SPEEDSTER

1003Dx

MYTEE PRODUCTS, INC | 13655 STOWE DRIVE | POWAY. CA 92064

PHONE: 858-679-1191 | FAX: 858-679-7814

WWW.MYTEE.COM

WARRANTY

Mytee Products, Inc. endeavors to provide high quality products and product support to its customers and therefore backs up

all of its new products purchased from Mytee Products Inc. (“Mytee”) or any authorized Mytee distributor/service center

with this limited warranty. This limited warranty begins on the date of the customer’s purchase and is valid and avail-

able to the original purchaser only. Mytee’s products are for commercial use only and are not intended for personal,

family or household uses.

HOWEVER, OTHER THAN SET FORTH HEREIN, MYTEE GIVES NO WARRANTY, EXPRESS OR IMPLIED, AS TO DESCRIP-

TION, QUALITY, MERCHANTABILITY, FITNESS FOR ANY PARTICULAR PURPOSE, PRODUCTIVENESS, INFRINGEMENT,

OR OTHER MATTER, OF ANY GOODS WHICH MYTEE SHALL SUPPLY. THERE ARE NO WARRANTIES WHICH EXTEND

BEYOND THE DESCRIPTION ON THE FACE HEREOF. MYTEE SHALL IN NO WAY BE RESPONSIBLE FOR THE PROPER

USE AND APPLICATION OF THE GOODS. MYTEE NEITHER ASSUMES NOR AUTHORIZES ANY OTHER PERSON TO

ASSUME FOR MYTEE ANY OTHER LIABILITY IN CONNECTION WITH THE SALE OF MYTEE’S GOODS. THIS LIMITED

WARRANTY POLICY MAY BE CHANGED OR WITHDRAWN BY MYTEE AT ANY TIME WITHOUT NOTICE

.

WEAR PARTS 90-DAY LIMITED WARRANTY: Mytee will replace all wear parts for 90 days from the date of original pur-

chase. “Wear parts” are items which wear out as a result of usage or the passage of time and are consumed despite

attempts to maintain them, such as gaskets, wheels, brass, cords, wires, electrical terminals, hoses, switches, ther-

mostats, plastisol parts, lters, bearings, brushes, solenoids, o-rings, bulbs, heating elements, castors, or other parts

deemed wear items in Mytee’s sole discretion. This warranty covers the cost of replacement only and does not cover

shipping or labor costs.

PUMP, VACUUM MOTOR AND HEATER 1-YEAR LIMITED WARRANTY: Mytee warrants that pumps, vacuum and oor

machine motors, and heaters will be free from manufacturing defects, defects in workmanship, and defects in material

for one (1) year from the date of original purchase. This warranty does not apply and is void if the pump, vacuum motor,

or heater has worn brush motors, water damage, chemical build-up, chemical damage, or evidence of abuse, neglect or

tampering. This warranty covers the cost of replacement or repair only and does not cover shipping or labor costs.

HOUSING 5-YEAR LIMITED WARRANTY: For ve (5) years from the date of purchase, Mytee warrants a percentage of the

cost of replacement of rotationally-molded housings pro-rated as follows: Mytee will pay 100% of replacement cost in

the rst year from the date of purchase, 75% of replacement cost in the second year from the date of purchase, 50% in

the third year, 25% in the fourth year, and 12% in the fth year. Replacement cost does not include the cost of shipping

or labor.

LIMITATION OF DAMAGES: THE REMEDY OF REPLACEMENT OR REPAIR OF ANY DEFECTIVE GOODS SHALL BE THE

EXCLUSIVE REMEDY UNDER ANY WARRANTY MADE BY MYTEE, WHETHER EXPRESS OR IMPLIED. IN NO EVENT

SHALL MYTEE BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES, PROPERTY DAMAGES, OR PER-

SONAL INJURIES.

All limited warranties are void for, and Mytee does not warrant in any way, any product that evidences misapplication,

improper installation, abuse, lack of maintenance, negligence in use or care, abnormal use, alteration of design, use of

incompatible or corrosive chemicals, use in a rental service, and/or servicing, installation of parts, or repairs by anyone

other than Mytee or a Mytee authorized distributor or service center.

Mytee may make changes in products it manufactures and markets at any time; these changes are made without obliga-

tion to change, retrot, or upgrade any product previously sold or manufactured. Mytee has no obligation to honor the

limited warranties set forth herein unless the original purchaser, promptly upon discovering the warranty claim and

prior to continuing to use the product, contacts Mytee or a Mytee authorized distributor or service center to describe

the claim and to receive and follow instructions for documenting and resolving the claim. In addition, the purchaser

must provide the product to which the claim applies to Mytee or a Mytee authorized distributor or service center for a

thorough inspection.

If any provision or portion of this limited warranty policy is found to be unenforceable, then the remaining provisions

and portions shall remain valid and enforceable. If any provision or portion of this limited warranty policy is found to

be limited by law, then that provision or portion shall be construed to make it effective within the bounds of law. For ex-

ample, if there are legal limitations on the duration of warranties, the warranties made herein shall be construed to have

the minimum duration required by law, or, if there are legal limitations of exclusion of remedies, the exclusions made

herein shall be construed to apply to the fullest extent possible without violating the law.

The validity, construction and performance of this warranty policy shall be governed by the laws of the State of Califor-

nia, without respect to conicts of laws principles. The exclusive jurisdiction of any legal action arising from or related

to this warranty policy shall be in the State of California and no legal action shall be commenced elsewhere.

UNPACKING THE MACHINE

Before unpacking the machine, inspect all boxes and pallets for signs of shipping damage.

Please be aware that all packages leave Mytee Products in perfect condition. Any equipment or

carton damage caused during shipping is the responsibility of the freight company, and should

be handled by ling a claim with the carrier.

H375 - Hose Hanger

E530 - (2) 12/3 50’

Yellow Safety Cord

H226 - 45O Drain Elbow

Speedster Extractor

SAFETY LABELS

The safety labels

appear on the

machine in the

locations indicated.

Replace labels if they

become damaged or

cannot be read.

WARNING: Flammable materials can cause an

explosion or re. Do not use ammable materials in

tank(s). Flammable materials or reactive metals can

cause explosion or re.

WARNING LABEL- Located on back. Label warns

operator of safe practices of equipment.

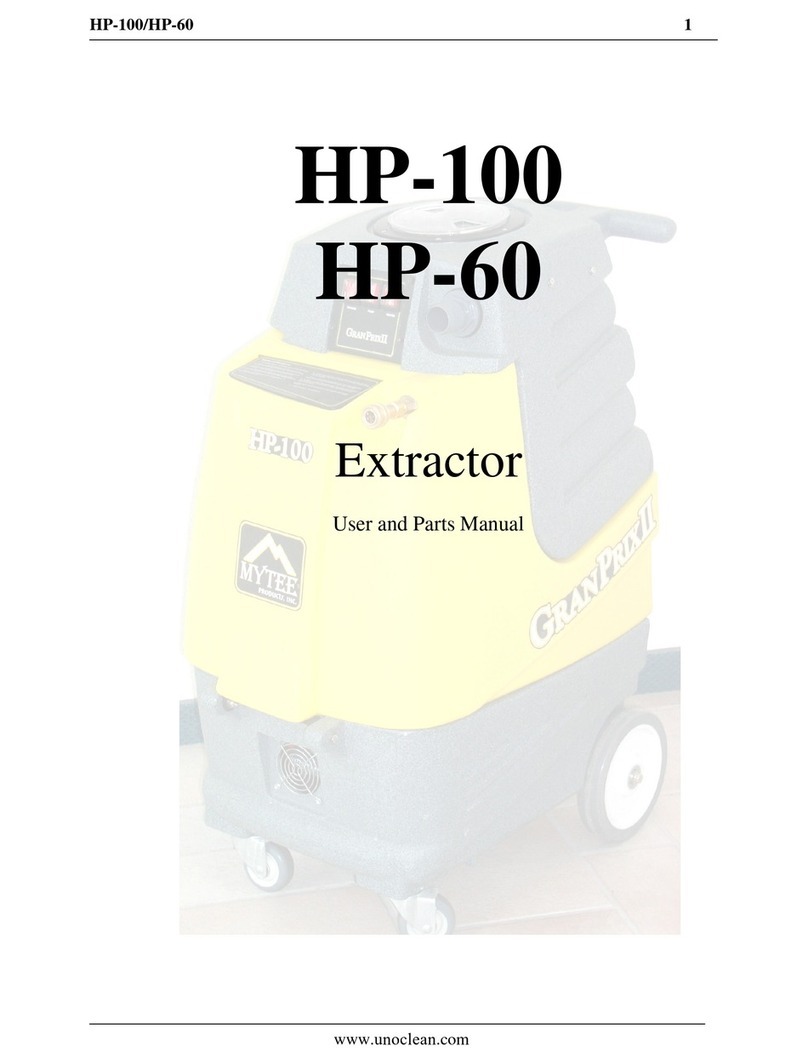

MACHINE COMPONENTS

Recovery

Tank

Solution

Tank

Motor

Housing/

Base

Vacuum

Hose

Connector

Solution

Hose

Connector

Pressure

Regulator

Prime Valve

SETUP

1. Open lid of solution tank. Fill solution tank with

water or approved cleaning agent.

WARNING:

Flammable materials can cause an

explosion or re. Do not use ammable solutions or

materials in tank(s).

FOR SAFETY: When using machine, follow mixing

and handling instructions on chemical containers.

ATTENTION: If using powdered cleaning chemicals,

mix prior to adding.

2. Attach solution hose. (Located front of machine.)

NOTE: Make sure the quick disconnects snap

together rmly. As you do this, always inspect

hoses for cracks or fraying. Do not use if hoses are

damaged.

3. Attach other end of solution hose to wand.

4. Attach vacuum hose to recovery tank.

5. Plug machine’s cord into a grounded wall outlet.

FOR SAFETY: Do not operate machine unless cord is

properly grounded.

FOR SAFETY: Do not operate machine with the use

of an extension cord.

PRE-OPERATION

1. Vacuum carpet and upholstery and remove

other debris.

2. Perform MACHINE SETUP procedures.

3. Inspect power cord for damage.

OPERATION

7. Turning machine on.

A. Turn pump switch on.

B. Pull up on power prime lever for 30 seconds.

This will prime the pump.

C. Pull up on wand lever to release air in the

line. Hold lever until you have a steady ow of

water coming out of the wand.

D. Once pump is primed and you have pressure

in the solution line, turn on heater switch(s) (if

model is equipped with heater) and wait a few

minutes for water to heat up.

E. Once water is heated, turn on vacuum

motors and begin cleaning.

NOTE: When cleaning upholstery, always check

manufacturer’s cleaning instructions.

DRAINING RECOVERY TANK

FOR SAFETY: When servicing machine, unplug cord from

wall outlet.

1. Turn machine off and unplug power cord.

2. Remove solution & vacuum hose.

3.Attach 45º-drain elbow to dump valve and lift up drain

valve lever to empty recovery tank.

TIPS

1. Work away from outlet and power cord to prevent cord

damage.

2. Use a recommended foam control solution in the

recovery tank to prevent vacuum motor damage.

Periodically check for excessive foam buildup in solution

tank, and recovery tank.

3. To clean heavily soiled areas, repeat cleaning path from

different direction.

4. When ball oat shuts off vacuum, it is time to empty the

dirty water from the recovery tank, and rell solution tank.

5. After cleaning, relieve water pressure from tool before

disconnecting hose. Squeeze trigger for ve seconds

after turning main power switch off.

MAINTENANCE

MACHINE MAINTENENCE

To keep machine in good working condition, simply follow

machine’s daily and weekly maintenance procedures.

Check valves and relief valves should be replaced

annually.

FOR SAFETY: When servicing machine, unplug cord from

wall outlet.

DAILY MAINTENANCE

1. Empty and rinse out solution tank thoroughly.

2. Wipe off power cord and check for damage, replace if

necessary. Coil cord neatly after use.

3. Clean machine with an all purpose cleaner and damp cloth.

WEEKLY MAINTENANCE

(EVERY 20 HOURS OF OPERATION)

1. Flush solution system with Mytee system

maintainer to dissolve normal chemical buildup.

a. Pour 7.5L (2 gal) of hot water 60°C

(140°F) into solution tank. Add Mytee

system maintainer according to mixing

instructions on bottle

FOR SAFETY: When using machine, follow

mixing and handling instructions on chemical

containers.

b. Operate machine for one minute.

c. Shut off machine and allow remaining

solution to break down chemical buildup

overnight.

d. Next day, spray out remaining

solution and ush system with 11L (3gal)

of clean water.

2. Inspect vacuum hoses for holes and loose

cuffs. Drain and dry the vacuum hose as well.

3. Inspect spray pattern for clogging. If

clogged, remove spray tips and soak them in

a recommended liquid neutralizer for up to six

hours. To remove spray tip, twist spray tip body

counter-clockwise.

4. Lubricate wheels with water resistant oil.

5. Inspect machine for water leaks and loose

hardware.

6. Remove oat shut-off screen from recovery

tank and clean.

NOTE: The oat shut off screen is not glued on.

Simply pull it off.

STORING MACHINE

1. Before storing machine, be certain to

completely drain and rinse tanks of all water and

solution.

2. Drain and dry the vacuum hose as well, using

the drain hose provided

3. Store machine in a dry area in the upright

position.

4. Open recovery tank cover to promote air

circulation

ATTENTION: Do not expose to rain. Store indoors.

ATTENTION: If storing machine in freezing

temperatures, be sure that machine and solution

system are completely drained and dry.

!

!

!

Instruction Manual

& Safety Guide