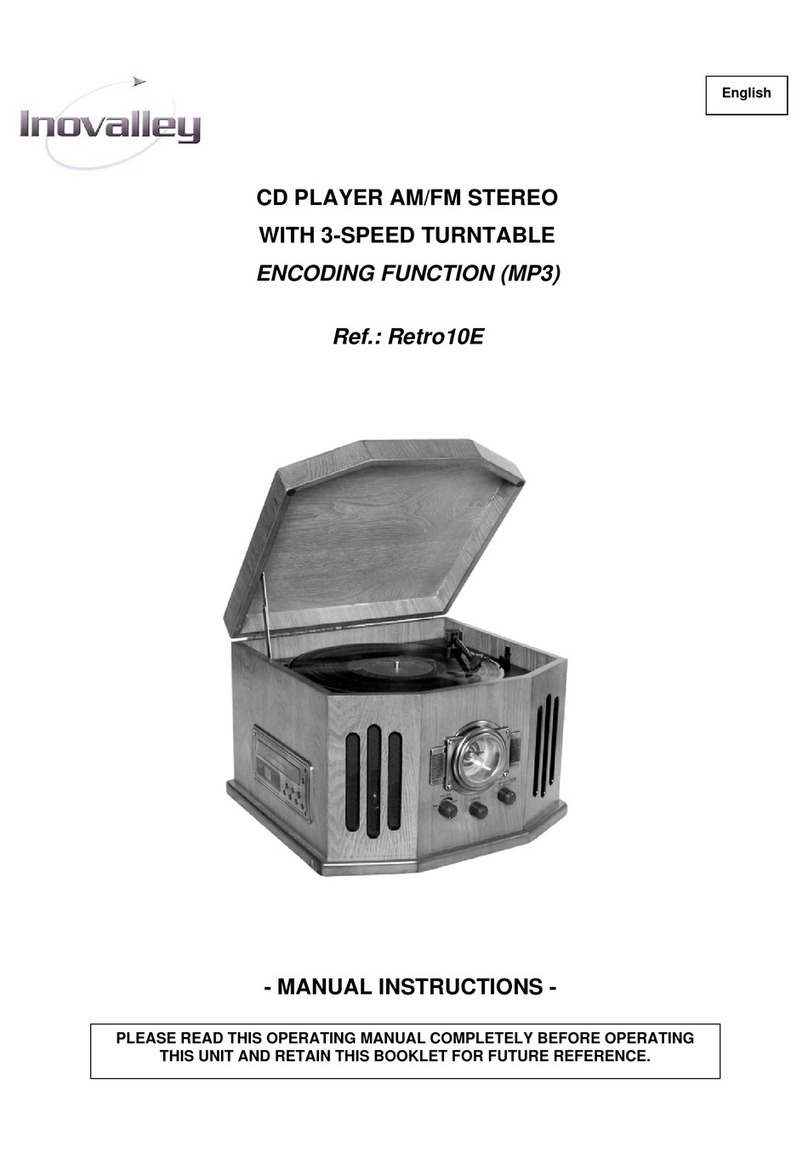

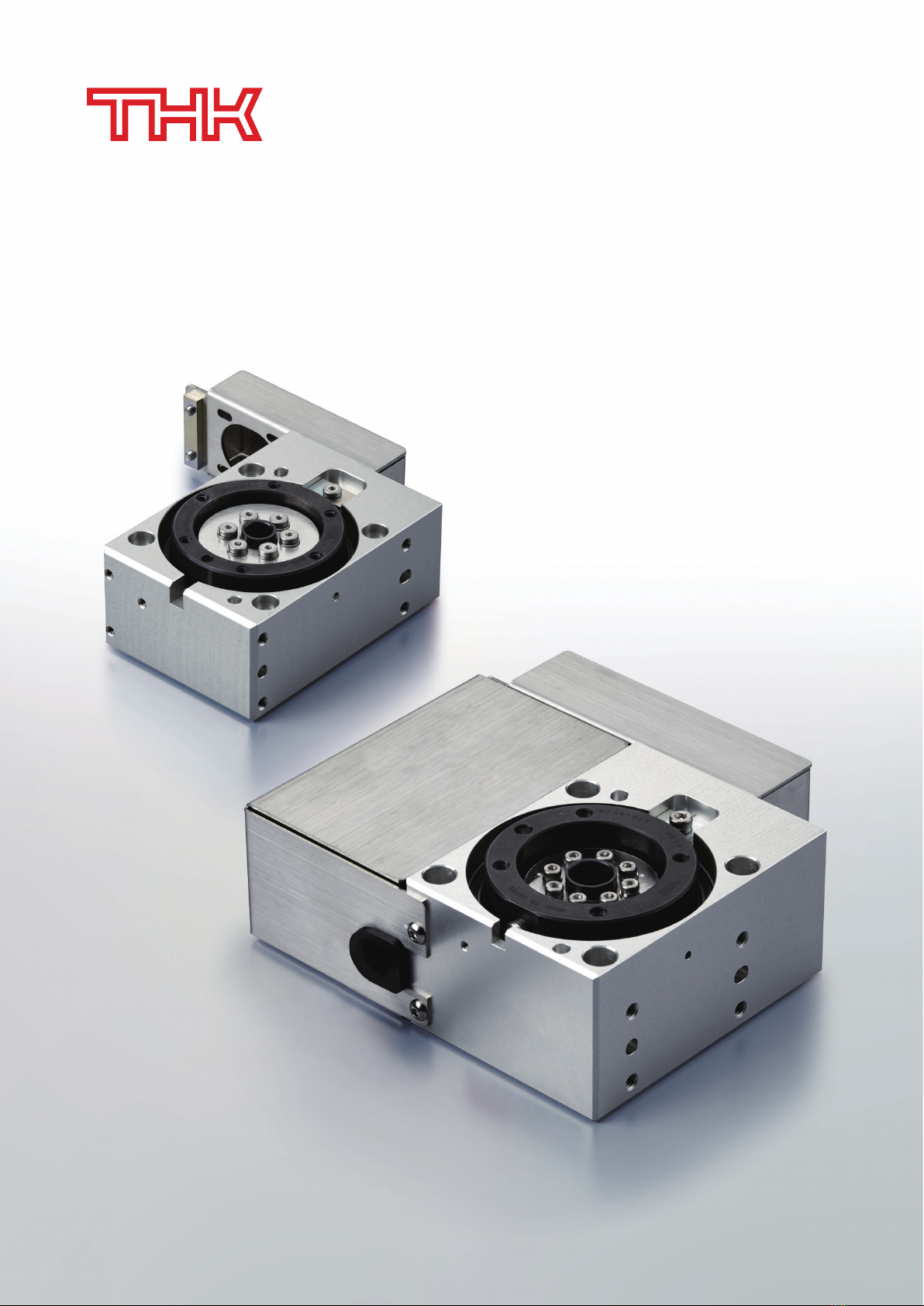

THK ET20 Series User manual

ET

High-precision multi-point positioning

with superior rotary performance

Thin Electric Turntable

ES/EC

○ Uses a ball screw to move with

higher precision than air cylinders.

○ Modularized structure reduces number

of components and both design and

assembly time.

○ Uses the Caged Ball LM Guide to

achieve long-term

maintenance-free operation (ES only).

Economy Series Electric Actuator

○ Capable of multi-point positioning,

opening and closing speed control,

and gripping force setting.

○ Smooth motion that withstands

repeated open/close operations.

○ Maintains gripping force even when

power is lost.

EG

Electric Gripper

○ Modularized structure reduces number

of components and both design and

assembly time.

○ Can be used in a horizontal,

wall-mounted, vertical,

or suspended orientation.

○ Optimal for high-precision positioning

and orthogonal-axis designs.

LM Guide Actuator

SKR/KR

Other Recommended Products

Thin Electric Turntable ET

All rights reserved.

LM Guide and Caged Ball are registered trademarks of THK CO., LTD.

The actual products may differ from the illustrations and photographs in this catalog.

Outward appearances and specifications are subject to change without notice for the purpose of improvement. Please consult with THK before using.

Although great care has been taken in the production of this catalog, THK will not take any responsibility for damages resulting from typographical errors

or omissions.

For exports of our products and technologies and sales for export, our basic policy is to comply with the Foreign Exchange and Foreign Trade Act and other

laws and regulations. Please consult us in advance if you want to export our products by the piece.

Headquarters 2-12-10 Shibaura, Minato-ku, Tokyo 108-8506 Japan

International Sales Department Phone: +81-3-5730-3860

www.thk.com

CATALOG No.397-4E ©THK CO., LTD. 202208

Ample rotary functions only possible

with an electric drive

Consistent movement at

any installation angle

Thin Electric Turntable ET

Multi-point positioning, multi-rotation control

(speed can also be adjusted)

The combination of an electric drive with position control makes it possible to easily set three or more

positions without stoppers.

Capable of multiple movements, including clockwise and counterclockwise rotation control, speed control,

and continuous rotation.

Stop positionStop position Mid position

Mid position

Home position

Home position

Multi-point positioning

Continuous rotation in one direction

Up to three stop positions with pneumatics

1

Ample rotary functions only possible

with an electric drive

Consistent movement at

any installation angle

Thin Electric Turntable ET

Multi-point positioning, multi-rotation control

(speed can also be adjusted)

The combination of an electric drive with position control makes it possible to easily set three or more

positions without stoppers.

Capable of multiple movements, including clockwise and counterclockwise rotation control, speed control,

and continuous rotation.

Stop positionStop position Mid position

Mid position

Home position

Home position

Multi-point positioning

Continuous rotation in one direction

Up to three stop positions with pneumatics

2

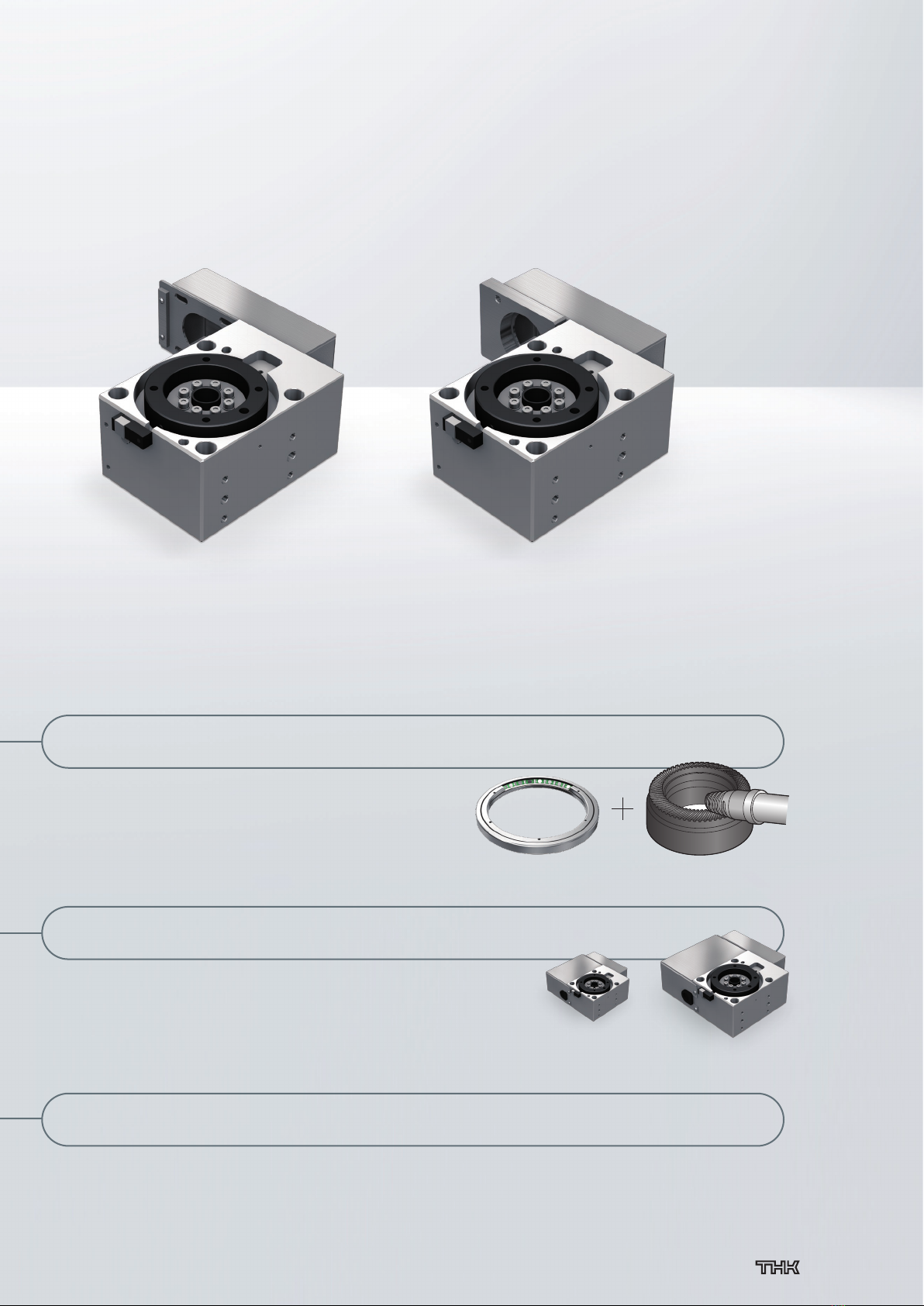

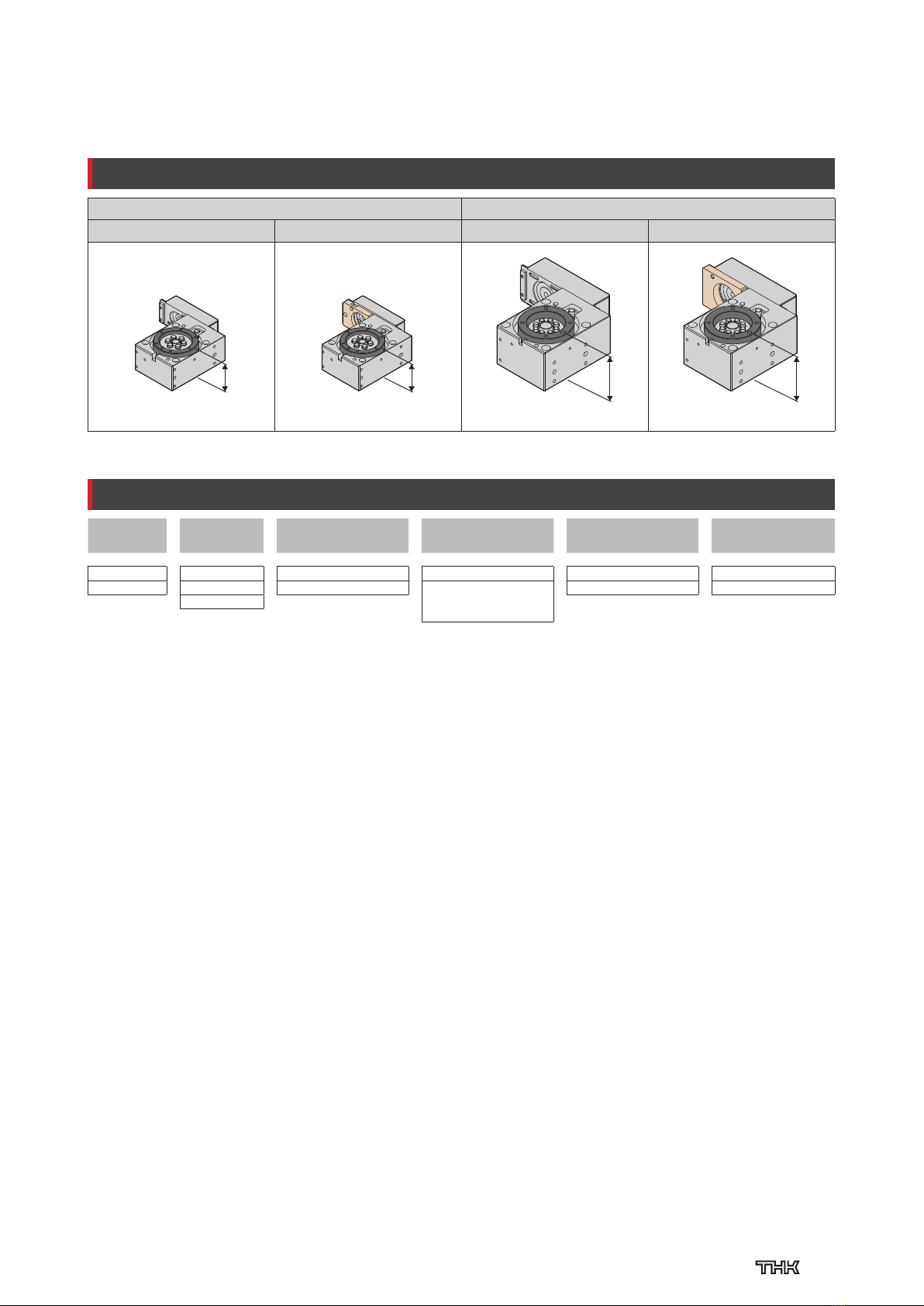

TSC specifications

Without motor

Stepper motor built in

Stepper motor specifications Servo motor specifications

Different varieties are available for purchase

This product can come with a motor that pairs with the THK controller, a motor that you specify, or no

motor installed.

Choose from 330° (mechanical homing type) or 360° (sensor homing type) to match your control application.

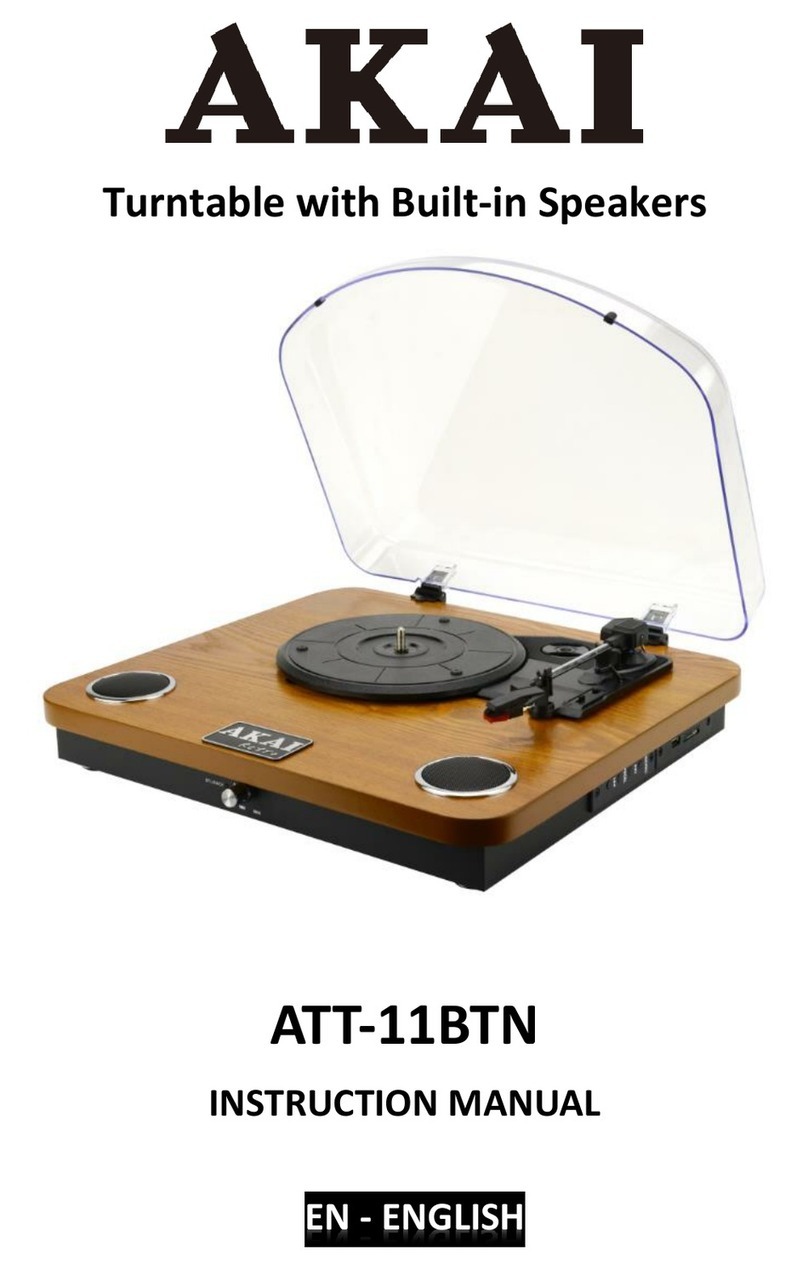

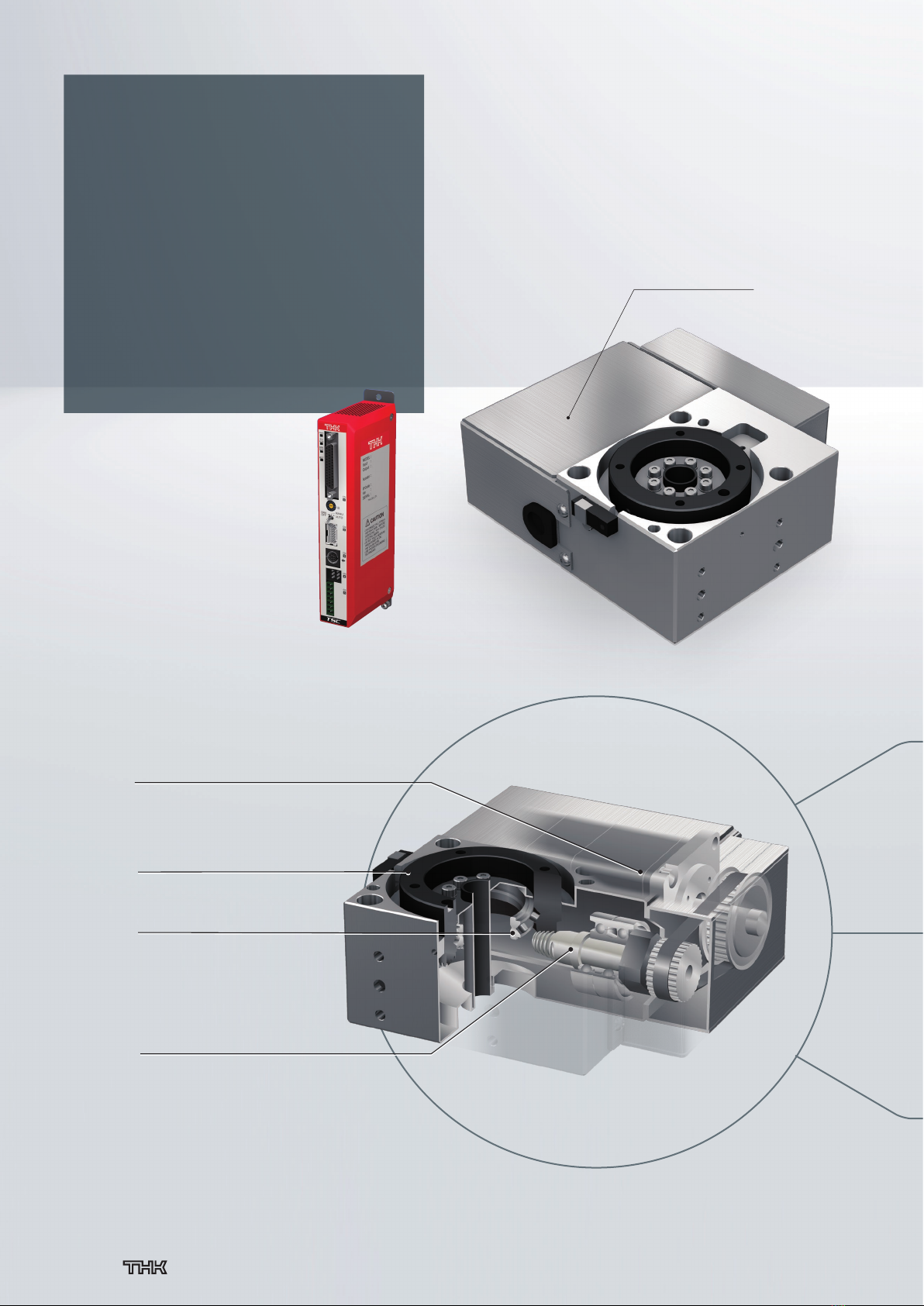

High-performance ET structure

A mechanism that achieves high rotational accuracy

The rotary structure combines

a THK cross-roller ring and hypoid gear.

Thin structure

Product height is reduced by providing a compact rotary table

and motor and integrating the cross-roller ring and hypoid gear.

This helps equipment take up less space.

Rotary table (330°, 360°)

Motor

Cross-roller ring

Hypoid gear

ET20 ET35

Cross-roller ring Hypoid gear

ET

Multi-point positioning

Continuous rotation in one direction

Rotation speed control

Freely set at any angle

Positioning repeatability: ±0.04 degrees

Stepper Driver

Controller TSC

3

TSC specifications

Without motor

Stepper motor built in

Stepper motor specifications Servo motor specifications

Different varieties are available for purchase

This product can come with a motor that pairs with the THK controller, a motor that you specify, or no

motor installed.

Choose from 330° (mechanical homing type) or 360° (sensor homing type) to match your control application.

High-performance ET structure

A mechanism that achieves high rotational accuracy

The rotary structure combines

a THK cross-roller ring and hypoid gear.

Thin structure

Product height is reduced by providing a compact rotary table

and motor and integrating the cross-roller ring and hypoid gear.

This helps equipment take up less space.

Rotary table (330°, 360°)

Motor

Cross-roller ring

Hypoid gear

ET20 ET35

Cross-roller ring Hypoid gear

ET

Multi-point positioning

Continuous rotation in one direction

Rotation speed control

Freely set at any angle

Positioning repeatability: ±0.04 degrees

Stepper Driver

Controller TSC

4

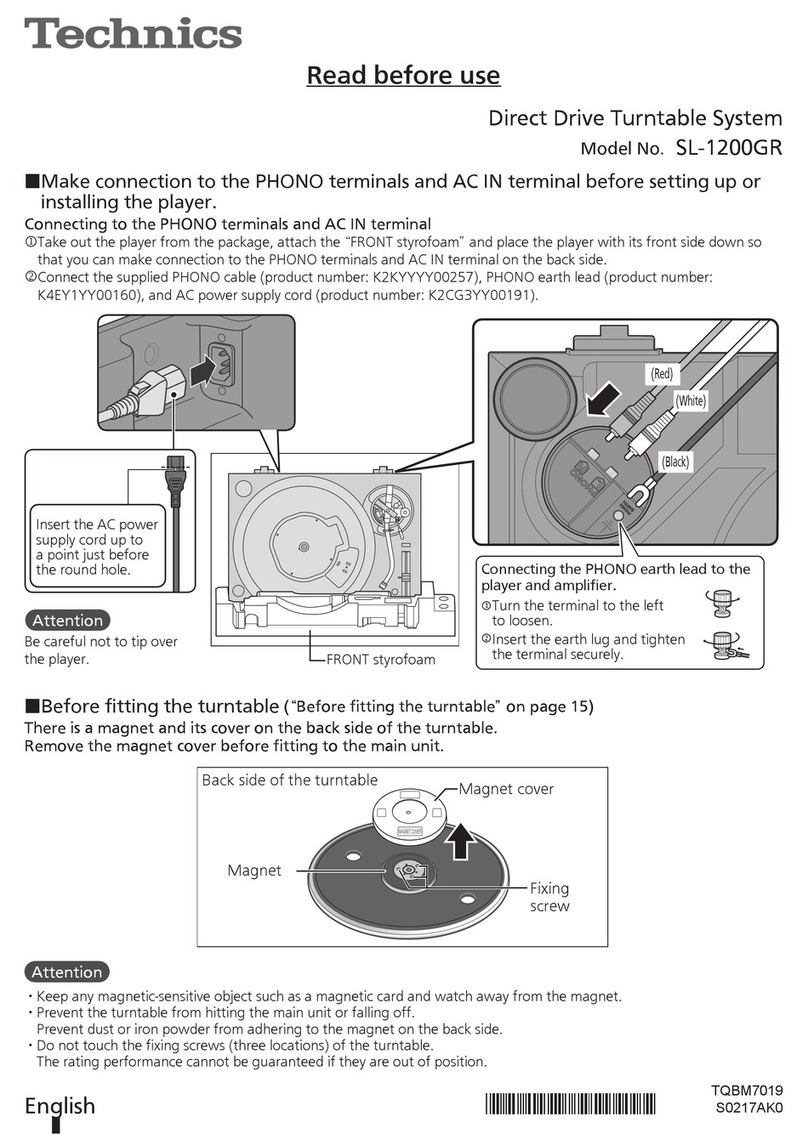

The ET is used in the hand rotary mechanism of the

orthogonal-axis robot. The reduced weight of the thin structure

allows for a decreased load on the lower axis.

The ET is used in the parts that rotate the table. The rotary

mechanism combines a cross-roller ring and a hypoid gear to

achieve highly accurate indexing.

θ

axis: ET

Model used

θ

axis: ET

Hand: EG

X, Y, and Z axis: KSF

Models used

Orthogonal-axis robot

General industry

Index table

General industry

Diversified Applications

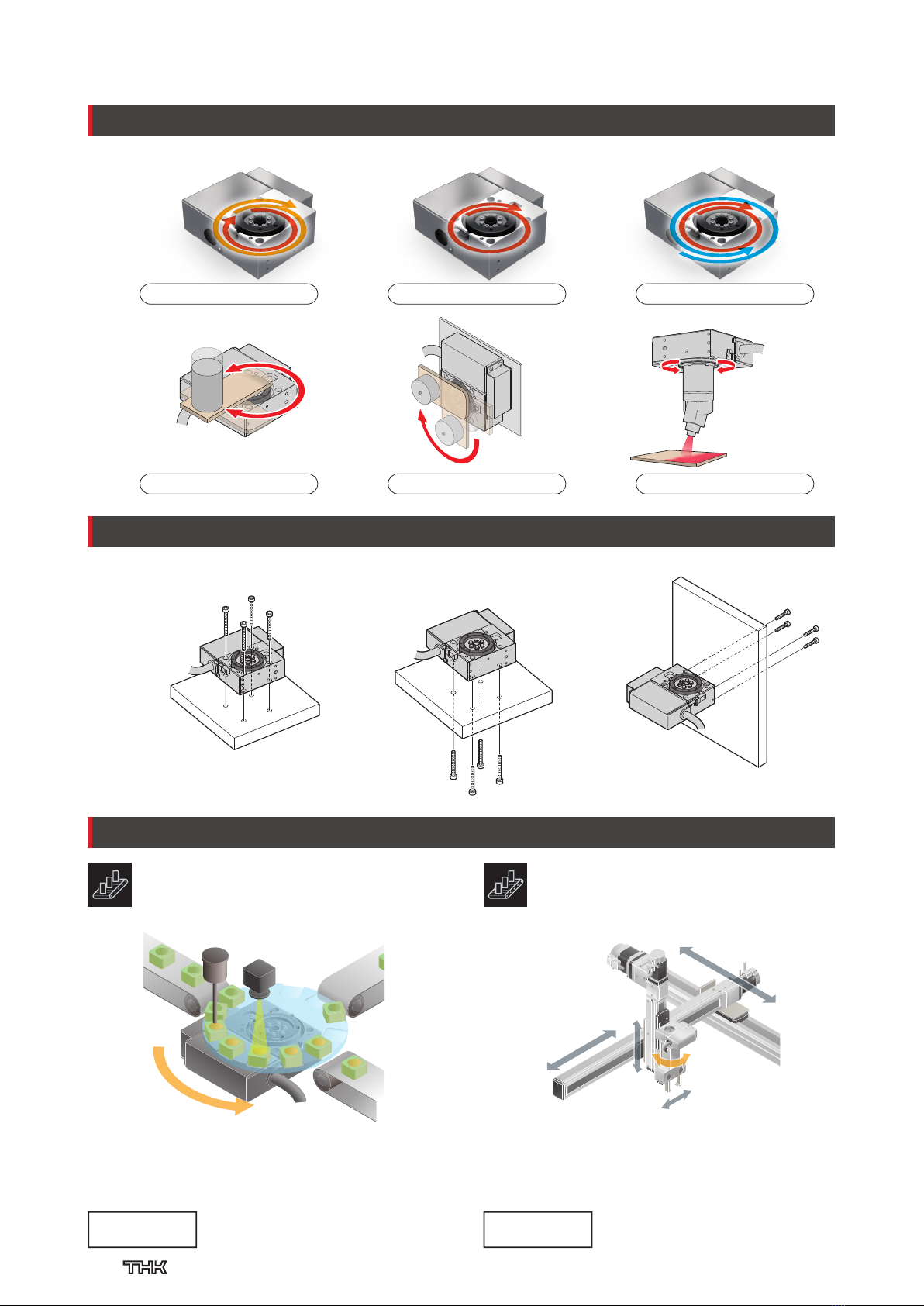

Basic Applications (Rotation)

330°/360° stroke rotation

Continuous rotation in one direction

Clockwise/counterclockwise rotation

Applied moment

No speed fluctuations from varying loads

Suspended installation

This product can be mounted from any surface, making it easy to install anywhere.

Note) This product cannot be installed with the

pulley facing downward. See the instruction

manual for details.

Upper surface

installation

Lower surface

installation

Side surface

installation

Two sizes are available: ET20 and ET35. The reduction ratio and motor size for each are given below.

Without motor: Servo motor specifications

TSC specifications

Without motor: Stepper motor specifications

Reduction ratio 45: 1/45

ET20

Reduction ratio 20: 1/20 30: 1/30

ET35

Reduction ratio 45: 1/45

ET20

Reduction ratio 20: 1/20 30: 1/30

ET35

Reduction ratio 45: 1/45

ET20

Reduction ratio

Motor size: 40×40

Motor size: 35×35

Motor size: 40×40

Motor size: 35×35

Motor size: 25×25

Motor size: 40×40

20: 1/20 30: 1/30

ET35

ETET

KSFKSF

KSFKSF

EGEG

KSFKSF

ETET

Applications

Mounting Methods

Example Applications

5

The ET is used in the hand rotary mechanism of the

orthogonal-axis robot. The reduced weight of the thin structure

allows for a decreased load on the lower axis.

The ET is used in the parts that rotate the table. The rotary

mechanism combines a cross-roller ring and a hypoid gear to

achieve highly accurate indexing.

θ

axis: ET

Model used

θ

axis: ET

Hand: EG

X, Y, and Z axis: KSF

Models used

Orthogonal-axis robot

General industry

Index table

General industry

Diversified Applications

Basic Applications (Rotation)

330°/360° stroke rotation

Continuous rotation in one direction

Clockwise/counterclockwise rotation

Applied moment

No speed fluctuations from varying loads

Suspended installation

This product can be mounted from any surface, making it easy to install anywhere.

Note) This product cannot be installed with the

pulley facing downward. See the instruction

manual for details.

Upper surface

installation

Lower surface

installation

Side surface

installation

Two sizes are available: ET20 and ET35. The reduction ratio and motor size for each are given below.

Without motor: Servo motor specifications

TSC specifications

Without motor: Stepper motor specifications

Reduction ratio 45: 1/45

ET20

Reduction ratio 20: 1/20 30: 1/30

ET35

Reduction ratio 45: 1/45

ET20

Reduction ratio 20: 1/20 30: 1/30

ET35

Reduction ratio 45: 1/45

ET20

Reduction ratio

Motor size: 40×40

Motor size: 35×35

Motor size: 40×40

Motor size: 35×35

Motor size: 25×25

Motor size: 40×40

20: 1/20 30: 1/30

ET35

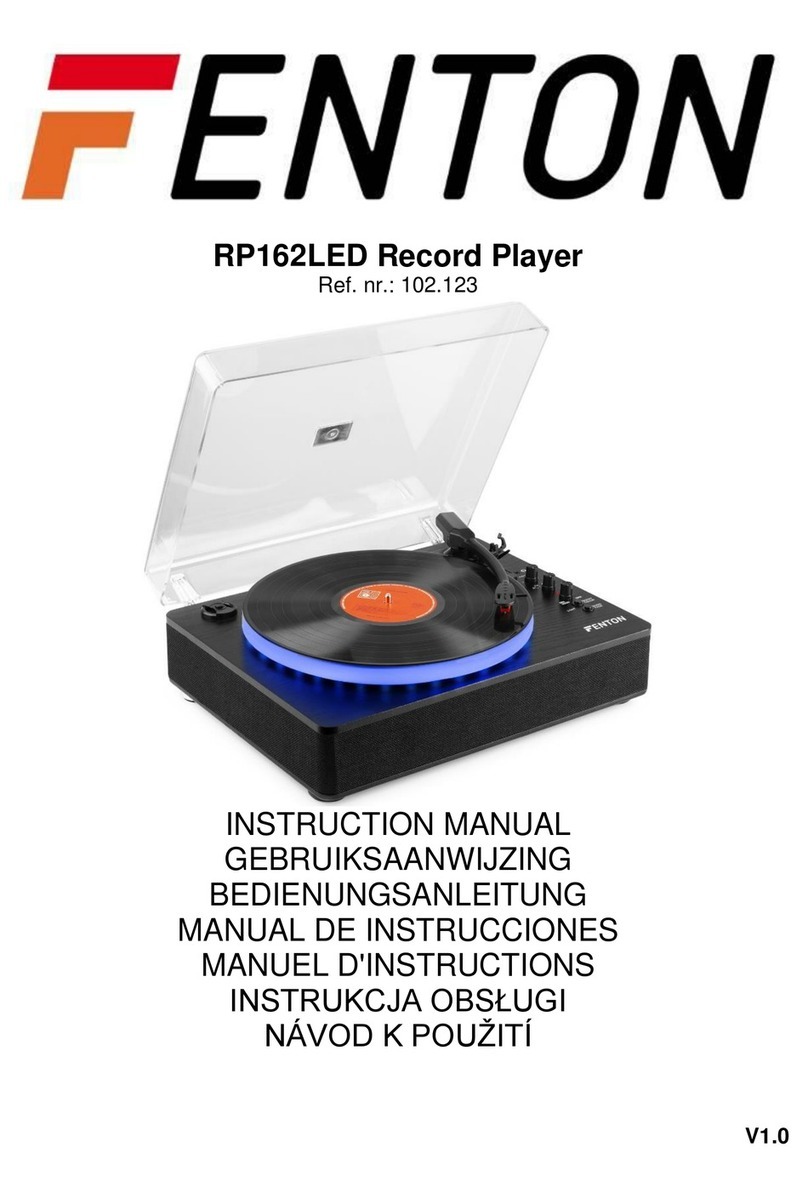

General Specifications

6

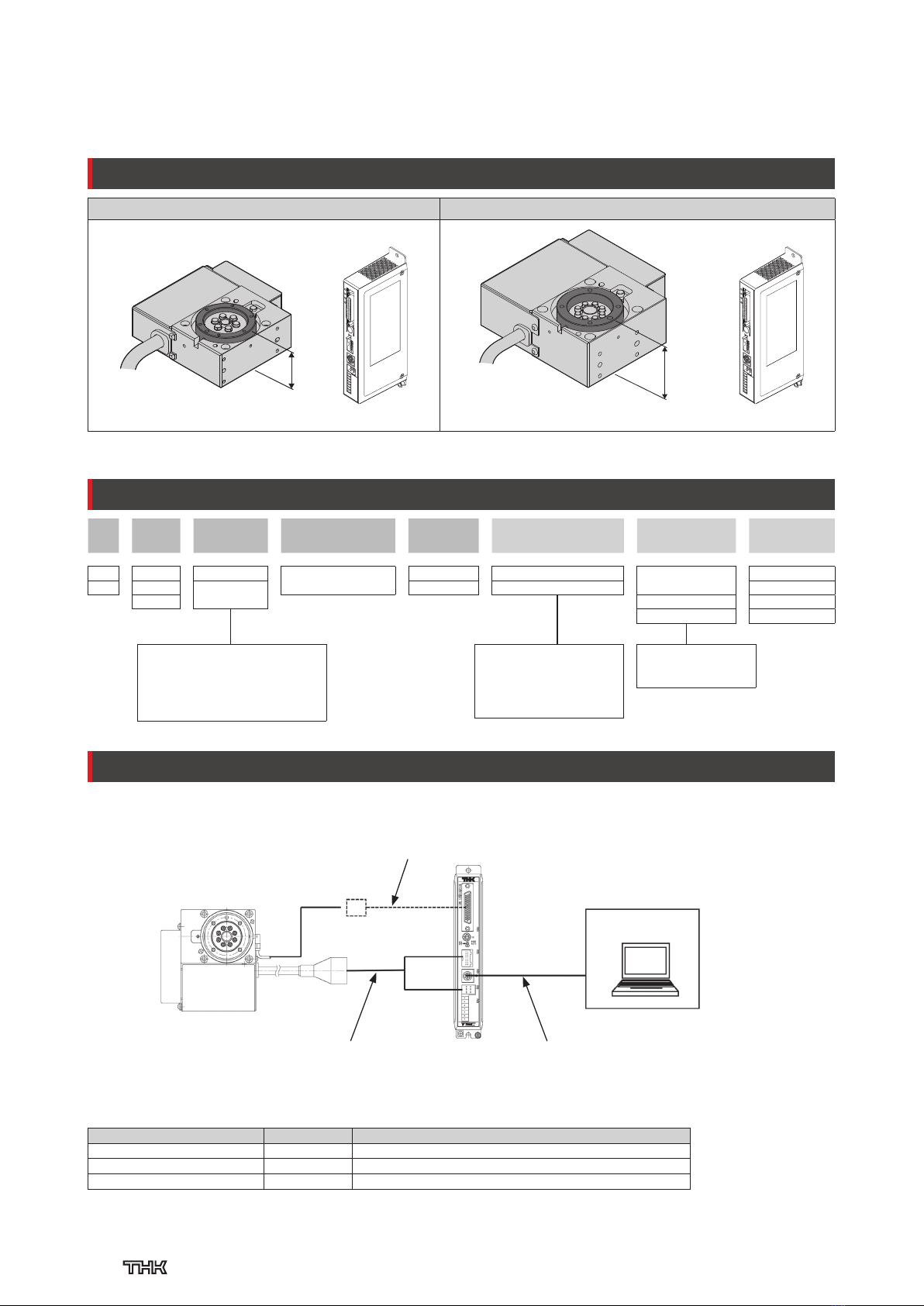

Lineup

ET20+TSC ET35+TSC

301

+

441

+

Users can select a reduction ratio.

1This dimension represents the distance from the bottom surface of the base to the top surface of the table.

ET (with Stepper Driver Controller TSC)

Combination with dedicated driver controller

Model Number Coding

The available motor options

vary based on the model.

ET20: 20P

ET35: 35P

D00 and R00 use

mechanical homing.

Model

Reduction ratio

Stroke Control device Options Motor size Home position Cable length

① ② ③ ④ ⑤ ⑥ ⑦ ⑧

ET20 — 45 — 330 — TS — / 20P — D00 — S3

ET20 20: 1/20 330: 330° TS: Stepper Driver

Controller TSC

No symbol

: None

20P: Stepper motor 20×20 No symbol:

Multi-rotation

specifications

No symbol: None

ET35 30: 1/30 360:

Multi-rotation

specifications

2

U: Sensor 35P: Stepper motor 35×35 S3: Standard 3 m

45: 1/45 D00:

Counter-clockwise movement

S5: Standard 5 m

R00:

Clockwise movement

SA: Standard 10 m

System Configuration

The customer must supply the wiring.

PC set-up software

D-step

Actuator cable (included)

CBL-TSC-AC-**-B

PC communication cable (sold separately)

CBL–COM–03

CN1

CN2

CN3

CN4

The system configuration is as follows when “360: Multirotation specifications” is selected.

Magnetic proximity switch: AH003 (ASA ELECTRONICS INDUSTRY CO., LTD.)

・Cable ends: multi-conductor cable

・Cable length: Longer than 1 m

(length of covered portion of the cable

from the switch end)

Note) When using a 10 m actuator cable, please insert a noise filter in the TSC power source.

We recommend the RSAN-2003 noise filter from the TDK-Lambda Corporation.

Cable List

Cable Quantity Notes

Actuator cable for TSC 1 Comes with compatible actuator

I/O cable 1 Sold separately (I/O connector for TSC side only comes with TSC)

PC communication cable 1 Sold separately

2There are conditions for using the

product under TSC specifications

in continuous rotation in one

direction. Please contact THK for

more information.

Controller must be procured

separately.

→p. 20

7

ET (Without Motor)

Main actuator unit only or equipped with motor specified by customer

Lineup

ET20 ET35

Stepper motor specifications Servo motor specifications Stepper motor specifications Servo motor specifications

30

30

44

44

Users can select a

reduction ratio.

Users can select a

reduction ratio.

Model Number Coding

Model

Reduction ratio

Stroke With/without motor Motor bracket Options

① ② ③ ④ ⑤ ⑥

ET20 — 45 — 360 — 0 — A — U

ET20 20: 1/20 330: 330° 0: Without motor A: Stepper motor No symbol: None

ET35 30: 1/30 360:

Multi-rotation specifications

1:

With motor (THK will purchase

and mount the motor you

specify)

B: Servo motor U: Sensor

45: 1/45

8

ET20

Controller Specification

Basic Specifications

Model Number Coding

Selection Information

Motor

wrap

Body height

30 mm

Stepper

motor

20×20

Turn

table

type

Servo motor

30 W

Servo motor

20 W

If "TS" is selected for ④With or without motor/controller type,

selections must be made for ⑦to ⑨.

Model

Reduction

ratio

Stroke With or without motor/

controller type

Motor

bracket Sensor Motor size Home position Cable length

① ② ③ ④ ⑤ ⑥ ⑦ ⑧ ⑨

ET20 — 45 — 360 — 0 — A — U / 20P — D00 — S3

ET20 45:

1/45

330: 330° TS: Stepper Driver

Controller TSC

No symbol: None

No symbol: None

20P:

Stepper motor

20×20

No symbol

: Multi-rotation

specifications

No symbol

: None

360:

Multi-rotation

specifications

1

A:

Stepper motor type

U: Sensor S3:

Standard 3 m

0: Without motor

D00

:

Counter-clockwise movement

S5:

Standard 5 m

1: With motor

(THK will purchase

and mount the

motor you specify)

B:

Servo motor type

R00

:

Clockwise movement

SA:

Standard 10 m

2Varies based on angular velocity. See p. 10 "Angular Velocity versus Output Torque" graph for

details.

Motor size 20×20

Stroke (one side) (°) 330 or 360

Drive system Hypoid gear

Output shaft bearing Cross-roller ring

Reduction ratio 1/45

Max. permissible load torque (N·m) 0.3

Max. permissible moment of inertia (kg·m2) 0.0057

Max. angular velocity (°/s) 270

Max. angular acceleration (°/s) 2000

Positioning repeatability (°) ±0.04

Backlash3(°) 0.2

Permissible axial load4, 5 (N) 30

Permissible radial load4, 5 (N) 13.2

Permissible moment4, 5 (N·m) 3.6

Permissible input torque (N·m) 0.039

Mass6(kg) 0.52 (0.35)

3Depending on usage conditions, minor wear to the hypoid gear may cause increased

backlash.

4Please use with a safety margin of 1.5 or greater.

5This is the permissible value when loaded in one direction.

6Values in parentheses are for no motor specifications.

Control device TSC

Motor size 20×20

Reduction ratio 1/45

Max. output torque2(N·m) 0.3

Max. permissible moment of inertia (kg·m2) 0.0057

Permissible Load and Permissible Moment

Axial

Moment

Moment

Radial

1There are conditions for

using the product under

TSC specifications in

continuous rotation in one

direction. Please contact

THK for more information.

The available sensor

options vary based on

the stroke.

330: No Symbol

360: U

360° stroke (multi-rotation)

uses a homing sensor (1 m

cable).

D00 and R00 use mechanical homing.

R00

D00

9

ET20

Angular Velocity versus Permissible Moment of Inertia

Angular Velocity versus Output Torque

Note 1) This graph represents cases where the angular acceleration is 2000°/s2.

Note 2) When the ambient temperature is low (below 10°C), the permissible moment of inertia will decrease in the high angular velocity range.

Note 3) When the ambient temperature is low (below 10°C), the output torque will decrease in the high angular velocity range.

Note 4) Please use a safety margin of 1.5 or higher for the output torque.

Motor Shaft Rotation Speed versus Internal Resistance Torque

0.000

0.001

0.002

0.003

0.004

0.005

0.006

0.007

0 50 100 150 200 250

0.0057

0.0027

0.0007

180

Permissible moment of inertia (kg·m2)

Angular velocity (°/s)

Ambient temperature: 10°C or more

Ambient temperature: Less than 10°C

0.00

0.05

0.10

0.15

0.20

0.25

0.30

0.35

0.40

0 50 100 150 200 250

0.14

0.30

0.03

180

Output torque (N·m)

Angular velocity (°/s)

Ambient temperature: 10°C or more

Ambient temperature: Less than 10°C

Motor Selection Information

Compatible Motors

Note 5) Internal resistance torque increases in low-temperature environments (10°C and below).

Therefore, it is recommended to use a higher safety margin when selecting a product.

0.000

0.005

0.010

0.015

0.020

0.025

0 500 1000 1500 2000

0.016

0.023

0.015

0.008

Internal resistance torque (N·m)

Motor shaft rotation speed (min-1)

Ambient temperature: 10°C or more

Ambient temperature: Less than 10°C

Reduction

ratio

Unit mass (with motor)

(kg)

Unit mass (without motor)

(kg)

Moving part mass

(kg)

Unit inertia

(kg·cm2)Efficiency Timing pulley Timing belt

1/45 0.52 0.35 0.07 0.004 0.47 P26-1.5GT-3-33F

(Manufactured by Gates Unitta Asia Company)

100.5-1.5GT-3

(Manufactured by Gates Unitta Asia Company)

AC servo motor

Motor rated

output (W)

Flange size Motor

bracket

YASKAWA Electric

Corporation

Σ

-Vmini SGMMV–A2 20 25×25 B

SGMMV–A3 30

Mitsubishi Electric

Corporation

MELSERVO J4 HG–AK0236 20 25×25 B

HG–AK0336 30

Stepper motor

Flange size Motor

bracket

ORIENTAL MOTOR CO., LTD.

2-phase PKP214D06* 20×20 A

Note 6) Please select and use a motor that is suited to the usage conditions. The table

shows only a portion of the model numbers for motors. For details regarding model

numbers, please see the catalog for each respective motor manufacturer.

Note 7) If the maximum torque of the installed motor will exceed the permissible input

torque (p. 9), please consider a safety measure to limit the torque.

Note 8) Please select a D-cut type motor output shaft.

Note 9) Installation may not be possible depending on the motor options, so please verify in

advance.

10

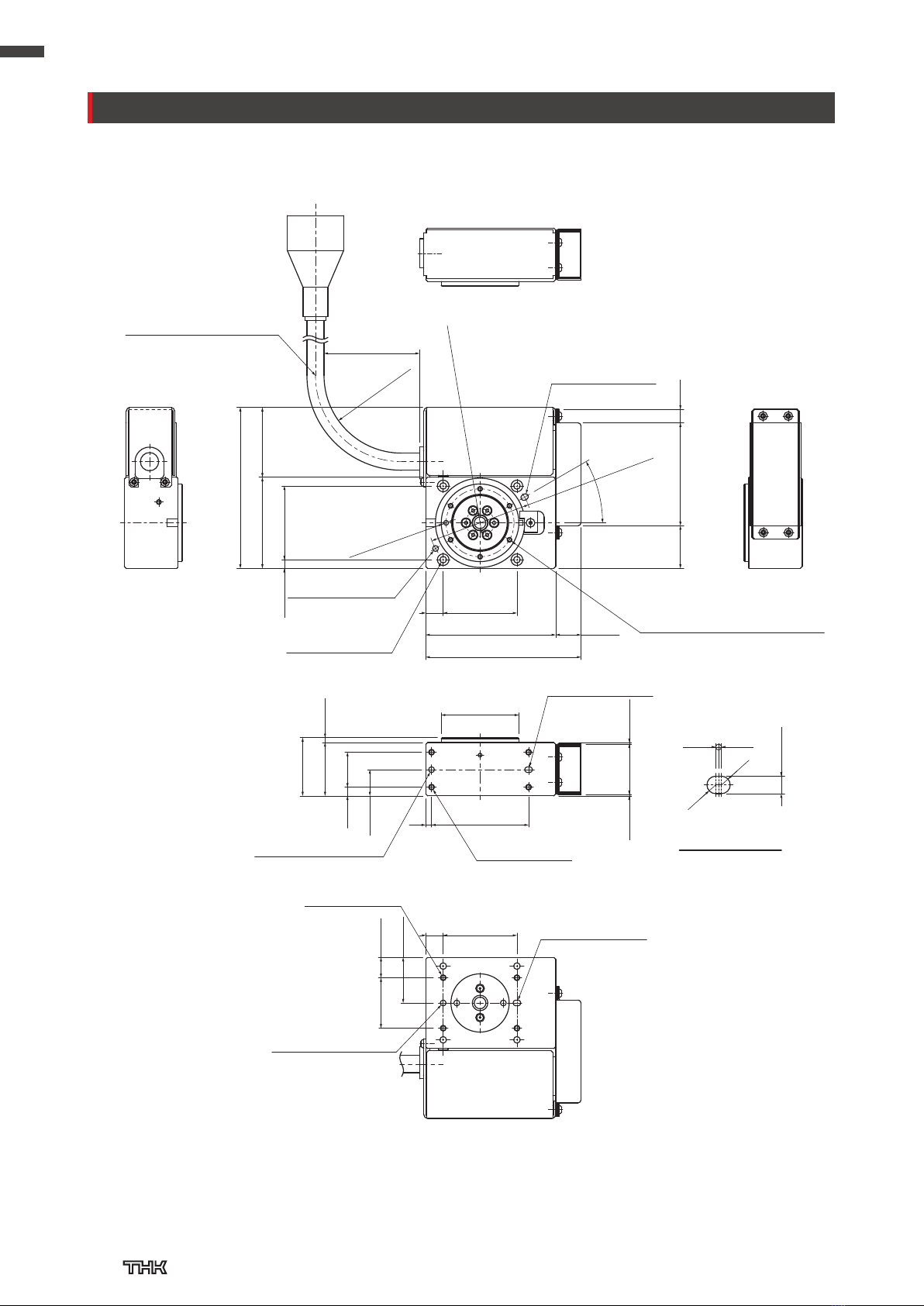

ET20

Elongated hole

details

50 mm or more

(83)

47 (36)

(4.5) 38

(22) (53) (7)

(80)

67 (13)

9 38

φ

40 -0.005

-0.025

(0.7) (26) (0.8)

30

27.5 (2.5)

4.5 18

13.5

3 50

4-M3 depth 6

Elongated hole

depth 2.5

10.526

23.5

9 38

0.5 0.5

3+0.03

0

(R)

30°

Elongated hole

depth 2.5

PCD 53

Elongated hole

depth 2.5

φ

3+0.02

0 depth 2.5

4-3.4 through,

φ

6 counterbore,

depth 3.5

φ

3+0.02

0 depth 2.5

φ

2.5H8

depth 2.5

4-M3 depth 5

φ

3+0.02

0 depth 2.5

6-M2.5 depth 4

PCD 35 (spaced every 60°)

0

+0.014

R40 or more

φ

6 through

Cable length: 332 mm

(R)

TSC Specifications

Dimensions

11

ET20

16

2.2

(5) 5

4.73.7

2.6

(10.5)

(25.7)

(Between shafts)

19.6 6.1

φ

4H7

φ

5H7 +0.012

0

2-3.4 drill through

45°

PCD 28

(25.3)

(Between shafts)

(16)

5.5

+0.012

0

330° specifications (D00)

Stopper details (D00)

Home

position

stopper

330° specifications (R00)

Stopper details (R00)

Home

position

stopper

360° specifications

Home

position

sensor

(5.5)

Homing Specifications

Without Motor (Stepper Motor Specifications)

Without Motor (Servo Motor Specifications)

Note) The homing stopper is for detecting the home

position. If a stopper is necessary to prevent

overrun, please prepare one separately.

Note) The homing stopper is for detecting the home

position. If a stopper is necessary to prevent

overrun, please prepare one separately.

Dimensions

12

ET35

Controller Specifications

Basic Specifications

Model Number Coding

Selection Information

Body height

44 mm

Servo motor

100 W

Motor

wrap

Stepper

motor

35×35

Turn

table

type

Servo motor

80 W

Servo motor

50 W

If "TS" is selected for ④With or without motor/controller type,

selections must be made for ⑦to ⑨.

Model

Reduction

ratio

Stroke With or without motor/

controller type

Motor

bracket Sensor Motor size Home position Cable length

① ② ③ ④ ⑤ ⑥ ⑦ ⑧ ⑨

ET35 — 20 — 360 — TS — — U / 35P — D00 — S3

ET35 20:

1/20

330: 330° TS: Stepper Driver

Controller TSC

No symbol: None

No symbol: None

35P:

Stepper motor

35×35

No symbol

: Multi-rotation

specifications

No symbol

: None

30:

1/30

360:

Multi-rotation

specifications

1

A:

Stepper motor type

U: Sensor S3:

Standard 3 m

0: Without motor

D00

:

Counter-clockwise movement

S5:

Standard 5 m

1: With motor

(THK will purchase

and mount the

motor you specify)

B:

Servo motor type

R00

:

Clockwise movement

SA:

Standard 10 m

Motor size 35×35

Stroke (one side) (°) 330 or 360

Drive system Hypoid gear

Output shaft bearing Cross-roller ring

Reduction ratio 1/20 1/30

Max. permissible load torque (N·m) 2.2 3.3

Max. permissible moment of inertia (kg·m2) 0.028 0.042

Max. angular velocity (°/s) 600 400

Max. angular acceleration (°/s) 3000

Positioning repeatability (°) ±0.04

Backlash3(°) 0.2

Permissible axial load4, 5 (N) 200

Permissible radial load4, 5 (N) 88

Permissible moment4, 5 (N·m) 17.7

Permissible input torque (N·m) 0.248

Mass6(kg) 1.2 (0.8)

3Depending on usage conditions, minor wear to the hypoid gear may cause increased

backlash.

4Please use with a safety margin of 1.5 or greater.

5This is the permissible value when loaded in one direction.

6Values in parentheses are for no motor specifications.

The available sensor

options vary based on

the stroke.

330: No Symbol

360: U

360° stroke (multi-rotation)

uses a homing sensor (1 m

cable).

D00 and R00 use mechanical homing.

R00

D00

Permissible Load and Permissible Moment

Axial

Moment

Moment

Radial

Control device TSC

Motor size 35×35

Reduction ratio 1/20 1/30

Max. output torque2(N·m) 2.2 3.3

Max. permissible moment of inertia (kg·m2) 0.028 0.042

2Varies based on angular velocity. See p. 14 "Angular Velocity versus Output Torque" graph for

details.

1There are conditions for

using the product under

TSC specifications in

continuous rotation in one

direction. Please contact

THK for more information.

13

ET35

Motor Selection Information

Compatible Motors

Angular Velocity versus Permissible Moment of Inertia

Angular Velocity versus Output Torque

Output torque (N·m)

Angular velocity (°/s)

0

.0

0

.5

1

.0

1

.5

2

.0

2

.5

3

.0

3

.5

4.0

0 100 200 300 400 500 600

3.3

0.9

2.2

0

.6

0.4

0.6

133

ET35–30 (Ambient temperature: 10°C or more)

ET35–30 (Ambient temperature: Less than 10°C)

ET35–20 (Ambient temperature: 10°C or more)

ET35–20 (Ambient temperature: Less than 10°C)

Motor Shaft Rotation Speed versus Internal Resistance Torque

Note 3) Internal resistance torque increases in low-temperature environments (10°C and below).

Therefore, it is recommended to use a higher safety margin when selecting a product.

0.000

0.010

0.020

0.030

0.040

0.050

0.060

0.070

0.080

0.090

0 500 1000 1500 2000

0.045

0.077

0.056

0.032

0.053

0.037

0.016

0.024

Internal resistance torque (N·m)

Motor shaft rotation speed (min-1)

ET35–30 (Ambient temperature: 10°C or more)

ET35–30 (Ambient temperature: Less than 10°C)

ET35–20 (Ambient temperature: 10°C or more)

ET35–20 (Ambient temperature: Less than 10°C)

Note 1) This graph represents cases where the angular acceleration is 3000°/s2.

Note 2) Please use a safety margin of 1.5 or higher for the output torque.

Permissible moment of inertia (kg·m2)

Angular velocity (°/s)

0

.000

0

.005

0

.010

0

.015

0

.020

0

.025

0

.030

0

.035

0

.040

0

.045

0.050

0 100 200 300 400 500 600

0.042

0.028

0.011 0

.007

0.007

0

.005

133

ET35–30 (Ambient temperature: 10°C or more)

ET35–30 (Ambient temperature: Less than 10°C)

ET35–20 (Ambient temperature: 10°C or more)

ET35–20 (Ambient temperature: Less than 10°C)

Reduction

ratio

Unit mass (with motor)

(kg)

Unit mass (without motor)

(kg)

Moving part mass

(kg)

Unit inertia

(kg·cm2)Efficiency Timing pulley Timing belt

1/20 1.2 0.8 0.17 0.012 0.72

P26-2GT-6-33F

(Manufactured by Gates Unitta Asia Company)

134-2GT-6

(Manufactured by Gates Unitta Asia Company)

1/30 1.2 0.8 0.17 0.015 0.71

P26-2GT-6-33F

(Manufactured by Gates Unitta Asia Company)

148-2GT-6

(Manufactured by Gates Unitta Asia Company)

AC servo motor

Motor rated

output (W)

Flange size Motor

bracket

YASKAWA

Electric

Corporation

Σ

-V

SGMJV–A5 50

40×40 B

SGMJV-01 100

SGMAV–A5 50

SGMAV-01 100

Σ

–7

SGM7J–A5 50

40×40 B

SGM7J-01 100

SGM7A–A5 50

SGM7A-01 100

Σ

-X

SGMXJ–A5 50

40×40 B

SGMXJ-01 100

SGMXA–A5 50

SGMXA-01 100

Mitsubishi

Electric

Corporation

MELSERVO

J4

HG–KR053 50

40×40 B

HG-KR13 100

HG–MR053 50

HG-MR13 100

J5 HK–KT053W 50 40×40 B

HK-KT13W 100

AC servo motor

Motor rated

output (W)

Flange size Motor

bracket

TAMAGAWA

SEIKI CO.,

LTD.

TBL-i

ⅡTS4602 50 40 × 40 B

TS4603 100

TBL-iⅣTSM3102 50 40×40 B

TSM3104 100

SANYO DENKI

CO., LTD. SANMOTION R

R2*A04005 50

40×40 BR2EA04008 80

R2AA04010 100

Stepper motor

Flange size Motor

bracket

ORIENTAL MOTOR CO., LTD.

2-phase PKP235* 35×35 A

Note 4) Please select and use a motor that is suited to the usage conditions. The table

shows only a portion of the model numbers for motors. For details regarding model

numbers, please see the catalog for each respective motor manufacturer.

Note 5) If the maximum torque of the installed motor will exceed the permissible input

torque (p. 13), please consider a safety measure to limit the torque.

Note 6) Please select a D-cut type motor output shaft.

Note 7) Installation may not be possible depending on the motor options, so please verify in

advance.

14

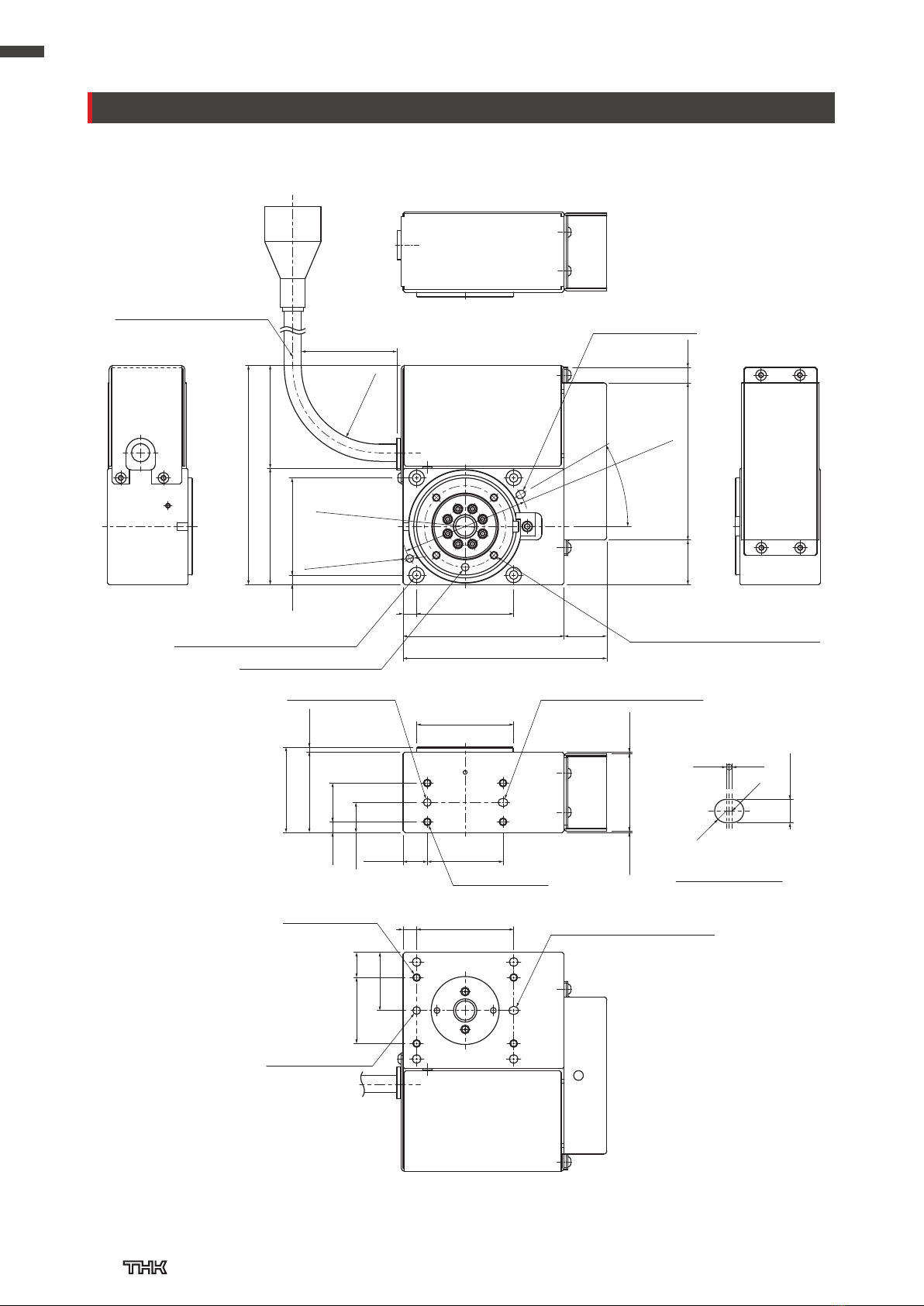

ET35

Elongated hole

details

φ

10 through

(113)

60 (53)

(5) 50

(23) (81) (8)

(105)

83 (22)

7 50

50 mm or more

PCD 66

-0.005

-0.025

44

41.5 (2.5)

5.5 20

15.5

12.5 39

(0.7) (40) (0.8)

7 50

1334

30

+0.03

0 depth 3

4-M4 depth 8

+0.03

0 depth 3

Elongated hole depth 3

Elongated hole

depth 3

Elongated hole depth 3

0.5 0.5

4+0.03

0

(R)

30°

4-M4 depth 8

φ

4+0.03

0 depth 3

4-

φ

4.5 through,

φ

8 counterbore, depth 9.5

φ

4H8

φ

4

φ

4

φ

50

+0.018

0 depth 4

4-M4 depth 7

PCD 42 (spaced every 90°)

R40 or more

Cable length: 332 mm

(R)

TSC Specifications

Dimensions

15

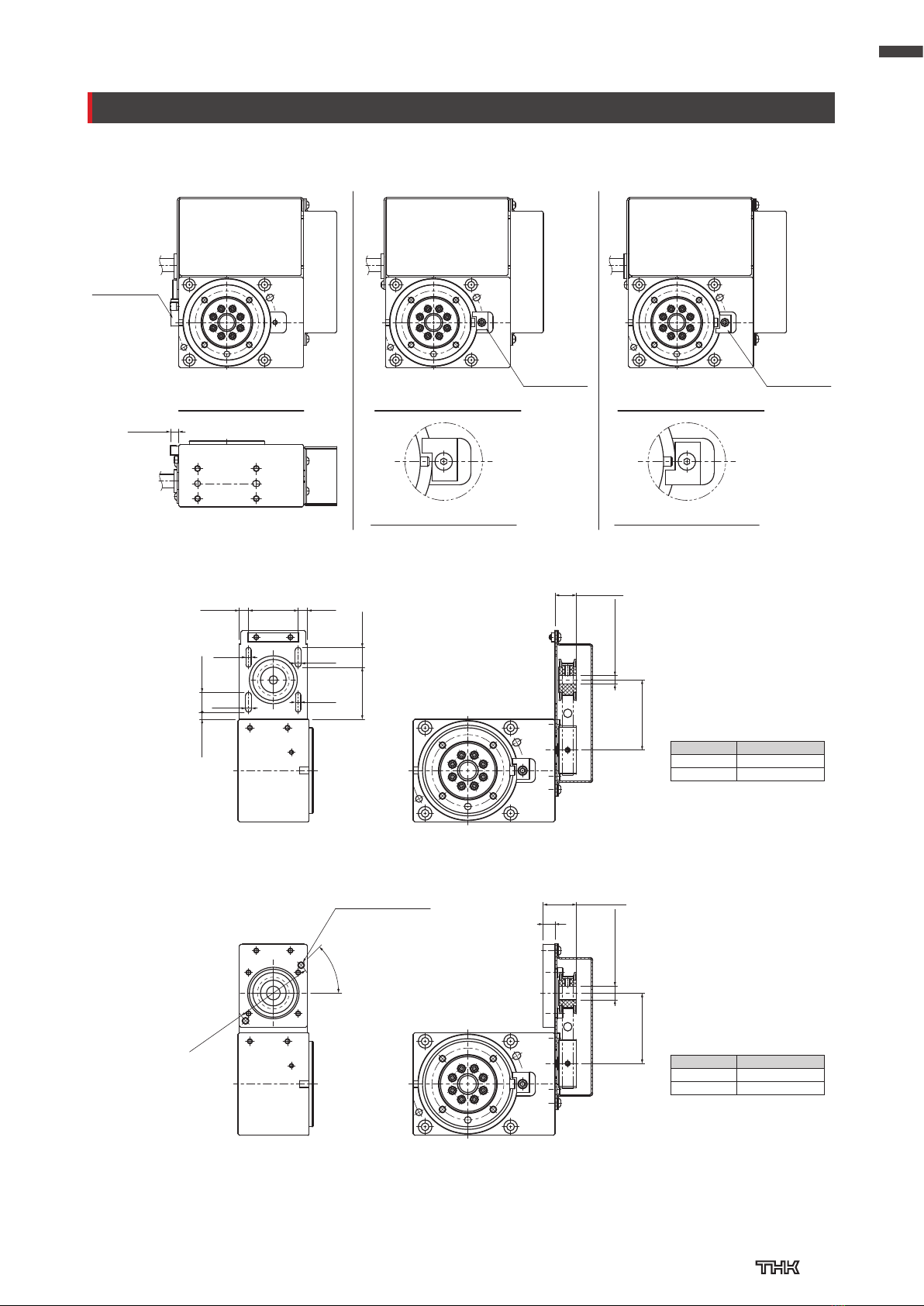

ET35

(5.5) 5.529

3.4

3.1

(12.5)

3.4 3.1

30.45 11.6

4.15 11.6

(Between shafts)

φ

5H7 +0.012

0

φ

8H7 +0.015

0

45°

2-M4 depth 7

PCD 46

(19.5)

(Between shafts)

7

Home

position

sensor

(5.5)

360° specifications

Stopper details (D00)

Home

position

stopper

330° specifications (D00)

Stopper details (R00)

Home

position

stopper

330° specifications (R00)

Note) The homing stopper is for detecting the home

position. If a stopper is necessary to prevent

overrun, please prepare one separately.

Note) The homing stopper is for detecting the home

position. If a stopper is necessary to prevent

overrun, please prepare one separately.

Dimensions

Homing Specifications

Without Motor (Stepper Motor Specifications)

Without Motor (Servo Motor Specifications)

Reduction ratio (Between shafts)

1/20 41

1/30 41.3

Reduction ratio (Between shafts)

1/20 41

1/30 41.3

16

Technical Materials

Selection Method

●Calculating the moment of inertia

Confirm whether or not the calculated moment of inertia satisfies the requirements for the permissible moment of inertia

for the model.

If the calculated moment of inertia is less than the permissible moment of inertia, the product may be used.

If the calculated moment of inertia is greater than or equal to the permissible moment of inertia, the product may not be used.

Please select a different model or reduce the mass or rotational radius.

For the permissible moment of inertia for each model, please consult the "Angular Velocity versus Permissible Moment of

Inertia" graph.

Confirm whether or not the calculated torque satisfies the requirements for the maximum output torque for the model.

If the calculated torque is less than the maximum output torque, the product can be used.

If the calculated torque is greater than or equal to the maximum output torque, the product cannot be used.

Please select a different model or reduce the mass or rotational radius.

For the maximum output torque for each model, please consult the "Angular Velocity versus Output Torque" graph.

When selecting a rotary shaft, calculate the moment of inertia and load torque for the usage conditions and make a selection

where the permissible moment of inertia and maximum output torque will not be exceeded.

Refer to the formula below as a representative example and calculate the moment of inertia for the workpiece and mounting

jigs you will be using.

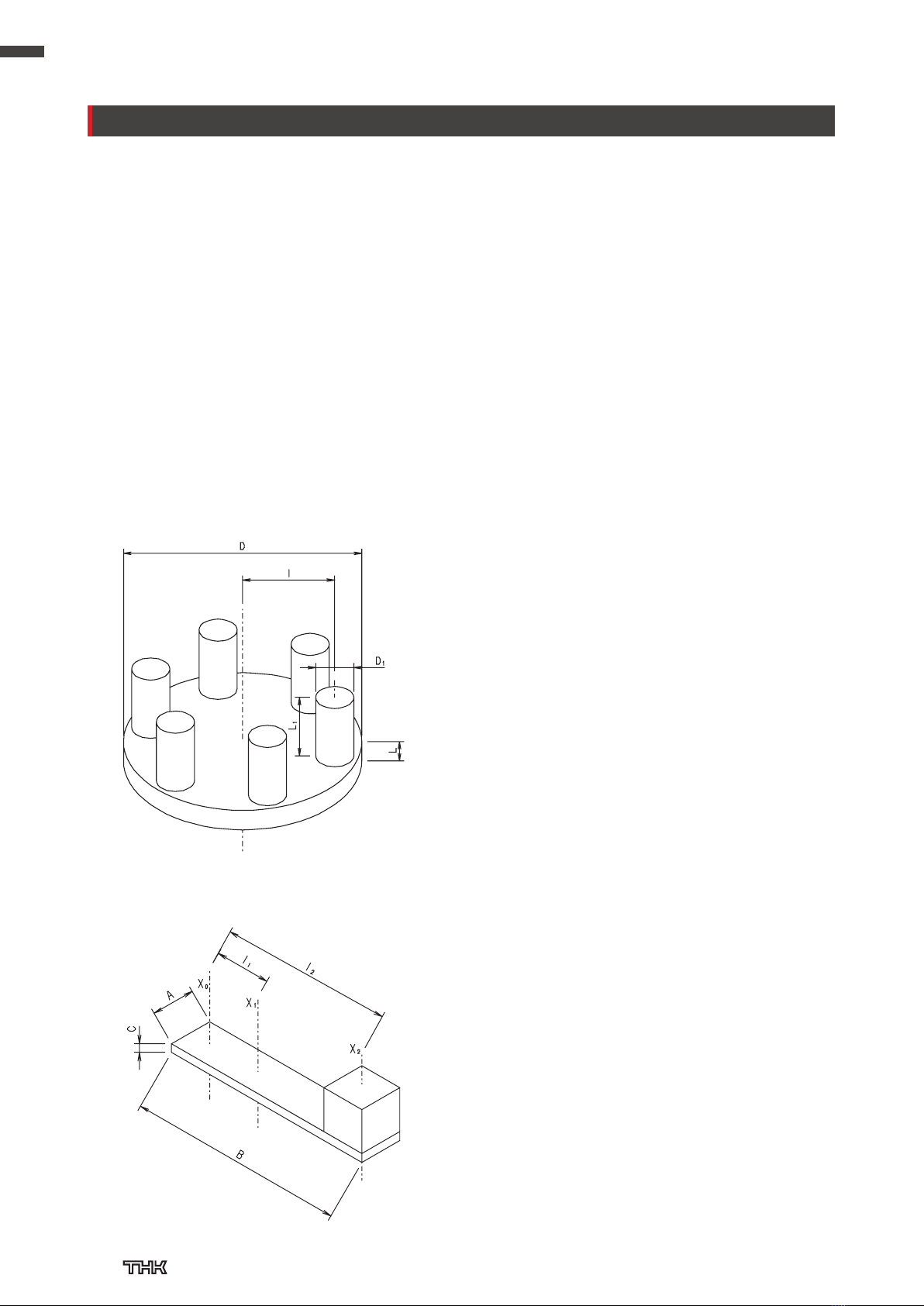

Table

Diameter:

D (m) Height:

L (m)

Mass:

m (kg)

Workpiece

Diameter:

D1(m) Height:

L1(m)

Mass:

m1(kg) Quantity: n (pieces)

Density: ρ (kg/m3)

(Notes)

・

All workpieces are considered to be of the same shape and mass.

・All workpieces are considered to be at the same distance from the

center point.

(Reference) Moment of Inertia for Multiple Rectangular Solids Combined

Rectangular solid:

Depth A (m), height B (m), width C (m), mass m1(kg)

Cube:

Depth A (m), height A (m), width A (m), mass m2(kg)

Density: ρ (kg/m3)

(Reference) Moment of Inertia for Multiple Cylindrical Columns Combined

Ix

1

–

8m·D2

1

–

8n·m·(D12+8l2)

=

m

m1

π

–

4ρ·L·D2

:

π

–

4ρ·L1·D12

:

+[k

g

·m2]

m2(2·A2 + 12·l2

2)

Ix

1

–

12 m1(A2 + B2 + 12·l1

2)

1

–

12

+

=

:

:

:

:

ρ·A·B·C

ρ·A3

Distance between X0and X1(center of rotation X0) (m)

m1

m2

l1

l2

Distance between X0and X2(center of rotation X0) (m)

[kg·m2]

Selection Procedure

17

Technical Materials

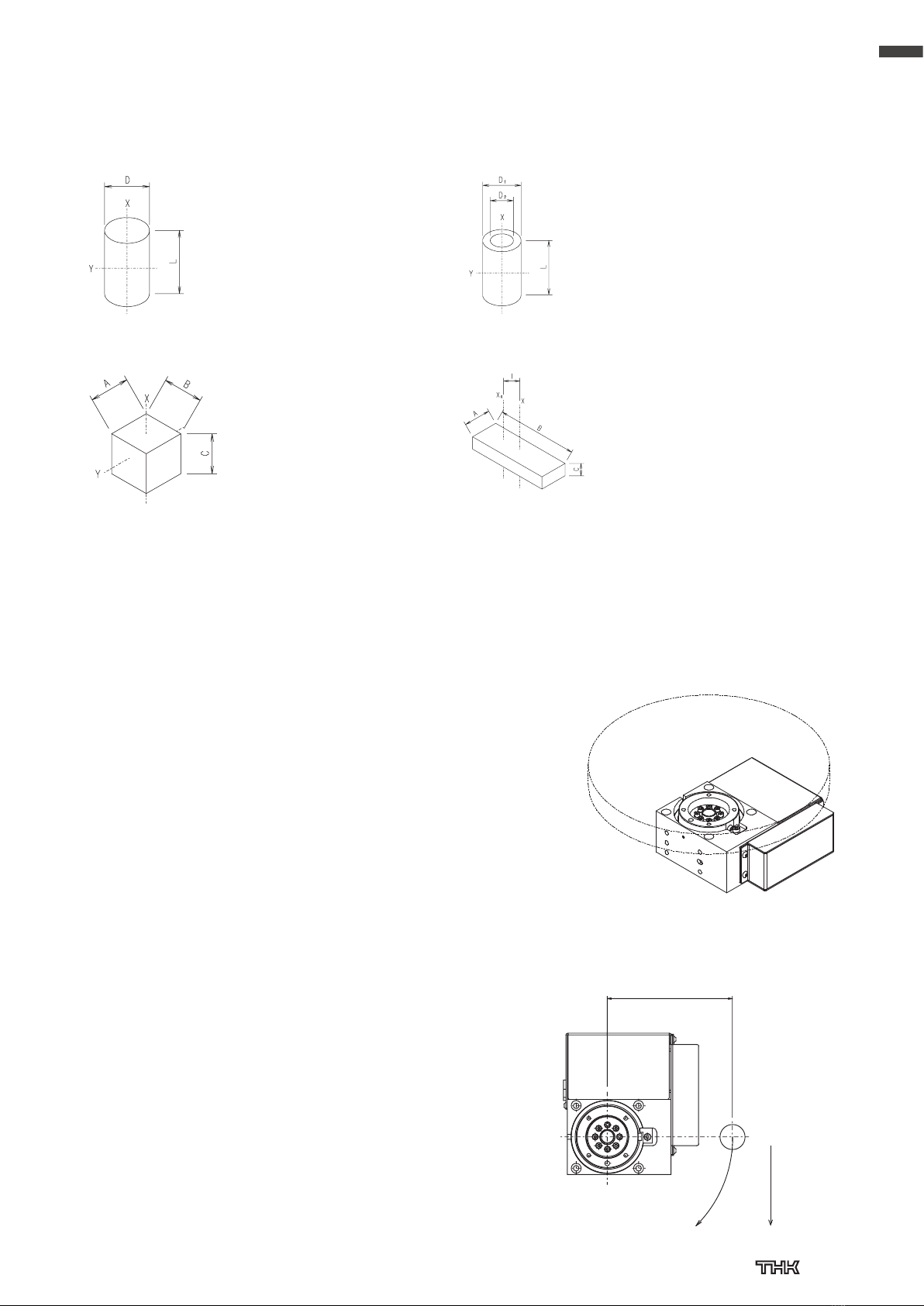

Moment of Inertia for a Cylinder

Moment of Inertia for a Rectangular Solid

Calculating Torque in Horizontal Applications (Installed from the Bottom Surface)

Moment of Inertia for a Hollow Cylinder

Moment of Inertia for an Object with Different Centers of Rotation and Gravity

Outer diameter: D (m)

Length: L (m)

Mass: m (kg)

Density: ρ (kg/m3)

Outer diameter: D1(m)

Inner diameter: D2

Length: L (m)

Mass: m (kg)

Density: ρ (kg/m3)

Depth: A (m) Width:

B (m)

Height: C (m) Mass:

m (kg)

Density: ρ (kg/m3)If Iis less than the permissible moment of inertia, the product can

be used.

If Iis greater than or equal to the permissible moment of inertia, the

product cannot be used. Please select a different model or reduce

the mass or rotational radius.

For the permissible moment of inertia for each model, please consult

the "Angular Velocity versus Permissible Moment of Inertia" graph.

I: Moment of inertia (kg·m2)

ω ′ : Angular acceleration (rad/s2)

Please ensure a safety margin of 1.5 or greater.

Example) External torque (friction torque)

External torque = μ

・

m

・

g

・

r

m: Workpiece mass (kg) g: Gravitational acceleration (m/s2)

μ: Friction coefficient ET20: 0.020 r: Rotary table radius ET20: 29 (mm)

ET35: 0.017 ET25: 34 (mm)

Confirm whether or not the calculated torque satisfies the requirements for the maximum

output torque for the model.

If T1is less than the maximum output torque, the product can be used.

If T1is greater than or equal to the maximum output torque, the product cannot be used.

Please select a different model or reduce the mass or rotational radius.

For the maximum output torque for each model, please consult the "Angular Velocity

versus Output Torque" graph.

Calculating Torque in Horizontal Applications (Installed from a Side Surface)

m: Workpiece mass (kg)

g: Gravitational acceleration (m/s2)

r: Radius (m) I: Moment of inertia (kg·m2)

ω ′ : Angular acceleration (rad/s2)

Please ensure a safety margin of 1.5 or greater.

Confirm whether or not the calculated torque satisfies the requirements for the

maximum output torque for the model.

If T2is less than the maximum output torque, the product can be used.

If T2is greater than or equal to the maximum output torque, the product cannot be

used.

Please select a different model or reduce the mass or rotational radius.

For the maximum output torque for each model, please consult the "Angular

Velocity versus Output Torque" graph.

T2 = (m·

g

·r + Iω' +external torque)× safety margin (Rotational radius)

r

m (Workpiece mass)

g(Gravitational

direction)

Ix

Iy

1

–

8

m( + )

π

–

32

= = ρ·L·D4

m·D2

=

1

–

4

D2

–

4

L2

–

3

=

[k

g

·m2]

[kg·m2]

Ix

Iy

1

–

8

m(+ )

π

–

32

=ρ·L·(D1

4−D2

4)m(D1

2+D2

2)

=

1

–

4

D1

2+D2

2

–

4

L2

–

3

=

=[k

g

·m2]

[kg·m2]

Iy

Ix

1

–

12 m(A2 + B2)

=

1

–

12 m(B2 + C2)

=

1

–

12

=ρ·A·B·C·(A2 + B2)

1

–

12

=ρ·A·B·C·(B2 + C2)

[kg·m2]

[kg·m2]

Ix

1

–

12

=

:

:

ρ·A·B·Cm

l

Distance between X and X0(center of rotation X0)

(m)

[k

g

·m2]

m(A2 + B2 + 12·l2)

T1 = (I × ω'+external torque)× safety margin

Rectangular solid:

Depth

A

(m), height

B

(m), width

C

(m), mass

m

(kg)

Cube:

Depth

A

(m), height

A

(m), width

A

(m), mass

m

(kg)

Density:

ρ

(kg/m

3

)

18

Technical Materials

0.000

0.001

0.002

0.003

0.004

0.005

0.006

0.007

0 50 100 150 200 250

0.0057

0.0027

0.0007

180

Permissible moment of inertia (kg·m2)

Angular velocity (°/s)

Permissible moment of inertia (kg·m2)

Angular velocity (°/s)

0.00

0.05

0.10

0.15

0.20

0.25

0.30

0.35

0.40

0 50 100 150 200 250

0.14

0.30

0.03

180

Output torque (N·m)

Angular velocity (°/s)

0.000

0.005

0.010

0.015

0.020

0.025

0 500 1000 1500 2000

0.016

0.023

0.015

0.008

0.000

0.010

0.020

0.030

0.040

0.050

0.060

0.070

0.080

0.090

0 500 1000 1500 2000

0.045

0.077

0.056

0.032

0.053

0.037

0.016

0.024

Internal resistance torque (N·m)

Internal resistance torque (N·m)

Motor shaft rotation speed (min-1) Motor shaft rotation speed (min-1)

Output torque (N·m)

Angular velocity (°/s)

0

.0

0

.5

1

.0

1

.5

2

.0

2

.5

3

.0

3

.5

4.0

0 100 200 300 400 500 600

3.3

0.9

2.2

0

.6

0

.4

0.6

133

Note) Internal resistance torque increases in low-temperature environments (10°C and below).

Therefore, it is recommended to use a higher safety margin when selecting a product.

0

.000

0

.005

0

.010

0

.015

0

.020

0

.025

0

.030

0

.035

0

.040

0

.045

0.050

0 100 200 300 400 500 600

0.042

0.028

0.011 0

.007

0.007

0

.005

133

ET35–30 (Ambient temperature: 10°C or more)

ET35–30 (Ambient temperature: Less than 10°C)

ET35–20 (Ambient temperature: 10°C or more)

ET35–20 (Ambient temperature: Less than 10°C)

ET35–30 (Ambient temperature: 10°C or more)

ET35–30 (Ambient temperature: Less than 10°C)

ET35–20 (Ambient temperature: 10°C or more)

ET35–20 (Ambient temperature: Less than 10°C)

ET35–30 (Ambient temperature: 10°C or more)

ET35–30 (Ambient temperature: Less than 10°C)

ET35–20 (Ambient temperature: 10°C or more)

ET35–20 (Ambient temperature: Less than 10°C)

Ambient temperature: 10°C or more

Ambient temperature: Less than 10°C

Ambient temperature: 10°C or more

Ambient temperature: Less than 10°C

Ambient temperature: 10°C or more

Ambient temperature: Less than 10°C

Angular Velocity versus Permissible Moment of Inertia

Angular Velocity versus Output Torque

Motor Shaft Rotation Speed versus Internal Resistance Torque

ET20

ET20

ET20

ET35

ET35

ET35

19

This manual suits for next models

1

Table of contents