Timber Tuff Tools TMW-84 User manual

Foot-Operated Kindling Splitter

OWNER’S MANUAL

WARNING:

Carefully read and understand all ASSEMBLY AND OPERATION INSTRUCTIONS

before operating. Failure to follow the safety rules and other basic safety precautions

may result in serious personalinjury.

Item# TMW-84

20200728

Thank you very much for choosing this product! For future reference, please complete

the owner’s record below:

Model: TMW-84 Purchase Date:

Save the receipt, the warranty, and these instructions. It is important that you read the

entire manual to become familiar with this product before you begin using it.

This product is designed for certain applications only. The manufacturer cannot be

responsible for issues arising from modification. We strongly recommend that this

product not be modified and/or used for any application other than that for which it was

designed. If you have any questions relative to a particular application, DO NOT use the

product until you have first contacted us to determine if it can, or should, be performed

on the product.

For technical questions, please call 1-218-943-6290.

INTENDED USE

Timber Tuff’s TMW-84 Foot-Operated Kindling Splitter is the easy way to split wood. It is

designed with a step ratchet and handles logs up to 18” long and 10” in diameter. It

easily splits wood using the power of your foot.

GENERAL SAFETY RULES

WARNING: Read and understand all instructions. Failure to follow all instructions

listed below may result in serious injury.

CAUTION: Do not allow persons to operate or assemble this Foot-Operated

Kindling Splitter until they have read this manual and have developed a thorough

understanding of how the Foot-Operated Kindling Splitter works.

WARNING: The warnings, cautions, and instructions discussed in this instruction

manual cannot cover all possible conditions or situations that could occur. It must be

understood by the operator that common sense and caution are factors that cannot be

built into this product, but must be supplied by the operator.

SAVE THESE INSTRUCTIONS

WORK AREA

•Keep work area clean, free of clutter, and well lit. Cluttered and dark work areas can cause

accidents.

•Keep children and bystanders away while operating a Foot-Operated Kindling Splitter.

Distractions can cause you to lose control, so visitors should remain at a safe distance from the

work area.

•Be alert of your surroundings. Using a Foot-Operated Kindling Splitter in confined work areas

may put you dangerously close to sharp tools and rotating parts.

PERSONAL SAFETY

•Stay alert, watch what you are doing, and use common sense when using a Foot-Operated

Kindling Splitter. Do not use a Foot-Operated Kindling Splitter while you are tired or under the

influence of drugs, alcohol, or medication. A moment of inattention while operating a

Foot-Operated Kindling Splitter may result in serious personal injury.

•Dress properly. Do not wear loose clothing, dangling objects, or jewelry. Keep your hair,

clothing, and gloves away from moving parts. Loose clothes, jewelry, or long hair can be caught

in moving parts.

•Use safety apparel and equipment. Use safety goggles or safety glasses with side shields that

comply with current national standards or, when needed, a face shield. Use a dust mask if

working in dusty work conditions. This applies to all persons in the work area. Also use non-skid,

safety shoes, hard hats, heavy-duty work gloves,dust collection systems, and hearing protection

when appropriate.

Foot-Operated Kindling Splitter USE AND CARE

•Do not modify the Foot-Operated Kindling Splitter in any way. Unauthorized modification may

impair the function and/or safety and could affect the life of the equipment. There are specific

applications for which the Foot-Operated Kindling Splitter was designed.

•Always check for damaged or worn-out parts before using the Foot-Operated Kindling Splitter.

Broken parts will affect the Foot-OperatedKindling Splitter operation. Replace or repair damaged

or worn parts immediately.

•Do not exceed the Foot-Operated Kindling Splitter load capacity.

•Distribute the load evenly. Uneven loads may cause the Foot-Operated Kindling Splitter to tip,

resulting in personal injury to the operator or others.

•Use the Foot-Operated Kindling Splitter on flat and level surfaces capable of supporting the

Foot-Operated Kindling Splitter and its maximum load. Pulling or pushing a load on a slanted or

uneven surface can result in loss of control.

•Store idle Foot-Operated Kindling Splitter. When Foot-Operated Kindling Splitter is not in use,

store it in a secure place out of the reach of children. Inspect it for good working condition prior to

storage and before re-use.

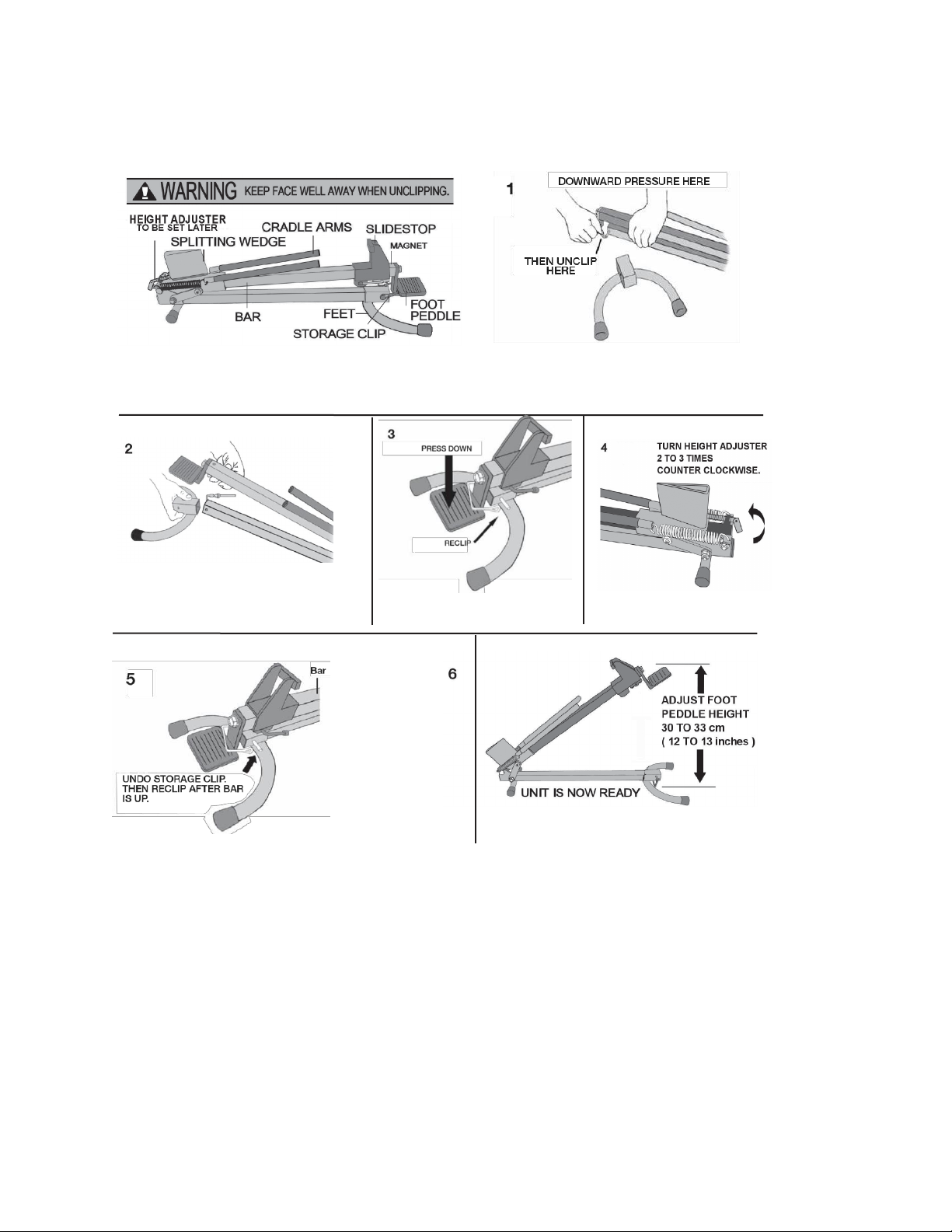

ASSEMBLY

UNIT COMES IN TWO PIECES. ASSEMBLY REQUIRED.

TAKEOUT STORAGECLIP, THEN SLOWLY RELEASE PRESSURE.

THEBAR

WILLRISETO2INCHES.

INSTALLFEET.RE-INSTALLSTORAGECLIP

NET WEIGHT: 21 LBS

CUTTING CAPACITY: 10in DIAMETER, 18in LENGTH

DIMENSIONS: 32.5in L x 10.5in W x 9in H

OPERATION

PLACE ON MAT TO PROTECTFLOORING.

TIPS

Wet or non-seasoned wood is more difficult to split than dry wood because the fibers

stick together. Reversing the block and splitting from the other end may help if you

cannot pull the wood apart.

Similarly large or multiple knots in a log make splitting more difficult. Usually if the log is

rotated so that the knots are vertical to the blade, the wood will split more easily and less

stress is placed on the splitter. This will reduce wear and tear or the possibility of

damaging some components of the splitter.

Damage from overstress or abuse may void the warranty on your firewood splitter. This

splitter is not designed to replace heavy-duty hydraulic powered equipment.

(MAGNET HOLDS SLIDE

STOP IN PLACE)

STEP DOWN AND REPEAT / MAY TAKE 3

TO 4 ATTEMPTS TO SPLIT AN AVERAGE

LOG

PARTS DIAGRAM:

PARTS LISTING:

Part#

Description

Qty.

Part#

Description

Qty.

1

Screw M10x25

1

22

Screw M5x10

2

2

Pedal

1

23

Condition Foot

1

3

Log Arm

1

24

Transport Lock

1

4

Magnet

1

25

Shaft

1

5

Arm

1

26

Screw M4x20

1

6

Splitting Wedge

1

27

Stand

1

8

Screw M12x60

1

28

Pin

2

9

Adjusting Screw

1

29

Screw M5x15

2

10

Spring

2

30

Washer Ø25mm

2

11

Rubber Pedal

1

31

Lever Arm

2

13

Stopping Lever

1

32

Lock Nut M10

2

14

Cap 38x38mm

1

33

Washer Ø20mm

2

15

Rubber Foot

2

34

Rubber Foot

2

16

Rubber Bracket

1

35

Lock Nut M12

1

18

Screw M6x20

1

36

Washer Ø24mm

1

19

Cap Ø20mm

2

37

Cap 32x32mm

1

20

Log Guide Bar

2

38

Adjust Nut M10

1

21

Stopping Lever Ball

2

For technical questions or replacement parts, please call 218-943-6290.

WARRANTY

One-year limited parts warranty.

BAC

PO BOX 155

Miltona, MN 56354

Made in China

Table of contents

Popular Media Converter manuals by other brands

Agilent Technologies

Agilent Technologies N8201A user guide

ADF Web

ADF Web BACnet Slave / S7comm user manual

Keysight Technologies

Keysight Technologies U3020AY03 user guide

Siedle

Siedle novotechnik MUP-410 manual

TR-Electronic

TR-Electronic CMS582M-4096/4096 IOL DMS 14H7 KRF Assembly instructions

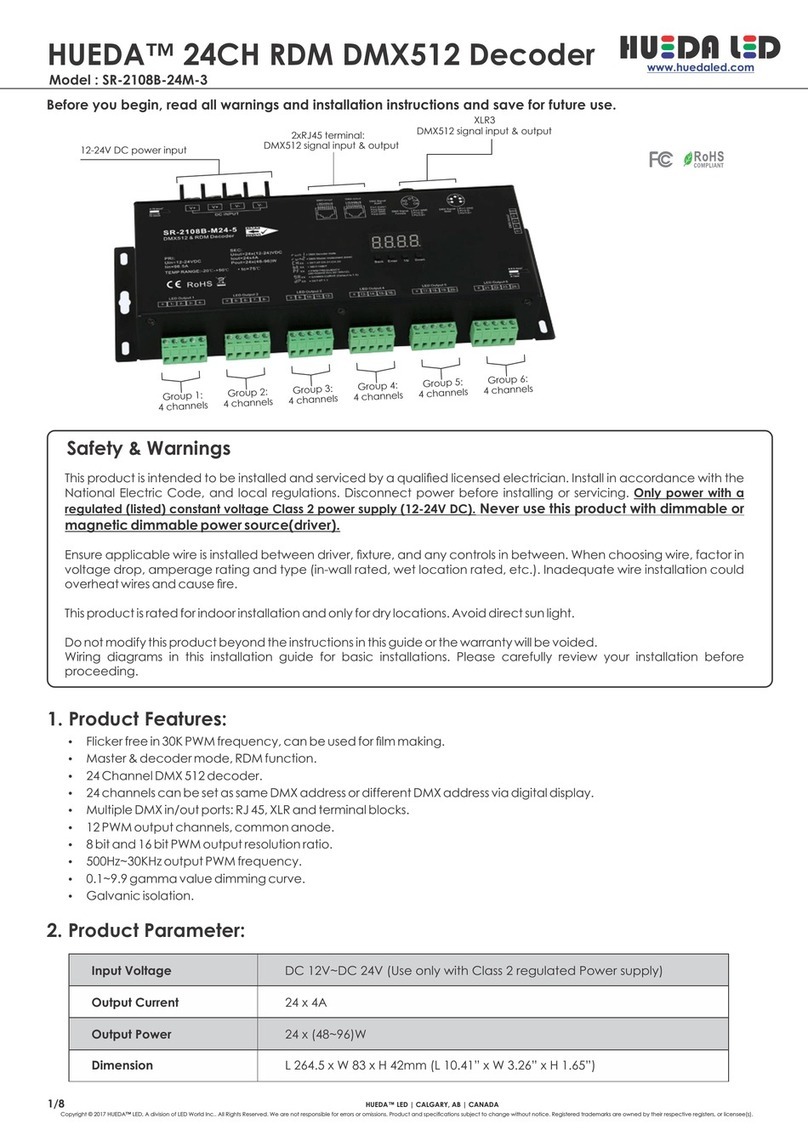

HUEDA LED

HUEDA LED SR-2108B-24M-3 installation instructions

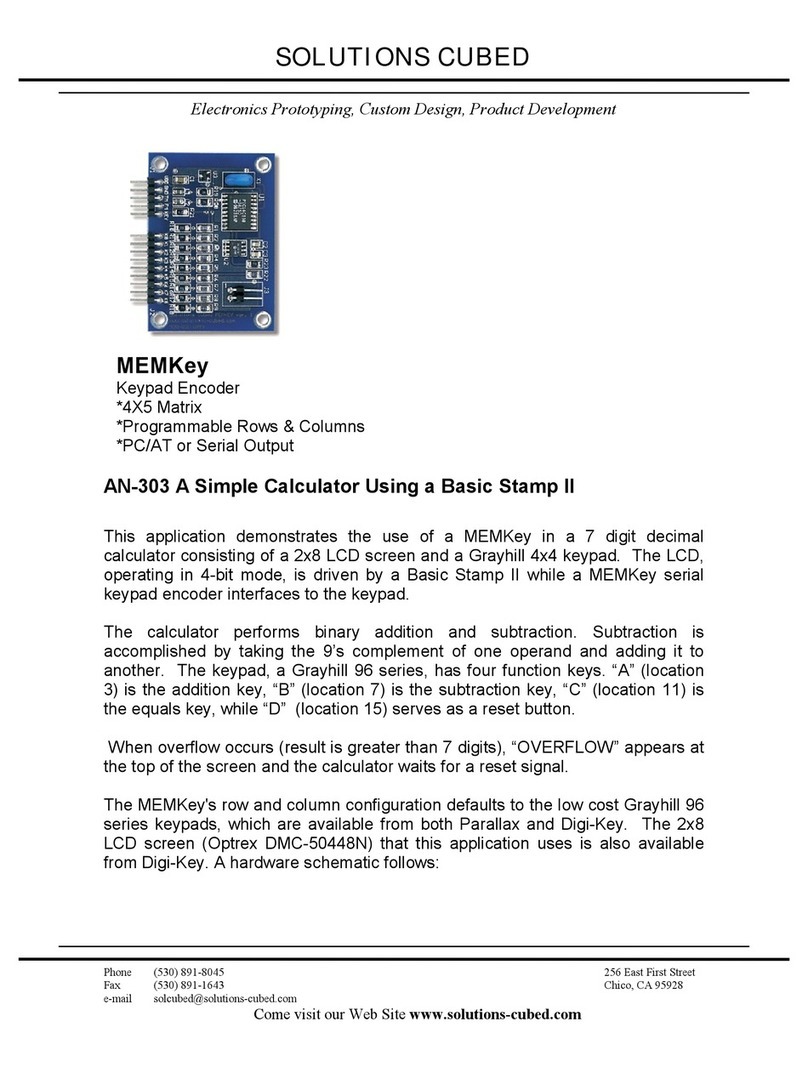

SOLUTIONS CUBED

SOLUTIONS CUBED MEMKey quick start guide

Elko

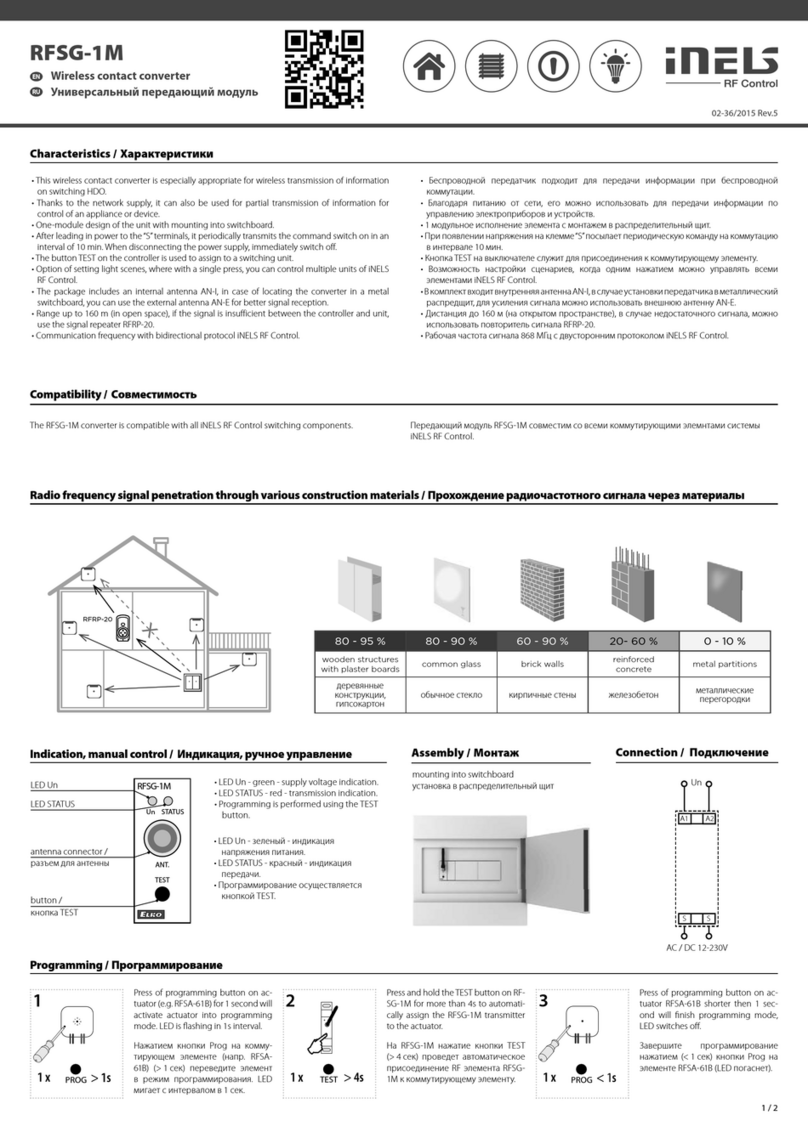

Elko RFSG-1M quick start guide

Intelix

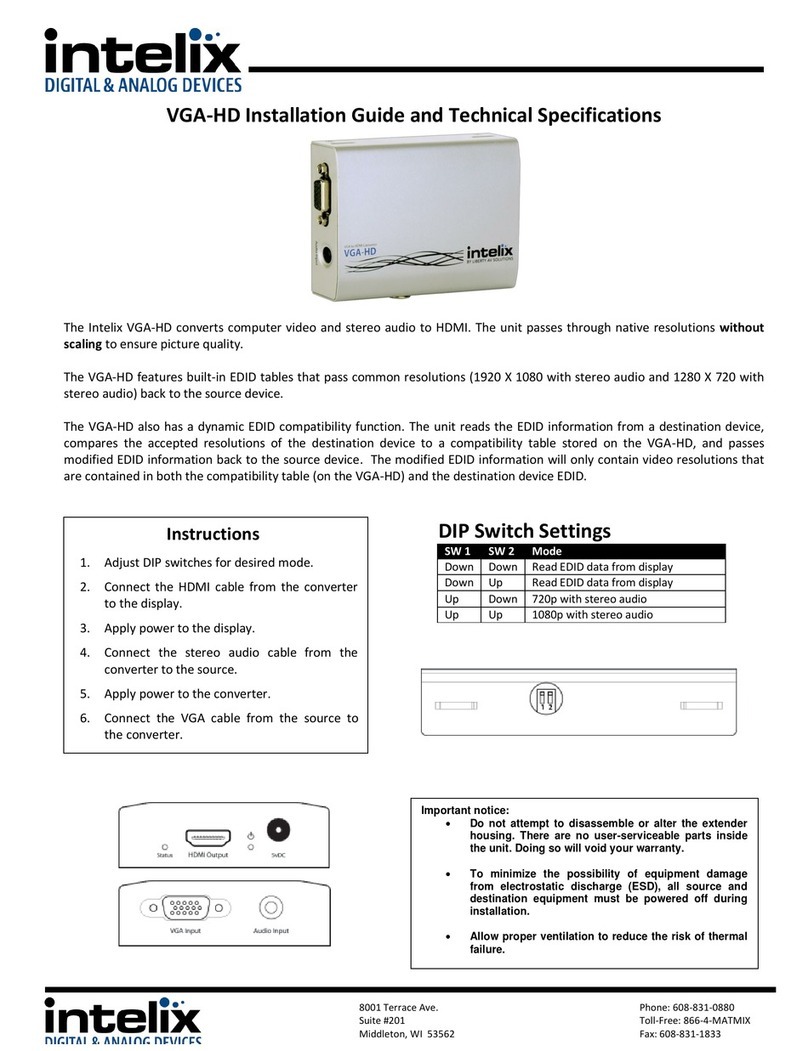

Intelix VGA-HD Installation guide and technical specifications

Delta Electronics

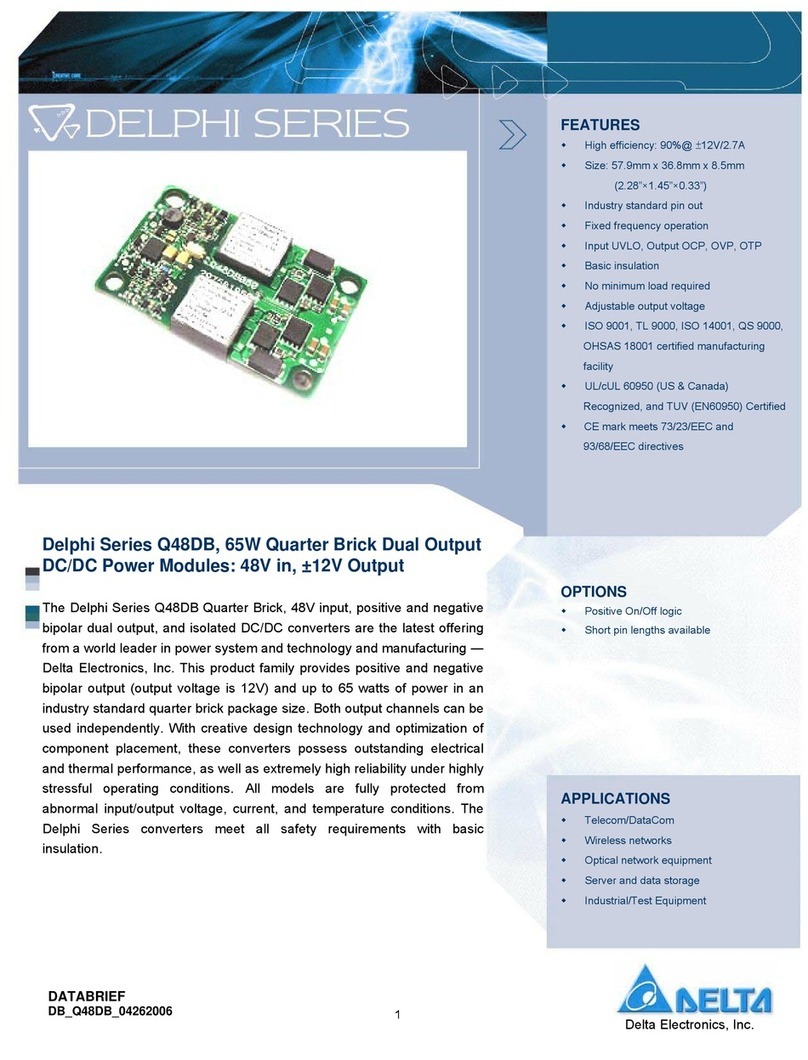

Delta Electronics Delphi Q48DB Specification sheet

Speaka Professional

Speaka Professional 1285734 operating instructions

Cobalt Digital Inc

Cobalt Digital Inc BBG-1002-UDX-FS product manual