ti.systems CTISr User manual

tire inflation systems

made in Germany

Operation manual

CTISr

Central Tire Inflation System removable

Welserstraße 1 |41468 Neuss |Germany

tel +4 2131. 1 53 18–0 mail info@ti.systems

fax +4 2131. 1 53 18–2 web www.ti.systems

ti.systems GmbH

Certified to DIN EN ISO 001:2015

DIN EN ISO 14001:2015

CTISr

33

Table of Contents

4 General Safety Information

4 Introduction

4 Safety Instructions and Warnings

6 Product Description

6 Product safety Instructions and Warnings

Operation | use

7

8 Adjusting the tire pressure

Storing the hose packets

10 Disconnecting the hoses from the rear axles

Connecting the hose packets to the coupling units and rotary unions

10 Dierent pressure settings by axle

10 Conventional tire pressure check

CTISr

11 Potential Faults and Troubleshooting

11 Disposal

11 Technical Data

4

General Safety Information

1. Introduction

Dear Customer,

You have purchased a product that conforms to the latest

state of the art. Please make sure to install, use and

maintain it as detailed in these operating instructions to

provide you with years of reliable use.

The product as supplied meets all functional and quality

requirements. In order to maintain its state and ensure

risk-free operation, you as the fitter and / or user will need

to read and understand these instructions.

If you have any queries please contact:

ti.systems GmbH

Welserstraße 1 |41468 Neuss |Germany

tel: 02131. 1 53 18–0

mail: info@ti.systems

1.1. Copyright

These operating instructions are a publication of

ti.systems GmbH. All rights, including translation, are

reserved. No part of these instructions may

be replicated in any form or stored in data processing

systems without the written consent of the publisher.

Reproduction in full or in part is not permitted. These

operating instructions reflect the current technical

specifications at the time of printing. We reserve the right

to changes in technology and equipment.

© Copyright 2016 by ti.systems GmbH

1.2.Intended use

The CTISr is intended to be used for inflation and deflation

of the tires of commercial vehicles or private expedition

vehicles with compressed air supply from the vehicle

compressor or a stationary compressor while the vehicle is

stationary and, if necessary, with the engine running.

Pneumatic tools may be operated additionally using the

separate coupling connector on the control box. Any other

use is not permitted and may cause damage to the

product. Do not inflate any other items.

Components of the system may not be transported in an

unsecured state in or on the vehicle. Do not modify the

product. Always follow the safety instructions!

1.3. Disclaimer

Defects caused by failure to comply with these operating

instructions will invalidate the warranty. ti.systems GmbH

takes no responsibility for consequential damage incurred

as a result.

2. Safety Instructions and Warnings

2.1. Basic safety instructions

• When carrying out work on the product, always secure

the vehicle against rolling away or tipping over. Switch

the engine o.

• When carrying out work on the product, always secure

the product against unintentional restarting. If neces-

sary, switch o the product and/ or disconnect it from

the power supply.

• Always ensure secure positioning of the product when

carrying out work which cannot be performed from

the ground. Use steps and grips or handles where

available. If necessary, use suitable aids.

• The product, or its parts, are permanently or tempora-

rily under pressure.

• Hoses or pipes which come uncoupled under pressure

may whip and cause serious injury. When carrying out

work on the product, always ensure that the product

and its parts are not under pressure. If work without

pressure is not possible, take the recommended safety

precautions and wear the recommended personal pro-

tective equipment (PPE). Keep other people away

from the danger zone.

CTISr

5

2.2. Types and meaning of safety information

Some processes need to be carried out in several steps.

Where any of these steps involves a risk, the safety advice

is included directly in its instructions.

The safety advice always precedes the risky step and is

printed in normal type using a signal word in bold and

capitals.

Example:

1. NOTE: Please note this information. It warns of a risk

involved in the next step.

2. Risky step.

• The operating controls of the product should be easy

to access and allow operation without risk of contact

with hot, sharpedged or moving parts.

• Always fit the product and / or components in such a

way that the controls/indicators and safety information

of the vehicle and /or other devices are not obstructed.

• The visibility range of the driver must not be obstructed

by fitted system components.

• Before using the product, familiarise yourself with its

features and operation. Always follow these operating

instructions.

• Do not use this product to inflate or deflate tires that

are not in good condition.

• When inflating tires always keep away from the

danger zone. Always follow the safety instructions of

the tire manufacturer.

• Always ensure that the tire pressure is within the

minimum and maximum range permitted by the tire

manufacturer taking account of the current wheel/axle

loads and the expected driving speed of your vehicle.

• In case of additional stresses due to dynamic wheel /

axle load shifts (e.g. when driving on inclines or slopes,

heavy pulling, heavy accessory equipment), adjust the

tire pressure in accordance with the manufacturer’s

instructions.

• Damaged parts may aect the operational safety of

the product and / or cause serious injury and therefore

must be immediately replaced with original parts.

• Never operate defect products and / or components.

DANGER indicates a risk that WILL result in serious

injury or death if not observed.

DANGER

WARNING indicates a risk that MAY result in serious

injury or death if not observed.

WARNING

CAUTION indicates a risk that MAY cause minor

injury.

CAUTION

NOTE indicates a risk that MAY cause material da-

mage or malfunctioning of the product, the vehicle

or other equipment.

NOTE

CTISr

6

Product description

The CTIS comprises the control unit, dual chamber

rotary unions for each wheel and tire valve connectors

on the tire valves as well as connecting tubes from the

control unit to the dual chamber rotary unions and the

air brake circuit.

The contol unit must be supplied with compressed air

for tire inflation from the vehicle (brake system priority

circuit).

Product safety Instructions and Warnings

The control unit must be easy to access and operate

without risk of contact with hot, sharp-edged or moving

parts.

Do not operate defect components. Hoses or pipes

which come uncoupled under pressure may whip

and cause serious injury. Exercise caution when

using pressure lines.

DANGER

NOTE

Always replace damaged parts immediately.

NOTE

CTISr

Operation | use

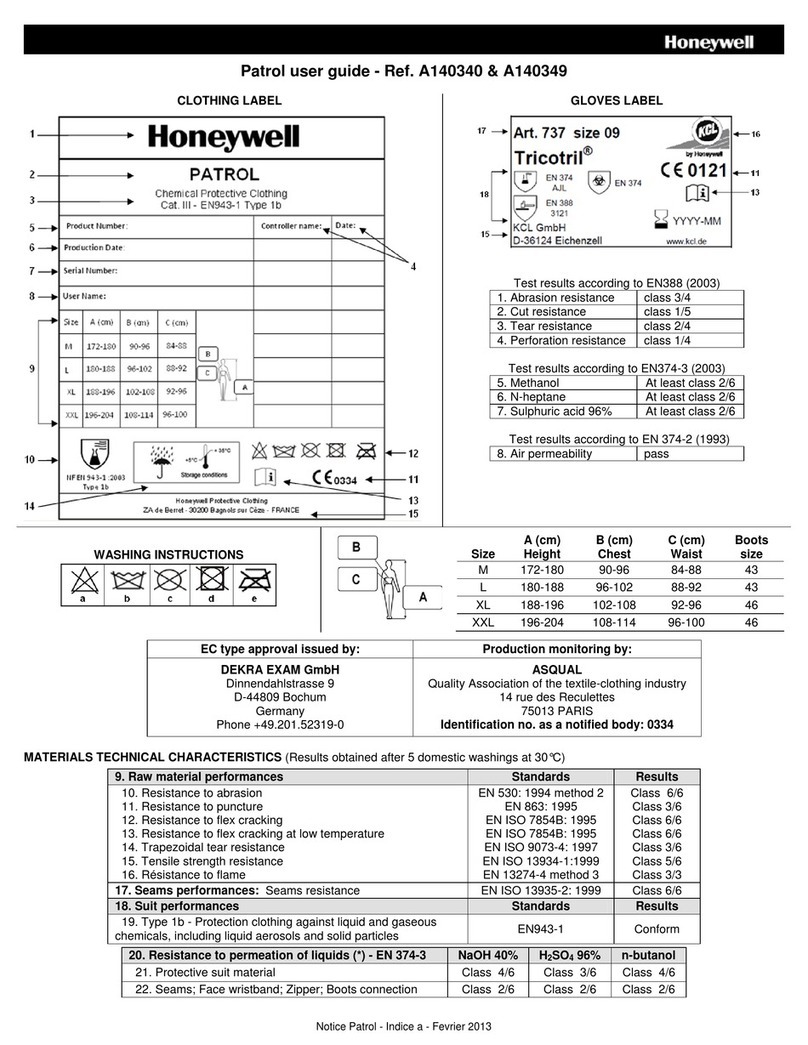

1. Connecting the hose packets to the coupling units and rotary

unions

Front axle:

Unclasp the snap hook to open the hose depot, remove the lid and

take out the required hose packets.

The hose packets are fitted with plug fittings on one end and with

lock couplings on the other. This means they cannot be connected in

the wrong way. The hose packets are braced at the plug fitting end to

prevent contact between the hose packet and tire/rim. Occasional

contact, especially in extreme situations, is not likely to cause a

problem.

Remove the protection caps from the plug fittings of the rotary

unions and from the couplings of the coupling unit.

Connect the hose packets successively, snapping the plug couplings

and plug fittings into place.

Rear axles:

The hoses are already connected to the tires from the initial

installation.

CTISr

7

Image 1

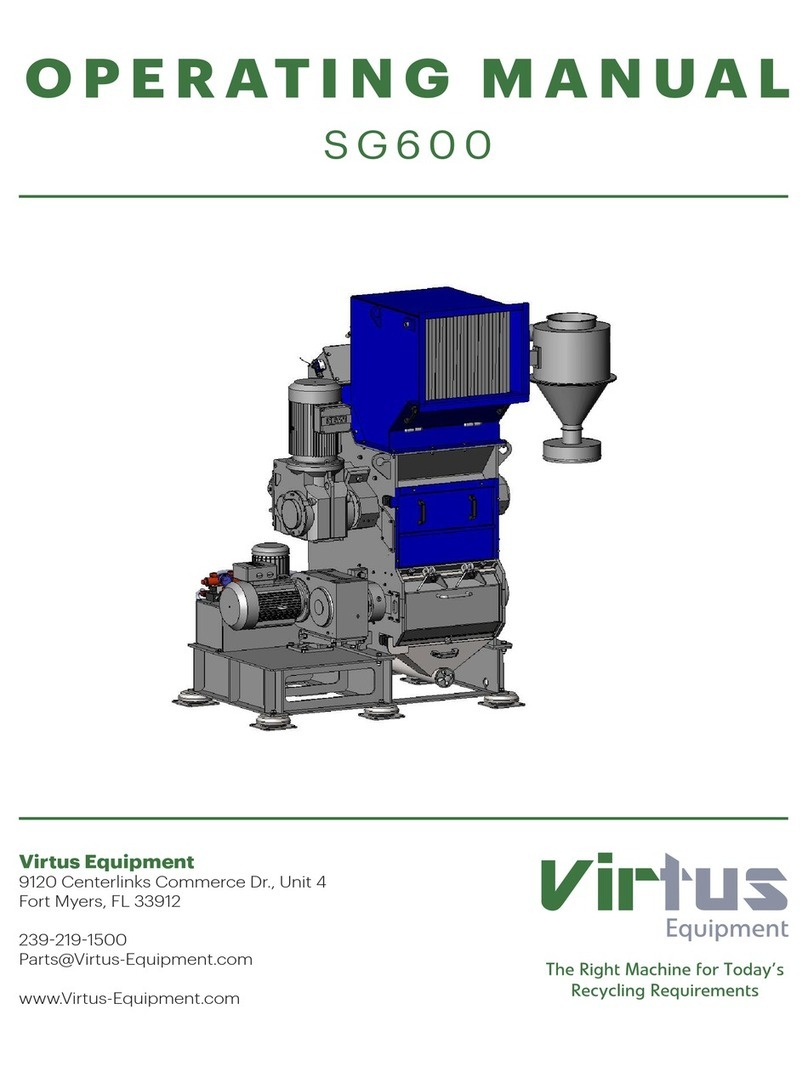

. Adjusting the tire pressure

The CTISr only works with the hoses connected and the ignition

switched on.

Once the compressed air system provides enough pressure, the 1l air

tank is filled and supplies the operating pressure for the control

panel.

The rotary switch is used to select between four dierent preset tire

pressures:

Highway (HWY)

O-road (OFR)

Sand | Mud (S/M)

Emergency (EMC)

Turn the ON|OFF switch to “ON”. This opens the tire valves to

regulate the selected pressure via the main control unit.

The pressure indicated on the actual pressure gauge moves towards

the preselected pressure. Due to the flow process, particularly when

deflating the tire, the indicated (dynamic) pressure is not the exact

same as the (static) pressure in the tires. The correct pressure will

only be indicated towards the end of adjustment.

When the required target pressure is reached, turn the ON|OFF

switch back to “OFF” to close the tire valves and depressurise the

rotary unions.

If the vehicle has previously been used to navigate mud flats, it is

advisable to set the control pressure initially below the current tire

pressure to activate the proportional valve so it lets pressure o via

the potentially soiled silencer and cleans the filter element.

CTISr

8

Image 2

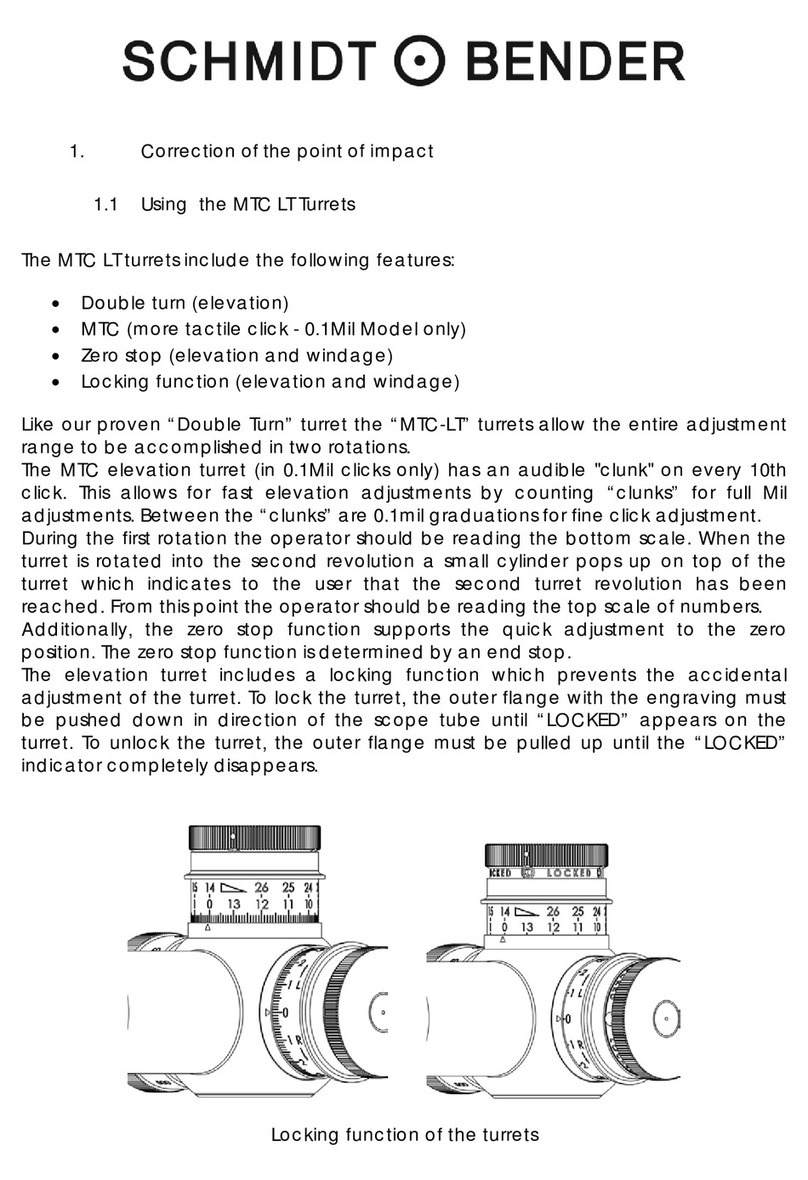

3. Storing the hose packets

When driving on public roads, local regulations may require

that the hose packets be removed from the rotary unions

and coupling units and be stored in a hose depot.

Switch o the system and disconnect the hose packets from

the rotary unions and the coupling units.

Unclasp the snap hook to open the hose depot, remove the

lid and store the hose packets inside. Close the lid and snap

the hook back into the D-ring on the hose depot.

CTISr

9

Image 3

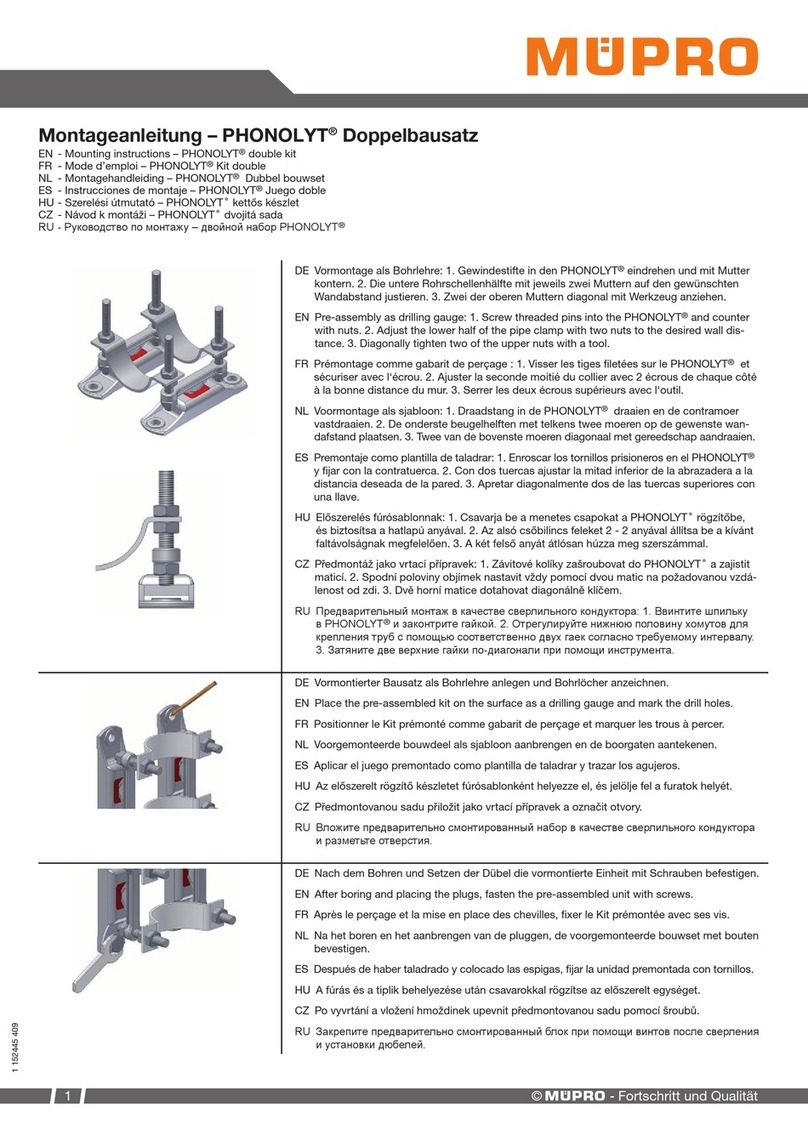

4. Disconnecting the hoses from the rear axles

In case the hoses from the rear axles have to be

disconnected from the rotary unions (e.g. for tire changing,

replacing the rotary union etc.), disconnect the couplings of

the working line (PA 12x1.5 bk) and the control line (PA 4x1

bl) from the rotary union. Then connect the two lines to the

blind connectors S26 and S21, which are installed on the

mud guard between the two rear wheels.

5. Dierent pressure settings by axle

To set dierent pressures by axle, follow these two steps:

First, connect all vehicle tires and inflate them to the lower

pressure required. Disconnect the lines that have reached

the target pressure and disconnect the hoses. Now select

the higher inflation pressure of the remaining tires and

proceed as described under 2.

When deflating, deflate all tires to the higher pressure,

disconnect the “finished” tires. Now select the lower

pressure on the control unit for the remaining tires.

6. Conventional tire pressure check

The tire pressure can always be checked or adjusted in the

conventional way by connecting the supplied gas station

adapter TIS-X-010-00 to the ti.systems tire valve.

CTISr

10

Image 4

Potential Faults and Troubleshooting

Tires do not inflate

• Pressure in the supply system is lower than the

current tire pressure or too low to overflow the

priority circuit of the brake system

fill brake air reservoir

• System has no power

replace fuse

• Hoses not properly connected to tire valves

connect properly

• Main control valve defect

replace valve in the workshop

• Pressure controller defect

replace controller in the workshop

Tires do not deflate

• Filter element of silencer excessively soiled

clean up silencer

• Hoses not properly connected to tire valves

connect properly

• Main control valve defect

replace valve in the workshop

• Pressure controller defect

replace controller in the workshop

• Valve inserts still in tire valves

remove the inserts from the tire valves and mount

ti.systems connectors properly

Disposal

If the system fails to work properly and can no longer be

repaired, please dispose of the product in compliance

with the applicable legal requirements.

Technical data

Maximum operating pressure: 12.5 bar

Adjustment range: 0.5 bar p 6.5 bar (single tires)

Thermal application range: -40°C – +70°C

Fording ability: yes

8.5 bar (twintires)

Certified to DIN EN ISO 001:2015

DIN EN ISO 14001:2015

11

Table of contents

Popular Industrial Equipment manuals by other brands

Ulvac

Ulvac OMT-050A instruction manual

Logan

Logan F400-1 instruction manual

Metra Electronics

Metra Electronics ADS-200 operating manual

SUHNER ABRASIVE

SUHNER ABRASIVE LTB 6 - 1030 Technical document

PCB Piezotronics

PCB Piezotronics ICP J353B31 Installation and operating manual

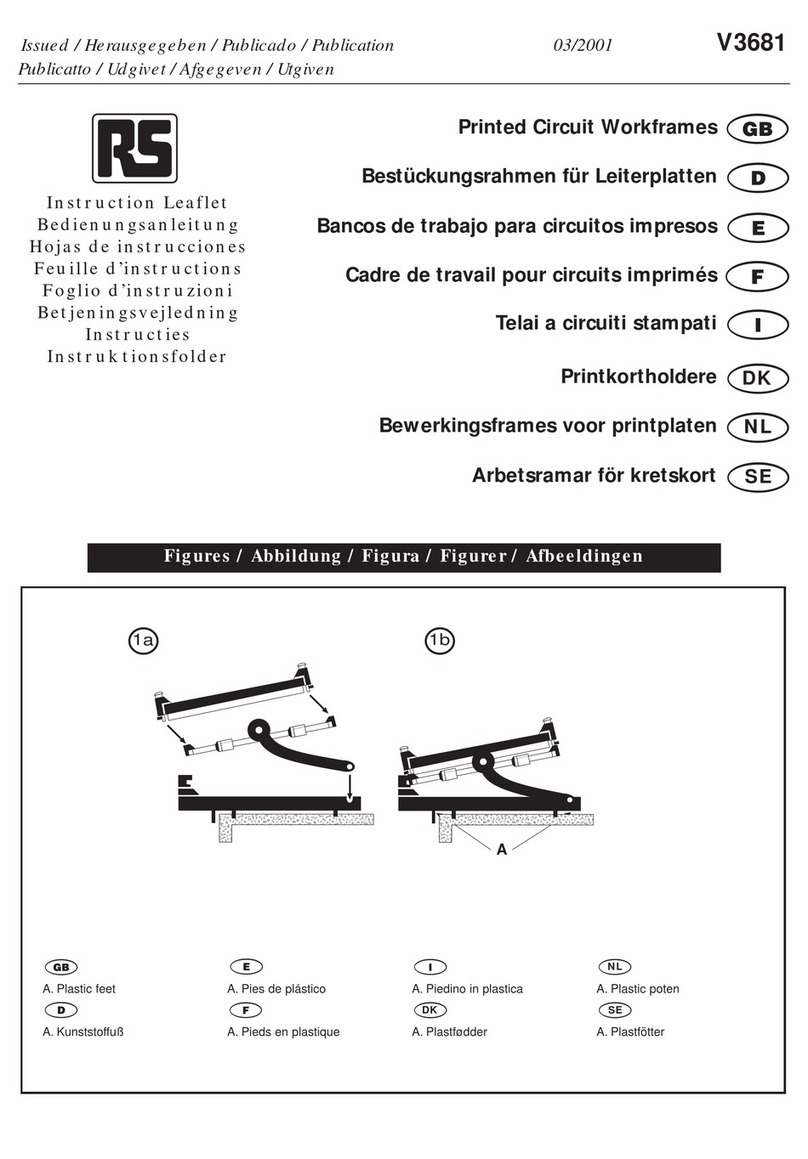

RS

RS V3681 Instruction leaflet