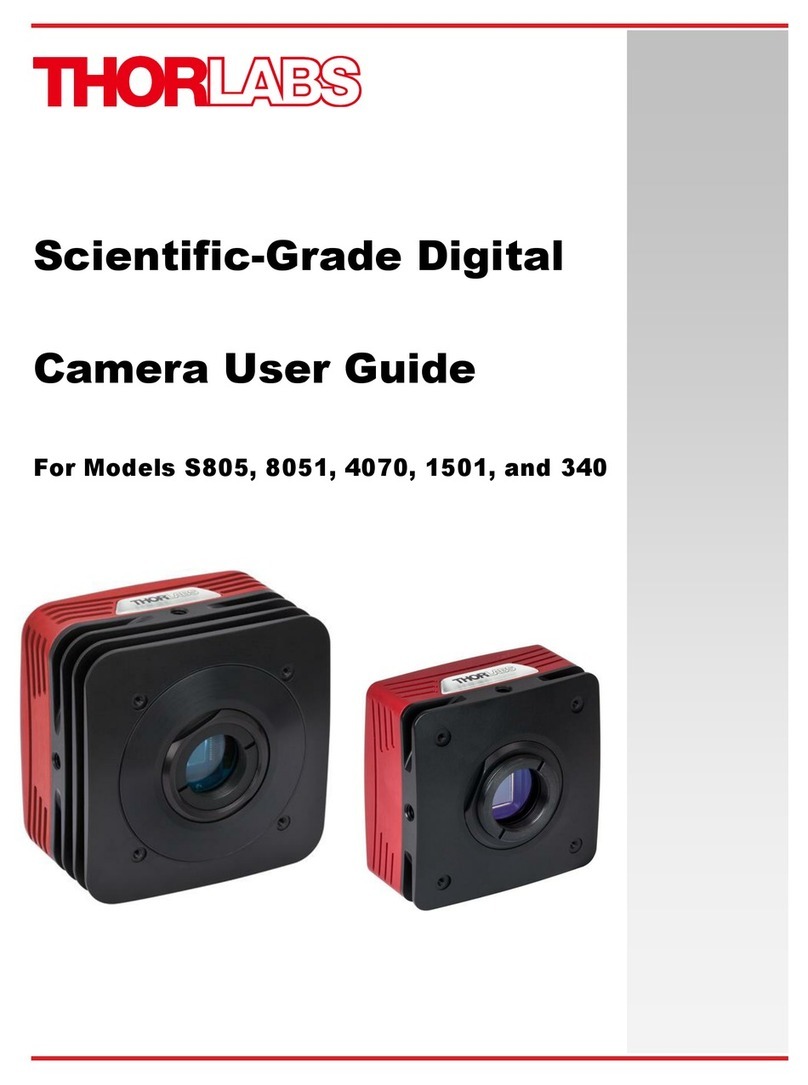

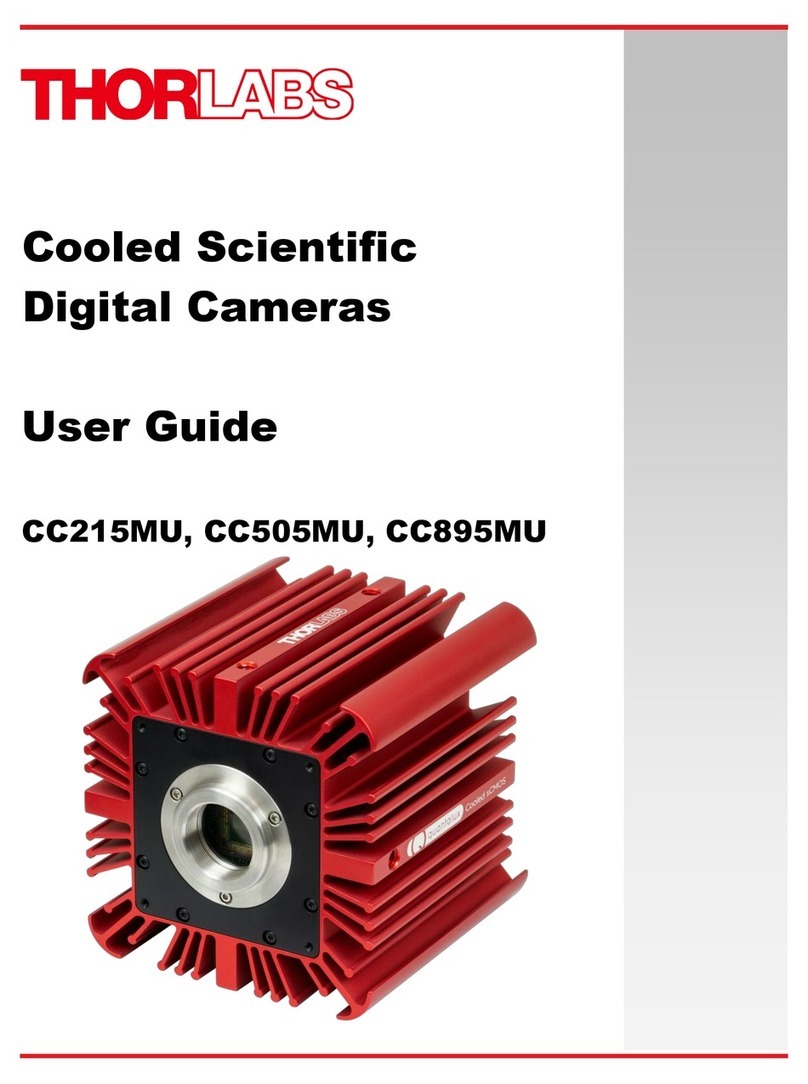

Compact Scientific Digital Cameras

Table of Contents

Chapter 1 Safety...................................................................................................................................1

1.1. Precautions................................................................................................................... 1

1.2. Warning Symbol Definitions........................................................................................ 2

1.3. Product Care................................................................................................................. 3

1.3.1. Service ..................................................................................................................................3

1.3.2. Accessories and Customization............................................................................................3

Chapter 2 Description .........................................................................................................................4

2.1. Introduction................................................................................................................... 4

2.2. Receiving and Unpacking............................................................................................ 4

2.3. Supplied Equipment..................................................................................................... 5

2.3.1. Optional Items.......................................................................................................................5

Chapter 3 Setup & Installation ...........................................................................................................6

3.1. Pre-Installation - USB 3.0............................................................................................. 6

3.2. Installing the Software.................................................................................................. 6

3.2.1. Download and Run the Installation File ................................................................................6

3.2.3. Driver Selection.....................................................................................................................6

3.2.4. Installing 3rd Party Software Application Support................................................................10

3.3. Connecting the Camera.............................................................................................. 11

3.3.1. Multiple Camera Operation.................................................................................................12

3.4. Optical and Mechanical Mounting Considerations .................................................. 13

3.4.1. Using a C-Mount Lens ........................................................................................................13

3.4.2. Mounting the Camera..........................................................................................................13

3.4.3. Using the Camera with a Cage System..............................................................................14

3.5. Optical Front End........................................................................................................ 15

3.5.1. Description of Components.................................................................................................15

3.6. Optical Front End Procedures................................................................................... 16

3.6.1. Window Removal and Replacement Procedure.................................................................16

3.6.2. Re-Assembly of the Window and C-Mount Adapter and Flange Focus Adjustment..........16

3.7. Auxiliary Connector.................................................................................................... 17

3.7.1. Pin Descriptions ..................................................................................................................17

3.7.2. Signal Descriptions .............................................................................................................17

3.7.3. Auxiliary I/O Cable Requirements.......................................................................................18

Chapter 4 Operation..........................................................................................................................19

4.1. Starting the Camera.................................................................................................... 19

4.2. Camera Timing Diagrams........................................................................................... 20

4.3. Equal-Exposure Pulse (CC215MU Quantalux Only)................................................. 22

4.4. Hot Pixel Correction................................................................................................... 23

Chapter 5 CC215MU Specifications.................................................................................................24

5.1. sCMOS Sensor Specifications................................................................................... 24

5.2. Quantum Efficiency.................................................................................................... 24