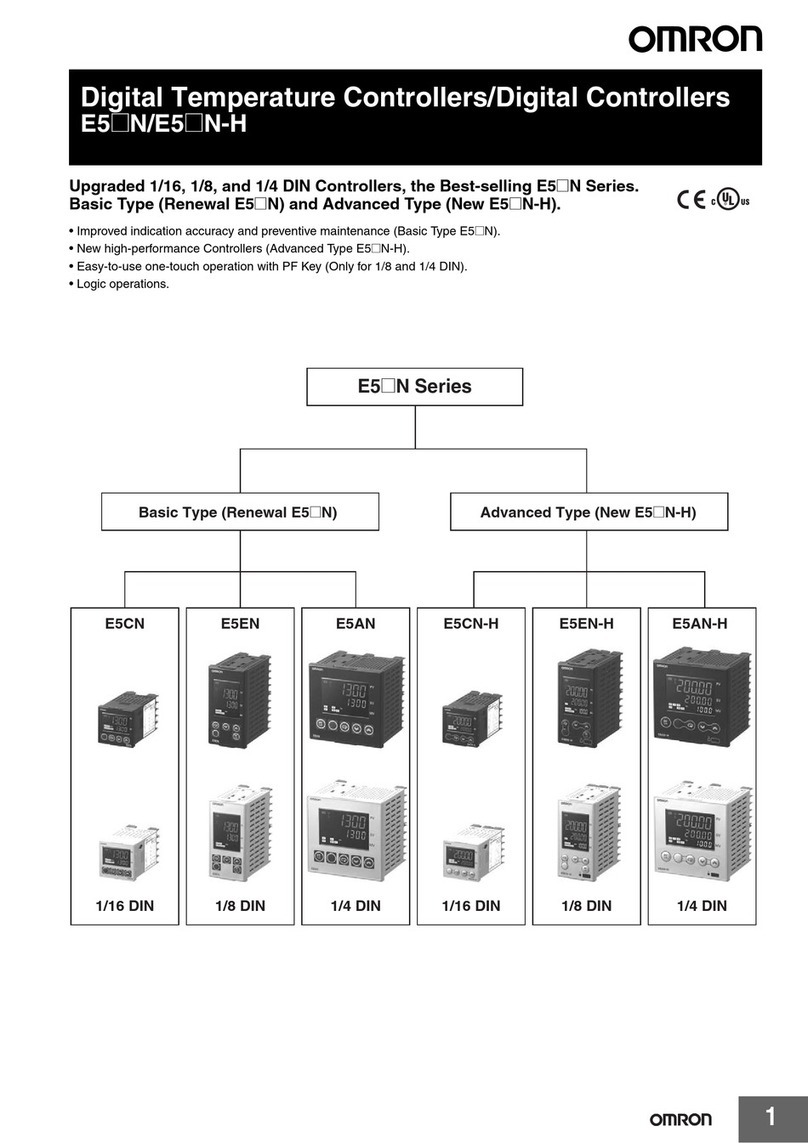

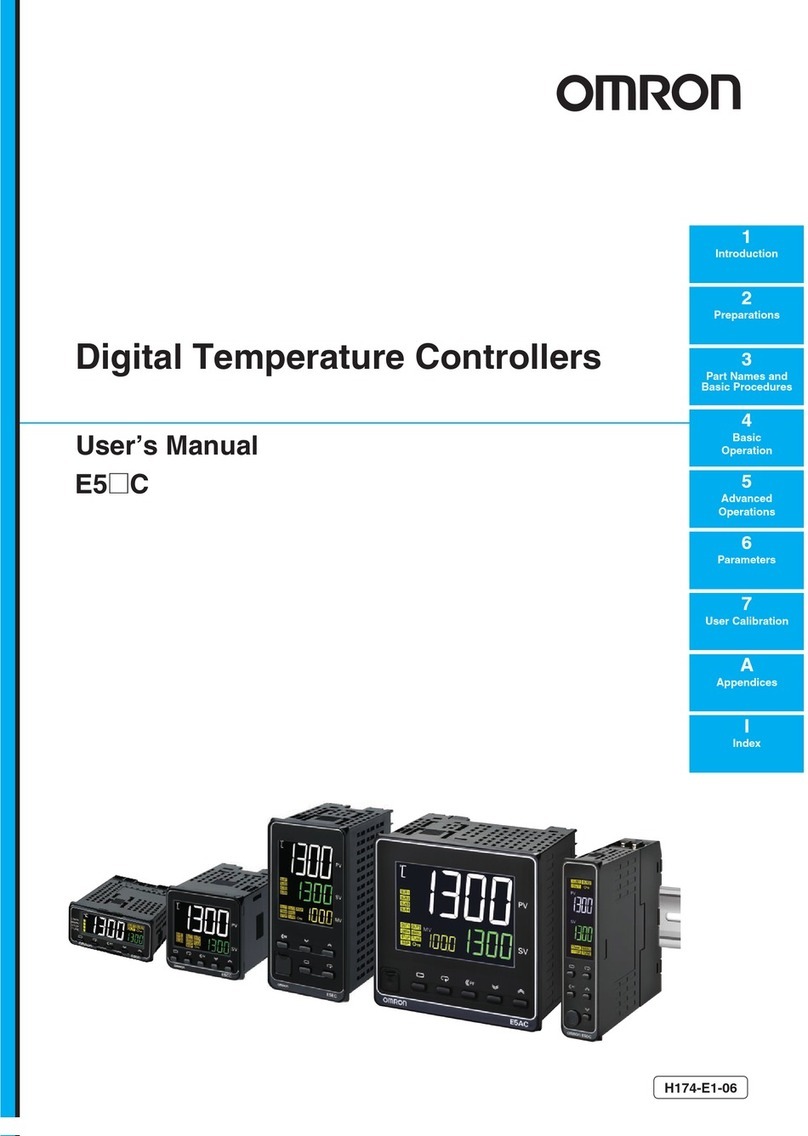

The E5CN, E5CN-U, E5AN, E5EN, and E5GN are Digital Temperature Controllers. The E5CN and

E5CN-U are both compact temperature controllers, with the E5CN featuring screw terminal connec-

tions, and the E5CN-U featuring socket pin connections. The E5GN can be connected using screw ter-

minals or screwless clamp terminals. The main functions and characteristics of these Digital

Temperature Controllers are as follows:

• Any of the following types of input can be used: thermocouple, platinum

resistance thermometer, infrared sensor, analog voltage, or analog cur-

rent.

• Either standard or heating/cooling control can be performed.

• Both auto-tuning and self-tuning are supported.

• Event inputs can be used to switch set points (multi-SP function), switch

between RUN and STOP status, switch between automatic and manual

operation, start/reset the simple program function, and perform other

operations. (Event inputs are not applicable to the E5CN-U.)

• Heater burnout detection, heater short (HS) alarms, and heater overcur-

rent (OC) functions are supported. (Applicable to E5CN, E5AN, E5EN,

and E5GN models with heater burnout detection function.)

• Communications are supported. (Applicable to E5CN, E5AN, E5EN, and

E5GN models with communications.)

• User calibration of the sensor input is supported.

• The structure is waterproof (IP66). (Not applicable to the E5CN-U.)

• Conforms to UL, CSA, and IEC safety standards and EMC Directive.

• The PV display color can be switched to make process status easy to

understand at a glance.

This manual describes the E5CN, E5CN-U, E5AN, E5EN, and E5GN for basic functions. Read this

manual thoroughly and be sure you understand it before attempting to use the Digital Temperature

Controller and use the Digital Temperature Controller correctly according to the information provided.

Keep this manual in a safe place for easy reference. Refer to the full manual for advanced settings:

E5CN/E5AN/E5EN/E5GN Digital Temperature Controllers User’s Manual (Cat. No. H156).

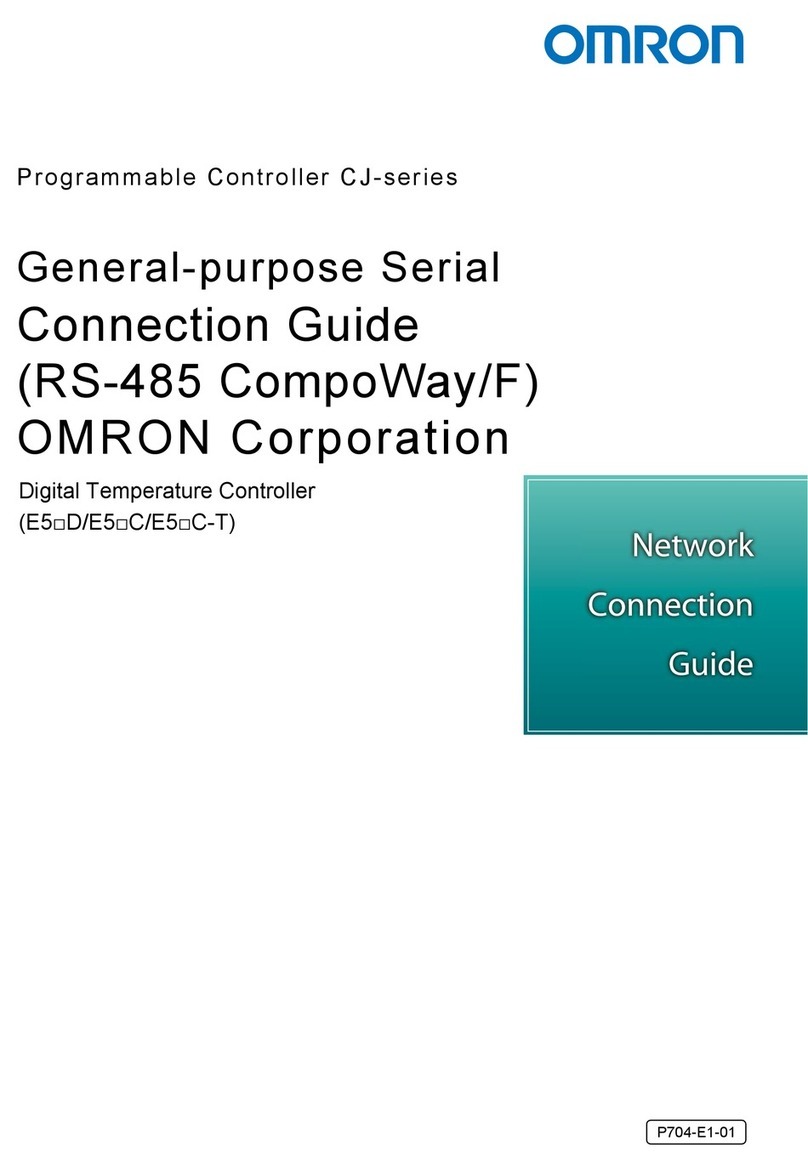

Refer to the following manual for further information on communications: E5CN/E5AN/E5EN/E5GN

Digital Temperature Controllers Communications Manual Basic Type (Cat. No. H158).

Refer to the following manual for information on the Advanced Type Controllers: E5CN/E5AN/E5EN-H

Digital Temperature Controllers User's Manual Advanced Type (Cat. No. H157).

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.