Thermoscreens C series Guide

4001160-6 UK Page 1 of 16

C RANGE AIR CURTAINS

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

PLEASE READ THESE INSTRUCTIONS CAREFULLY BEFORE ATTEMPTING INSTALLATION

Thermoscreens Ltd

St. Mary’s Road Nuneaton

Warwickshire England

CV11 5AU

Email: [email protected]

Tel: +44 (0) 24 7638 4646

Fax: +44 (0) 24 7638 8578

www.thermoscreens.com

4001160-6 UK Page 2 of 16

UN-PACKING YOUR C AIR-CURTAIN

The following items are supplied and packaged within the boxes.

C Air Curtain

Please note end caps are supplied loose

and can be fitted during installation

Motorised Valve

(Ecopower LPHW units only)

Remote Control

Ecopower

Electric & LPHW

Manual

Ambient

Wall Brackets & Fixing Bolts

(additional bracket and bolts supplied

for C1500/C2000 models)

Note Optional filters are available on Water and Ambient models only

and are packed separately.

If anything is missing or damaged please contact your place of purchase immediately.

For your records

Date of Purchase……………………………..

Place of Purchase…………………………….

Serial Number…………………………………

For warranty purposes proof of purchase is necessary so please

keep a copy of your invoice.

(All documentation supplied with each unit should be stored and kept for future reference).

4001160-6 UK Page 3 of 16

INSTALLATION OF YOUR HORIZONTAL APPLICATION C AIR-CURTAIN

The C air curtain has been designed for surface mounting only inside of

the building.

Location

Ensure that the unit is mounted within its height

specification of 1.8m minimum to 3.0m maximum

(from floor level to the underside of the unit) and

that it is situated as close to the door as possible

with a 100mm air gap above the air curtain (see

adjacent figure). In some cases it may not be

possible to mount the air curtain as close to the

door as possible as the air stream may strike the

top edge of the doorway, a structural beam or a

door opening device etc, therefore this will have

to be taken into account when locating the unit.

Wall Fixing

Bolt the wall brackets to the rear face of the unit

as shown in the adjacent figure (using the bolts

supplied). Before fitting the unit to the wall obtain

suitable fixing bolts, taking into account wall type

and unit weight (see table 1).

Step 1. Refer to Figure 1 for mounting details

and drill the wall accordingly.

Step 2. Screw in the top bolts leaving a small

gap between the head and the wall; lower the

unit onto the bolts via key hole slots in the top of

the wall brackets and then screw in the bottom

bolts.

Step 3. Ensure all fixing bolts are tightened to

stop the unit being lifted off the wall.

Ceiling Suspension

6mm threaded inserts are provided in the top

face of the casing (4 x M6 on the 1m and 6 x M6

on the 1.5/2m models, for dimensions see Figure

1) allowing the unit to be suspended on threaded

rod (threaded rod is not provided). Ensure each

of the threaded rods are secured on to a suitable

structure that can support the weight of the unit

(for unit weights see Table 1)*. When fitting the

threaded rod ensure that it does not interfere with

internal components. Fit locking nuts (not

supplied) and ensure they are engaged by a

minimum of 20mm to stop the threaded rod

rotating and coming away from the casing.

*Please note it is the sole responsibility of the installer to ensure that the fixing points

and bolts used are suitable for the air curtain being installed.

4001160-6 UK Page 4 of 16

connection interface

Remote control

suitable for 25mm gland

Electrical supply inlets

C1500

C(mm) N/A

E(mm)

F(mm)

D(mm) N/A

161

710

B(mm)

A(mm) C1000

1137

908

275

Rp 1/2 (1/2in. BSP female)

LPHW connections

964704

161

874

1748

604

170

1208

21 120

1928

2200

C2000

1408

1669

M6 inserts

C

B

A

C

198 100

(min)

220

E

D

E

33

F

75

Figure 1

4001160-6 UK Page 5 of 16

Safety and Electrical Connections

All electrical wiring and connections MUST be carried out by a competent qualified

electrician in accordance with the latest edition of the IEE wiring regulations and/or

local statutory regulations.

A single phase or 3 phase local isolator with a contact separation of at least 3mm in all

poles must be fitted to the supply wiring (the isolator must be fitted in an accessible

position).

The air curtain must be earthed.

The appliance must be connected by means of wires having an appropriate

temperature rating (heat resistant) (electric models only).

Ensure that the supply cables, circuit breakers and other electrical installation

equipment are correctly sized for the air curtain being installed; see Table 1 for Power

Ratings. See also data badge on the left hand side of unit under end cap.

On a 3 phase electrical supply the unit requires a neutral connection (3N~).

Cable glands used for the Electrical Input must be rated IP21 or higher.

Table 1

Air Curtain Electrical

Supply

(V/ph/Hz)

Rated Power

Input (kW) Current per

phase (A) Heat Output

(kW) Weight

(kg)

C1000A 230/1/50 0.15 0.7 N/A 15

C1500A 230/1/50 0.20 0.9 N/A 21

C2000A 230/1/50 0.25 1.1 N/A 31

C1000W 230/1/50 0.15 0.7 6.0 18

C1500W 230/1/50 0.20 0.9 9.0 26

C2000W 230/1/50 0.25 1.1 12.0 37

C1000E 400/3/50 9.15 13.7 4.5/9.0 16

C1500E 400/3/50 12.20 18.3 6.0/12.0 23

C2000E 400/3/50 18.25 27.2 9.0/18.0 33

To gain access to the electrical

connections the air intake grilles must

be removed. Ensure electrical mains

supply to the unit is isolated. If end

caps are already fitted, remove them

from the air curtain first (see insert).

Two air inlet grilles are fitted on 1m,

three on 1.5m and four on 2.0m

models.

Remove intake grilles by unfastening

two screws on each grille; M4 x 10mm

Pozi No.2 screws accessed via larger

hole in the bottom of the grille (see

adjacent figure).

Optional filter fits inside

curve of inlet grille

4001160-6 UK Page 6 of 16

Access can now be gained to make the

electrical connections.

Once connections have been

completed the inlet grilles should be

refitted and if fitted the end caps clipped

into place (see insert).

Please note the panels of the air curtain are coated in a protective film which should be

removed before use.

LPHW Models

For LPHW models ensure suitable water mains isolation valves are fitted in the flow and

return pipework. When fitting the 3-port valve ensure that the pipe connections are fitted

as detailed below and are in accordance with the manufacturers leaflet supplied with the

valve.

Air Curtain Water Flow Rate (l/s)

82/72°C Coil Water Pressure Drop (kPa)

C1000W 0.14 2.77

C1500W 0.21 6.74

C2000W 0.29 13.40

Ambient Models

Ambient units are supplied with a remote switch unit.

The switch unit allows the air curtain to be powered

ON/OFF and select one of three fan speeds.

AB

A/B

22mm pipe

22mm pipe

22mm pipe

15mm pipe R

E

T

U

R

N

F

L

O

W

4001160-6 UK Page 7 of 16

Fitting/Connecting the Remote Control

The Ecopower Plus controller uses extra low voltage to communicate via the RJ control

cable supplied. The controller should be located in a suitable place for easy access, it

can be fixed to the wall via various fixing slots

provided in the back case or onto an electrical

switch box (not provided). To mount controller

onto an existing switch box, feed one end of the

control cable through the switch box (see insert).

Using a screwdriver undo screw mounted on

the top of the controller case. Pull the front case

slightly forwards and lift the back case away.

Feed and secure the RJ control cable through

one of the openings in the back case and

secure back case to switch box using 2 x M3.5

mounting screws (not provided).

With the cable RJ plug locking clip lying nearest

to controller PCB, connect the RJ plug to the RJ

socket on the board.

Note: For controller DIP switch options refer to

Ecopower Plus Remote Control Operation and

DIP Switch Settings.

Refit the controller front case to the back case.

The air curtain end of the control cable should be

connected to one RJ socket fitted either on the

top panel for NT or the Ecopower motherboard

inside a recessed air curtain. Ensure the control

cable is safely secured.

Multiple Installation (Ecopower only)

To Master/Slave two or more air curtains together a suitable RJ lead should be

connected from the Master to the Slave unit. Thermoscreens 3.0m RJ extension leads

must be ordered separately. Additional air curtains, up to a maximum of eight units,

may be connected as indicated below. For Master/Slave configuration an independent

mains supply must be supplied to each air curtain.

4001160-6 UK Page 8 of 16

Ecopower Controller Motherboard

Function

Control

Comments

Standard

Fan Heat Interlock –

The heat output is governed by the

fan speed. If low or medium fan

speed is selected the heat output

will operate on only first heat stage.

Second stage heating will only

operate on high fan speed.

DIP1 Option Suitable on vertical electrically

heated Designer air curtain.

Maximum heat output achieved if

maximum fan speed selected.

Independently set-up DIP switch

on each mother board. This

feature operates in manual or

auto mode.

As supplied, the

default setting would

be for heat and fan

settings to be

independent (DIP1

OFF).

Disable Fan Run-on –

Disable fan run-on.

DIP2 Option

(LPHW &

Ambient only)

Must only be used for LPHW and

Ambient air curtains.

Independently set-up DIP switch

on each mother board.

As supplied, the

default setting would

enable fan run-on

(DIP2 OFF).

Thermostat Master –

Only the air sensor thermistor in

the master air curtain will be used

for measuring the reference air

temperature for the whole

master/slave installation.

DIP3 Option

The air sensor thermistors in all

the slave air curtains will be

ignored. This will then avoid

situations on larger doorways with

master/slave air curtains where

some units can blow cold air

whilst others can blow warm air,

because they currently all refer to

their own air sensor for control of

the heat output of each air

curtain.

The master air curtain need not

be the one that the wall control is

plugged into. This dip switch

setting must also be used for

Global Switching (Master/Slave)

via the INHIBIT terminal – see

next page.

As supplied, the

default setting would

be for the air sensor

thermistor on all

units to be

measuring

(DIP3 OFF).

Overheat Fan Disable –

If DIP4 is on and thermal cut-out(s)

operate both heat and fan circuits

are isolated and LED’s on wall

switch flash. If DIP4 is off and

thermal cut-out(s) operate, only the

heating circuit is isolated and the

LED’s on the wall switch flash.

DIP4 Option

(Electric only)

Independently set-up DIP switch

on each mother board.

To remove fault, isolate electrical

supply to air curtain, reset TOC

and reconnect supply.

As supplied, the

default setting would

enable fan if TOC

trips (DIP4 OFF).

Fan run-on time set two minutes. Built-in If “FAN ONLY” has been

selected, at switch off, no fan run-

on.

- white rectangle indicates the moveable head of each 4 way DIP switch

DIP switches fitted on the Ecopower board provide a selection of optional features as

described above. Isolate and switch electrical power off before configuring and/or

changing any DIP switch settings.

ON

OFF

1 2 3 4

ON

OFF

1 2 3 4

ON

OFF

1 2 3 4

ON

OFF

1 2 3 4

4001160-6 UK Page 9 of 16

Easy plug-in arrangement for remote air sensor thermistor on a 1m lead. Plugging-in

the remote air sensor to J3 disables the standard air sensor thermistor already fitted

on the Ecopower board. As supplied, the board will not have the remote air sensor

fitted.

An INHIBIT two screw terminal fitted on the Ecopower board for BMS remote On/Off

feature. If the terminal is linked, i.e. by 2 wires to a remote volt free contact, the unit will

run. If it is open circuit across the terminal the unit will switch off. This remote On/Off

feature has global switching logic, i.e. if you master/slave several units together you

need connect the remote contact to only one of them to turn all units on and off in the

master/slave system. For global switching to work on the slave units, need to set DIP3

Option (see previous page) on the unit that the remote contact is wired to and have

previously turned the unit on with the wall switch. As supplied, a wire link will be fitted

to the terminal block on every unit. For summer settings place a 3.3kΩresistance

across the INHIBIT terminal, with these settings fans only will run even if controller is

requesting for heat.

ECOPOWER BOARD

Customer Building Management System

A HEALTHY two screw terminal is included on the board for a fault signal indication if

the electric elements overheat cut-out has operated. A healthy system provides a 24V

DC signal at the terminals compared to an overheat fault which provides OV DC.

4001160-6 UK Page 10 of 16

4001160-6 UK Page 11 of 16

4001160-6 UK Page 12 of 16

4001160-6 UK Page 13 of 16

Ecopower Plus Remote Control Operation and DIP Switch Settings

On/Off (I/O)

Press On/Off switch (1) to turn the air curtain

On and operate as follows:-

Press Auto switch (2) to cycle between Manual

and Automatic modes. The Auto on indicator

LED is lit for "Auto Mode" and un-lit for "Manual

Mode".

Manual:

Heat output can be selected as Zero, Half Heat

or Full Heat. Heating levels are selected by

stepping up or down with switches (3) and (4).

Heating level indicator LED's go 0%, 50% or

100% to show the level selected.

Automatic:

If DIP switches 1, 2 and 4 on the Ecopower

motherboard are set to OFF, the air curtain

measures the incoming air temperature and

automatically selects the necessary amount of

heat to keep it at the level selected.

Fan Speed

Switches (5), (6) and (7) select fan speed low,

medium or high respectively. The appropriate

LED above each fan speed indicator is

illuminated to show which fan speed is selected.

Pressing the On/Off switch (1) again switches the

air curtain off with all the LED’s switched off. If a

heated air curtain is heating when switched off

the fan will run-on at low fan speed for an

extended time (approx. 2 minutes) to dissipate

excess heat.

DIP Switch Settings

At the back of the Ecopower Plus remote

control PCB there are four DIP switches (see

above) that provide the following optional

features.

DIP1 Restart on Power-Up – If electrical

supply to the air curtain is

interrupted, upon restoring electrical

supply, the customer’s settings on

the remote control will be retained.

The default is with this feature ON.

DIP2 Stop Fan on Cold – Fans switch off

when heating level is achieved

(Automatic mode only). The default

setting is with this feature OFF.

DIP3 Never Blow Cold – Unit always

heats in Automatic mode (i.e. will

not go to ambient mode). The

default setting is with this feature

OFF.

DIP4 Air Sensor in Controller – The air

sensor in the remote controller is

enabled (DIP4 ON) and the air

sensor on the Ecopower

motherboard in the air curtain is

disabled. Temperature control for

Automatic Mode is then done at the

remote control, which may be an

advantage to limit overheating of the

door entrance area. The default

setting is with this feature OFF.

Do not switch the air curtain On/Off from the isolator. If the mains supply is

isolated or cuts-out during operation the safety thermal cut-out(s) for electric

heated air curtains within the air curtain may operate. If this happens the

thermal cut-out(s) will need to be reset by a competent technician.

2

1

3

4

5

6

7

Heating Level

Scale

4001160-6 UK Page 14 of 16

Commissioning

Set the discharge grille vanes so they point straight downwards over the doorway. Once

the air curtain is functioning check that the fans operate at Low, Medium and High

speeds, that there is no excessive mechanical noise coming from the fans and that all

fans are working. If the unit is electric or water heated check that the air stream from the

discharge grille warms up across the whole length of the air curtain when heating is

selected. Check that heating increases as higher heat is selected and feel to see that

the warm air stream is reaching across the doorway with door open or closed. If

necessary the vanes of the discharge grille can be angled either inwards or outwards if

this gives better penetration/warming of any incoming draughts. If an Ecopower

controller is being used check its operation in Manual Mode. Then select Auto Mode and

increase the heating set point until the air stream warms up. Reduce the heating set

point until the air stream goes cold.

Explain to the end user that the doorway should be closed whenever possible but that

during times of high pedestrian use it will become effectively ‘open doorway’. The air

curtain serves an essential purpose by saving energy and providing comfort to the

occupants when compared to an open doorway with no air curtain fitted.

Before leaving site it is important that the air curtain installation is “Handed-Over” to the

end user or his representative and the operation of it is fully explained and that they

understand how it operates. Explain also the service intervals and that the unit must be

regularly cleaned and if it has filters fitted that these require regular cleaning or

replacement.

Fault Conditions

In the event of a fault the thermal cut out(s) (Note: If the mains supply is isolated during

operation then the thermal cut outs may operate) or internal fuses may operate. The

thermal cut out(s) are located on the top face of the unit directly above the element

banks (one on the 1 & 1.5m and two on the 2m model). For Ecopower units two internal

electrical fuses are located on the Ecopower board; 6.3A (T) supplies the fan motors

within the air curtain and 125mA (F) controls the operation of the Ecopower board. For

Ambient and Standard LPHW units the fuse is located within the control panel at the left

hand end of the air curtain.

If for an electric heated air curtain an overheat fault occurs, or if J2 link is missing for

LPHW models, the LED’s on the remote control will flash and the Ecopower board status

LED on the board will be permanently red to indicate a fault.

In the case of a fault condition (refer to flowchart) do not attempt to reset the thermal cut

outs or replace the fuses, arrange for a Thermoscreens appointed technician or certified

electrician to attend the unit to investigate the reason why the thermal cut outs/fuse(s)

have operated. Once the cause has been determined and rectified, they will

reset/replace the thermal cut out/fuse and function test the unit.

PCB Status

Fitted on the PCB board inside of the air curtain is an LED shown as LED1 on wiring

diagrams that will indicate the Ecopower control status.

1. LED flashing green – operation normal.

2. LED flashing red – low supply voltage or controller not plugged into Ecopower

motherboard.

3. LED permanently red – thermal cut outs open circuit (electrically heated models) or

J2 link missing (LPHW models). Remote Control LED’s will also flash to indicate the

thermal cut-out(s) has operated or J2 link is missing.

Note to reset the thermal cut outs please refer to Fault Conditions section detailed above.

4001160-6 UK Page 15 of 16

User Fault Finding Flowchart (for Ecopower Control)

Yes

Unit is working

satisfactorily

Switch on Electrical

Power

Connect remote control

and push On/Off switch

to turn unit on

Select heat output

Contact Installer

Service Agent to

investigate why

thermal cut-out(s)

have operated

Service Agent to

reset thermal cut-

out(s)

Contact Installer

Yes

No

Yes

Yes

No

No

No

Yes Yes

No

No

Is Electrical

Power

switched on

Are the fans

operating

correctly

Is the unit

discharging

warm air

Check if thermal

cut-out(s) have

tripped (Electric

Heated only)

Do the LED’s

light up on

the remote

control

Is the remote

control

plugged in

and turned

on

4001160-6 UK Page 16 of 16

Service & Maintenance

Always disconnect and isolate the mains electricity supply before installing,

maintaining or repairing this equipment. Note: All maintenance/repairs should

only be carried out by a competent electrician or Thermoscreens appointed

technician.

Once the mains supply is isolated, remove end caps from the air curtain (if fitted).

Remove each air intake grille by unfastening two screws on each grille - M4 x 10mm

Pozi No.2 screws accessed via the larger hole at the bottom of each grille.

To ensure the air curtain operates at full efficiency the inlet/outlet grilles, fan impellers,

housings and motors must be kept free of dust and debris. Build up of dust on the fan

impellers can cause vibration, noise and excessive wear on the motor bearings.

Frequency of cleaning will depend on the environment, but we would recommend that

the unit be cleaned a minimum of every 3 months (failure to adequately maintain the

unit and provide a suitable cleaning schedule will result in performance degradation

and reduce the life expectancy of the air-curtain).

Vacuum and clean the build-up of dirt and debris within the air-curtain (please note

that the motor(s) are permanently lubricated and require no additional lubrication).

If filters are fitted, ensure these are regularly inspected and cleaned or replaced. All

dirty or blocked filters should be immediately replaced.

Once the air curtain has been cleaned check all electrical connections within the unit

ensuring terminals are tight and that crimped connections have not become loose.

Refit inlet grilles and end caps. Reconnect the electrical supply and fully function test

the air-curtain to ensure correct operation (See Commissioning).

If the outer casing requires cleaning this should be done using a warm soft cloth.

Do not use solvents or abrasive materials.

Warranty

If any problems are encountered, please contact your installer/supplier. Failing this

please contact the Thermoscreens warranty department. All units are covered by a two

year warranty period.

Care has been taken in compiling these instructions to ensure they are correct, although

Thermoscreens disclaims all liability for damage resulting from any inaccuracies and/or

deficiencies in this documentation. Thermoscreens retain the right to change the

specifications stated in these instructions.

Thermoscreens Ltd

St. Mary’s Road Nuneaton

Warwickshire England

CV11 5AU

Email: [email protected]

Tel: + 44 (0) 24 7638 4646

Fax: + 44 (0) 24 7638 8578

www.thermoscreens.com

Other manuals for C series

1

This manual suits for next models

9

Popular Fan manuals by other brands

Hunter

Hunter 29562 Manual de instalación

Nu Age Fans

Nu Age Fans NB-98 manual

Vortice

Vortice EVOLUTION LIGHT KIT Instruction booklet

Nordic

Nordic HVLS Series Standard Installation Manual

Panasonic

Panasonic Whisper-Lite FV-08VQL4 installation instructions

Carrier

Carrier FSFXXAOA1180 Installation and user instructions

Homewerks

Homewerks 7130-18-BT manual

Beper

Beper 70.241 Additional safety and use instructions

NuTone

NuTone 690NT Architectural & engineering specifications

Greenheck

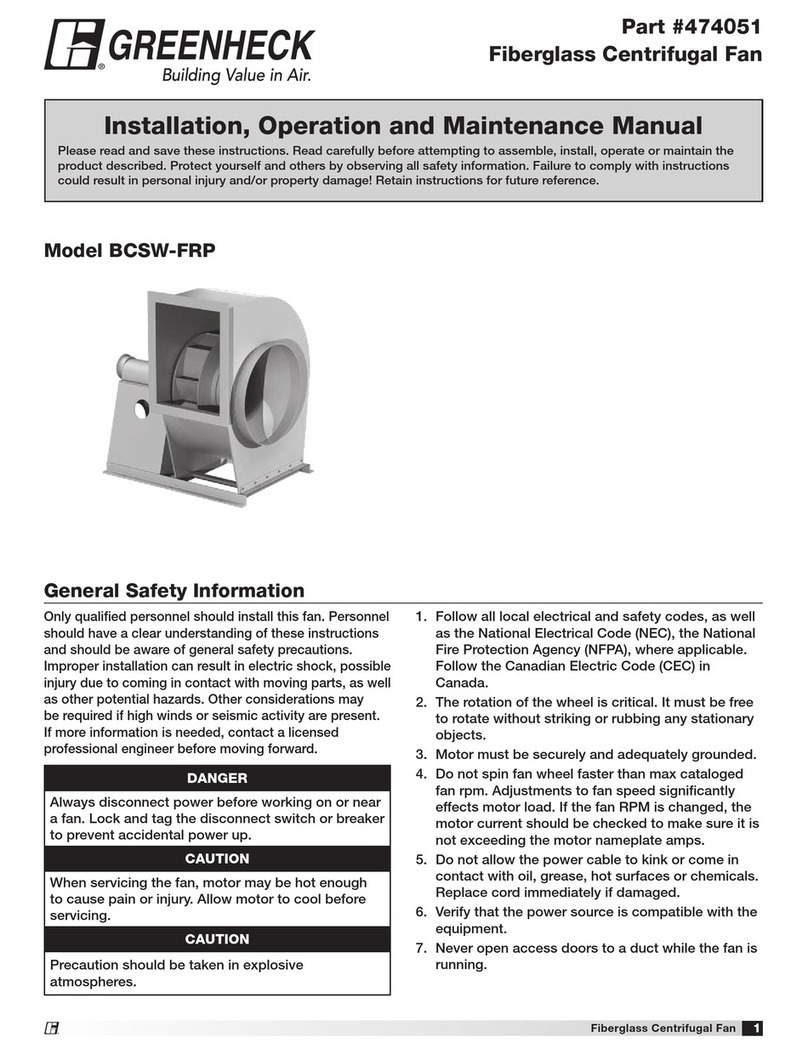

Greenheck 474051 Installation, operation and maintenance manual

Salda

Salda RIS 2500HE EKO 3.0 Technical manual

Addvent

Addvent AVX100WIDT Installation and maintenance instructions