TIELBURGER tw50 User manual

Trademark

This document is a publication by Julius Tielbürger GmbH & Co. KG, Postdamm 12, D-32351 Stemwede-Oppenwehe, Germa-

ny (www.tielbuerger.de).

The document is up to date with the latest technology at the time of printing. Subject to technical and equipment changes. The

drawings and illustrations shown may differ from the original.

$OOULJKWVUHVHUYHGLQFOXGLQJWKRVHRIWUDQVODWLRQ$Q\W\SHRIUHSURGXFWLRQVXFKDVSKRWRFRS\PLFUR¿OPRUVWRULQJLQHOHF-

tronic data processing systems, requires written authorisation from the publisher. Any reproduction, whether in whole or in

part, is prohibited.

All trademarks, registered trademarks, trade names and brand names are the property of their rightful owners and are acknowl-

edged by us.

© Copyright 2017 by Julius Tielbürger GmbH & Co. KG

3

Content

1 Operating instructions.................................................................................................................................................... 4

1.1 General ...................................................................................................................................................................... 4

1.2 Warnings and symbols............................................................................................................................................... 5

2 Basic safety instructions ................................................................................................................................................. 6

2.1 Intended use............................................................................................................................................................... 6

2.2 Organisational measures............................................................................................................................................ 6

3HUVRQQHOVHOHFWLRQDQGTXDOL¿FDWLRQVEDVLFREOLJDWLRQV.......................................................................................... 7

3 Scope and condition of delivery..................................................................................................................................... 8

4 Illustration of the machine and danger zone, component description and position of safety stickers .................. 9

5 Installation..................................................................................................................................................................... 10

6 Start-up .......................................................................................................................................................................... 14

6.1 Basic safety instructions for normal operation........................................................................................................ 14

6.2 Operating the machine in winter ............................................................................................................................. 14

6.3 Adjusting the height of the handlebar...................................................................................................................... 15

6.4 Bristle pressure ........................................................................................................................................................ 16

6.5 Brush drive .............................................................................................................................................................. 17

6.6 tw50s steerable freewheel ....................................................................................................................................... 18

6.7 Starting/switching off the engine (quick guide) ...................................................................................................... 19

6.8 Charging the B&S InStart battery ........................................................................................................................... 21

6.9 Connecting the battery to the engine....................................................................................................................... 24

6.10 Starting/switching off the engine........................................................................................................................... 25

6.11 Disconnecting the battery from the engine............................................................................................................ 26

6.12 Support roller (accessory) ..................................................................................................................................... 27

6.13 tw50 lateral protective cover (accessory).............................................................................................................. 27

7 Maintenance and care.................................................................................................................................................. 28

7.1 Basic safety instructions.......................................................................................................................................... 28

7.2 Refuelling ................................................................................................................................................................ 29

7.2 Refuelling ................................................................................................................................................................ 30

7.3 Checking the oil....................................................................................................................................................... 31

7.4 Battery and charger.................................................................................................................................................. 32

7.5 Replacing the twisted knot brushes ......................................................................................................................... 33

7.6 Cleaning the implement........................................................................................................................................... 35

7.7 Setting and readjusting the Bowden cables............................................................................................................. 36

7.8 Checking and correcting the tyre pressure .............................................................................................................. 37

&OHDQLQJWKHDLU¿OWHU............................................................................................................................................... 38

7.10 Storage................................................................................................................................................................... 38

7.11 Maintenance plan................................................................................................................................................... 38

8 Faults and how to rectify them .................................................................................................................................... 39

9 Transport ....................................................................................................................................................................... 41

7HFKQLFDOVSHFL¿FDWLRQV............................................................................................................................................... 42

7HFKQLFDOVSHFL¿FDWLRQV............................................................................................................................................... 43

11 EC Declaration of Conformity................................................................................................................................... 44

These operating instructions are intended to help users

familiarise themselves with the machine and use it in

line with its intended applications.

The operating instructions contain important informa-

tion on how to operate the machine safely, properly and

economically. Observing these operating and installa-

tion instructions helps to avert risks, to reduce repair

costs and downtime and to increase the reliability and

service life of the machine.

The operating instructions must be supplemented by

the relevant national rules and regulations for accident

prevention and environmental protection.

The operating instructions must always be available

wherever the machine is in use.

1.1 General

The operating instructions must be read and applied

by any person in charge of carrying out work with or

on the machine, such as:

2SHUDWLRQ LQFOXGLQJ VHWWLQJ XS IDXOW UHFWL¿FDWLRQ

in the course of work, removal of production waste,

maintenance and disposal of operating and auxiliary

materials

-Maintenance (servicing, inspection, repair) and/or

-Transport.

The generally recognised rules of technology for safe

and proper working must be observed in addition to

the operating instructions and mandatory regulations

for accident prevention which apply to the country

and place of use.

Operating instructions

1 Operating instructions

4

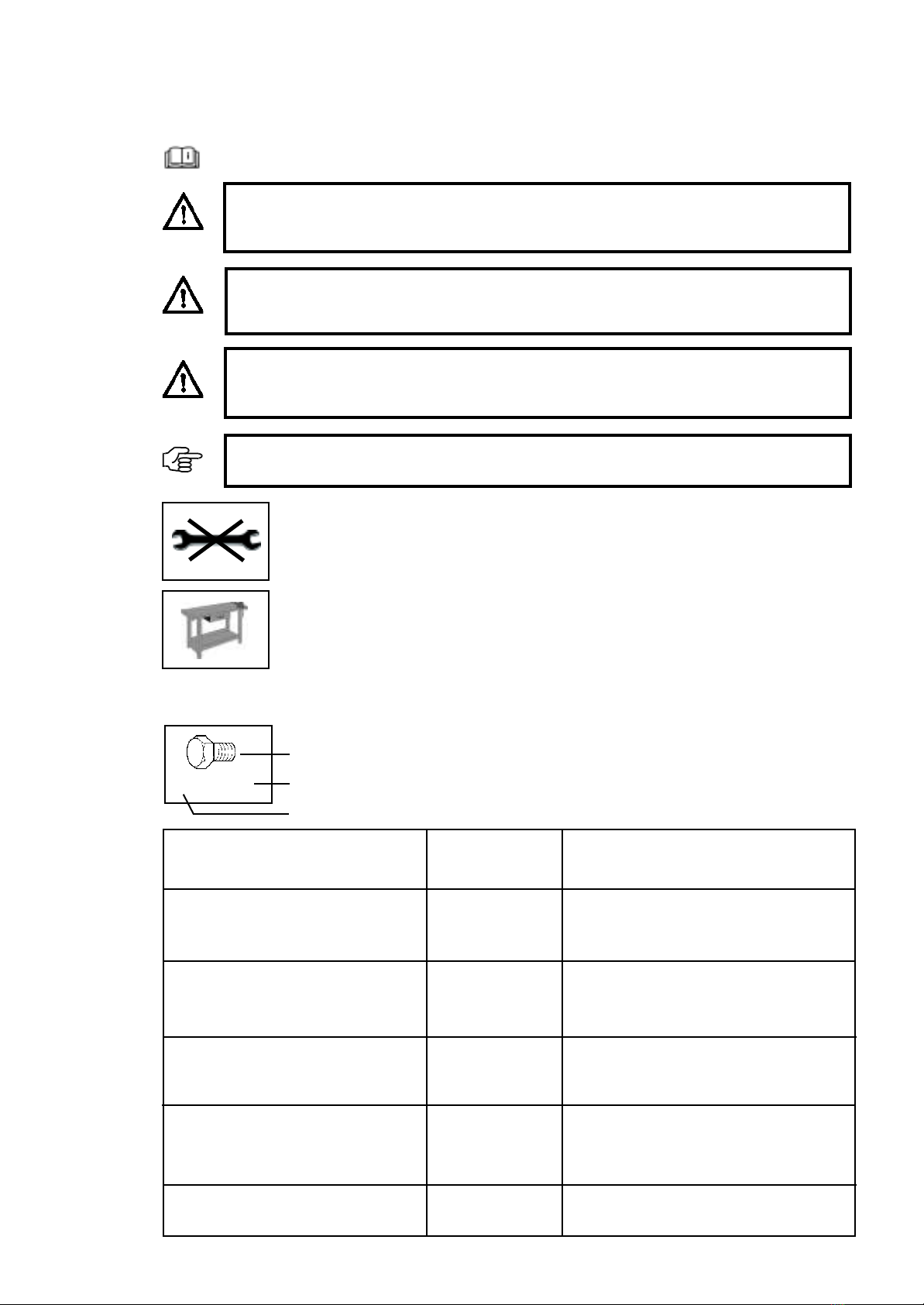

Read the operating instructions

1.2 Warnings and symbols

DANGER!

Indicates an immediate threat of danger. If this instruction is ignored, there is a risk of death

or extremely serious injury.

WARNING:

Indicates a potentially hazardous situation. If this instruction is ignored, there may be a risk

of death or extremely serious injury.

CAUTION:

Indicates a potentially hazardous situation. If this instruction is ignored, there may be a

risk of minor injury.

IMPORTANT:

Indicates operating tips and other useful information.

5

Operating instructions

Work on a workbench

Do not use a tool

Symbol

Type

Quantity

2x M8 x 20

Symbol

Bolt

Washer

Nut

Combination spanner

Hexagon head screwdriver

Screwdriver

Crosshead screwdriver

Example

types:

M8 x 16

8,1 - 58 - 5

M8 (L)

8

PZ 2

PH 2

Explanation

M=Metric

S=Diameter in mm

16 =Length in mm

8.1 =Inner diameter

58 =Outer diameter

5 =Material thickness in mm

M=Metric

8 =Inner diameter in mm

(L) =Lock nut

8 =Size in mm

PZ 2 = Pozidriv size 2

PH 2 = Phillips size 2

2.2 Organisational measures

The operating instructions must always be to hand

wherever the machine is in use.

In addition to the operating instructions, observe and

follow the generally valid legal regulations and any

other binding regulations for accident prevention and

environmental protection.

Such obligations may also include handling hazard-

ous substances or making available/wearing personal

SURWHFWLYHHTXLSPHQWDQGFRPSO\LQJZLWKURDGWUDI¿F

regulations, for example.

Supplementthe operating instructions withinstructions

including site management and reporting obligations

concerning special operational requirements, for ex-

DPSOHZLWKUHJDUGWRZRUNRUJDQLVDWLRQZRUNÀRZV

personnel used, etc.

Any personnel instructed to perform work on the ma-

chine must have read the operating instructions before

VWDUWLQJZRUNVSHFL¿FDOO\WKHVHFWLRQHQWLWOHG6DIHW\

LQVWUXFWLRQV5HDGLQJWKHLQVWUXFWLRQVDIWHUZRUNKDV

begun is too late. This applies in particular to person-

nel who only work on the machine occasionally, for

example for set-up and maintenance.

At least occasionally, check that the personnel are

working with safety and hazards in mind and are fol-

lowing the operating instructions.

Personnel must not have long hair which is not tied

back or wear loose clothing or jewellery including

rings. There is a risk of injury from being caught or

drawn into the machine, for example.

Wear personal protective equipment if necessary or

required by regulations.

Observe all safety and hazard notices on the machine.

Ensure that all safety and hazard notices at/on the

machine can be read in full at all times.

,QWKHHYHQWRIDQ\PRGL¿FDWLRQWRWKHPDFKLQHRUDQ\

change in the machine's performance that may affect

safety, shut down the machine immediately and report

WKHIDXOWWRWKHUHVSRQVLEOHLQGLYLGXDORURI¿FH

Do not modify, convert or attach equipment to the ma-

chine without approval from the supplier if this could

LPSDLUVDIHW\7KLVDOVRDSSOLHVWR¿WWLQJDQGDGMXVWLQJ

safety equipment and valves, as well as for welding

on supporting parts.

6SDUHSDUWV PXVWIXO¿OWKHWHFKQLFDOUHTXLUHPHQWV

determined by the manufacturer. This must always be

guaranteed for genuine spare parts.

Adhere to the prescribed time periods or those indi-

cated in the operating instructions for recurring tests/

inspections.

Workshop equipment which is appropriate for the work

is mandatory for carrying out maintenance measures.

0DNH SHUVRQQHO DZDUH RI WKH ORFDWLRQ RI ¿UH H[WLQ-

guishers and how to use them.

2EVHUYHWKH¿UHDODUPDQG¿UH¿JKWLQJSURFHGXUHV

2.1 Intended use

The machine has been constructed using state-of-the-

art technology and in line with the recognised technical

safety regulations. However, use of this machine may

still result in the risk of injury or death to the user or

third parties, or of damage to the machine and other

material assets.

Only use the machine in technically perfect working

order, for its intended use and with safety and hazards

in mind, in compliance with the operating instructions.

In particular, you must immediately rectify faults that

FRXOGLPSDLUVDIHW\RUKDYHVXFKIDXOWVUHFWL¿HGLP-

mediately by a third party.

The machine is solely intended for the removal of

weed growth on paved, concrete and/or tarmac sur-

faces outdoors. Any other or additional form of use

is considered non-compliant with the intended use.

For example, the machine must not be used to sweep

animal feed. Twisted knot brushes can come loose and

be consumed by animals, causing harm to them. The

manufacturer/supplier shall not be held liable for any

damage or loss suffered as a result. The risk is borne

solely by the user. Intended use also includes comply-

ing with the operating instructions and adhering to the

inspection and maintenance conditions.

The machine may only be operated with twisted knot

brushes that have been approved by the manufacturer.

Basic safety instructions

2 Basic safety instructions

6

3HUVRQQHOVHOHFWLRQDQGTXDOL¿FDWLRQVEDVLFREOLJDWLRQV

Work on/with the machine may only be carried out by

reliable personnel. Observe the legal minimum age.

Only use trained or instructed personnel and clearly

GH¿QHWKHUHVSRQVLELOLWLHVRIWKHSHUVRQQHOIRURSHUD-

tion, set-up, maintenance and repair.

Ensure that only authorised personnel work on the

machine.

Appoint an operator responsible for the machine –

LQFOXGLQJZLWKUHJDUGWRWUDI¿FUHJXODWLRQV±DQGJLYH

them the authority to refuse instructions issued by third

parties that may cause a hazard.

Only allow personnel who are yet to complete training,

instruction and induction or who are still completing

ageneral apprenticeship to carry out work on the

machine under the constant supervision of an expe-

rienced person.

Work on the machine's electrical equipment may only

EHFDUULHGRXWE\DTXDOL¿HGHOHFWULFLDQRUE\WUDLQHG

personnel under the guidance and supervision of a

qualified electrician in accordance with electrical

engineering regulations.

Work on chassis, braking and steering systems must

RQO\EHFDUULHGRXWE\TXDOL¿HGSHUVRQQHOWUDLQHGIRU

such work.

Clean the implement regularly, particularly in the ex-

haust and engine area. Otherwise, there is an increased

ULVNRI¿UH

Basic safety instructions

7

Scope and condition of delivery

8

4) Please recycle the packaging material .

The product is delivered in a collapsible box:

1 Weed brush

1 Accessories bag containing

- Operating instructions

- Operating instructions for the engine

Accessories (must be ordered separately)

- Impact guard

- Support roller

3 Scope and condition of delivery

1) Product packaging 2) Inspect the original packaging

3) tw50s weed brush as-delivered condition

Installation

5 Installation

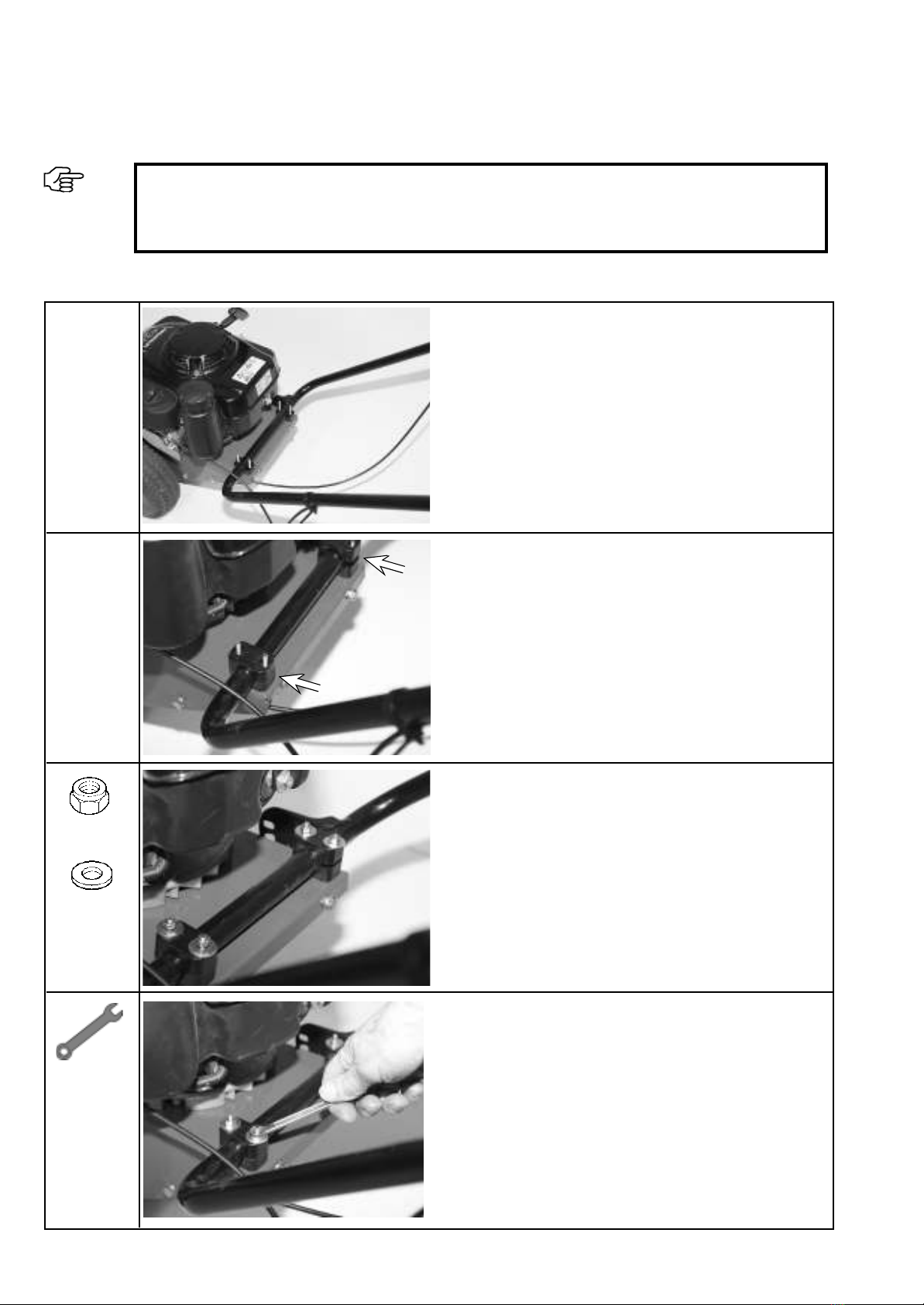

IMPORTANT:

'RQRW¿OOWKHHQJLQHZLWKDQ\RLORUSHWURODWWKLVSRLQW

Before you begin, acquire an overview of the installation sequence and the required parts and tools.

10

Position the handlebar.

Place the handlebar on the pipe brackets.

Place the pipe brackets onto the bolts.

Preassemble the handlebar with the washer and lock nut.

Only tighten the nuts to the point that the handlebar can still

move without dropping on its own.

4x M6

4x 6.4-16-1.6

11

Installation

Attach the washer.

Screw down the nut.

Undo the star grip.

Adapt the height of the handlebar to the height of the op-

erator.

Insert the hex bolt with washer.

Install the throttle regulation lever.

Position the throttle cable.

Secure the handlebar using the star grip.

1 x 6x65 x 20

1x M6

2x 6.4-12-1.6

Installation

12

Tighten the bolt.

Install the clutch lever.

Undo the hex socket bolt.

Keep the lateral grip pushed down.

Position both halves of the lever on the handlebar pipe

so that they can be connected to each other.

IMPORTANT:

Push down the lateral grip to prevent the com-

pression spring jumping out.

Installation

13

Tighten the hex socket bolt.

Correctly installed clutch lever.

Connect the two halves of the lever.

IMPORTANT:

Check that the lateral grip works properly.

6.1 Basic safety instructions for normal operation

6 Start-up

Never operate the machine in a manner that could

compromise safety.

Before beginning work, familiarise yourself with the

work environment at the location where the machine

is used. The work environment includes, for example,

REVWDFOHVLQWKHZRUNDQGWUDI¿FDUHDWKHORDGEHDULQJ

FDSDFLW\RIWKHÀRRUDQGWKHUHTXLUHGPHDQVRIFRUGRQ-

ing the location where the machine is used off from

WKHSXEOLFWUDI¿FDUHD

Take appropriate measures to ensure that the machine is

only operated in a safe and fully functional condition.

Only operate the machine when all protective equip-

ment and safety-critical equipment, for example

detachable protective equipment, sound-insulating

equipment and extraction equipment, is present and

in proper working order.

Always check for externally visible damage and de-

fects before using the machine. Report any machine

PRGL¿FDWLRQVLQFOXGLQJFKDQJHVLQSHUIRUPDQFHLP-

PHGLDWHO\WRWKHRI¿FHSHUVRQUHVSRQVLEOH6KXWGRZQ

the machine immediately and secure it if necessary.

In the event of a malfunction, shut down and secure

WKHPDFKLQHLPPHGLDWHO\ +DYHIDXOWV UHFWL¿HG LP-

mediately.

Only start the machine from the driver's seat.

Switch the machine on and off in accordance with the

operating instructions, observing the control displays.

Before switching on/starting up the machine, ensure

that no one can be endangered by the machine starting

up.

Beforetravelling withthemachineorbeginning work,

check that the brakes, steering, signal and lighting

systems are fully functional.

Before moving the machine, always check thatthe

accessories are securely in place.

When driving on public roads and paths and in public

SODFHVFRPSO\ZLWKWKHDSSOLFDEOHURDGWUDI¿FUHJX-

lations and bring the machine into a condition which

LVSHUPLWWHGE\URDGWUDI¿FUHJXODWLRQVLQDGYDQFH

,QSRRUYLVLELOLW\RULQWKHGDUNDOZD\VHQVXUHVXI¿-

cient lighting.

Always maintain an adequate distance from pit edges

and slopes.

Prohibit any manner of working that may impair the

stability of the machine.

'R QRWGULYHDFURVV VORSHVDOZD\V WUDQVSRUWZRUN

equipment and loaded goods close to the ground,

particularly when descending hills.

Always adapt your driving speed to the conditions

on sloping terrain. Never change to a lower gear on a

VORSH\RXVKRXOGGRWKLVEHIRUH\RXUHDFKWKHVORSH

Upon leaving the machine, always secure it against

accidentally rolling away and unauthorised use.

Start-up

14

6.2 Operating the machine in winter

&KHFNLIWKHDLU¿OWHULVGU\DWUHJXODULQWHUYDOV,IWKH

¿OWHULVGDPSEHFDXVHRIFRQGHQVDWLRQDOORZLWWRGU\

RYHUQLJKW2WKHUZLVHWKHUHLVDFKDQFHWKDWWKHDLU¿OWHU

will freeze and the engine will not start. Before start-up,

spray the throttle cable, throttle regulation lever and

the linkage on the engine with silicone spray. Move

the throttle regulation lever into both end positions so

that the Bowden pull cable on the engine and on the

throttleregulation lever is lubricated as well. This pre-

vents frozen condensation obstructing the mechanics.

Siliconesprayis recommendedformaintaining the

Bowden pull cables on the other levers as well.

After sweeping, clear any snow off the machine using

a brush.

IMPORTANT:

Store the machine in a room protected from frost. Prevent the machine freezing. If a component has

been frozen solid, this could damage the machine.

Silicone spray attracts dust. This means that it is only suitable as a care product in the winter when

there is snow.

DANGER!

1HYHUVSUD\VLOLFRQHVSUD\RQWKHHQJLQHZKLOHLWLVKRW7KLVFRXOGFDXVHD¿UH)ROORZWKHLQVWUXF-

tions on the spray can.

CAUTION:

Switch off the engine and allow it to cool down. Secure the machine to prevent it from being started

inadvertently.

CAUTION: Make sure that the star grip is securely tightened.

1) Undo the star grip and select the required position.

6.3 Adjusting the height of the handlebar

2) Note the settings available.

CAUTION:

Switch off the engine. Secure the machine to prevent it from being started inadvertently.

Start-up

15

3)You can fold the handlebar all the way forward and

therefore reduce the amount of space required by

the machine for storage purposes or when it needs

to be set aside temporarily.

DANGER!

Wearing clothing with loose sleeves runs the risk of the handlebar grip becoming caught in the

sleeve. This can prevent the gear lever disengaging. Wear appropriate clothing. It may help to set

the handlebar to a lower position.

6.4 Bristle pressure

Start-up

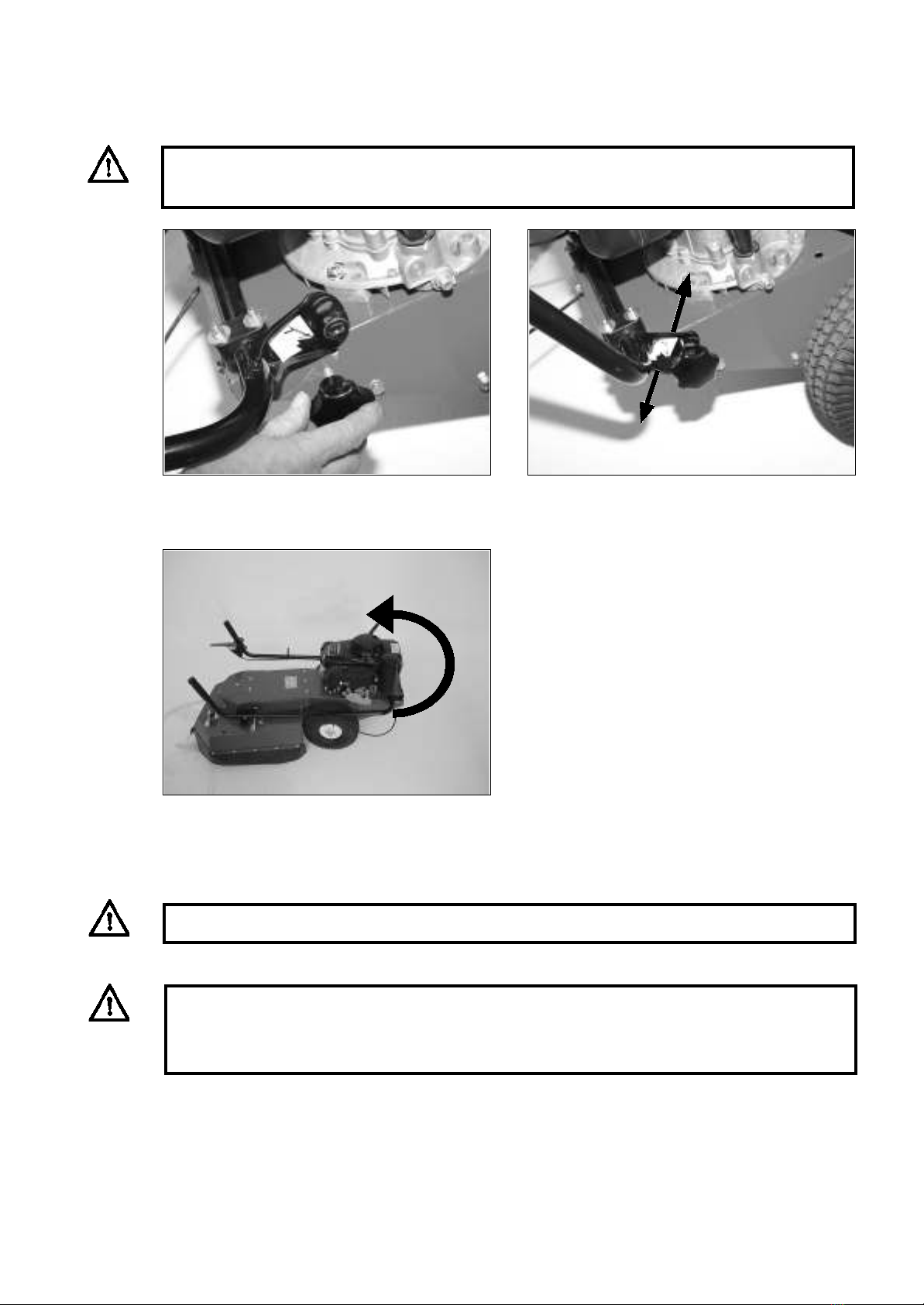

3) Remove the linchpin. Set the required height.

1) The bristle pressure can be adjusted. This is why

the height of the support wheel is adjustable.

2) Adjusting the height of the bristles

The height is adjusted by rearranging the washers.

IMPORTANT:

If you are using a badly worn brush or working on cobblestones, lower the brush by an additional

washer.

Please note: Excessive brush pressure impairs cleaning effectiveness because the bristles will be

too bent.

Reduce the pressure on the brushes after each use. Raise the brush.

4) Reinsert the linchpin.

16

6.5 Brush drive

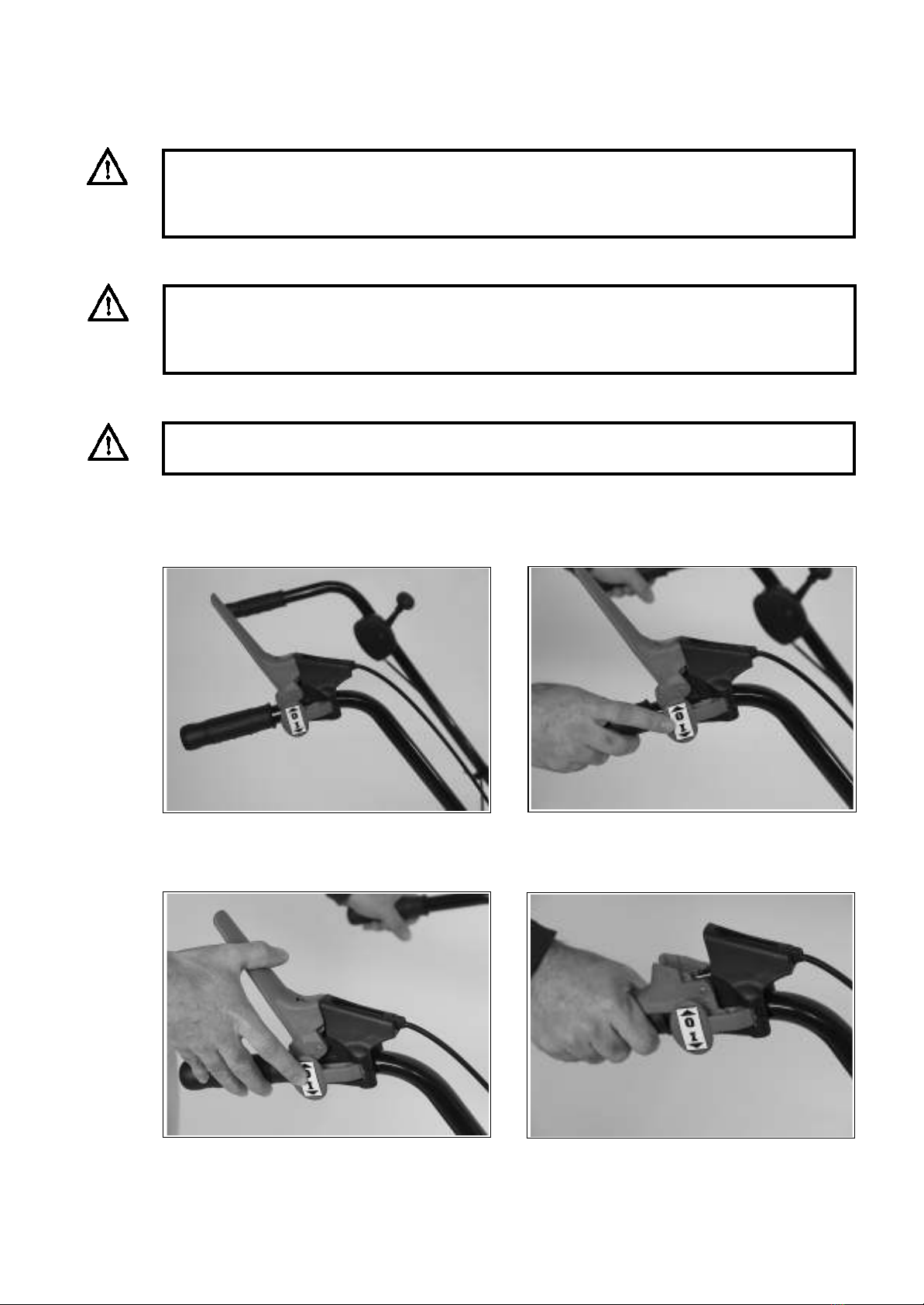

4)Operating the gear lever switches on the brush

drive.

Start-up

CAUTION:

7KHKDQGOHEDUPXVWEH¿UPO\VHFXUHGDWWKHUHTXLUHGKHLJKW

2) Unlock the lever.

17

3) Move the lever into position.

1)The gear lever for the sweeper brush drive is located

on the handlebar.

DANGER!

Wearing clothing with loose sleeves runs the risk of the handlebar grip becoming caught in the

sleeve. This can prevent the gear lever disengaging. Wear appropriate clothing. It may help to set

the handlebar to a lower position.

WARNING:

Ensure that no persons or property are located in the danger zone, as otherwise this could result in

injury or material damage. Secure the machine to prevent it from being started inadvertently.

18

6.6 tw50s steerable freewheel

Start-up

1. Engage the steerable freewheel: Insert the linchpin

through the axle only.

2)Disengagethesteerablefreewheel: Insertthelinch-

pin through the axle and the hub (e.g. for sweeping

on inclines)

WARNING:

Switch off the engine. Secure the machine to prevent it from being started inadvertently.

7KHZHHGEUXVKLV¿WWHGZLWKDVWHHUDEOHIUHHZKHHO7KLVPDNHVLWHDVLHUWRWXUQWKHZHHGEUXVK

.

6.7 Starting/switching off the engine (quick guide)

Start-up

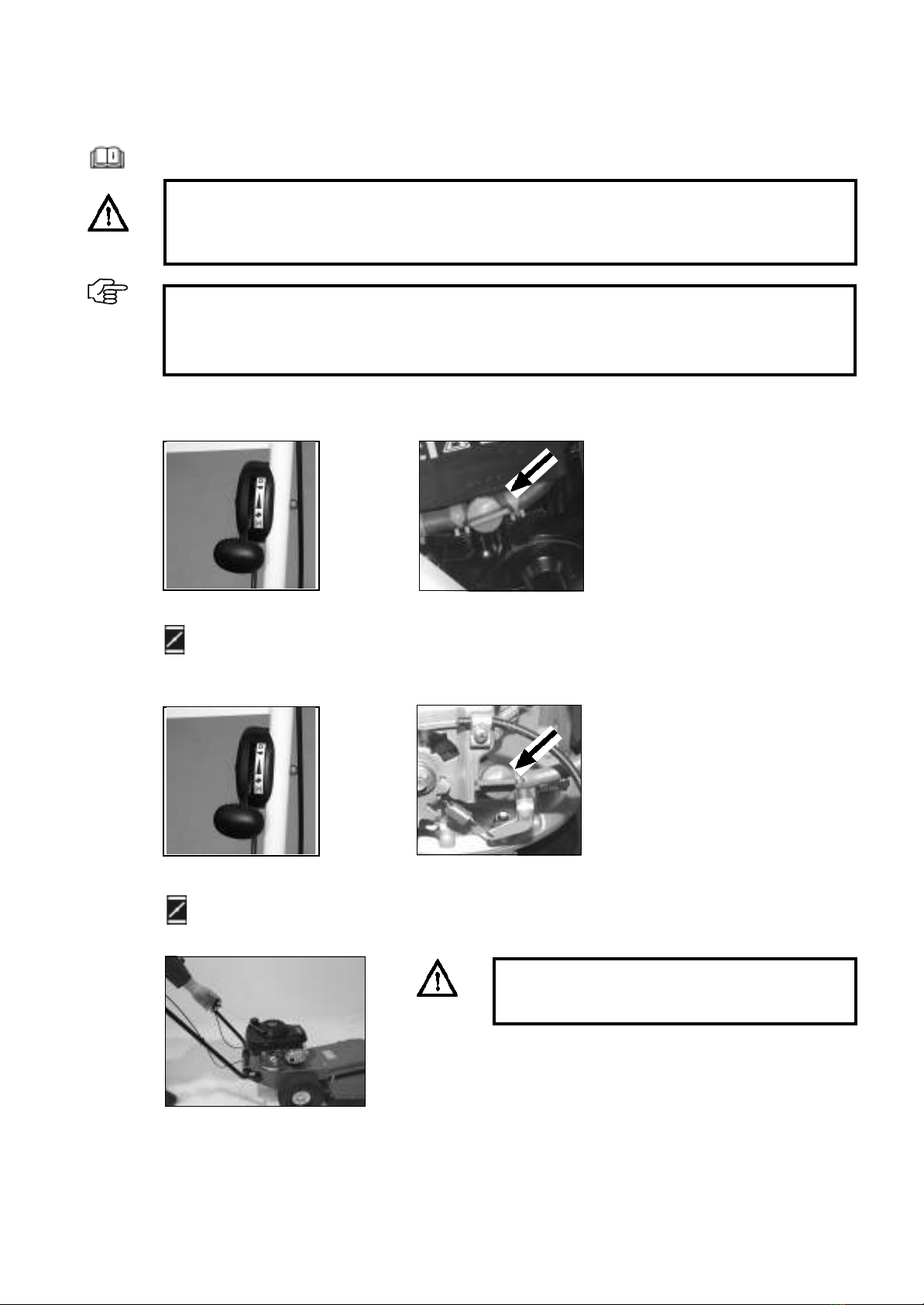

IMPORTANT:

%HIRUHVWDUWLQJWKHHQJLQHSOHDVHFKHFNWRHQVXUHWKDWWKHHQJLQHFUDQNFDVHLV¿OOHGZLWKDVXI¿FLHQW

TXDQWLW\RIRLO)RUUHDVRQVUHODWLQJWRWUDQVSRUWWKHHQJLQHLVQRWVXSSOLHG¿OOHGZLWKHQJLQHRLOZKHQ

the sweeper is delivered.

DANGER!

1HYHUDOORZWKHHQJLQHWRUXQLQFORVHGRUFRQ¿QHGVSDFHV7KHH[KDXVWJDVHVFRQWDLQSRLVRQRXV

carbon monoxide gas. Ensure that the travel drive and brush drive are switched off.

The handlebar must be securely locked at the required height.

Read the operating instructions provided by the engine manufacturer.

1. Starting the engine

1) Move the throttle regu-

lation lever to

2) Open the fuel cock (on the

right of the engine in the

direction of travel).

3) Pull on the starter cable. En-

sure that you are behind the

handlebar and outside of the

danger zone.

19

the choke position.

Briggs & Stratton

1) Move the throttle regu-

lation lever to

the choke position.

Honda

2) Open the fuel cock (on the

left of the engine in the

direction of travel).

DANGER!

Never push downa lever while pulling on the starter

cable.

2. Controlling the engine speed

Slow = Move the throttle regulation lever to

3. Switching off the engine

1) Move the throttle regu-

lation lever to .

2) Close the fuel cock (on

the right of the engine in

the direction of travel).

IMPORTANT:

Once the engine has warmed up, the throttle regulation lever must be taken out of the choke position.

The choke must not be used when the engine is warm or when the air temperature is high.

Fast = Move the throttle regulation lever to

Start-up

20

Briggs & Stratton Honda

3. Switching off the engine

1) Move the throttle regu-

lation lever to

2) Close the fuel cock (on

the left of the engine in

the direction of travel).

Briggs & Stratton

Honda

0

0

This manual suits for next models

6

Table of contents