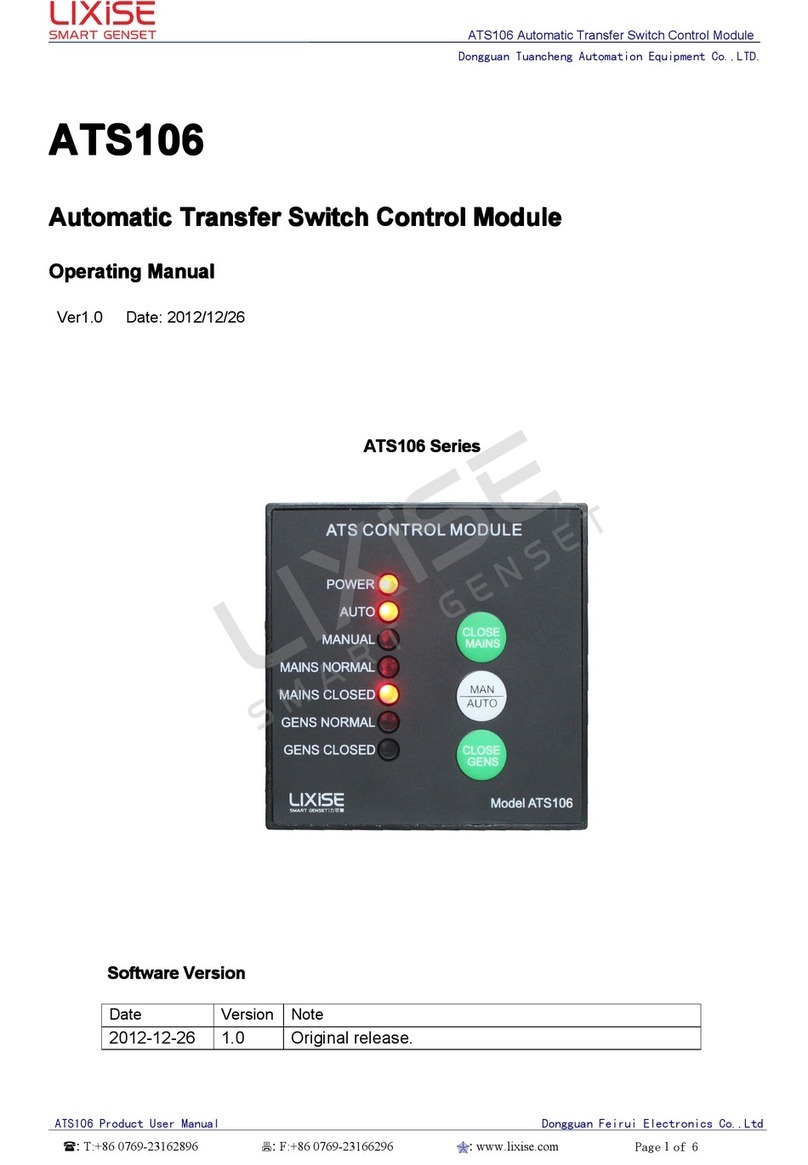

Diagram 3 E - Push Button

B - Button Piston Assembly

D - Clamping Nut

C - Button Shroud

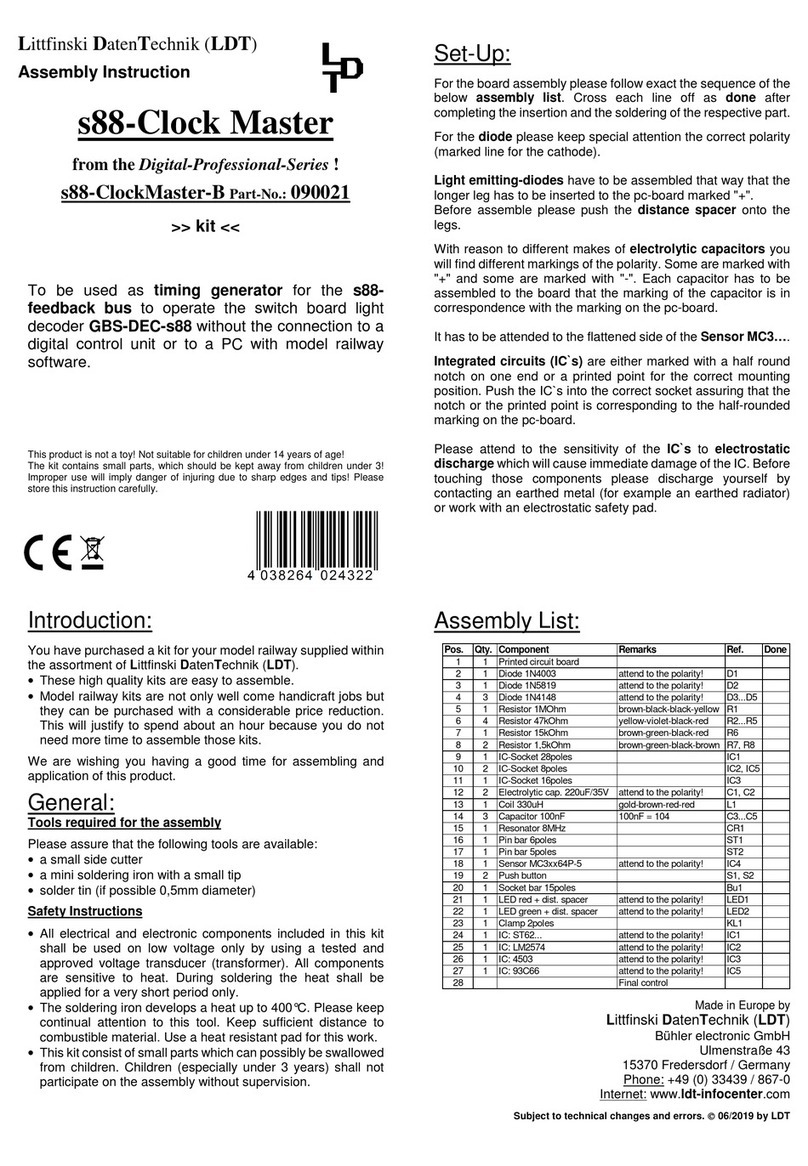

1. Fitting Valve to Cistern. See Diagram 1

Separate valve assy (1) from body assy (2) by

twisting anti-clockwise (see diagram).

2. Fitting the Push Button - See Diagrams 2 - 4

Insert air flow pipe (A) into the rubber connector

on the valve, and cut to minimum length required.

Cover the air flow pipe (A) with the protective

corrugated pipe, cut to length to suit air flow pipe.

Position the button shroud (C) into the panel, and

and clamp into position using nut (D).

Insert the air flow pipe (A) into the rubber connector

on the button assembly (B).

Insert the button piston assembly (B) from the rear of

the panel rotating clockwise until it locks in position.

Insert the push button (E) into the shroud (C) and push

fully onto stem of button assembly. The push button

should be level with the shroud when released.

For Panel Fixing -

Turn off water supply, operate full flush to empty

cistern.

Rotate valve assembly (1) anti-clockwise to

separate it from the body assembly (2).

With a clean wet cloth, carefully wipe around the

seal area of the moulding still attached to the

cistern. Stubborn mineral deposits may be

removed using a non-abrasive bathroom cleaner.

Clean the rubber seal on the valve assembly in

the same way as the seal face described earlier.

Do not use solvents to clean any part of the

valve and take care not to damage the sealing

faces.

Diagram 1

2 - BODY ASSEMBLY

RUBBER WASHER

1 - VALVE ASSEMBLY

4. Maintenance of the Valve.

Mineral deposits from the water supply or other

foreign material can cause the valve not to seat

properly and thus water leakage may occur.

A trickle of water running into the W.C pan is

the result.

Reassemble the valve assembly in the cistern as

described earlier.

Turn on the water supply to the cistern and test the

valve.

Screwdriver

Tools you will require for installation

PLEASE KEEP THESE INSTRUCTIONS IN A

SAFE PLACE FOR FUTURE REFERENCE.

Water pump pliers or adjustable grips

Should the seal become damaged enough to

impair the valves performance a replacement

seal can be purchased through your local

Thomas Dudley supplier.

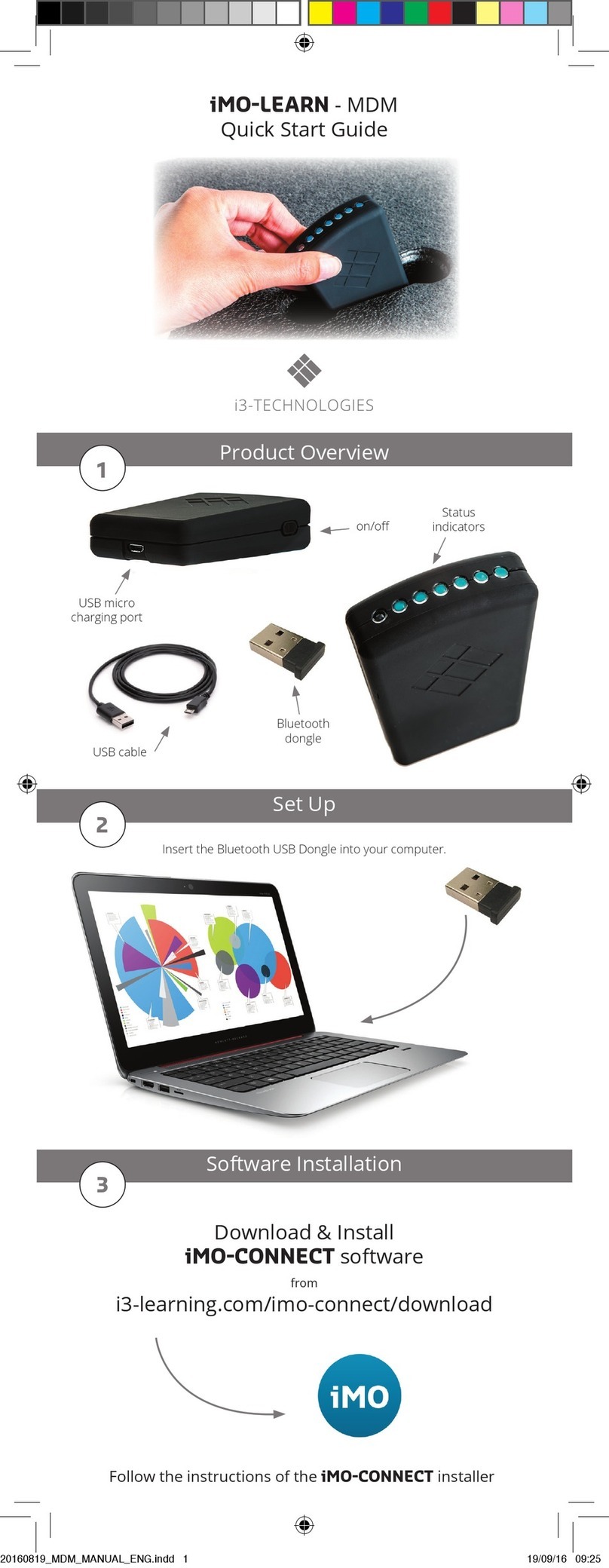

Diagram 2

A - Air Flow Pipe

A - Air Flow

Pipe

Rubber Connector

Protective Corrugated Pipe

With bowl in place, under the lip of the valve,

fit rubber washer over thread of valve. Place

into cistern and secure with backnut or adaptor.

Tighten enough to prevent leakage but make sure

the bowl is not trapped on the washer and is loose

after tightening.

The warning pipe is preset