642704 06/05

Outer edge of housing

STEP 5. Rotate shaft so the key way is in the 3:00 position, and

using access holes on the top of the housing, insert 1/4” Allen®

hex, and loosen the eccentric set screw. Rotate shaft so that

the key way is now in the 12:00 position, and remove the next

set screw from the eccentric. Slide connecting rod assembly off

and discard.

CAUTION:With a pencil, mark the shaft where the inboard

connecting rod is located. This is only for reference, and not

to be used for exact measurement, or damage will occur.

STEP 6. Rotate shaft so the key way is in the 9:00 position, and

using access holes on the top of the housing, insert 1/4” Allen®

hex, and loosen the eccentric set screw. Rotate shaft so that

the key way is now in the 12:00 position, and remove the next

set screw from the eccentric. Slide connecting rod assembly off

and discard.

Note: Remove the key and discard spring. Replace the key for

assembly.

WARNING: New connecting rod assemblies must hand slide

on shaft without using force.

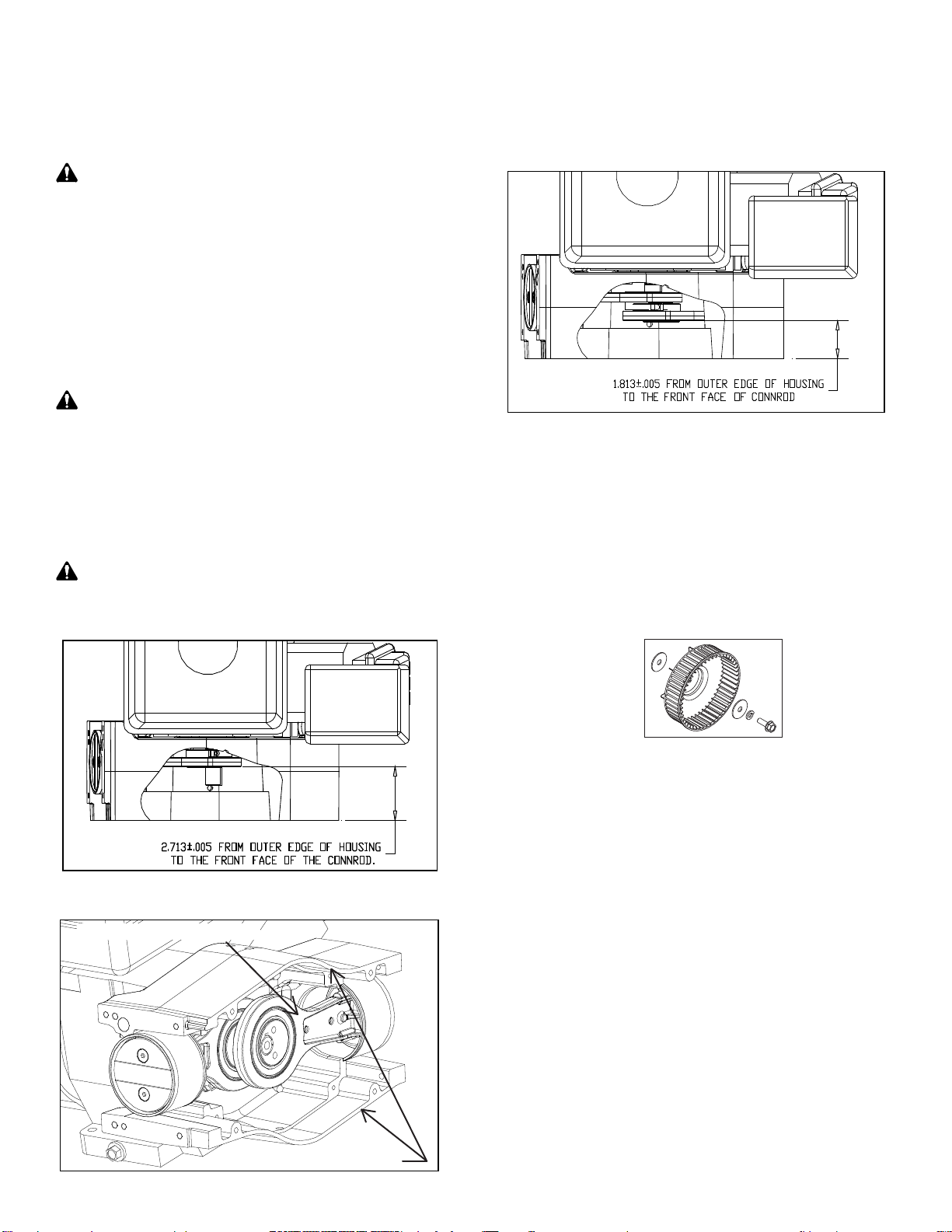

STEP 7. Rotate shaft so the key way is in the 9:00 position. Slide

inboard connecting rod assembly (stamped “580”) onto shaft

with eccentric in, and the sleeve in the 9:00 position. Do not

remove the sleeve. The distance from the face of the connecting

rod to the edge of the housing must be 2.713 ±.005. Torque the

eccentric screw to 100 in-lbs.

CAUTION: Use the pencil mark only as reference. Using

the mark for the only means of measurement will result in

damage.

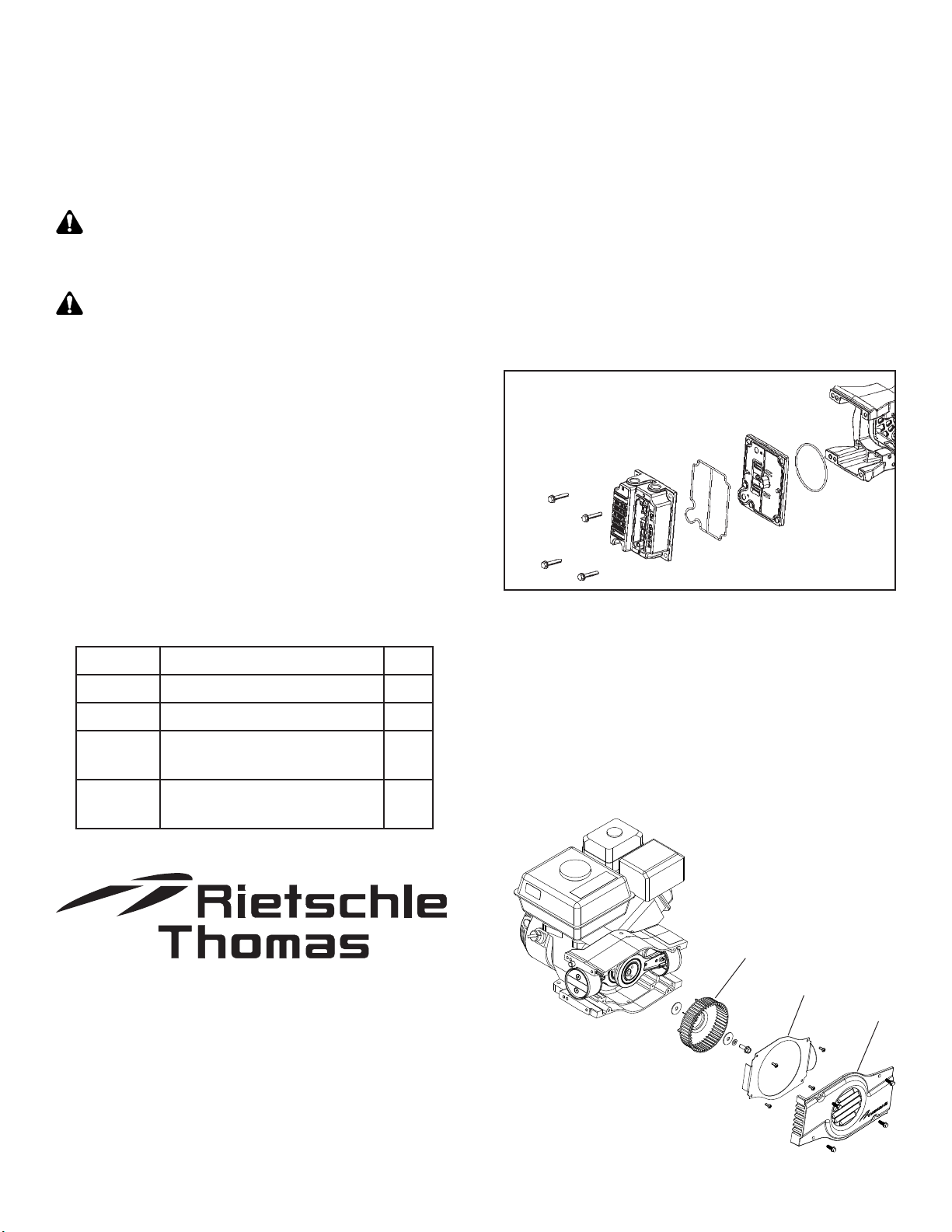

STEP 8. Rotate shaft so the key way is in the 3:00 position. Slide

outboard connecting rod assembly (stamped “572”) onto shaft

with eccentric in, and the sleeve in the 3:00 position. Do not

remove the sleeve. The distance from the face of the connecting

rod to the edge of the housing must be 1.813” ±.005. Torque the

eccentric screw to 100 in-lbs.

Front Face of Connecting Rod

STEP 9. Rotate shaft so the key way is in the 12:00 position.

Using a punch, tap in the key until it’s flush to outboard rod

assembly. Using the two access holes in the top of the housing,

torque the two key way set screws to 100 in-lbs.

STEP 10. Replace deflector cover. Secure to housing with 4

- Torx® T-25 screws, and torque to 45 in-lbs.

STEP 11. Apply 242 Loctite® to threaded hole of the engine

shaft. Assemble fan, pictured below, and torque screw to 120

- 130 in-lbs.

STEP 12. Obtain one of the heads, and remove the two filter

cover screws using T-25 Torx® screwdriver. Under the filter, locate

the retaining screw, and remove with T-25 Torx® screwdriver.

Flip over to valve plate side, and remove the screw securing the

head. Seperate valve plate from head, remove o-ring, discard,

and replace with new o-ring from kit. Reassemble head and valve

plate. Torque the retaining screw on the head side to 45 in-lbs.

Turn over, torque the screw on the valve plate side to 110 in-lbs.

Reinstall filter. Orient filter cover to head with opening (intake

port) pointing down and torque two screws to 40 - 50 in-lbs.

Repeat this step for other head.

STEP 13. Assemble cylinder sleeve o-ring into groove of valve

plate, and secure to housing using 4 screws, and torque to 110

in-lbs. Check that cross through tube is seated in head. Repeat

this step on other side.

STEP 14. Assemble front cover to housing and torque 4 screws

to 110 in-lbs.

STEP 15. Apply sealant to 2nd - 3rd thread of pipe thread, and

fasten hose to head using 11/16” wrench.

TTable of Contents

Page 7