Thinicon GM8010 User manual

Manual

GM8010/8011/8012

Genset controller

TH101132ER1

Manual TH101132ER1 THINICON

The Interpretation of the symbol

WARNING:

A WARNING indicates a potentially hazardous situation which, if not

avoided, could result in death, or equipment damage.

NOTE:

Provide the user's help is very useful information and tips or alert the

operator to the correct operation.

History

No.

Rev.

Date

Editor

Validation

Changes

1

TH101132ER1

2018.8

L

C

NEW

2

Manual TH101132ER1 THINICON

WARNING:

Read this entire manual pertaining to the work to be performed before

installing, operating, or servicing this controller. Practice all plant and safety

instructions and precautions. Failure to follow instructions can cause

personal injury and/or property damage.

The engine or other type of prime mover should be equipped with an

overspeed shutdown device to protect against runaway or damage to

the prime mover with possible personal injury, loss of life, or property

damage.

The overspeed shutdown device must be totally independent of the

prime mover control system. An over temperature or low pressure shutdown

device may also be needed for safety, as appropriate.

CAUTION:

To prevent damage to a controller that uses an alternator or battery-charging

device, make sure the power cable of charge or charger and controllers is

turned off before disconnecting the battery from the system.

CAUTION:

Controllers contain static-sensitive parts. Observe the following

precautions to prevent damage to these parts.

Do not disassemble the rear back of controller and touch the components or

conductors on a printed circuit board.

CAUTION:

The controller comes with the factory settings. As the factory settings may

not fully meet the actual user needs,the generator settings must be checked

before.

Manual TH101132ER1 THINICON

Page 1/57

Contents

1 Description................................................................................................................2

2 The Outline Dimension Drawings and Controller Wiring ......................................3

3 Panel Operation ......................................................................................................13

4 Control and Operation Instruction ........................................................................15

5 Measure and Display Data .....................................................................................21

6 Pre-alarm and Shutdown Alarm.............................................................................22

7 Parameters Setting.................................................................................................23

8 Installation Guide....................................................................................................52

9 LCD displays and Menu System............................................................................53

10 Technical Specification..........................................................................................58

Manual TH101132ER1 THINICON

Page2/57

1 Description

GM8010/GM8011/GM8012 is a new generation of generator set intelligent controller, using a new

form structure, refine and improve the performance of the controller, so that the product fully meet of

generator users or professional assembly plants of different types of generator sets , including oil and

gas generator sets to open automatic stop control and protection needs.

Features:

True RMS measure of voltage and current.

The controller has two operating modes: automatic/manual, and the two operating modes are

selected by the buttons on the panel.

The controller displays the control status, operating status and related measurement data of

the generator set through the LED on the panel.

USB communication port, communicate with PC, can read and set the operating parameters of

the controller

It is very easy and convenient to connect, move, repair and replace the equipment through the

pin terminal connection.

Model Comparison:

Model

GM8010

GM8011

GM8012

Generator Volt.

Three-phase

Single phase

Single phase

Generator Current

—

Single phase

Single phase

Number of digital inputs

4

4

2

Number of control relay output

4

4

4

Analog sensor count

—

—

2

“—”:without “●”:Standard configuration

Manual TH101132ER1 THINICON

Page3/57

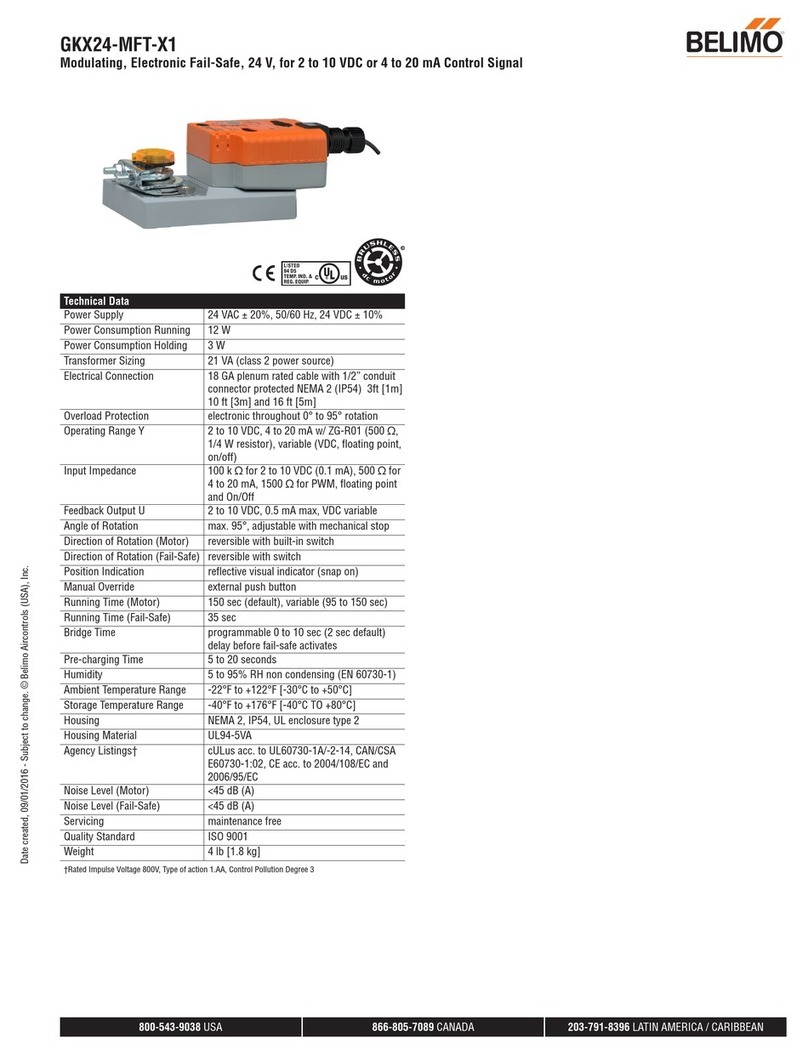

2 The Outline Dimension Drawings and Controller Wiring

2.1 Following Details:

Module Dimensions

W118mm×H92mm

Panel Cutout

W98mm×H77mm

Thickness

D37.5mm

GM8010

Manual TH101132ER1 THINICON

Page4/57

GM8011

Manual TH101132ER1 THINICON

Page5/57

Manual TH101132ER1 THINICON

Page6/57

GM8012

Manual TH101132ER1 THINICON

Page7/57

Manual TH101132ER1 THINICON

Page8/57

2.2 Terminal Connections:

GM8010

Terminal

Function

Signal

Connection

1

Battery supply (+B)

12V/24V (8-35Vdc continuous)

2.5mm²

2

Battery supply (-B)

2.5mm²

3

Relay output 1

N.O. contact, 3A/30Vdc, defined (1)

1mm²

4

Relay output 2

N.O. contact, 3A/30Vdc, defined (2)

1mm²

5

Relay output 3

N.O. contact, 3A/30Vdc, defined (3)

1mm²

6

Relay output 4

N.O. contact, 3A/30Vdc, defined (4)

1mm²

7

D-Input 1

Defined (1)

1mm²

8

D-Input 2

Defined (2)

1mm²

9

D-Input 3

Defined (3)

1mm²

10

D-Input 4

Defined (4)

1mm²

11

Magnetic pick-up signal {+}

1-70Vac

Two-core

shielded

cable

12

Magnetic pick-up signal {-}

13

GEN. VL1-N input

0-346Vac

1mm²

14

GEN. VL2-N input

0-346Vac

1mm²

15

GEN. VL3-N input

0-346Vac

1mm²

16

GEN. Neutral

1mm²

GM8011

Terminal

Function

Signal

Connection

1

Battery supply (+B)

12V/24V (8-35Vdc continuous)

2.5mm²

2

Battery supply (-B)

2.5mm²

3

Relay output 1

N.O. contact, 3A/30Vdc, defined (1)

1mm²

4

Relay output 2

N.O. contact, 3A/30Vdc, defined (2)

1mm²

5

Relay output 3

N.O. contact, 3A/30Vdc, defined (3)

1mm²

6

Relay output 4

N.O. contact, 3A/30Vdc, defined (4)

1mm²

7

D-Input 1

Defined (1)

1mm²

8

D-Input 2

Defined (2)

1mm²

9

D-Input 3

Defined (3)

1mm²

10

D-Input 4

Defined (4)

1mm²

11

Magnetic pick-up signal {+}

1-70Vac

Two-core

shielded

cable

12

Magnetic pick-up signal {-}

13

No

14

No

15

GEN. VL1-N input

0-346Vac

1mm²

16

GEN. Neutral

1mm²

17

No

18

No

19

I1 Gen current input (S1)

0-5A

2.5mm²

20

Comm. port for current inputs

(S2)

2.5mm²

Manual TH101132ER1 THINICON

Page9/57

GM8012

Terminal

Function

Signal

Connection

1

Battery supply (+B)

12V/24V (8-35Vdc continuous)

2.5mm²

2

Battery supply (-B)

2.5mm²

3

Relay output 1

N.O. contact, 3A/30Vdc, defined (1)

1mm²

4

Relay output 2

N.O. contact, 3A/30Vdc, defined (2)

1mm²

5

Relay output 3

N.O. contact, 3A/30Vdc, defined (3)

1mm²

6

Relay output 4

N.O. contact, 3A/30Vdc, defined (4)

1mm²

7

D-Input 1

Defined (1)

1mm²

8

D-Input 2

Defined (2)

1mm²

9

LOP detection

Resistive pressure sensor (<1KΩ)

2.5mm²

10

HET detection

Resistive temperature sensor (<1KΩ)

2.5mm²

11

Magnetic pick-up signal {+}

1-70Vac

Two-core

shielded

cable

12

Magnetic pick-up signal {-}

13

No

14

No

15

GEN. VL1-N input

0-346Vac

1mm²

16

GEN. Neutral

1mm²

17

No

18

No

19

I1 Gen current input (S1)

0-5A

2.5mm²

20

Comm. port for current inputs

(S2)

2.5mm²

Manual TH101132ER1 THINICON

Page10/57

2.3 Typical Wiring Diagram:

GM8010

Manual TH101132ER1 THINICON

Page11/57

GM8011

Manual TH101132ER1 THINICON

Page12/57

GM8012

Manual TH101132ER1 THINICON

Page 13/57

3 Panel Operation

The operation panel consists of 3 sections: 4-digit LED digital tube displays measurement

parameters and operating status, common warning/fault indicator, operation buttons and control mode

selection buttons

The LED digital tube display and its control buttons provide the operator with a friendly operator

interface that allows the operator to read information and set operating parameters.

Control buttons and LEDs

Function Description

Tag

Scroll Button

Scroll menu for parameters display

Enter into or exit parameters setting by pressing and holding this

button for 2sec.

AUTO Mode Button/ RETURN

This button controller operation mode, press this button repeatedly,

can choose automatic mode and nonautomatic mode, when the LED

indicator light on this button, the controller running in automatic mode.

When in parameters setting mode,this button is used to return to the

last page.

START Button / “+” Value Increase

The push button is used for manually start the Genset. When controller

is running in MANUAL mode, press this button to start the generator.

When in parameters setting mode,this button is used to increase

value or scroll up menu。

STOP / RESET Button / “-” Value Decrease

The push button is used for manually stop the Genset.When controller

is running in MANUAL mode, press this button to stop the generator.

If failure occurs, press this button, the shutdown alarm lockout can be

cleared.

No matter what mode the controller is running, the "Stop" button is

valid. In the "automatic" or other mode of operation, press and hold

this button for 2sec to stop the generator, the controller automatically

from other modes to manual mode.

When executing the program in a shutdown of the generator set, press

the button again, immediate shutdown and the cessation of associated

control output.

When in parameters setting mode, this button is used to decrease

value or scroll down menu.

Shutdown Alarm (FAILURE) LED

The LED will illuminate when pre-alarm occurs。

The LED will illuminate permanently when shutdown alarm occurs.

Start failure light

The LED will illuminate when pre-alarm occurs.

The LED will illuminate permanently when shutdown alarm occurs.

Low oil pressure lamp

When the controller has a low oil pressure warning, the indicator light

flashes.

When the controller has a low oil pressure shutdown fault, the indicator

light is on.

Manual TH101132ER1 THINICON

Page14/57

High water temperature lamp

When the controller has a high water temperature warning, the

indicator light flashes.

When the controller has a high water temperature shutdown fault, the

indicator light is on.

Overspeed light

The indicator flashes when the controller has an overspeed warning.

When the controller has an overspeed shutdown fault, the indicator

light is on.

Emergency stop light

When a digital input that is defined as an emergency stop is active, the

indicator light is on.

Manual TH101132ER1 THINICON

Page 15/57

4 Control and Operation Instruction

The controller has a variety of control mode, the operator panel can be set to automatic mode and

the non-automatic mode. Non-automatic mode there are two kinds of situations, such as no definable

switch is set to "activate the test mode", for the manual operation mode; if a definable switch is set to

"Enable Test Mode" and effective, then is test operation mode.

4.1 Operation Mode Setting:

Description

Action

Press the ―AUTO‖ button, the LED is illuminated, the controller is

running in ―AUTO‖ mode.Press the "AUTO mode" button again, the

LED is off, the controller is running in non-automatic operation mode.

Note:

Controller keeps the states for the previous mode when changing the

operation mode, then implements the control procedure of the next mode

according to the present states.

Note:

If a defined panel lock switch input will not change the operating mode of the

controller.

Manual TH101132ER1 THINICON

Page16/57

4.2 AUTO Control Sequence

The controller is running in ―AUTO‖ mode.

Generator Auto Start Sequence:

Generator in the standby mode, only in the following situations occur, generator start-up program

began:

Definable input port for the remote control load a definition.

Definable input port for the remote control no-load a definition.

The start delay timer is activated, when it times out, the Preheat relay output is energised (if

preheat function selected), the timer starts. When it times out, the fuel relay output is energised, and

operates the fuel solenoid of the engine. After 300ms delay, the start relay output is energised, the start

motor engages and begins to crank. When the engine speed reaches the crank cutout RPM, the start

relay output is de-energised and the safety-on delay starts. When the safety-on times out, if the

controller detects that the parameters of the Genset such as voltage, frequency, oil pressure, coolant

temperature are normal, and no other failure is detected this indicates the Genset has successfully

started and running normally. The LED displays the Genset Measurement Parameters.

If you have selected idle function, the idle relay will be closed at the same time as the start relay is

closed, the idle timer will begin counting down after successful crank, when it times out, the idle relay

opens, other procedure is the same as above.

Note:

When the engine is running at idle period, the controller does not detect

thefailure of low-voltage, low-frequency, low-speed and charging failure.

When no one input port as defined as remote start, the "remote start"

signal is not as boot judgment condition.

NOTE:

The start motor will power off while cranking if there are one of the following

conditions occur:

The generator’s frequency reaches the preset value (configurable

cranking cutout value);

The AC engine speed reaches crank cutout value;

Generator’s voltage reaches the crank cutout value (optional);

Cutout P-delay time’s up (optional);

Cranking time’s up.

The controller can not implement crank procedure in one of the following

conditions:

A. The generator’s frequency reaches the preset value (configurable

cranking cutout value);

B. The AC engine speed reaches crank cutout value;

C. Generator’s voltage reaches the crank cutout value (optional);

D. Oil pressure switch is opened or oil pressure is higher than crank

cutout value (optional).

Manual TH101132ER1 THINICON

Page17/57

CAUTION:

If the control system does not use the speed sensor, that is, the engine cut

off the signal from the generator frequency, must ensure that the generator

in the process of turning, the output voltage is greater than the controller

measure the voltage to avoid damage to the motor.

Repeat Start: During the crank period, if the engine can not ignite and controller will not output start

signal during crank rest. Once crank rest timer times out the start relay energises once again and will

attempt to start engine again. The above procedure will be repeated until engine successfully ignites or

reaches the preset number of crank attempt.

If any shutdown alarm occurs during operation, controller will stop the control output immediately, and the

Gensetonlycan be restarted afterclearing the failureand reset.

Start Failure: When the procedure above repeats again and again and reaches the preset number

of crank attempt, the crank relay output is then de-energised. The failure LED illuminates and the LED

digital tube displays fail to start.

CAUTION:

If fail to start occurs, operator must check the whole Genset system to

find out failure reason, only after clearing the failure can press ―reset

button to relieve fault lock out status, and restart the genet.

Power supply process:

When the generator running, the generator voltage and frequency reaches to the the generation

load voltage and power generation with load frequency, power generation delay timer is started, time’s

up, the GCB relay closure outputs, the transfer switch power generation side switch is closed, power

supply.

Generator unloading and shutdown process

Under the following conditions, the controller sends the generator uninstall command:

Loading remote signal of definable input port is invalid.

In GOB, cooling delay began to countdown , when it times out, the controller fuel relay action,

immediately disconnect the fuel solenoid ,into standby generator.

Stop Failure: When cool down times out, the fuel relay action and the timer for stop delay begins.

If the controller detects that the voltage of the generator is greater than the cutout values, or the speed

is greater than the RPM, or the oil pressure switch is off, or the oil pressure is greater than the crank

cutout oil pressure, the failure LED illuminates and the LED digital tube displays Fail to stop.

NOTE:

After stop failure occurs and the generator can not be started unless it is

removed and reset .

This manual suits for next models

2

Table of contents

Popular Controllers manuals by other brands

Spirax Sarco

Spirax Sarco LC2250 Installation and maintenance instructions

Motrona

Motrona CT340 operating instructions

Crouzet

Crouzet em4 B26 manual

National Instruments

National Instruments cRIO-9030 Getting started guide

White Rodgers

White Rodgers 1127 installation instructions

VMK

VMK VMK-I88plus instruction manual