Tietzsch VARIOSAFE EXM 25 User manual

Rudolph Tietzsch GmbH & Co. KG

Willringhauser Straße 18

D-58256 Ennepetal

Telefon +49 2333-75989

Telefax +49 2333-75257

E-Mail: [email protected]

www.tietzsch.de EXM_BA_12-10

User Instructions

VarioSafe EXM 25

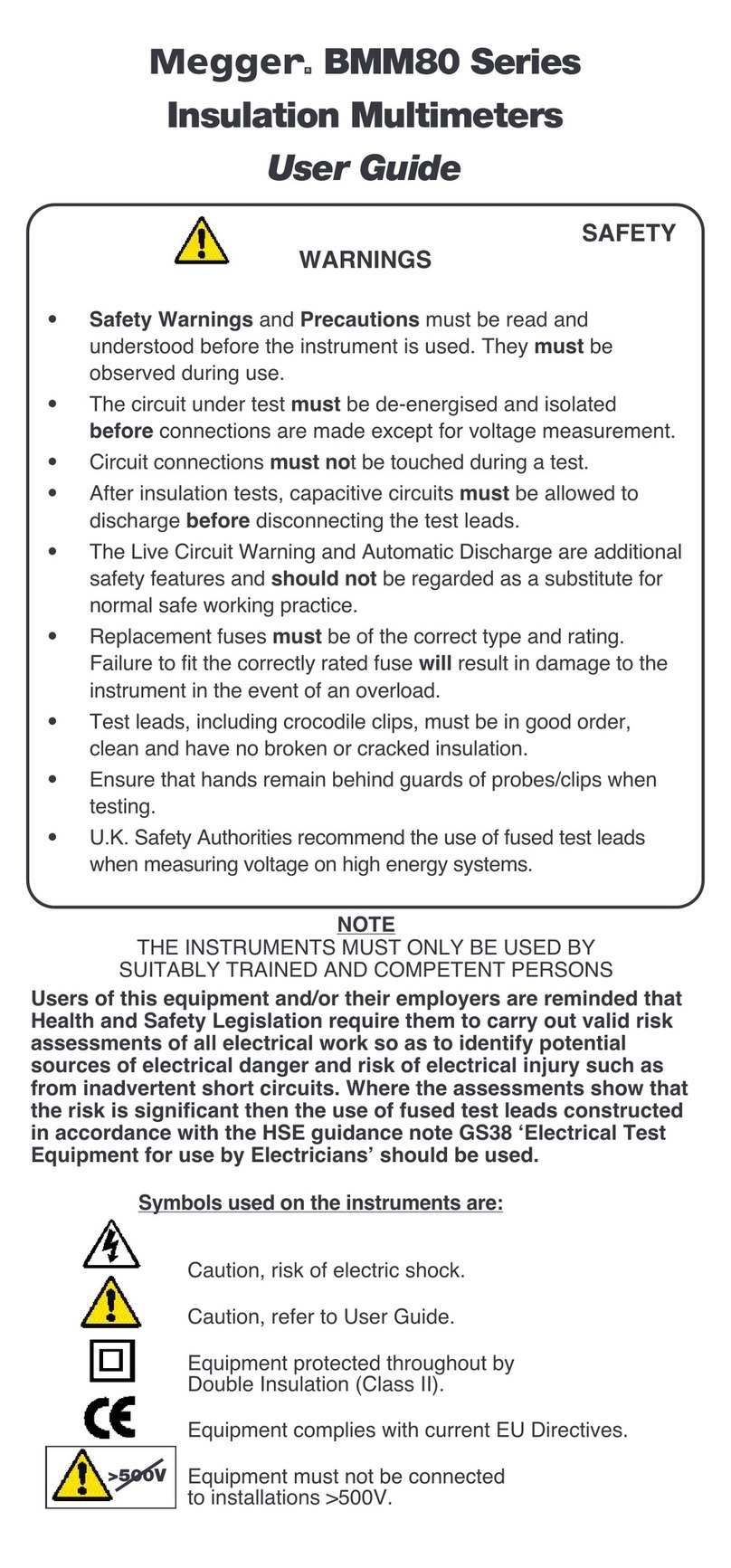

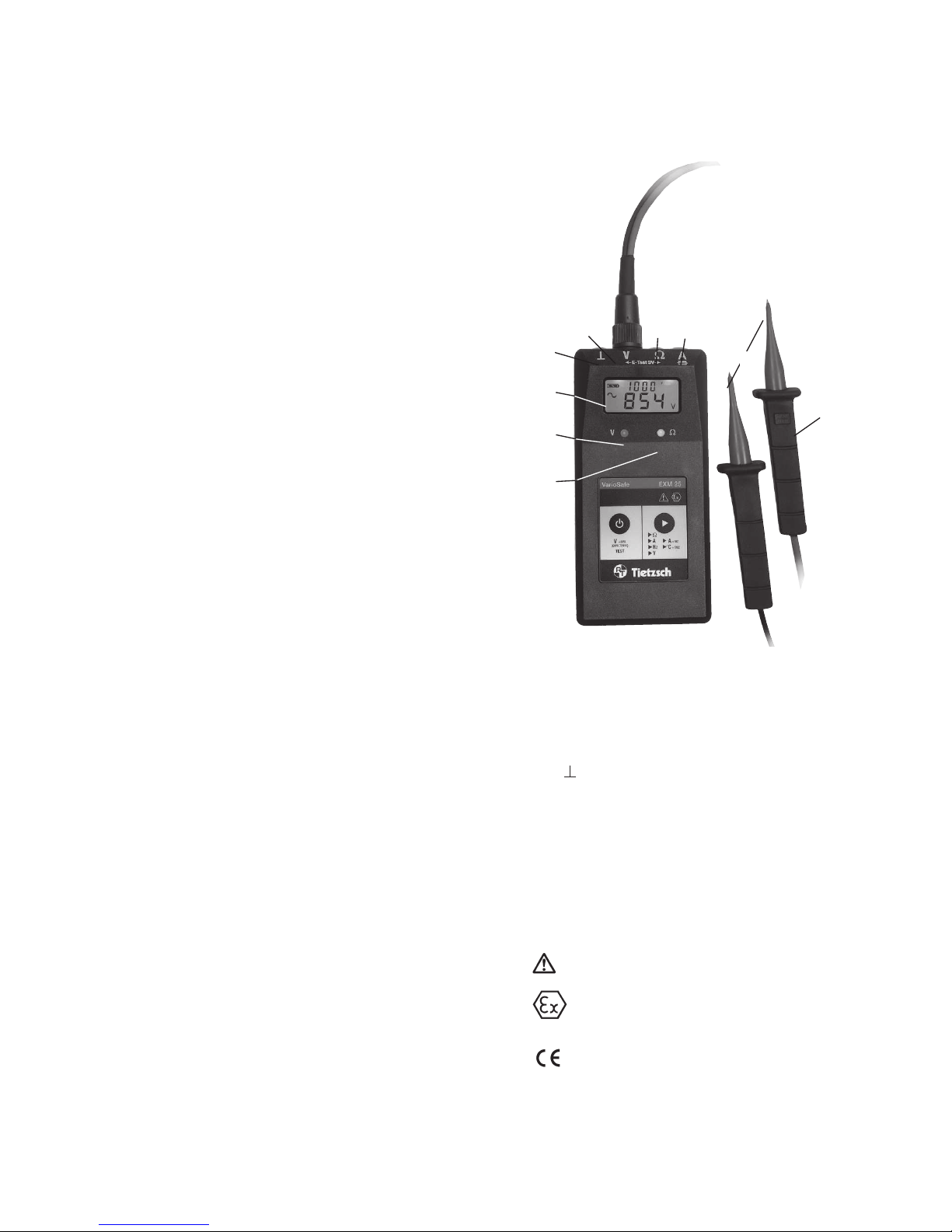

Symbols on the instrument

Attention! Observe user instructions!

EC-conformity

16

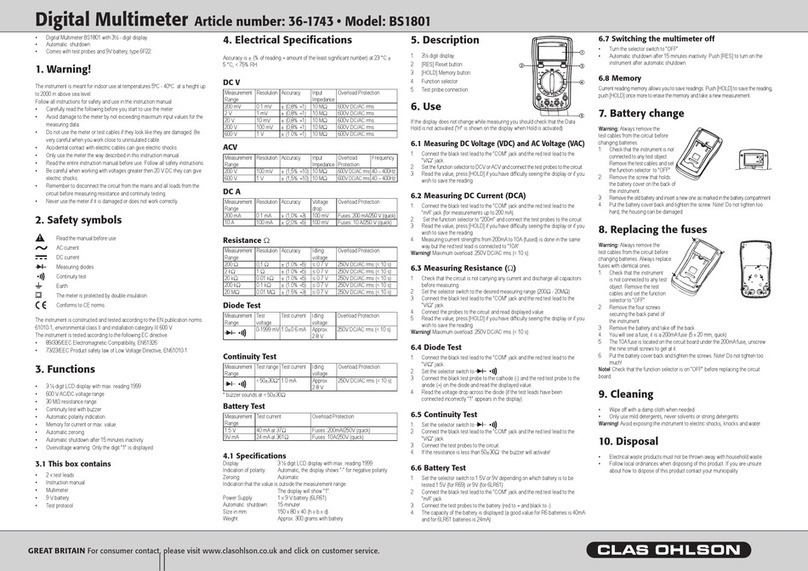

1 Test electrodes of voltage measuring line

(red conductor + /black conductor -)

2 Button DATA-HOLD

3 LED Ω (green): 0 ... 10 kΩ

4 LED Volt (red): 12 - 1000 V

5 LCD display

6 -socket, black standard socket

7 7-pin universal connector for voltage meauring

lines, temperature transmitter, clamp-on

ammeter and power supply unit

8 Ω-socket, red standard socket for resistance

measurements

9 A-socket, blue standard socket

fuse socket for current measurements

1

4

3

5

7 8 9

6

2

Ex marking:

Approved for potentially explosive atmospheres

in accordance with ATEX (EN 60079-0 and EN

60079-11) see sectionl 5.1

17

1. Application

The VarioSafe EXM 25 is an intrinsically safe multime-

ter which can be used in areas with a potentionally

explosive atmosphere in accordance with ATEX (EN

60079-0 and EN 60079-11) and EN/IEC 61010 for vol-

tage, resistance, current, frequency measurements

with measurement accessories for measurement of

temperature and high current.

2. Safety Precautions

When used for its intended purpose, safety of the

operator, as well as that of the instrument, is assured.

The voltage measurement tips contain moulded

multipliers within both test prods. They are extreme-

ly safe and comply with overvoltage category CAT IV.

In order to maintain awless technical safety condi-

tions, and to assure safe use, it is imperative that you

read these operating instructions thoroughly and

carefully before placing your instrument into service,

and that you follow all instructions contained

therein.

†

The device may only be used in the designated

Ex zones (section 5.1) and inside of the safety-

related limit values (section 5.2).

†

Before starting resistance measurements make

sure that the test object is at zero-potential.

†

Perform zero-potential tests at most up to the

following voltages:

Ex-class II up to 690 V, Ex-class I up to 1000 V and

with measurement tip 72011 up to 2000V.

†

Before putting into operation for the rst time and

at every day of use the VarioSafe EXM 25 has to be

checked at a known voltage source - e.g. a 230 V

socket to ensure that it works properly and

faultlessly (see display test and self test). If

indication of one or several systems fail in the

course of performing the self test according to

section 3, if function standby is not indicated or if

the device is damaged, the VarioSafe EXM 25 must

not be used again.

†

Maintainance is only allowed by the manufacturer

or explicitly authorised repair shops

(see section 7).

†

The measurement tips with extended (12 mm)

not insulated test electrodes are designed for use

at untouchable machinery materials. You may use

the extentions in EX-areas only when an uninten-

tional connection between conductive parts

(e.g. by short-circuit between test electrodes) can

denitely be excluded.

18

3. Putting into operation

3.1 Battery

Your instrument is already supplied with an energie-

block. Solely use the following energyblocks:

NiMH accumulator for class I and II T4:

type EXM 72025 (rechargeable)

Lithium battery for class I and II T6:

type EXM 72026 Li/T6

Attention!

Please observe section 6 before initial startup or

after your device has been in storage for a long

period of time.

3.2 Testing display and function

At every day of use the VarioSafe EXM 25 has to

be checked to ensure that it works properly and

faultlessly.

Self test 1 (Display test):

Press and hold button „ON/OFF“.All display seg-

ments light up on the display, additionally the V-LED

and the Ω-LED light up. When you release button

„ON/OFF“, the value 000 ... 001 V is indicated on the

display.

Self test 2 (Voltage measuring line):

Connect and lock the voltage measurement tips

type 72010/11 to the 7-pin universal connector.

Switch-on the device. Display: 000..001 V, in the

upper display line 1000 or 2000V. Put the test

electrodes, one after another, inclined 5 mm into the

W-socket.

Display shows‘Test’ and ‘rdy’ and green LED lights

up.

Note! In case the display continues showing 000 V

the measurement tip is damaged, please exchange.

Self test 3 (Voltage indication):

Check functions at a known voltage source - e.g. a

230 V socket.

Self test 4 (Resistance measurement):

Put the standard test lines into the Ω- and -socket.

Adjust the device to Ω, display: OL kΩ, hold test

prods together, display indication needs to be about

0.0 Ω and the green LED needs to light up.

Attention!

If indication of one or several systems fail in the

course of performing the self test, if function stand-

by is not indicated or if the device is damaged, the

VarioSafe must not be used again.

19

4. Measuring and testing

4.1. General information

The upper display line

shows currently selected

measurement range.

When this indication

is ashing you have to

connect special accesso-

ries e.g. TMZ clamp-on

ammeter.

The lower display line

shows the actual

metered value.

The instrument is switched o automatically

approximately 60 seconds after the last

measurement in order to extend battery life. In the

display the indication„o“ appears (exception: see

frequency measurements). The backlight turns o

when no measurement result is applied or when the

battery is low.

With the ON/OFF button engaging the

VarioSafe EXM 25 to voltage, call the

display test and switch-o the device.

With the function button you can select

the designated measurement range:

Function upper

display line

Voltage with tip EXM 72010 1000 V

Voltage with tip EXM 72011 2000 V

Voltage, automatic range mV, V AuTo

resistance

Ω

current I

current

with clamp-on ammeter

I ashes*

frequency FrE

temperature with TMZ T ashes*

* When the measurement ranges are indicated by a

ashing symbol the connection of special

accessories is necessary, e.g. a clamp-on ammeter or

the temperature transmitter

leading sign

battery status (see section 6)

►

4.2 Testing voltage and polarity

Attention!

Connect the voltage measurement tips to the

7-pin universal connector only when the device is

switched-o. Switch-on the device not until they are

locked and select rang if necessary.

Note!

If Hold appears permanently, probably the 7 kV tip

has been attached when the device was switched-

on. Put both test prods with safe contact onto the

metering point and the voltage value is indicated

in the lower display line. At a voltage of 12 V ashes

the red LED and button functions are locked.

Note!

Because of integrated multipliers the device indi-

cates few mV while in open-circuit operation, this

has no inuence on the result of measurement.

1000 / 2000 V voltage range (1000 V) / (2000 V)

The voltage range adjusts automatically to the used

DATA-HOLD measurement tip type 72010 or 72011.

The measurement range serves for a fast detection

of measurement values between 0 – 1000 / 2000 V

without decimal places.

The display range of the VarioSafe EXM 25 extends

to 1150 V AC / 1600 V DC with 72010 and 2 kV with

72011. Observe the safety precautions (see section

2) for Ex-areas.

Indication of polarity

Type of voltage is indicated by the symbols

~ and – . Direct voltage: is minus applied to the test

prod with Hold button, the leading sign„-“ appears,

is plus applied no leading sign appears in front of

the indicated value.

HOLD function

The maximum voltage value can be„stored“ on the

display when activated the button„HOLD“. The value

is recorded for approx. 30 seconds or until you press

button„HOLD“ again. The Hold-function is stopped

when again a voltage is impressed.

Note! When the measured value does not vary for

2 sec, then the maximum value is recorded.

20

Automatic voltage range (AuTo)

The voltage range adjusts automatically to the used

voltage measurement tip type 72010 or 72011.

The measurement range serves for a fast detection

of measurement values between 1 mV – 1000 /

2000 V, the optimal measurement range is selected

automatically.

4.3 Resistance measurements (Ω)

Before taking any resistance measurements always

check that the test object is at zero-potential.

Connect 4 mm standard test lines to the Ω- and

-socket. Adjust the device to Ω. Ohm is indicated in

the upper display line.

Note!

The arrow signalizes „out of measurement range“.

The measurement range serves for a denite

determination of impedances of 0,1 Ω – 20 MΩ.

A selection between Ω-, kΩ- and MΩ ranges occurs

automatically after applying to the impedance.

The green LED signalises resistance values that a

lower than 10 kΩ.

4.4 Current measurement (I)

Attention!

You may perform current measurement in Ex-areas

only in measuring circuits with peak values of

maximum 50 V.

You may only measure currents up to maximum 2 A.

Connect 4 mm standard test lines to the A- and

-socket.

The measurement range serves for measuring

AC/DC currents in the range of 1 mA – 2 A.

A selection between mA and A occurs automatically

after attaching the test prods.

The moulded fuse activates with currents of more

than 2 A.

The fuse can only be changed by the manufacturer

(Service section 7).

4.5 Current measurement with clamp-on ammeter

MZ 1005 (ashes)

Measurements with MZ 1005 are only permissible

in Ex I-areas.

Please observe the separate user instructions of the

clamp-on ammeter MZ 1005. Connect the MZ 1005

to the 7-pin universal connector.

Within the clamp-on ammeter range you can mea-

sure AC/DC currents between 0,1 and 1000 A, the

optimal measurement range is selected automati-

cally.

21

22

4.6 Frequency measurements (FrE)

Connect the voltage measurement tip type 72010 to

the 7-pin universal connector.

The measurement range serves for measurements of

frequencies in the range of 0,1 Hz – 10 kHz with

voltages > 5 V. A selection between Hz and kHz

occurs automatically after attaching the test prods.

Note!

While the device is in open-circuit operation the

display may show 0,00 Hz/kHz ±1 digit.

With low frequencies the measurement signal needs

to be placed for a few seconds before it indicates a

reliable value.

The automatic shout-down can be deactivated by

interfering signals, e.g. because of low frequencies

with attached measurement tips.

4.7 Temperature measurements with TMZ 25

(T ashes)

Measurements with the intrinsically safe TMZ 25 and

a Fe-CuNi-sensor are only permissible in Ex I- and Ex

II-areas. Connect the TMZ 25 to the 7-pin universal

connector and plug temperature sensor on the TMZ

until it’s catched.

With the TMZ 25 you can measure temperatures bet-

ween – 80 and + 600 °C. The optimal measurement

range is selected automatically.

Note!

With the universal sensor indication on the display is

rst readable after approx. 30 s, with surface sensors

after approx. 10 s. Special sensors can be delivered.

23

5. Characteristic Values:

5.1 Identication marking / Ex zones

EC-Type Examination Certicate

DMT 03 ATEX E 013

II 2G Ex ib IIC T4/T6

I M2 Ex ib I

5.2 Safety-related limit values

Intrinsically electric circuits

Voltage (by 50 V tip) 2 A

Internal inductance Li < 5 μH

Voltage with measurement tips:

Type EXM 72010, 72011, 72012

Class IIC AC/DC ≤ 690 V with tip 72010

Class IIB AC/DC ≤ 690 V with tip 72010

Class I AC/DC ≤ 1000 V with tip 72010

Class I AC/DC ≤ 2000 V with tip 72011

Resistance ranges maximum values in case of fault:

Voltage 3,6 V

Current 4 mA

Maximum permissible external

capacitance/inductance:

Class IIC 200 mF/1000mH

Class IIB 3000 mF/1000mH

Class I 3000 mF/1000mH

Frequency 2 up to 10 kHz

Current (up to 50 Vpeak) 2 A

internal inductance Li < 5 μH

Energie source (moulded design):

NiMH accumulator

Type EXM 72025/T4

Nominal voltage DC 8,4 V

Maximum voltage U011,2 V

Temperature range T4

Lithium battery

Type EXM 72026 Li/T6

Nominal voltage DC 3,6 V

Maximum voltage U03,9 V

Temperature range T6

Temperature with TMZ 25:

-80°C <TA< +600°C

Curent with clamp-on ammeter type MZ 1005:

(solely for class I)

AC/DC 1000 A

Frequency up to 500 Hz

24

5.3 Technical data

Digital display:

Type 7-segment-gures,

2 lines, backlight

Display range 0 ... 1999 digit

Bleeder indication „OL“ indicated

Electromagnetic compatibility

EMV requirements DIN-EN 61326

Ambient conditions

Operating temperature -10 ... + 40°C

Mechanical construction

Casing impact resistant antistatic

plastic housing (R < 109Ω ) with

unbreakable display cover

Protection

category IP 54

Circuit points 3 standard jacks, thereof

1 fuse socket

7-pin universal connector

Weights approx. 350 g (incl. battery)

Measurement ranges

automatic range connection

1000 V AC/DC with 72010, xed range

2000 V AC/DC with 72011, xed range

Auto- range (solely 72010/11)

AC 10, 100, 1000 V (1150 V) TRMS up to 500 Hz

DC 1, 10, 100, 1000 V (1600 V)

200, 2000 Ω (diode test) 20, 200 kΩ, 2 MΩ

20 MΩ

AC/DC 1000 mA, 2 A

(solely with clamp-on ammeter)

AC/DC 100, 1000 A

200, 2000 Hz,

10 kHz, with voltage measurement tip 72010

(solely with TMZ) 150 °C

600 °C

Resolution

1 V

0,01 ... 1 V

0,001 ... 1 V

0,1... 1000 Ω

10k Ω

1 ... 10 mA

0,1 ... 1 A

0,1 ... 1 Hz

0,01 kHz

0,1 °C

1 °C

Limiting deviation

at +10...30°C

±1% +2 digit

±2,5% +5 digit

AC ±1% +2 digit

DC ±0,5% +2 digit

±1% +5 digit±

5% +10 digit

±1% +2 digit

±1,5% +2 / 3digit

±1% +2 digit±

3% +2 digit

±1,5% +3 digit±

1,5% +2 digit

On/O-button / Display test

Function taster

Function returns to the 1000 V (2000 V) -range, see above

25

6. Maintainance

The EXM is completely maintainance-free except for

ist own energy source (see section 6.1). Nevertheless,

for safe operation observe the following information:

The VarioSafe is to be stored in a dry place.

The plastic housing can be cleaned with a cloth dam-

pened with alcohol (isopropyl) or soapy water.

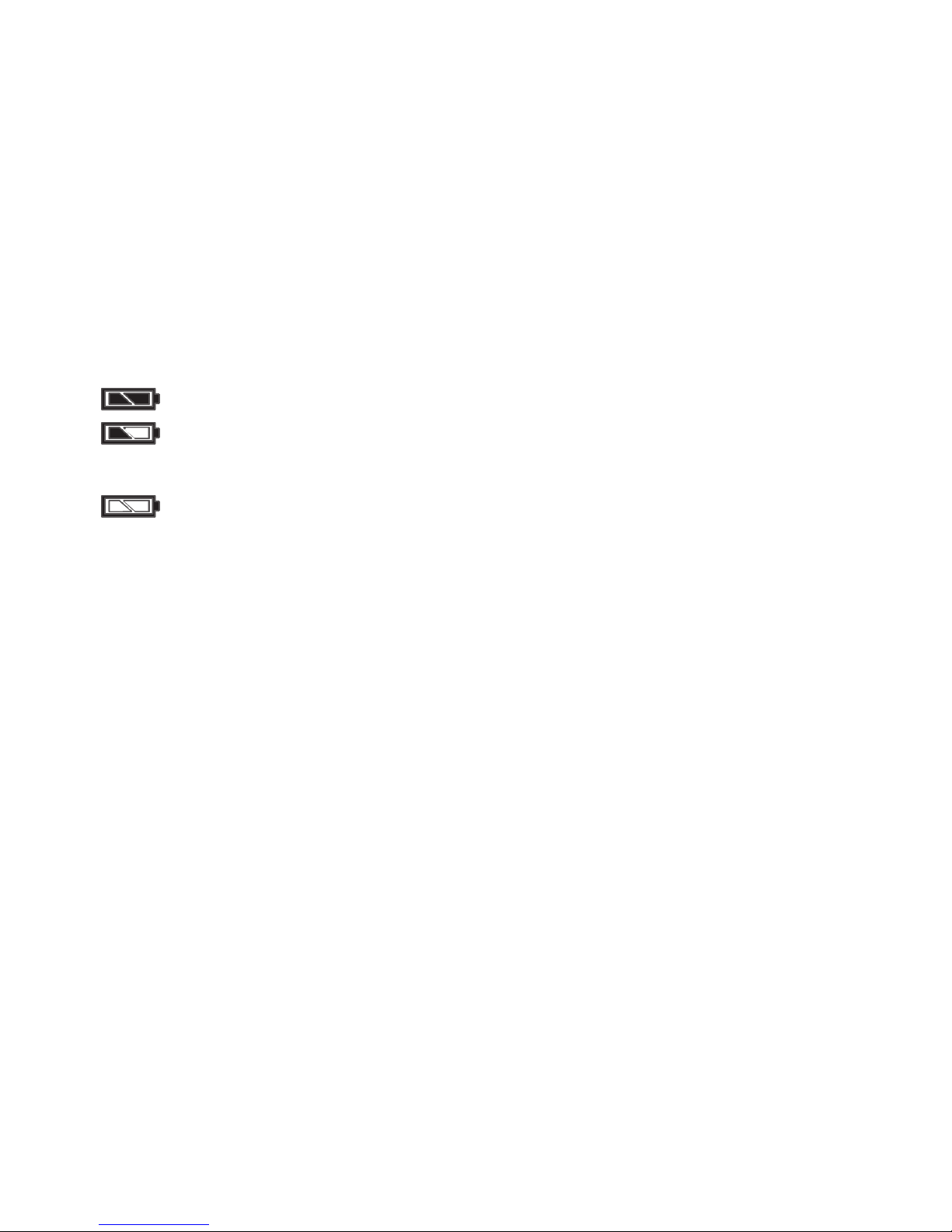

6.1 Battery status

The latest status of the battery or the accumulator is

symbolised by a 3 stage battery symbol in the display.

=

battery full

=

battery half-full.

Many measurements still

can be performed.

=

batterie empty.

The backlight deactivates

automatically.

Attention!

When the empty battery symbol ashes, taking

measurements is not possible anylonger. The battery

needs to be exchanged or the accumulator recharged

immediately.

6.2 Change battery

The change of battery is possible in Ex-areas.

Solely use the following energyblocks:

Lithium battery for class I and II T6:

type EXM 72026 Li/T6

NiMH accumulator for class I and II T4:

type EXM 72025/ T4 (rechargeble)

26

6.3 Recharge battery

Attention!

Recharge accumulators outside of Ex-areas.

Recharging occurs with the power supply unit NG4

without removing the accumulator from the EXM:

The NG4 is connected with the 7-pin universal

connector of the EXM and put into the 230 V/50 Hz

socket. Charging normally takes 14 hours.

Note!

Accumulators were only shortly charged by the

manufacturer, so that it’s necessary to perform a

charging (approx. 24 hours) before initial startup.

This applies as well to longer periods of storage

(more than 6 months). Full capacitance of NiMH

accumulators ist rst reached after 2 - 3 cycles of

charging and discharging.

For preservation of full capacitance the accumula-

tors should not be recharged until they are empty

(BAT symbol = maximum half box). The accumulator

suers damages with frequent supercharging.

6.4 Storage

The VarioSafe is to be stored in a dry place in tempe-

ratures of -20°C to +80°C. If the unit is to be stored

for a lengthy period of time the battery should be

removed and the unit packed in dust-tight packing.

7. Repair

Repairing is only allowed by the manufacturer or

explicitly authorised repair shops.

In case of damages at the VarioSafe EXM 25, in case

of failure of the function test according to section

3.2 or for a detailed inspection and calibration

please contact:

manufacturer (address see page 1) with a

description of failure.

27

8. Accessories / Spares

Leather bag EXMLED:

The case for the EXM and the test cables is designed

in such a way that the unit does not have to be

taken out for measurements.

Using the additional lugs and push-buttons on the

shoulder strap and case the unit can be secured in a

comfortable position to facilitate readings.

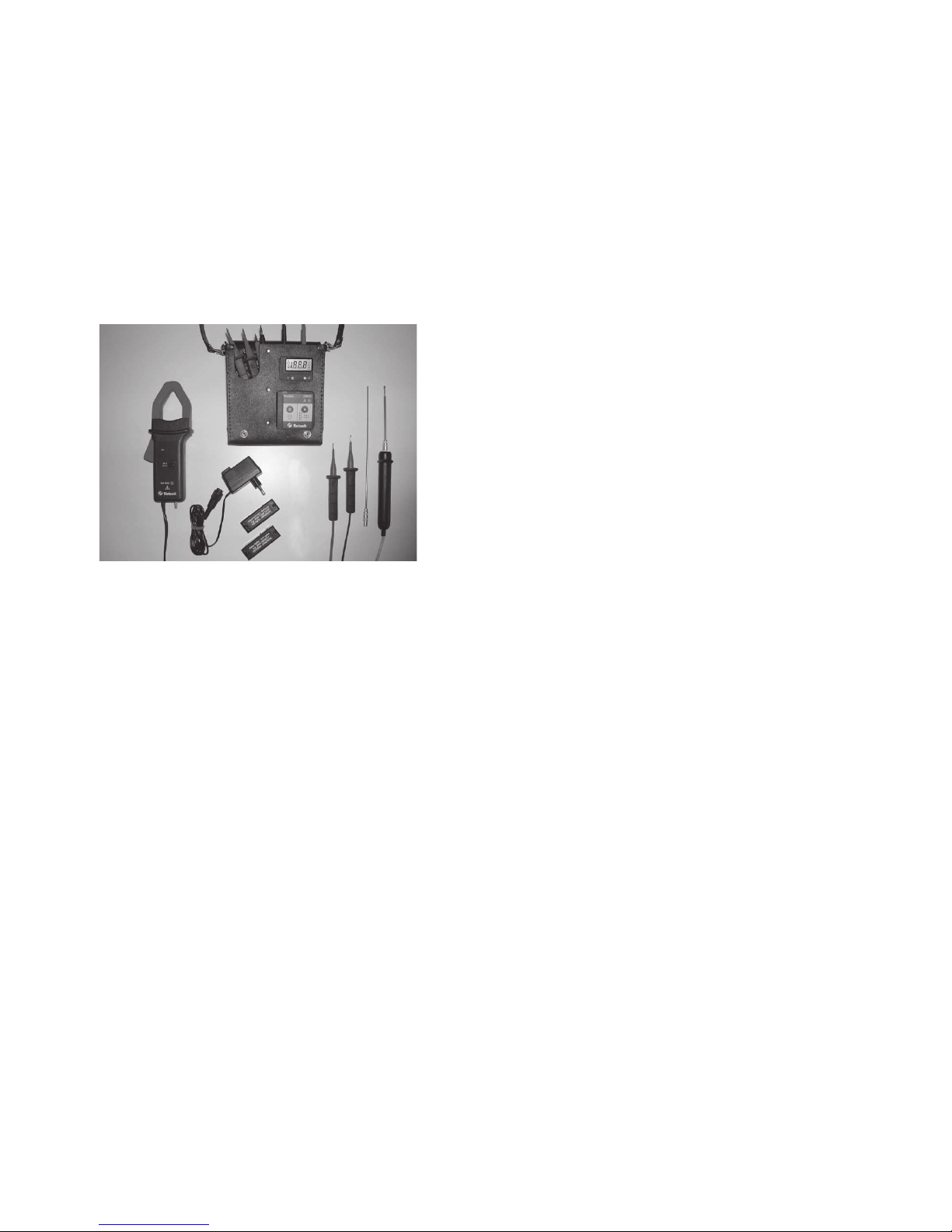

Clamp-on ammeter MZ 1005

Clamp-on ammeter for current measurements of

0,1 – 1000 A in Ex – I areas.

Power supply unit NG64 for charging the

accumulator

NiMH accumulator AK72025/T4

Lithium battery LB 72026Li/T6

Temperature transmitter TMZ 25

For temperature measurements between – 80 and

+ 600 °C in Ex-I and Ex–II areas with universal sensor

EXMTFU or surface sensor EXMTFO

Voltage measurement tips

SPA up to 690 V Ex II and 1000 V Ex I:

voltage measurement tips with DATA-HOLD button

EXM 72010 standard with short test electrodes

EXM 72010-L with large test electrodes *

SPA HS2 up to 2000 V Ex I:

EXM 72011* HS- voltage measurement tips 2 kV

*Attention!

Please observe the particular security advice (see

section 2) for extended measurement tips (12 mm)

with not insulated test electrodes.

Quick user guide VarioSafe EXM 25

This quick user guide serves für a quick start. In regard

of your own safety please observe safety-related Ex-

characteristic values and for further information the

detailed user instructions.

On/O/test Select function

28

Attach tips or accessories

1

Switching-on and self-test

2

* When the measurement ranges are indicated by a ashing

symbol the connection of special accessories is necessary, e.g.

clamp-on ammeter or temperature transmitter.

The upper display

line shows currently

selected measurement

range.

The lower display

line shows the actual

metered value.

battery status

leading sign

Function upper

display line

Voltage with tip EXM 72010 1000 V

Voltage with tip EXM 72011 2000 V

Voltage, automatic range mV / V AuTo

resistance

Ω

current I

current

with clamp-on ammeter

I ashes*

frequency FrE

temperature with TMZ T ashes*

Select range/function

3

Voltage Resistance Current

Ex-Group 0,1Ω - 20 MΩ 1 mA - 2 A

IIC ≤ 690 V

IIB ≤ 690 V Attention: At first Attention: Up to

I ≤ 1000 V check voltage-free max. 50 V only!

Temperature with TMZ parts!

Current with MZ

Other manuals for VARIOSAFE EXM 25

1

Table of contents