Thinkpower S3600TL User manual

Introduction

About Think Power

Thank you for using the PV grid-connected inverter of Think Power.

Established in 2011, Wuxi Xinqi Power New Energy Technology Co., Ltd. is

located in Wuxi, the Changjiang River delta plain hinterland, close to the

Changjiang River in the north and Taihu Lake in the south, whose geographical

location is superior. The registration fund of Xinqi is 20 million, specialized in

researching developing, producing, selling and providing customer service

in the PV Grid-Connected Inverter products in the type of solar

households.

For readers

This manual is applicable for technicians of inverter installation, operation and

maintenance. The readers shall be familiar with electrical knowledge.

About this manual

Please read this manual carefully before using products. This manual shall be

kept in a place which is convenient to use. Operator using this manual must be

a qualified electrical engineer certified by the local electrical authority.

Copyright

The copyright of this manual belongs toWuxi Xinqi Power New Energy

Technology Co., Ltd. Any part or the entire of this manual cannot be carried in

public without a written permission.

Because of the continuous product upgrading, this manual will be updated

correspondingly, and thus there will be some unconformity between the manual

description and the products, and the user can acquire the most updated

version from www.xqsolar.com

or Think Power will not be responsible for

informing the user of the manual upgrading.

Introduction

Since its inception, our company focused on the technology, guided by

products, had a fully automatic production line and the international R&D team,

mastered

international

leading

core

technology,and

constantly developed

stable and reliable products to meet the growing energy demand of the global

residents. Advanced in technology, excellent in quality, stable and reliable

products

of

Xinqi

will

utilize

it’s

strong

technology

and

excellent

craftsmanship to show the strong competitive power in domestic and

international markets.

Introduction

Applicable Models

●S3600TL ●S4400TL ●S5000TL

Revised version No. Date Description

XQ-UMT1.0.0EN 2012.08.01 Rev.1

Revision

Important safety instruction

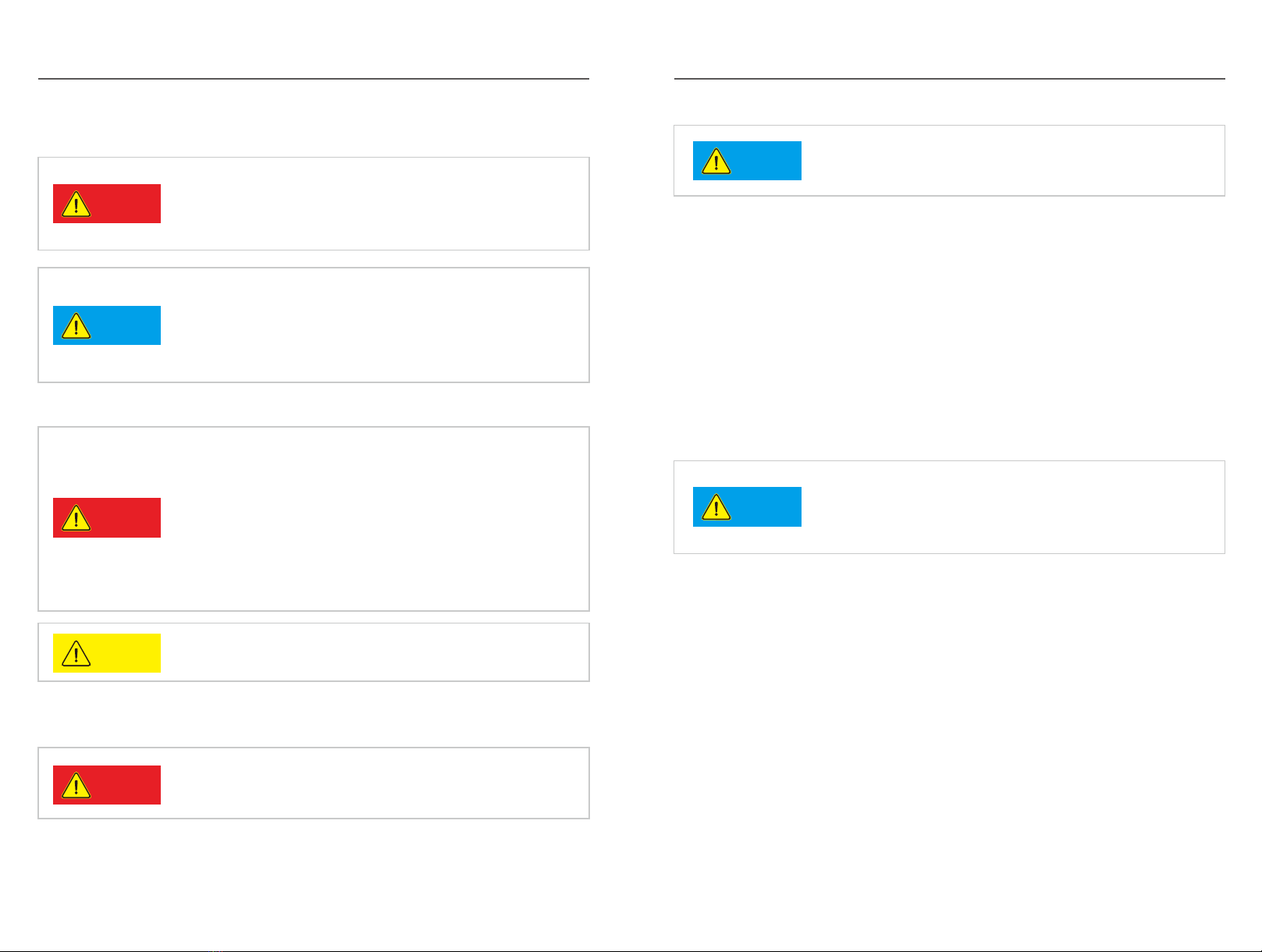

Symbols in this manual

To ensure the personal and property safety in using the photovoltaic inverter

and the high efficiency of the product, related safe operation notices are

provided in the manual, and corresponding symbols are used for emphasizing

the importance. These important notices must be fully understood and

followed. Symbols used in this manual are listed below to help you carefully

read and use this manual.

It means a highly potential danger which may cause a

serious personal injury or death directly if this warning is

neglected.

Danger

Warning

Caution

Notice

It means a moderately potential danger which may cause

a serious personal injury or death directly if this warring is

neglected.

It means a lightly potential danger which may cause a light

or moderate personal injury or serious property loss if this

warning is neglected.

It means a potential risk which may cause device

malfunction or property loss if this warning is neglected.

It means an additional notice emphasizing or complementing the

content, or providing a tip for optimizing the product operation,

and further helps you solve some problems or save some time.

Tip

It means a helpful reference or notice.

Introduction

This manual provides the installation, operation and maintenance of

PV grid-connected inverters Song 3600-Song 5000. The following models

of inverter are related:

Symbols on the inverter

The inverter is attached with some labels related to operation safety. Please

don’t install the device before carefully reading through and fully

understanding these labels.

It means there is still residual voltage in the inverter! The

capacitor is still electrified after the AC/DC side of the inverter is

cut off, so the inverter cannot be maintained within 10min till the

capacitor is completely discharged.

10 min

Earth line!

Acceptable in the test of insulation and voltage resistance.

Acceptable in the function test.

Acceptable in the quality inspection.

Danger of high voltage and electric shock!

Danger of high temperature and burn injury!

The wasted product must be sent to the authorized collecting

center.

Please carefully read through and fully understand the

instruction manual before using the product.

Contents

1 Safety instruction……………………………………………………………………1

1.1 Before installation…………………………………………………………… 1

1.2 During installation…………………………………………………………… 2

1.3 Operation………………… …………………………………………………2

1.4 Repair………………………………………………………………………… 2

1.5 EMC…………………………………….........……………………………… 3

2 Product description………………………………………………………………4

2.1 Product applicability………………………………………………………… 4

2.2 Circuit structure……………………………………………………………… 4

2.3 Product introduction………………………………………………………… 5

2.3.1 Electrical connecting part………………………….....………………5

2.3.2 Dimensions and weight ……………………………………………… 6

2.3.3 LCD Displaying panel………………………………………………… 6

2.3.4 Product label ………………………………………………………… 7

3 Installation…………………………………………………………………… …… 8

3.1 Safety instruction…………………………………………………………… 8

3.2 Installation procedures……………………………………………………… 8

3.3 Preparation before installation………………………………………… 9

3.3.1 Unpacking and checking……………………………………………… 9

3.3.2 Preparation for tools………………………………………………… 10

3.4 Selection for installation position………………………………………10

3.5 Inverter……………………………………………………………………….12

3.5.1 Installation on a wall………………………………………………12

Introduction Contents

3.6 Electrical connection………………………………………………………14

3.6.1 Electric and electrical system structure……………………………14

3.6.2 Structure of the communication system……………………………16

3.6.3 Wiring terminals and cable specification……………………………18

3.6.4 Steps for electrical connection………………………………………20

3.6.4.1 Steps for DC connection..………………………………………21

3.6.4.2 Steps for AC connection.........................................................23

3.6.4.3 DC /AC teminal Connection....................................................25

3.6.4.4 Connect RS485 as per the following steps..............................26

3.6.5 Earthing requirement.......................................................................28

4 Trial operation………………………………………………………………….......29

4.1 Check before operation………………………………………………………29

4.1.1 Check for reliabilily of mechanical installation……………………… 29

4.1.2 Check for connecting cables…………………………………………29

4.1.3 Electrical check……………………………………………………… 29

4.2 Electrify the inverter………………………………………………………… 29

5 Human-machine interaction……………...........…………………………………30

5.1 LCD interface………………………………………………………………… 30

5.2 Internal data storage………………………………………………………… 31

5.3 Introduction to the function of monitor software…………………………31

5.3.1 Main interface………………………………………………………… 32

5.3.2 Parameter setting…………….......………………………………… 32

5.3.3 Device management ....................…………………………………… 33

5.4 Inverter working mode……………………………………………………… 33

5.4.1 Standing-by mode………………………………………………………34

5.4.2 Ready mode ...............………...………………………………………34

5.4.3 Power generating mode….........................…………………………35

5.4.4 Protection mode..................……..........………………………………35

5.4.5 Fault state………………………………………………………………36

5.5 LCD panel mode….……...………...……………………………………… 37

6Troubleshooting and maintenance………………………………………………38

6.1 Troubleshooting………………………………………………………………38

6.2 Daily maintenance…….……………………………………………………41

7

Uninstallation

………………….................................………………………… 42

7.1 Uninstallation steps………………..……………………………………… 42

7.2 Packing……………………………………………………………………… 43

7.3 Storing……………………………………………………………………… 43

8 Technical parameters……………………………………………………………44

9 Quality assurance……………………………………………………………… 46

9.1 Warranty Policy.....…………………………………………………………46

9.2 Exception clause…………………………………………………………… 46

9.3 Warranty card……….............………………………………………………47

10 Contact Think Power……………………………………………………………48

Contents Contents

5.6 LED blink table

….……...…………..……………………………………… 37

1Safety instruction

Please contact Think Power if you have any problems .

Tip

Song Series inverters are designed, manufactured and tested as per

international safety standards. However as an electrical and electric product, it

must be installed, operated and maintained strictly according to related safety

notices.

If you have any problems, please contact the nearest service center or

authorized dealer. Please do NOT install or repair the product by anyone who

is not qualified by local authority.

Think Power is not responsible for any damage or loss caused by misuse or

misunderstanding the information in this manual.

Misuse or misoperation may harm:

●The personal safety of the operator or a third person.

●The property safety of the inverter or any other property.

Warning

Notice

Warning

1.1 Before installation

The inverter cannot be connected to the grid unless

approved by the electrical authority, and it must be

installed according to the local standard and related

standard for an electrical enterprise.

Please check if there is any damage on the package or

the product before installing.The inverter is electrical

radioactived, Please choose a suitable place for

installing.

Safety instruction

1

Safety instruction

32

1.2 During installation

Keep the PV array covered and the DC circuit breaker

OFF. High voltage will be generated by PV array

exposed under sunshine. All the cablesmust be

connected firmly.

The inverter must be installed by a qualified electrical

engineer certified by the local authority, and the

installation manual must be read through before

installation. It must be installed according to the local

standard and related standard for an electrical enterprise.

1.3 Operation

●High voltage is a hazard, make sure keep the device

away from children.

●Any touch with the device or terminal may cause

electric shock or fire. Please follow all the safety

instructions.

●A damaged device or system fault can cause electric

shock. Make sure that you have checked the package

and the device before installation to avoid unnecessary

damage or loss.

Be aware of the hot surface while the device is running.

1.4 Repair

Completely switch off the connection between the inverter

and the grid, DC side connection. Wait for 10 minutes

until the internal elements are fully discarged.

Do NOT restart the inverter before all the hazards have

been removed. Please contact your local dealer and

always have licensed trader do the repairing.

1.5 EMC

EMC(ElectroMagnetic Compatibility) means the resistance of a device or

system against generating any ElectroMagnetic interference to the

environment without influencing the normal operation in the ElectroMagnetic

environment.

●Immunity tothe own noise; Immunity tothe internal electrical noise.

●Immunity to the external noise; Immunity to the external ElectroMagnetic

noise.

●Noise radiation level: influence of ElectroMagnetic radiation to the

environment.

●The ElectroMagnetic radiation of the inverter is harmful

for health.

●Please never stay within 20cm from a running inverter

for long.

Safety instruction

Notice

Notice

Caution

Notice

Danger

Danger

Danger

Product description Product description

54

2Product description

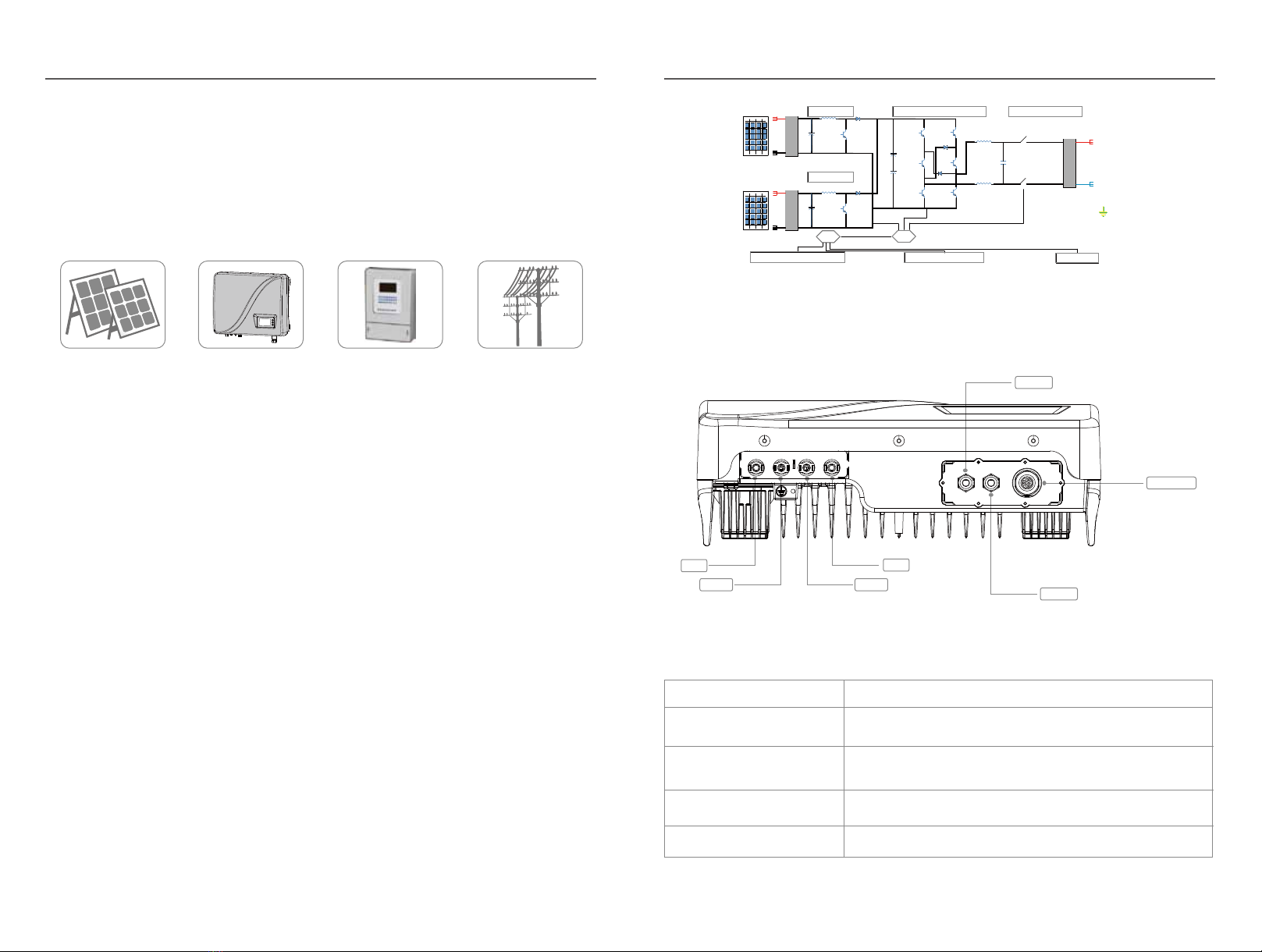

2.1 Product applicability

PV Array Inverter Metering Grid

Fig. 2-1

The research, development and manufacture of Song series are integrated

with the most updated techniques and public confirmed safety regulations.

However, improper operation or misuse may still cause injury or loss.

Instruction and information provided in this manual must be followed all the

time.

2.2 Circuit structure

Fig.2-2 shows the internal functional diagram of Song series inverter. After the

PV array input enters the voltage boosting circuit via the filter circuit,the input

DC voltage is boosted and stabilized to BUS value for the full-bride inverter

circuit, and in this process, the MPP tracer in the inverter will ensure the DC

energy generated in the photovoltaic array can be used by the inverter circuit

at maximum and the DC current will be conveyed into the grid.

The joint of the input and output EMC can effectively reduce the interference

between the inverter and outside.CPU1 and CPU2 control the inverter

operation and monitor the operation state, and in any abnormal working

condition, it will protect the inverter and external device and personal safety

according to the reserve program thus extremely improve the stability and

reliability of the system.

Fig.2-2

2.3 Product introduction

Fig.2-3

2.3.1 Electrical connecting part

Tab. 2-1: Description for the electrical connecting part of the inverter

Name

DC+ (1/2)

DC- (1/2)

WiFi/RS485

AC Output

Description

The positive part of terminals connecting the

PV array

The negative part of terminals connecting the

PV array

Communication mode

Connected tothe grid

By Song seriesinverter, the DC voltage generated in the PV array can be

transformed into AC voltage and supplied to the grid. The PV power

generating system consists of PV arrays,inverters, meters and a public

grid.

RS485

WiFi

DC2+

DC1+

DC2-DC1-

AC Output

EMC

DC+

DC-

EMC

DC+

DC-

PV1

PV2

EMC

L

N

PE

CPU1

CPU2

LCD DISPLAY PANEL

COMMUNICATION INTERFACE RS485/WiFi

BOOST MPPT2

BOOST MPPT1 FULL BRIDGE INVERTER GEID-CONNECT RELAY

I nstallation

8

3 I nstallation

3.1 S afety instruction

3.2 I nstallation procedures

Fig.3-1

See the following instruction for details.

Start Prepare Inverter install Electrical install

End Test Check

Danger

I nstallation

9

3.3 Preparation before installation

3.3.1 U npacking and checking

Fig. 3-2

Tab. 3-1: Package list

The DC voltage at the PV array and the AC voltage

at the grid side are both higher than the safe voltage.

I t is forbidden to touch any electrified terminal directly.

M ake sure the DC side is not electrified before

installation and maintenance.

The inverter must be installed, operated or maintained as per the following

standard and instruction, and it can not be connected to the grid for power

generating unless approved by the local power supply authority, and all

operation must be performed by a qualified electrical engineer.

●All electrical installation must be performed according to the local standard of

electrical installation.

●No internal part except the wiring terminal can be touched during installation.

●A running inverter has a high voltage, so no internal operation can be made

within 10 min at least after the AC and DC power supply of the inverter is cut off

and it is made sure by measuring the DC voltage by a multimeter that the

capacity is fully discharged.

●Take care of the hot surface of the inverter. For example, the heat radiator of

the power semiconductor will be kept in a high temperature after the inverter is

shut down.

●The inverter is deliver without any user’ s self-maintenance assembly, so

please contact the local authorized installation and maintenance technist if

you need to maintain your inverter.

The product is carefully tested and checked before transportation, however it is

still possible to be damaged during transportation, please check the device

again before installation. I f any damage, please contact the transportation

agency or directly contact Wuxi X inqi Power New Energy Technology Co., L td.

1I nverter 1

2I nstallation Back Board 1

14 Certification 1

3Positive DC Connector Packet 1For the connection of PV panel

4Negative DC Connector Packet 1For the connection of PV panel

5AC Connector Packet 1For the connection of grid

6Euro Terminal Block Packet 1For the RS 485 communication

8I nstallation S crew Packet 1 For the back board installation

9U ser M anual 1 Please read through carefully

12 Package L ist 1 Check the delivery according

to the package list

No. Q ty Remark

Description

13 Warranty Card 1Please well keep for filling and returning us

if there become any fault in the inverter

Antenna

71For the WiFi communication

11 1I nstruction on how to install the inverter

I nstallation G uide

10 1I nstructions on connecting your inverter

to your WiFi

WiFi setup G uide

Inverter

Antenna

Instllaon back

board

Posive DC

Connector

Negave DC

Connector AC Connector

EuroTerminal

Block User manual

Package list Warranty card

U s e r M a n u a l

Installer

Operator

Maintainer

PV G rid-Connected I nverter

S3600TL S 4400TL S 5000TL

U s e r M a n u a l

I nstaller

Operator

Maintainer

U s e r M a n u a l

I nstaller

Operator

Maintainer

S ong S eries

S ong S eries lnverter lnstallation& DC/AC

Terminal Connection G uide

Installaon

Guide

WiFi setup Guide

Danger

Notice

Notice

Installation

10

3.3.2 Preparation for tools

The following tools will be used for installing the inverter:

∮

Fig.3-3

3.4 Selection for a installation position

●

●

11

Detailed requirement for installation position:

※

※

※

※

※

※

※

※

※

※

Fig.3-4

Installation

The inverter with a protection level of IP65 can be installed in the open air.

The inverter can not be installed under direction sunshine, or the internal

temperature of the inverter will be excessively high and thus the inverter

performance will be degraded for protecting the internal elements; or even

the temperature protection will be activated by the excessively high

temperature.

The inverter shall be installed in a cool & dry place with temperature from

-25℃-+60℃;The environmental relative humidity is not higher than 95%

and without any condensation.

The inverter LCD shall be leveled with eyes and with enough space in the

front for inspection.

To avoid of burning or electric shock, the inverter shall be installed beyond

reach of children. The temperature of some parts (e.g. : the heat radiator)

is high when the inverter is running.

Make sure the installation position does not shake.

The inverter shall be installed in a well ventilated place to ensure the

normal heat radiation.

The installation place shall be firm enough to support the inverter weight.

The inverter shall be installed on a vertical wall, or within 15°at most if

backwards tothe wall.

Connecting terminal is located at the bottom.

Some parts ( e.g.: heat radiator) of the inverter runs with

a high temperature, so it is not suitable for installing near

inflammables or explosives.

When selecting an installation position, please avoid the influence

of noise and electromagnetic radiation to the environment.

The inverter can not be installed near any place of high external

electromagnetic radiation(e.g.: a TV tower, communication signal

tower or HV cables).

The inverter performance will be degraded if the environmental

temperature is 45℃ above. Make sure the inverter is installed in a

well ventilated place so that the power generation can be

maximized. MAX 15°

I nstallation

Fig.3-8

Fig.3-7

4) Fix the back board tothe wall using the tapping screws tightly.

Fig.3-9

7) The installation is finished

13

I nstallation

12

Tab.3-2: Effective spacing dimensions

Fig. 3-5

3.5 I nverter installation

3.5.1 I nstallation G uide

Fig. 3-6

Danger

1) Take out the back board and fix it tothe wall; then peel the four green logos

on the back board and attach them tothe wall through the hole. Thus the

installation holes are marked.

Please check that the open circuit voltage, short circuit

current and maximum power at S TC of the PV array are

within the capacity of the solar inverter.

The full load M PPT voltage range is within the

250V-480V .

2) Drill holes in the marked position as per the siz e of expansion screws.

3) I nsert the expansion tubes into the hole, knock the tubes into the hole and

make them level with the wall surface.

5) K eep the inverter tilts slight upward, and attach it tothe wall bracket slightly

to the top of its final position, and then visually check if the inverter is correctly

installed on the bayonet.

6) After installing the inverter, adj ust the screw on the back of the box to

ensure that the inverter is parallel tothe wall.

60mm

60mm

50mm

Installation

14 15

Tab.3-4: suggested RCD parameter

Tab.3-3: suggested max power input

Number of

inverter(s)/parallel Suggested RCD parameter(mA)

1

2

3

......

n

≥50×1

≥50×2

≥50×3

......

≥50×n

input1 3KW max

No load can be directly connected to the output side of the inverter.

Installation

Recommended Voltage/Current for DC Breaker is 600V/25A.

Recommended Voltage/Current for AC Breaker is 270V/35A.

If the inverter is equipped with the “AC Breaker including the RCD”, the

parameter of the RCD refers to the following:

Danger

Warning

3.6 Electrical connection

After the inverter is correctly installed on the wall or support, the next step is the

electrical connection for the inverter. Electrical connection must be performed

according to related safety standards.

A misoperation electrical connection may cause personal injury or

death or damage the inverter irreversibly. Wiring operation must be

performed by a qualified electrical engineer.

All electrical installation must be complying with local and national

electrical standards.

Warning

Warning

The inverter cannot be connected to the grid unless approved

by the local electrical authority and all electrical connections

are completed by a qualified electrical engineer.

Please use cables of specification recommended by us,

or the system safety may be deraded.

The electrical connection for an inverter covers electrical cable connection and

communication cable connection.

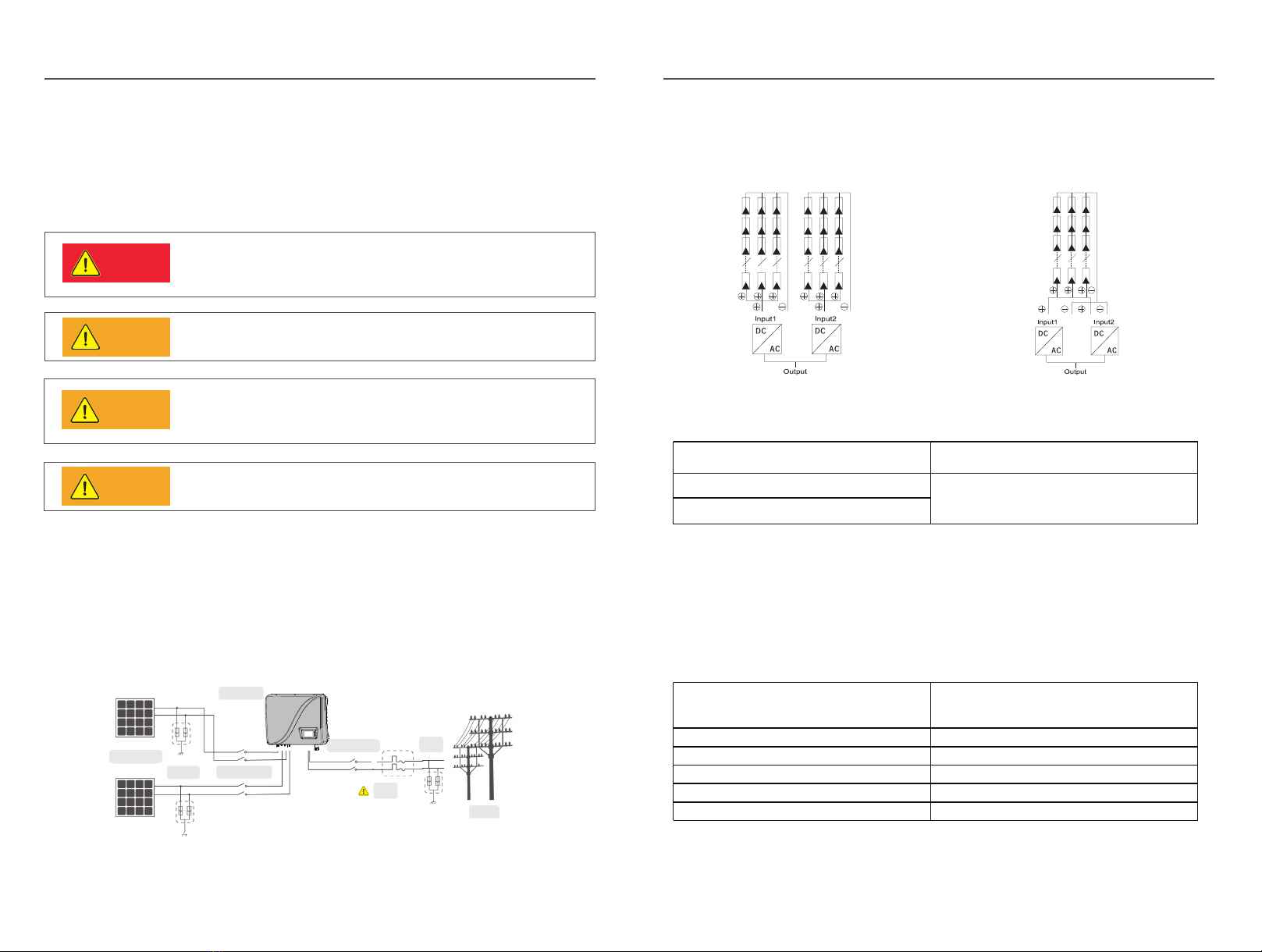

3.6.1 Electric and electrical system structure

The electric and electrical connection for the whole solar energy power

generation system is shown as below:

Fig.3-10

There are 2 independent MPP trackers in inverter. You can choose multi-strings

input connection(Fig3-11)and common-string input connection(Fig3-12). We

recommend that choose multi-strings to harvest max. PV power.

Fig.3-11 Fig.3-12

multi-strings input connection common-string input connection

input2 3KW max input1+input2 5KW max

I nstallation

16 17

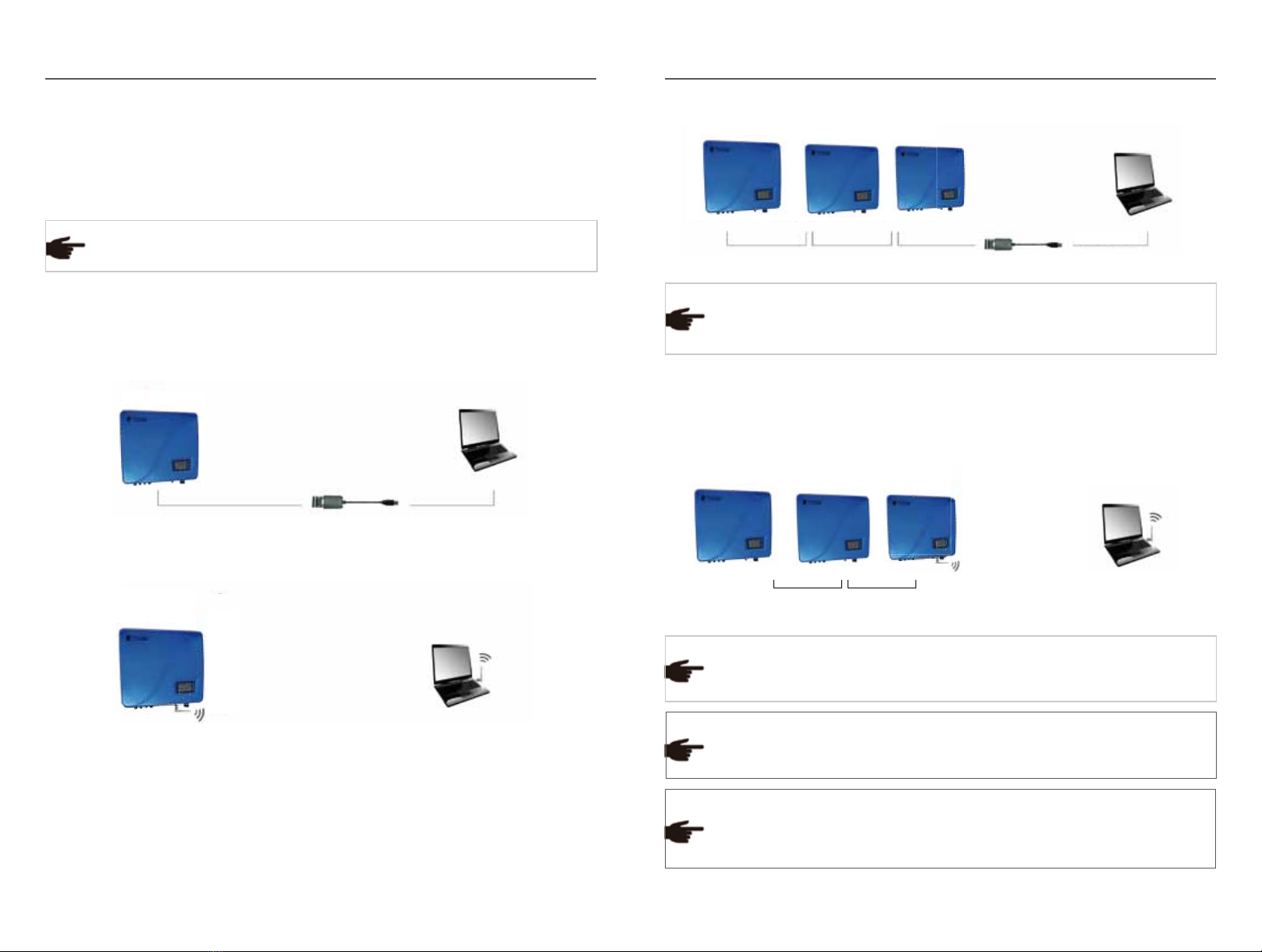

3.6.2 S tructure of the communication system

S ong series supports two flexible communication modes: RS 485 and optional

wireless WI FI . The topological structure of the communication connection is

introduced below.

S ee 3.6.3 for the detailed wiring terminals and 3.6.4 for the detailed wiring

steps.

Tip

Communication between a single device and a PC

1) S ingle device communication mode 1( RS 485)

S ee the figure below for the connecting method, a pair of A/B terminals on the

inverter is connected to the A/B terminals on the RS 485/U S B switch, and the

other end of the switch is connected to the computer.

●

Fig.3-13

2) S ingle device communication mode 2 ( WI FI module)

The connecting method is shown below, and a pair of wireless WI FI modules are

installed on the inverter and computer.

Fig.3-14

Communication between multiple devices and a PC

1) M ulti-device communication mode 1 ( RS 485)

S ee the figure below for the connecting method, A/B terminals on the inverter are

paralleled and then connected to the A/B terminal on the RS 485/U S B switch,

and the other end of the switch is connected to the computer.U p to 32 inverters can

be connected by this mode.

●

Fig.3-16

The“ M ulti-device communication mode 2” with RS 485 and WI FI is

applicable for centralize d installation where wiring is not convenient

between the computer and devices.

Tip

Fig. 3-15

The“ M ulti-device communication mode 1” with RS 485 is applicable for

centralize d installation where wiring is convenient for the computer

and devices.

Tip

2) M ulti-device communication mode 2 ( RS 485 and WI FI module)

S ee the figure below for the connecting method, A/B terminals of inverters are

paralled, and a pair of WI FI module is installed on any one of the inverter and the

PC. U p to 32 inverters can be connected by this mode.

Tip

Tip

RS 485/U S B switch module and WI FI wireless module are serial products

orderable from X inqi Power RS 485/U S B switch module can be

purchased by the user of own.

I f RS 485 communication mode is selected, it is recommended to use

two-core dual-twisted shield cable. The recommended specification is

RV V P2*1.0. The maximum transmission distance of RS 485

communication mode is 1200m.

I nstallation

I nstallation I nstallation

18

3.6.3 Wiring terminals and cable specification

1) DC wiring terminals

No load can be directly connected to the output side of the inverter.

The wring terminals as following:

Fig.3-18 Fig.3-19

Fig.3-20 Fig.3-21

19

3) Communication terminals

2) AC terminals

Tip

Notice

Fig.3-17

Fig.3-22 Fig.3-23

Fig.3-24 Fig.3-25

WI FI wireless communication is functioning within 400m

in an opening distance, but interference and barrier shall

be put into consideration because the actual transmission

distance is influenced by the installation field and external

interference.

The DC side of inverter has 4 terminals totally, including two DC positive

wiring terminals and two DC negative wiring terminals. S ee the figure below:

The two pairs of A/B RS 485 communication wiring terminals at

the inverter communication side are equivalent.

●S ingle-device communication: Either pair of A/B RS 485

communication wiring terminals can be connected if RS 485

module is connected.

●M ulti-device communication: Either pair of the A/B RS 485

communication wiring terminals can be connected to the WI FI

module and the other pair to RS 485 if WI FI module and RS 485

are both connected.

●M ulti-device communication: Two routes of RS 485 can be

connected, and either pair of A/B RS 485 communication wiring

terminals can be used as the input and the other pair as the

output.

Danger

Danger

Caution

Notice

Installation

20

4) Cables of the following specification will be equipped by the user.

21

3.6.4 Steps for electrical connection

Tab.3-5: Recommended cable specification

DC cable(+) 2 4 4

DC cable(-) 2 4 4

AC cable(L) 4 6 6

AC cable(N) 4 6 6

AC cable(GND) 4 6 6

Communication

cable (RS485)

Name

3.6.4.1 Steps for DC connection

Tip

Tip

Tip

Tip

Fig.3-26 Fig.3-27

Steps for DC cable wiring

Installation

0.5 1.5 1

DC cable between the inverter and the assembly shall be the

special PV cable. The voltage drop from the terminal box to the

inverter is about 1-2%. It is recommended the inverter is

installed on the assembly support for generation to reduce the

cable cost and the DC loss.

High performance and high quality PV array shall be used. The

open circuit voltage in the serial array must be lower than the

maximum DC input voltage in the PV grid-tied inverter, and the

working voltage of the serial array must comply with the MPPT

voltage of the serial array must comply with the MPPT voltage

in the PV grid-tied inverter.

● Protect the LCD panel during wiring;

● Protect the LCD panel and other elements from scratch or

damage by cables or tools.

1) Using the striping tool to cut the PV cable, and makes the cooper wire

reveal as 0.7cm.

In order to balance each PV series, Cable shall be with the same

sectional area.

Different colors of cables shall be used for differentiating in

assembling. For example: the positive pole is connected by a red

cable and the negative by a blue cable.

When designing the PV array, make sure the maximum

open circuit voltage is not higher than 550V at each series

of PV group. Otherwise the inverter will be damaged

irreversibly

If the inverter has been electrified and tested before

connection, wiring can not be performed unless the AC and

DC power supplies are cut off for 10min and a multimeter

shows that the DC side is tatally discharged.

Please cover the PV array by lightproof material or switch

off the DC circuit breaker before electrical connection. A

dangerous voltage will be generated by the PV array

exposed in the shine.

Installation

22

2) Using the crimping tool and put terminal into mold of crimping tool, The terminal size is

4.0mm, so put it into the mold of 4-6mm.

3) Process crimping.

4) Crimp closely between the terminal and PV cable.

5) The terminal is crimped well with PV cable wire.

6) Put terminal into connector.

7) The DC wiring finished.

3.6.4.2 Steps for AC connection

Steps for AC cable wiring:

23

Installation

Fig.3-31

Fig.3-28

Fig.3-29

Fig.3-30

Fig.3-32

Fig.3-33

Installation

24 25

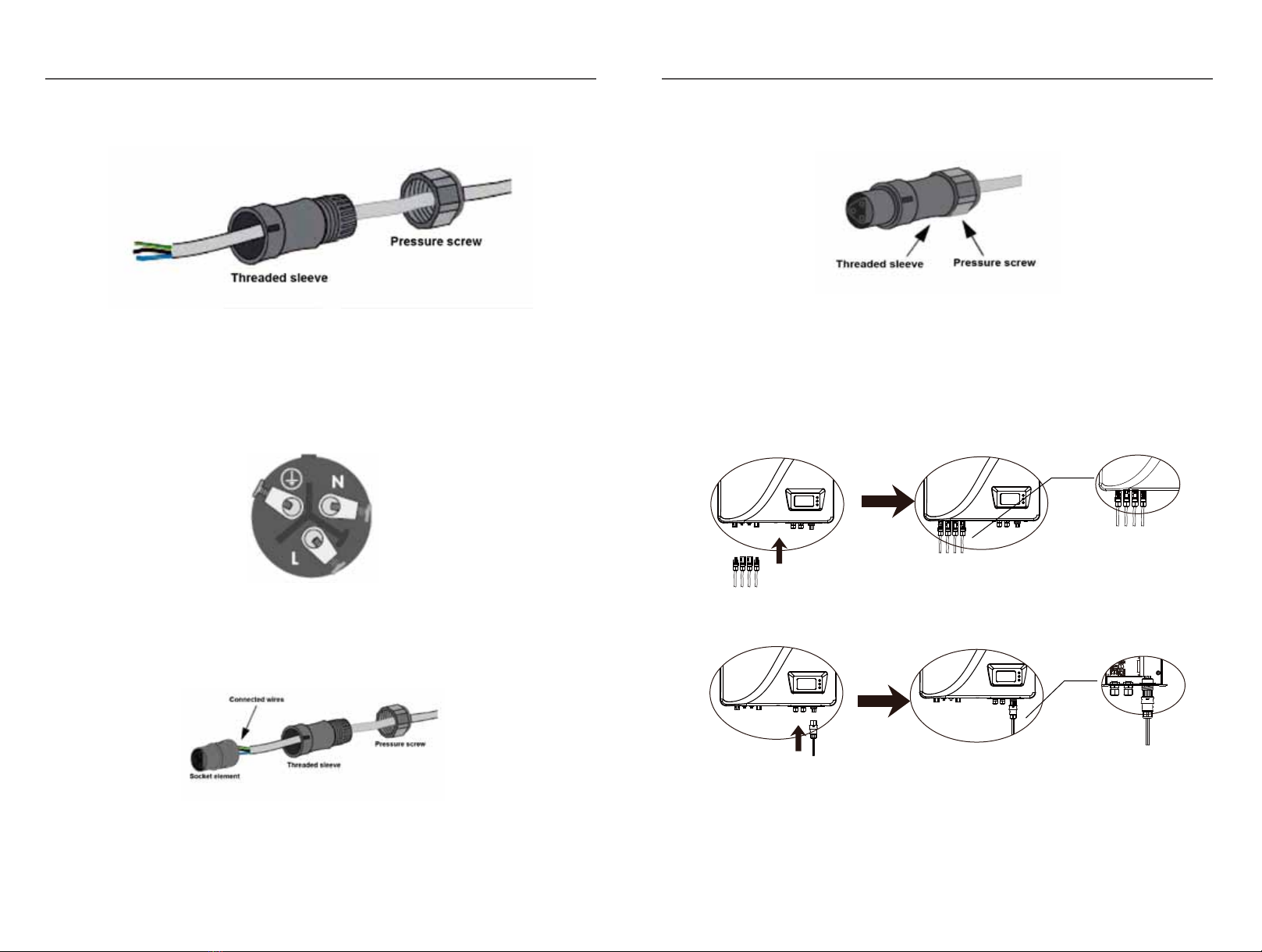

1) Put the threaded sleeve and pressure screw of AC wring terminal and the AC wire.

2) Wire the AC wire refers to below instructions.

Fig.3-34

Fig.3-35

3) Confirm all the wires should be screwed down.

4) Screw down the threaded sleeve and the pressure screw.

5) The AC connection finished.

Fig.3-36

Fig.3-37

3.6.4.3 DC/AC terminal connection:

1) Make sure that the DC/AC breaker is switched off.

2) Insert the DC+/- wiring terminal into corresponding DC+/- terminal.

Fig.3-38

3) Insert the AC wiring terminal into the AC terminal.

4) Switch on the AC breaker.

5) Switch on the DC breaker.

Installation

Screw the green-yellow wire to the ground terminator in the AC Connector

Screw the blue wire to the N(Natural) terminator in the AC Connector.

Screw the brown wire to the L(Line) terminator in the AC Connector.

DC1+ DC1- DC2- DC2+ AC

OUTPUT

DC1+ DC1- DC2- DC2+ AC

OUTPUT

AC

OUTPUT

A1 B2B1 A2

+5V

GND

098-06013-00

710-06013-00

1 9

210

CN1

U4

85

4

U3

LD2

LAB1

1

J1

ATT

U2

U1

TVS1

R7

R6

R5

R4

R2

R1

LD1

JP2

12

JP1

C7

C4

C2

R9

R10

C3

Fig.3-39

AC

OUTPUT

AC

OUTPUT

A1 B2B1 A2

+5V

GND

098-06013-00

710-06013-00

1 9

210

CN1

U4

85

4

U3

LD2

LAB1

1

J1

ATT

U2

U1

TVS1

R7

R6

R5

R4

R2

R1

LD1

JP2

12

JP1

C7

C4

C2

R9

R10

C3

Installation

26

Fig.3-40 Fig.3-41

27

3.6.4.4 Connect RS485 as per the following steps.

Fig.3-42

Fig.3-43

Installation

7)Start the monitor software on the PC and start to communicate.

2) Remove the waterproof cover from the RS485 communication waterproof

terminal, lead the cable through the cover and then to the device via the

waterproof terminal.

3) Estimate the cable length to the terminal, peel off the cable as pre the length

of the metal section of the tube type pre-insulated terminal, and press on the

terminal by a pair of wire end-sleeve pliers reliably.

1) Remove the 6 screws on the inverter bottom cover by wrench, and open the

bottom cover.

4) Press down the top of the terminal by a flat screw driver, insert the cable into

the terminal A/B.

Fig.3-45

A1 B2B1 A2

+5V

GND

098-06013-00

710-06013-00

1 9

210

CN1

U4

85

4

U3

LD2

LAB1

1

J1

ATT

U2

U1

TVS1

R7

R6

R5

R4

R2

R1

LD1

JP2

12

JP1

C7

C4

C2

R9

R10

C3

A1 B2B1 A2

+5V

GND

098-06013-00

710-06013-00

1 9

210

CN1

U4

85

4

U3

LD2

LAB1

1

J1

ATT

U2

U1

TVS1

R7

R6

R5

R4

R2

R1

LD1

JP2

12

JP1

C7

C4

C2

R9

R10

C3

5)Cover the bottom cover of the inverter.

Fig.3-44

6) Connect the other side of the communication cable to the 485/USB

connector and then connect the USB to the PC.

28

3.6.5 Earthing requirement

29

4Trial operation

4.1 Check before operation

4.1.1 Check for reliability of mechanical installation

4.1.2 Check for connecting cables

4.1.3 Electrical check

Make sure the grid parameters are complying with the inverters parameters.

4.2 Electrify the inverter

Installation Trial operation

Warning

Caution

Necessary safety check must be performed before the

inverter is electrified for trial operation!

The inverter is a device with no transformer, neither the

positive nor the negative pole of the PV assembly DC side

can be earthed, or the inverter will not work normally, or even

be damaged irreversibly.

In Song series PV power generating system, all device shells, assembly supports

and the GND terminal of the inverter must be safety and reliably earthed. Check if the inverter is firmly installed and if all bolts are reliably tightened. For

an inverter installed on a metal supporter, make sure each bolt is tightened and

support has enough load bearing capacity.

Check if all cables in the system are firmly connected without any missed or

wrong connection, and especially check if all positive and negative poles are

correct. If a DC switch is equipped on the inverter, the DC switch shall be turn

to the “OFF” state.

Make sure the DC input voltage of the inverter is lower than 550V (with the

temperature decrease of the PV array, the open circuit voltage will be

increased, so a residual voltage at the low temperature must be put into

consideration).

The inverter can be started up as per the following steps after all testing and

checking steps are performed.

Switch on the DC breaker, and turn the DC switch to the “ON” state if a DC

switch is equipped on the inverter.

Switch on the AC breaker.

See Part 5 of this manual for “Human-machine interaction” after the inverter is

started up. If enough power energy can be generated in the solar array, the

inverter will be started up automatically, and LCD will display the normal status

which means the inverter is successfully started up. If the inverter is not

normally started up, please refer to Part 6 “Troubleshooting and maintenance”.

This manual suits for next models

5

Table of contents

Other Thinkpower Inverter manuals

Popular Inverter manuals by other brands

ABB

ABB UNO-DM-TL-PLUS-US product manual

Growatt

Growatt MID 33-50KTL3-X2 quick guide

Apex Digital

Apex Digital APEX-E-P3-5000L user manual

Generac Power Systems

Generac Power Systems Guardian 004721-0 owner's manual

Winco

Winco Home power HPS12000HE Installation and operator's manual

MAC3

MAC3 E-Power e-MM user manual