ORIGINAL INSTRUCTION

PART A: Basic machine

SG600

VIRTUS EQUIPMENT 2023, All right

Page 4

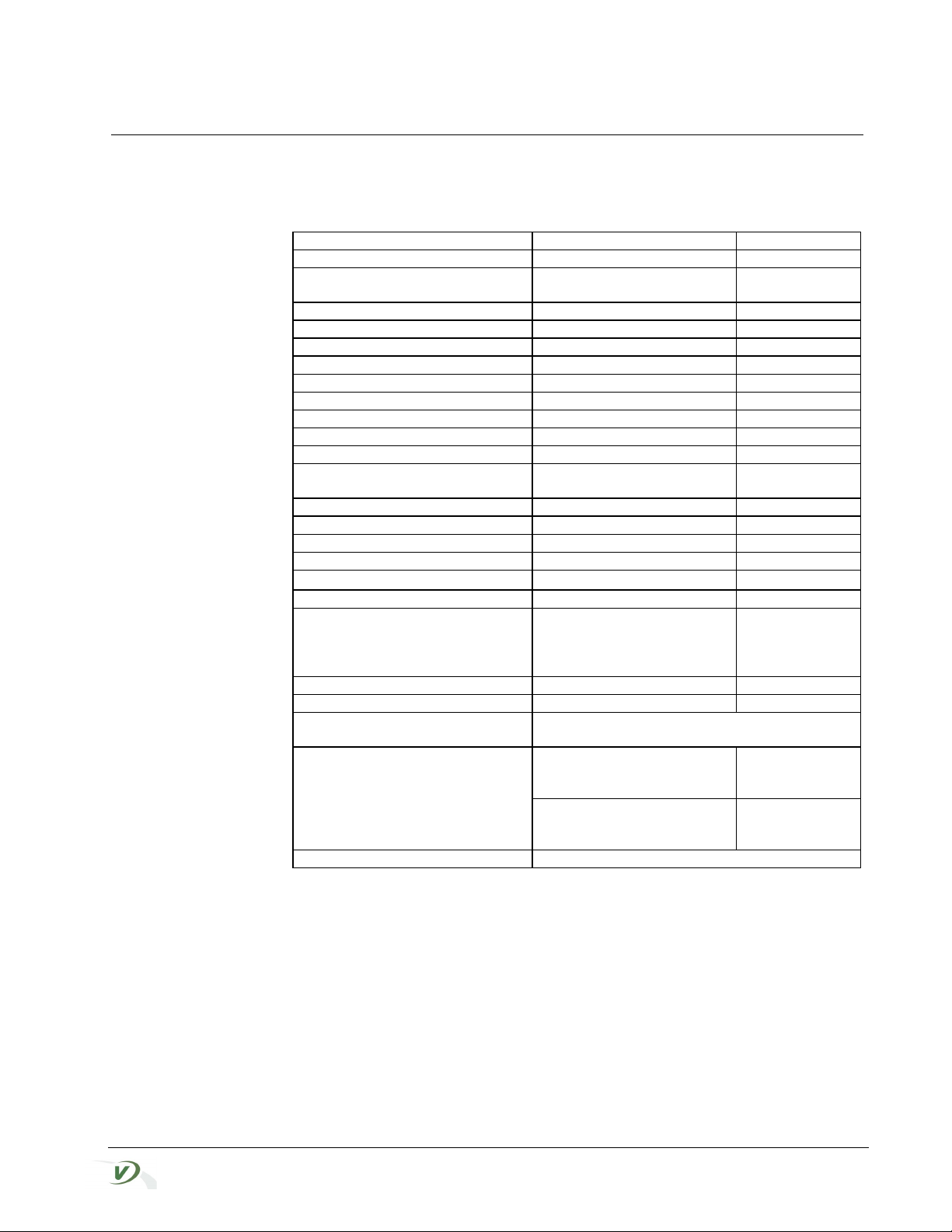

8.5 Replacing the gearmotors _______________________________________________54

8.5.1 Dismounting the gearmotors _________________________________________________ 54

8.5.2 Mounting to the rotors ______________________________________________________ 54

8.6 Replacing the rotor for shredder _________________________________________55

8.6.1 Dismounting the rotor_______________________________________________________ 55

8.6.2 Mounting the rotor _________________________________________________________ 56

8.7 Replacing the main bearings for shredder _________________________________57

8.7.1 Dismounting the main bearings _______________________________________________ 57

8.7.2 Mounting the main bearing___________________________________________________ 58

8.8 Replacing the main bearings for Granulator ________________________________59

8.8.1 Dismounting the main bearings _____________________________________________ 59

8.8.2 Mounting the main bearing _________________________________________________ 60

8.9 Lubricating the main bearings ___________________________________________61

8.9.1 Lubrication intervals: _______________________________________________________ 61

8.9.2 Check lubricant quality ______________________________________________________ 61

8.9.3 Replacing or refilling lubricant ________________________________________________ 61

8.9.4 List of lubricants ___________________________________________________________ 63

8.10 Working on the cutting knives for shredder_______________________________64

8.10.1 Replacing and checking the cutting knife mountings _______________________________ 64

8.10.2 Checking the condition of the cutting knives _____________________________________ 65

8.10.3 Dismounting the rotor knives _________________________________________________ 66

8.10.4 Dismounting the rotor knife holders ____________________________________________ 67

8.10.5 Dismounting the stator knives ________________________________________________ 69

8.10.6 Mounting the rotor knife holders_______________________________________________ 70

8.10.7 Mounting the rotor knives____________________________________________________ 71

8.10.8 Mounting the stator knives ___________________________________________________ 72

8.10.9 Sharpening cutting knives ___________________________________________________ 74

8.10.10 Setting the cutting knives __________________________________________________ 75

8.10.11 Transporting and storing the cutting knives ____________________________________ 76

8.11 Working on the cutting knives for Granulator _____________________________77

8.11.1 Replacing and checking the cutting knife mountings ___________________________ 77

8.11.2 Checking the condition of the cutting knives __________________________________ 78

8.11.3 Dismounting the cutting knives _____________________________________________ 79

8.11.4 Mounting the cutting knives ________________________________________________ 80

8.11.5 Sharpening cutting knives _________________________________________________ 81

8.11.6 Setting the cutting knives __________________________________________________ 84

8.11.7 Transporting and storing the cutting knives ___________________________________ 86

9Troubleshooting__________________________________________________ 87

9.1 Machine blocks or switches itself off ______________________________________87

9.2 Rotor does not grip bulky material ________________________________________87

9.3 Overheating of the grinding material ______________________________________87

9.4 Unusual vibrations _____________________________________________________87

9.5 Extreme cutter wear ____________________________________________________88

9.6 Bearings too hot _______________________________________________________88

9.7 Too many fines in grinding material_______________________________________88

9.8 Cutting gap alters during operation _______________________________________88

ORIGINAL INSTRUCTION

PART A: Basic machine

Slow speed Granulator A18 Series

Virtus Equipment 2023, All rights reserved

Table of Contents

1Information on this instruction manual ________________________________ 7

2Technical data ____________________________________________________ 8

3General Information _______________________________________________ 12

3.1 Copyright____________________________________________________________ 12

3.2 Application __________________________________________________________ 12

3.3 Safety_______________________________________________________________ 12

3.4 Inspection of goods ___________________________________________________ 12

4General safety advice _____________________________________________ 13

4.1 Safe operation of the machine __________________________________________ 13

4.2 Use in accordance with the regulations___________________________________ 14

4.3 Liability and Responsibility _____________________________________________ 16

4.4 Structural changes, spare parts, accessories ______________________________ 17

4.5 Operation manuals from other manufacturers _____________________________ 17

4.6 Noise levels and noise control measures _________________________________ 18

4.7 Work stations ________________________________________________________ 18

4.8 Remaining risks ______________________________________________________ 19

4.8.1 Mechanical dangers ________________________________________________________ 19

4.8.2 Electrical dangers__________________________________________________________ 20

4.8.3 Dangers caused by the control system _________________________________________ 21

4.8.4 Thermal dangers __________________________________________________________ 21

4.8.5 Dangers caused by noise____________________________________________________ 21

4.8.6 Dangers caused by vibration _________________________________________________ 22

4.8.7 Dangers caused by materials and substances____________________________________ 22

4.8.8 Danger caused by manipulation of the protective devices ___________________________ 22

4.9 Protective devices ____________________________________________________ 23

4.9.1 Safety device for screen holder _______________________________________________ 23

4.9.2 Safety device for hopper ____________________________________________________ 24

4.9.3 Safety device for suction trough _______________________________________________ 25

4.9.4 Splash guard _____________________________________________________________ 26

4.9.5 Safety markings ___________________________________________________________ 26

4.10 Authorized persons__________________________________________________ 27

4.11 Personal protective gear _____________________________________________ 28

4.12 Safety measures at the application site _________________________________ 29

4.13 Fire fighting agents __________________________________________________ 29

4.14 Cleaning agents_____________________________________________________ 29

4.15 Conduct in case of an emergency ______________________________________ 29

4.16 Classification of specific safety advice__________________________________ 30