Timberjack 745 Installation instructions

Timberjack

Harvester Head

F062419

Operator’s and Maintenance

Manual

Serial number 00FY0462...00FY0468

and WH0745X000469-

ENG

OPERATOR’S AND

MAINTENANCE MANUAL

Timberjack

745

1

2

3

4

5

6

7

8

9

10

11

12

INTRODUCTION

WARRANTY

SAFETY INSTRUCTIONS

PLANNING YOUR WORK

MAINTENANCE

HYDRAULIC SYSTEM

ELECTRICAL SYSTEM

TECHNICAL DATA

OPTIONAL EQUIPMENT

The information contained in this manual is comprised

of regulations and instructions which will assist the

operator to operate the machine in a safe and efficient

manner. Make sure this manual is always close at hand

andavailabletoallwhoworkonthemachine.

Should this manual be lost or should it deteriorate to

an unintelligible state, contact Timberjack or your nea-

rest Timberjack dealer for a replacement manual.

If you sell the machine, be sure to give this manual to

the new owners.

Continuing product improvement made by Timber-

jack may result in changes to the machine which are

not covered in this manual. Shoulf you need up-to-date

information about your machine or should you have

questions in regards to this manual, please contact

Timberjack or your Timberjack dealer.

WARNING

Only persons whose training has been

approvedbyTimberjackarepermittedto

operate Timberjack machinery.

Improper operation and maintenance of

this machine can be hazardous and

could result in serious injury or death.

Therefore,itisofparamountimportance

that all the instructions given in this

manual and during training be followed

when the machine is operated or servi-

ced.

The safety rules are given in chapter 3.

0-1

PageIssue

08/01-08

Timberjack 745

1. Introduction 1-1.............................................

1.1 General 1-2.....................................................

1.2 Single-grip harvester head 1-3.....................................

1.2.1 Main components 1-4.......................................

2. Warranty 2-1................................................

2.1 Warranty service 2-1.............................................

3. Safety instructions 3-1........................................

3.1 Warning Symbol 3-1.............................................

3.1.1 Meaning of warnings 3-2....................................

3.2 General safety rules 3-3...........................................

3.3 Operating safety precautions 3-4...................................

3.3.1 Before a new shift 3-5.......................................

3.3.2 Transport by road 3-5........................................

3.4 Servicing safety precautions 3-6....................................

3.5 Working with oils and chemicals 3-8................................

5. Planning Your Work 5-1.......................................

5.1 General 5-1.....................................................

5.2 Example of how a map sketch may look 5-2.........................

5.3 Thinning 5-3....................................................

5.4 Regeneration harvesting 5-5.......................................

5.5 Working technique for regeneration harvesting 5-6...................

5.5.1 Felling into trees 5-6.........................................

5.5.2 Felling outwards from the stand 5-7...........................

5.5.3 Felling in both directions 5-8..................................

5.6 Working technique for thinning 5-9................................

5.6.1 Thinning with a harvester alone 5-9............................

5.6.2 Thinning with a harvester and chain saw 5-10....................

5.6.3 Thinning between logging roads 5-11...........................

5.7 Felling 5-12......................................................

5.7.1 Stump height 5-12...........................................

5.7.2 Felling stage 5-12............................................

5.7.3 When felling on sloping ground 5-14............................

5.7.4 Felling trees with large roots 5-15...............................

5.8 Delimbing, Crosscutting 5-16.......................................

0-2

Page Issue

08/01-08

Timberjack 745

5.9 Checklist 5-18....................................................

5.9.1 Felling/Crosscutting 5-18......................................

5.9.2 Delimbing 5-19..............................................

5.9.3 Feeding 5-20................................................

6. Maintenance 6-1.............................................

6.1 Servicing safety precautions 6-2....................................

6.2 Saw unit safety 6-4..............................................

6.2.1 When replacing the saw chain 6-4.............................

6.3 Instructions for greasing 6-5.......................................

6.4 Oil recommendations 6-6.........................................

6.4.1 Grease 6-6.................................................

6.4.2 Hydraulic oil 6-6............................................

6.4.3 Saw chain oil 6-7............................................

6.4.4 Greasing the diameter and lenght measurement sensors 6-7.......

6.5 Tightening torques for bolt fastenings 6-7...........................

6.6 Daily maintenance or after every 10 hours 6-8.......................

6.7 Weekly maintenance or after every 50 hours 6-9.....................

6.8 Service after every 250 hours 6-9..................................

6.9 Chain saw maintenance 6-10.......................................

6.9.1 Tightening the saw chain 6-11.................................

6.10 The feeding system 6-12...........................................

6.10.1 Feeding rollers 6-12..........................................

6.10.2 Tightening the feeding roller chains 6-13........................

6.10.3 Feeding roller motors 6-14.....................................

6.10.4 The feeding roller hubs at the bevel shaft 6-14...................

6.11 Saw components 6-15.............................................

6.11.1 Saw unit 6-15...............................................

6.11.2 Replacing the tip sprocket 6-17.................................

6.11.3 Replacing the guide bar and saw chain 6-17......................

6.11.4 Sharpening the saw chain (.404 chain pitch) 6-18.................

6.11.5 Saw guide bar maintenance 6-20...............................

6.11.6 Checking/Replacing the tip sprocket 6-21........................

6.12 Length measurement system 6-22...................................

6.13 Diameter measurement system 6-24.................................

6.13.1 Checking the TJ 3000 / TimbermaticZ300 set values 6-24.........

6.13.2 Checking the diameter potentiometer, TimbermaticZ10 6-25......

6.13.3 Checking the diameter potentiometer, Lokomatic 6-25.............

0-3

PageIssue

08/01-08

Timberjack 745

6.13.4 Adjustment 6-26.............................................

6.13.5 Mounting the diameter sensors 6-29............................

6.14 Sharpening the delimbing knives 6-30................................

6.15 Installation of inductive switches 6-31................................

6.15.1 The adjustment of the “Saw bar home” sensor 6-31...............

6.15.2 The adjustment of the positional sensor of the saw bar 6-31........

6.16 Troubleshooting 6-34..............................................

7. Hydraulic system 7-1.........................................

7.1 Hydraulic components 7-3........................................

7.2 Hydraulic diagram 7-3............................................

7.3 Checking and adjusting pressures 7-9...............................

7.3.1 Adjusting the main pressure relief valve (13) 7-10.................

7.3.2 Checking the adjustment of the main pressure relief valve (13) 7-11.

7.3.3 Checking/Adjusting the pressure reducing valve for the upper

pressure of the delimbing knives (Upper knives; 41) 7-11...........

7.3.4 Checking/Adjusting the pressure relief valve for the lower

pressure of the delimbing knives (Upper knives; 34) 7-12...........

7.3.5 Checking/Adjusting the pressure relief valve (28) for the lower

squeeze pressure of the feeding rollers 7-13......................

7.3.6 Checking/Adjusting the pressure relief valve (29) for the increased

squeeze pressure of the feeding rollers 7-14......................

7.3.7 Checking/Adjusting the pressure reducing valve (31) of

the harvester head lift 7-15....................................

7.3.8 Adjusting the pressing power on the saw 7-16....................

7.3.9 Adjusting the flow control check valve (70) 7-16..................

7.3.10 Adjusting the pilot pressure 7-17...............................

8. Electrical system 8-1..........................................

8.1 Control and measuring system 8-2.................................

8.2 Connectors 8-3..................................................

8.2.1 HHM 8-3..................................................

8.2.2 HM, attachment 8-7.........................................

8.3 Wiring diagram 8-9..............................................

0-4

Page Issue

08/01-08

Timberjack 745

11. Optional equipment 11-1......................................

11.1 Dye marking system 11-1..........................................

11.1.1 Putting the system into use 11-1...............................

11.1.2 Maintenance 11-2............................................

11.1.3 Useful tips 11-4..............................................

11.1.4 Technical specifications of color pump 11-4......................

11.2 Saw equipment 11-5..............................................

11.2.1 Saw components 11-5........................................

11.2.2 Hydraulic pressures and volyme flows 11-6.......................

11.2.3 Tightening torques for bolt fastenings 11-6......................

11.2.4 Maintenance 11-6............................................

11.2.5 Description of operation 11-7..................................

11.2.6 Special tools 11-8............................................

11.2.7 Chain lubrication system 11-9..................................

11.2.8 Chain tensioning in conjunction with sawing 11-10.................

11.2.9 Bleeding the chain tensioning system 11-11.......................

11.2.10 Adjusting the pressure of the chain tensioner 11-12................

11.2.11 Changing the saw chain 11-13..................................

11.2.12 Changing the saw bar 11-14....................................

11.2.13 Changing the bar holder 11-15..................................

11.2.14 Bleeding the chain lubrication system 11-16.......................

11.2.15 Adjusting the sensors 11-17.....................................

11.2.16 Hydraulic diagram, SuperCut 11-17..............................

12. Technical data 12-1............................................

1-1

PageIssueSerial no 08/01-0800FY0462-

Timberjack 745

1. Introduction

This operator’s manual describes the operation

of your Timberjack 745 harvester head.

This machine may only be operated by those

who have successfully completed a Timberjack

course for 745 operators.

The operator must also have read and under-

stood the entire operator’s manual.

This manual will provide you with information

about the construction and operation of the ma-

chine that is essential in order to use and look af-

ter the machine correctly. It will also serve as

guidance for maintenance and certain adjust-

ments.

For more complicated maintenance or repairs

you should contact your nearest authorized ser-

vice workshop. Our service personnel have the

experience and specialist tools that are necessary

for more complicated work.

The excavator or any other machine and the

boom which are modified to be used as the har-

vester head carrier must fulfill the following re-

quirements:

- The machine must be CE-certified when

working in an European Union country.

- EU machine directive 89/392/EEG

- EMC directive

- The machine must fulfill all other national

and international regulations.

NOTE

Make sure that the carrier fullfills all

above mentioned requirements.

- The base machine and the boom must be suit-

able for use in a mechanized logging applica-

tion.

1-2

Page Issue Serial no

08/01-08 00FY0462-

Timberjack 745

1.1 General

This head is designed to fell, delimb and cross-

cut trees.

Regular servicing and correct operation are vital

to ensure a long service life. You should there-

fore follow carefully the instructions in this

manual.

Experience shows that a thorough inspection of

the machine at regular intervals is a guarantee

for favourable cost efficiency. The combination

of your care and experience and the high quality

of construction will ensure minimum downtime

and high performance throughout the life of the

machine.

1-3

PageIssueSerial no 08/01-0800FY0462-

Timberjack 745

1.2 Single-grip harvester head

The Timberjack 745 is a compact harvester head

designed for felling, limbing and cross-cutting

trees.

The head is mounted on the tip of a boom to fa-

cilitate simple and efficient sorting and high-

level stacking.

The Timberjack 745 can also be used for early

thinning and regeneration harvesting of trees up

to the maximum diameter specified in the Tech-

nical Data. Because it can handle fallen trees the

745 can also be used as a processor.

1-4

Page Issue Serial no

08/01-08 00FY0462-

Timberjack 745

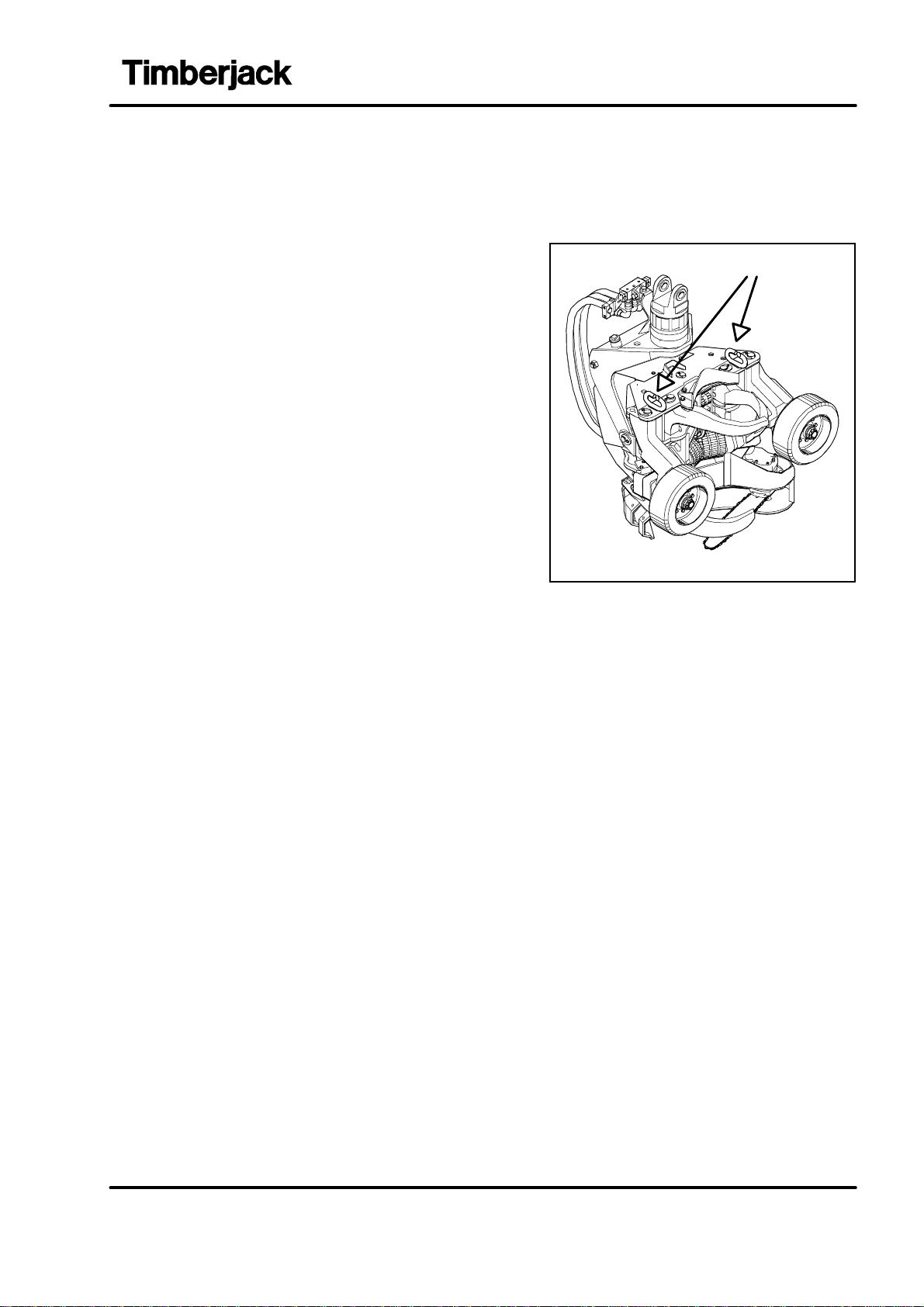

1.2.1 Main components

13

10

1211

1

2

3

4

5

6

7

8

9

10

1. Rotator.

2. Fixed delimbing knife.

3. Moving delimbing knife (left).

4. Motor for left feeding roller 500 cubic cm.

5. Saw guide bar and motor, standard

(SuperCut saw unit as option)

6. Moving delimbing knife

(lower; optional equipment).

7. Equipment for measuring of length.

8. Motor for right feeding roller 500 cubic cm.

9. Serial number of harvester head.

10. Two diameter sensors (on upper delimbing

knives).

11. Valve block for harvester head control (not

shown).

12. Upper feeding roller (left).

13. Motor for left upper feeding roller 315 cubic cm.

2-1

PageIssueSerial no 08/01-0800FY0462-

Timberjack 745

2. Warranty

Timberjack guarantees its machine in com-

pliance with the standard warranty conditions of

the Timberjack group.

Our responsibility for machines manufactured

by us requires that:

- the machine is used and maintained by skilled

and trained persons only.

- the machine is used and maintained in com-

pliance with this operator’s manual and the

service manual for this machine.

- the fuel and oil specifications stated in this

manual are adhered to.

- only Original Timberjack Spare Parts are

used.

2.1 Warranty service

The machine was checked and test driven before

delivery, and it can be put to use immediately.

However, to ensure good reliability it is very im-

portant to thoroughly service the machine once

it has been put to use.

The warranty given by Timberjack will be valid

provided that the machine is handed over for af-

ter sales maintenance after appr. 250 running ho-

urs, the service shop being one authorized by

Timberjack .

CAUTION

The harvester head may be

badly damaged if you work

on trees that are oversize!

Do not use the harvester for

the processing of trees that

exceed maximum ratings!

2-2

Page Issue Serial no

08/01-08 00FY0462-

Timberjack 745

3-1

PageIssueSerial no 08/01-0800FY0462-

Timberjack 745

3. Safety instructions

If any information or instructions in this manual

does not agree with local legislation you should

follow the local legislation.

The head may only be used and maintained by

personnel who have undergone training ap-

proved by Timberjack.

Make sure you are familiar with local occupa-

tional safety legislation on working with forest-

ry machinery, as well as the safety precautions

that apply to operation of the Timberjack har-

vester head. You can read about them later in this

manual and on decals affixed to the machine.

3.1 Warning Symbol

This warning symbol is used throughout the

manual wherever there is a risk of personal inju-

ry or damage to the machine if you do not follow

the instructions.

3-2

Page Issue Serial no

08/01-08 00FY0462-

Timberjack 745

3.1.1 Meaning of warnings

DANGER indicates a risk of fatal injury. There

is a risk of serious or fatal injury if the necessary

measures are not taken.

WARNING indicates dangerous situations.

There is a risk of accident resulting in serious or

fatal injury if the necessary measures are not

taken.

CAUTION indicates hazardous situations.

There is a risk of minor personal injury if the

necessary measures are not taken. The word

CAUTION may also be used to warn of unsafe

methods of working in situations that can lead to

personal injury, or to point out particularly im-

portant facts.

DANGER

WARNING

CAUTION

3-3

PageIssueSerial no 08/01-0800FY0462-

Timberjack 745

3.2 General safety rules

CAUTION

The machine may only be used by

operators who are properly trained to

operate and use the machine.

- Check the machine for potential faults before

starting each shift.

- Before starting always ensure that no-one is

near the machine where there is risk of per-

sonal injury!

- Standing in front of or behind the chain saw

(in the longitudinal direction of the saw bar)

is absolutely prohibited. Watch especially the

area in line with the saw chain!

- Avoid crosscut felling when the cabin is on

the sawing line.

- Never stand in front of a saw chain when it is

running.

- Regularly check: Saw bar, saw chain and s-

procket wheel for secure mounting, damage,

etc.!

3-4

Page Issue Serial no

08/01-08 00FY0462-

Timberjack 745

3.3 Operating safety precautions

- Do not allow anyone within a risk zone of 70

metres from the machine! Stop the machine

immediately, if someone steps to this area.

Watch especially the area in line with the saw

chain!

- Never leave the machine unattended while

the engine is running.

- Keep all doors and windows closed during

operation. When you are learning to use the

machine or demonstrating it, stay in the cab.

- Notice the safety distances to electric lines.

- Notice the weakness and inclination of the

ground. Follow the information package of

the stand.

- Check that no-one is in the line of the blade

during sawing. Should the saw chain break,

fragments may fly off causing a risk of acci-

dents.

- Avoid sawing above the lower edge of the

cabin window.

- Only chains, guide bars and tip sprockets

from a well-known manufacturer should be

used.

- Never saw with a damaged or worn-out guide

bar or chain.

- Follow up cut times. There is an automatic

cut time supervision in Tj 3000 / Timber-

maticZ300. Change a worn chain when

needed.

- Use as short guide bar as possible.

- Never saw with a bent or poorly aligned guide

bar.

- Check that the saw bar returns immediately

after sawing through. Avoid sawing through

too large stems. If the bar goes too far, the

chain may jump off or possibilities of sawing

to a stone grows. See additional instructions

on regulating the control system saw depth.

3-5

PageIssueSerial no 08/01-0800FY0462-

Timberjack 745

3.3.1 Before a new shift

- Test all the machine functions!

3.3.2 Transport by road

In the event of transport by road, the harvester

head is suspended from chains.

The chains may be attached only by using the ap-

propriate holes (A), see illustration.

A

3-6

Page Issue Serial no

08/01-08 00FY0462-

Timberjack 745

3.4 Servicing safety precautions

DANGER

You must never carry out service on the

machine while the engine is running.

WARNING

Never touch pressurised cylinders orhy-

draulic hoses or stand in the vicinity of

them.Donottightenleakingconnectors

whenthemachineisrunning.Highpres-

sure jets of oil can be fatal!

- The manufacturer cannot take any responsi-

bility for conversion of the head’s construc-

tions or electrical and hydraulic systems if

these are not the same as the original.

- Never modify the hydraulic system to speed

up the chain rotation.

- Rest the harvester head firmly and safely on

the ground and release the hydraulic rams.

However, do not operate the cylinders all the

way to the end limiters.

- Lock the harvester head so that it cannot fall

over. See group 6.1.

- Stop the engine.

- You must never stand between the delimbing

tools, feed rollers or in front of the saw bar

while the engine is running!

- When washing the harvester head with pres-

surized water, be careful with the electrical

components: make sure no water gets inside.

Table of contents

Popular Industrial Equipment manuals by other brands

Clemco

Clemco Zero BNP6012P manual

Eaton

Eaton NZM-XMC-KIT-630 Instruction leaflet

Precision Rated Optics

Precision Rated Optics OFS-945S Operation guide

Mayr

Mayr EAS-NC Installation and operational instructions

Tyco Electronics

Tyco Electronics AMP-TAPETRONIC 69875 Customer's manual

MHS Boilers

MHS Boilers XenoROL XR40 Installation, operation & maintenance manual