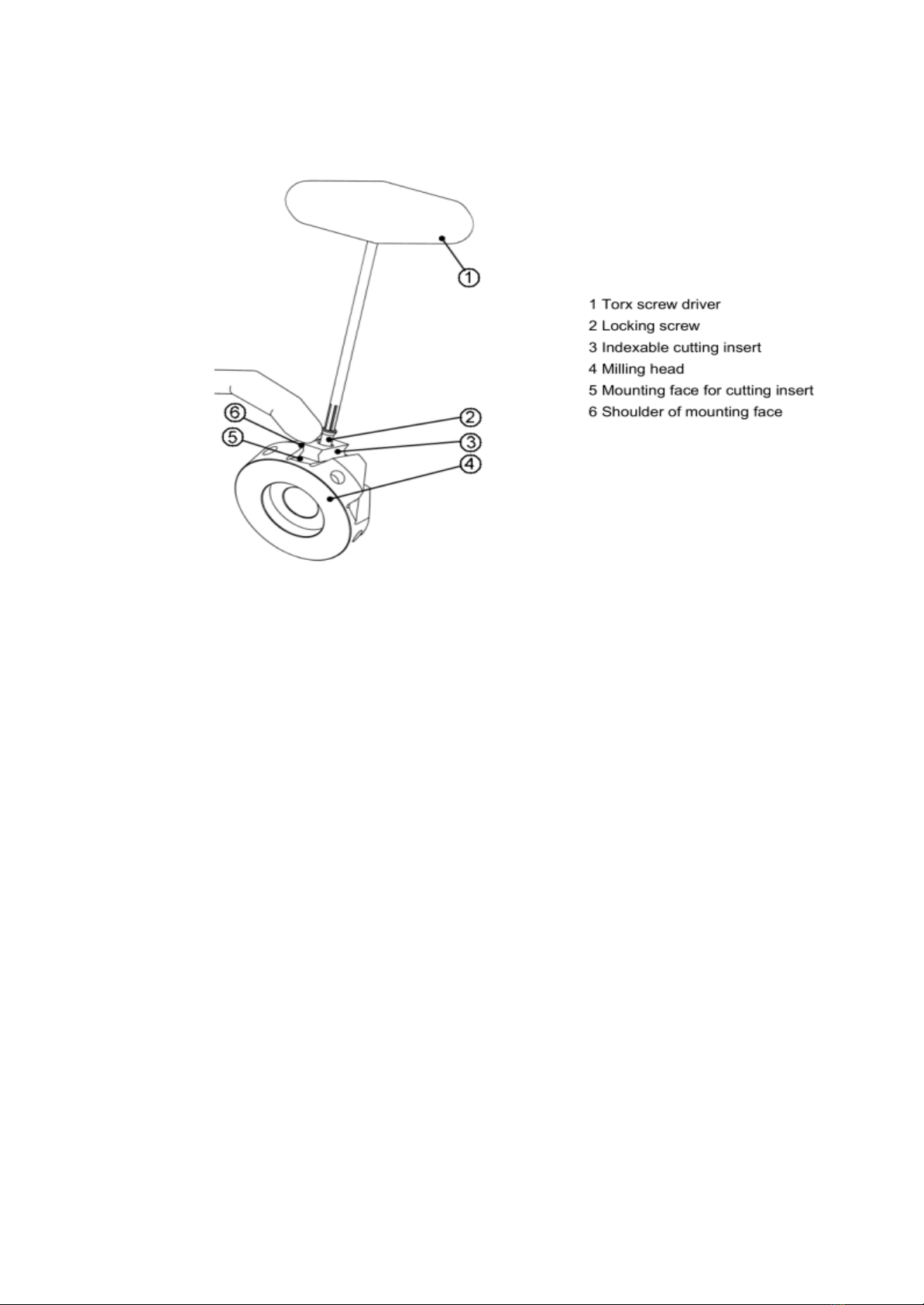

7. Fitting New Indexable Cutting Inserts

Procedure

●Switch off the machine by releasing the on/off switch.

●Pull out the power cable plug from the mains socket.

●Press and hold down the safety button on the top of the gearing housing.

●Loosen the locking screw and remove the cutting insert.

●Clean the area where the insert sits (mounting face and shoulder) and check for damage

●Always rotate or exchange all the inserts on the milling head at the same time

●Make sure that the new inserts are all of identical type

●Press each insert into position so that it lies perfectly flat on the lower part of the

mounting face (5)

●With the insert still properly positioned, tighten the screw with the Torx screwdriver (1)

hand tight so that the insert lies up against the shoulder of the mounting face

●Once all inserts are in position, retighten each of the screws

●Check to make sure that all the indexable inserts on the milling head are of the same

type, that each insert is properly located on the mounting surface and butted up against

the shoulder, and that all screws are tight

●Start with a small bevel and guide the machine slowly onto the material to be milled. If

the machine kicks back, switch off the machine immediately and check again that the

indexable inserts are all of the same type and that they have been fitted exactly as

described above. If the machine kicks back again, you will need to replace the entire set

of inserts.