Smartgen HGM9580 User manual

HGM9580 Bus Tie Bus Parallel Unit

USER MANUAL

Smartgen Technology

Chinese trademark

English trademark

Smartgen —make your generator smart

Smartgen Technology Co., Ltd.

No. 28 Jinsuo Road

Zhengzhou city

Henan Province

P. R. China

Tel: +86-371-67988888/67981888

+86-371-67991553/67992951

+86-371-67981000(overseas)

Fax: 0086-371-67992952

Web: http://www.smartgen.com.cn

http://www.smartgen.cn

Email: [email protected]

All rights reserved. No part of this publication may be reproduced in any material form (including

photocopying or storing in any medium by electronic means or other) without the written

permission of the copyright holder.

Smartgen Technology reserves the right to change the contents of this document without prior

notice.

Version history

Date

Version

Contents

2014-02-16

1.0

Original release

HGM9580 BUS TIE BUS PARALLEL UNIT

HGM9580 Bus Tie Bus Parallel Unit ISSUE 2014-02-16 Version 1.0 Page 3 of 33

This manual is suitable for HGM9580 bus tie bus parallel unit only.

Clarification of notation used within this publication.

SIGN

INSTRUCTION

NOTE

Highlights an essential element of a procedure to ensure correctness.

CAUTION!

Indicates a procedure or practice, which, if not strictly observed, could result in

damage or destruction of equipment.

WARNING!

Indicates a procedure or practice, which could result in injury to personnel or

loss of life if not followed correctly.

HGM9580 BUS TIE BUS PARALLEL UNIT

HGM9580 Bus Tie Bus Parallel Unit ISSUE 2014-02-16 Version 1.0 Page 4 of 33

CONTENTS

1OVERVIEW.......................................................................................................5

2PERFORMANCE AND CHARACTERISTICS...................................................6

3SPECIFICATION...............................................................................................7

4OPERATION.....................................................................................................8

4.1 INDICATOR LIGHT .........................................................................................................8

4.2 PUSHBUTTONS .............................................................................................................9

4.3 LCD DISPLAY ...............................................................................................................10

4.3.1 MAIN DISPLAY..........................................................................................................10

4.3.2 USER MENU AND PARAMETERS SETTING MENU ...............................................10

4.4 AUTO OPERATION.......................................................................................................13

4.5 MANUAL OPERATION..................................................................................................14

5PROTECTIONS...............................................................................................15

5.1 WARNING ALARMS......................................................................................................15

5.2 TRIP ALARM.................................................................................................................16

6WIRING CONNECTION ..................................................................................17

7SCOPES AND DEFINITIONS OF PROGRAMMABLE PARAMETERS...............................20

7.1 CONTENTS AND SCOPES OF PARAMETERS............................................................20

7.2 ENABLE DEFINITION OF PROGRAMMABLE OUTPUT PORTS..................................24

7.2.1 DEFINED COMBINATION OUTPUT .........................................................................26

7.3 DEFINED CONTENTS OF PROGRAMMABLE INPUT PORTS (ALL ACTIVEWHEN

CONNECT TO GRAND (B~))....................................................................................................27

8TYPICAL DIAGRAM.......................................................................................29

9TYPICAL APPLICATION................................................................................30

10 INSTALLATION ..............................................................................................31

11 USB.................................................................................................................32

12 FAULT FINDING.............................................................................................33

HGM9580 BUS TIE BUS PARALLEL UNIT

HGM9580 Bus Tie Bus Parallel Unit ISSUE 2014-02-16 Version 1.0 Page 5 of 33

1 OVERVIEW

HGM9580 Bus Tie Bus Parallel Unit is designed for manual/auto parallel system which composed

by multi-way bus and multi-way bus. It allows automatic parallel running function. It fit with LCD

display, graphic display, optional Chinese, English and other languages interface, and it is reliable

and easy to use.

HGM9580 Bus Tie Bus Parallel Unit controls a bus breaker which can control the controller to

synchronize the two ways buses via MSC CAN if the synchronization requirements have satisfied.

The powerful 32-bit Microprocessor contained within the unit allows for precision parameters

measuring, fixed value adjustment, time setting and set value adjusting and etc..Majority

parameters can be configured from front panel, and all parameters can be configured by USB

interface (or RS485) to adjust via PC. It can be widely used in all types of automatic genset

parallel system with compact structure, simple connections and high reliability.

HGM9580 BUS TIE BUS PARALLEL UNIT

HGM9580 Bus Tie Bus Parallel Unit ISSUE 2014-02-16 Version 1.0 Page 6 of 33

2 PERFORMANCE AND CHARACTERISTICS

With ARM-based 32-bit SCM, high integration of hardware and more reliable;

480x272 TFT LCD with backlight, multilingual interface (including English, Chinese or other

languages) which can be chosen at the site, making commissioning convenient for factory

personnel;

Improved LCD wear-resistance and scratch resistance due to hard screen acrylic;

Silicon panel and pushbuttons for better operation in high/low temperature environment;

RS485 communication port enables remote control, remote measuring, remote

communication via ModBus protocol.

Suitable for 3-phase 4-wire, 3-phase 3-wire, single phase 2-wire, and 2-phase 3-wire systems

with voltage 120/240V and frequency 50/60Hz;

Collects and shows 3-phase voltage and frequency of Bus 1/Bus 2.

Bus 1 Bus 2

Line voltage (Uab, Ubc, and Uca) Line voltage (Uab, Ubc, and Uca)

Phase voltage (Ua, Ub, and Uc) Phase voltage (Ua, Ub, and Uc)

Phase sequence Phase sequence

Frequency (Hz) Frequency (Hz)

Synchronization parameters:Voltage Difference Between Bus 1 and Bus 2, Frequency

Difference Between Bus 1 and Bus 2, Phase Difference Between Bus 1 and Bus 2;

All output ports are relay output;

Parameter setting: parameters can be modified and stored in internal EEPROM memory and

cannot be lost even in case of power outage; most of them can be adjusted using front panel

of the controller and all of them can be modified using PC via USB or RS485 ports;

Widely power supply range DC(8~35)V, suitable to different starting battery voltage

environment;

Event log, real-time clock function;

All parameters used digital adjustment, instead of conventional analog modulation with

normal potentiometer, more reliability and stability;

IP55 waterproofness level can be achieved with the help of rubber-ring gasket between shell

and control panel.

Metal fixing clips enable perfect in high temperature environment;

Modular design, self extinguishing ABS plastic shell, pluggable terminal, built-in mounting,

compact structure with easy installation;

HGM9580 BUS TIE BUS PARALLEL UNIT

HGM9580 Bus Tie Bus Parallel Unit ISSUE 2014-02-16 Version 1.0 Page 7 of 33

3 SPECIFICATION

Parameter

Details

Working Voltage

DC8. 0V to 35. 0V, continuous power supply

Overall Consumption

<4W (Standby mode: ≤2W)

AC Input:

3 Phase 4 Wire

3 Phase 3 Wire

Single Phase 2 Wire

2 Phase 3 Wire

AC15V - AC360V (ph-N)

AC30V - AC620V (ph- ph)

AC15V - AC360V (ph-N)

AC15V - AC360V (ph-N)

Alternator Frequency

50Hz/60Hz

Flexible Relay Output 1

7A DC28V power supply output

Flexible Relay Output 2

7A DC28V power supply output

Flexible Relay Output 3

7A DC28V power supply output

Flexible Relay Output 4

7A AC250V volts free output

Flexible Relay Output 5

7A AC250V volts free output

Flexible Relay Output 6

7A AC250V volts free output

Flexible Relay Output 7

16A DC28V power supply output

Flexible Relay Output 8

16A DC28V power supply output

Case Dimensions

266mm x 182mm x 45mm

Panel Cutout

214mm x 160mm

Working Conditions

Temperature: (-25~+70)°C Humidity: (20~93)%RH

Storage Conditions

Temperature:(-25~+70)°C

Protection Level

IP55 Gasket

Insulation Intensity

Apply AC2.2kV voltage between high voltage terminal and low

voltage terminal;

The leakage current is not more than 3mA within 1min.

Weight

0.95kg

HGM9580 BUS TIE BUS PARALLEL UNIT

HGM9580 Bus Tie Bus Parallel Unit ISSUE 2014-02-16 Version 1.0 Page 8 of 33

4 OPERATION

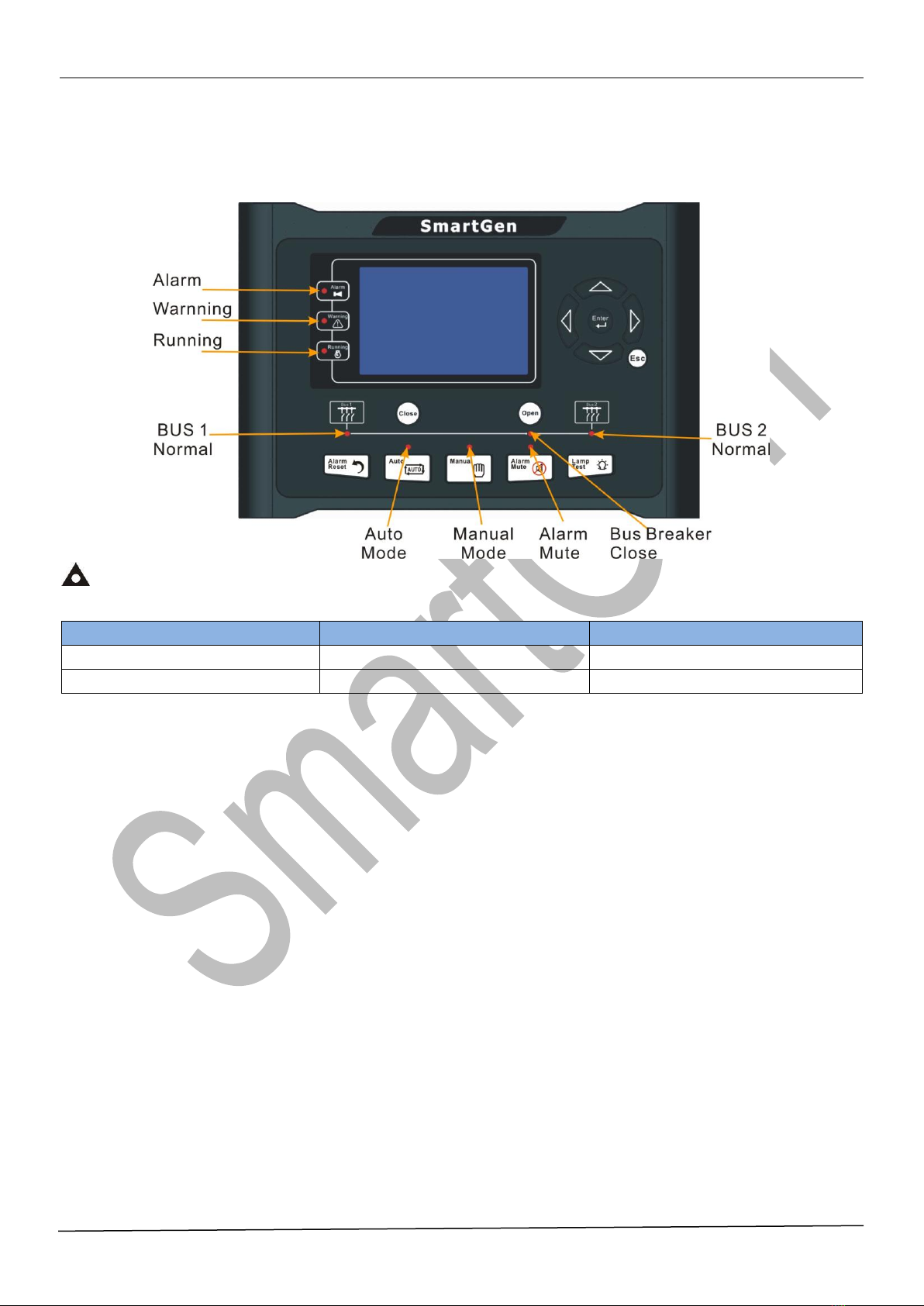

4.1INDICATOR LIGHT

NOTE: Selected light indicators description:

Warning indicator and Alarm indicator:

Alarm Type

Warning Indicator

Alarm Indicator

Warning

Slow flashing

Slow flashing

Trip Alarm

Off

Fast flashing

Running indicator: It is light on when both of bus 1 and bus 2 are normal; off when either of them

is abnormal.

Bus 1 normal light:It is light on when bus 1 is normal; off when bus 1 is abnormal.

Bus 2 normal light:It is light on when bus 2 is normal; off when bus 2 is abnormal.

HGM9580 BUS TIE BUS PARALLEL UNIT

HGM9580 Bus Tie Bus Parallel Unit ISSUE 2014-02-16 Version 1.0 Page 9 of 33

4.2PUSHBUTTONS

Alarm Reset

If alarm occurs, pressing the button can reset this alarm.

Manual Mode

Press this key and controller enters in Manual mode.

Auto Mode

Press this key and controller enters in Auto mode.

Mute

Alarming sound off.

Lamp test

Press this key can test the lamp is normal or not (lamp

test).

Close

Can control bus to switch on in Manual mode.

Open

Can control bus to switch off in Manual mode.

Up/Increase

1) Screen scroll;

2) Up cursor and increase value in setting menu.

Down/Decrease

1) Screen scroll;

2) Down cursor and decrease value in setting menu.

Left

1) Screen scroll;

2) Left move cursor in setting menu.

Right

1) Screen scroll;

2) Right move cursor in setting menu.

Set/Confirm

1) Pressing and holding for more than 3 seconds enters

parameter setting menu;

2) In settings menu confirms the set value.

Exit

1) Return to main menu;

2) Return to previous menu in setting menu.

WARNING: Default password is 00318, user can change it in case of others change the

advanced parameters setting. Please clearly remember the password after changing. If you forget

it, please contact Smartgen services and send all PD information in the controller page of

“ABOUT” to us.

HGM9580 BUS TIE BUS PARALLEL UNIT

HGM9580 Bus Tie Bus Parallel Unit ISSUE 2014-02-16 Version 1.0 Page 10 of 33

4.3LCD DISPLAY

4.3.1 MAIN DISPLAY

Main screen show pages; use to scroll the pages and to scroll the screen.

★Main Screen, including as below,

Bus 1: voltage, frequency, active power, reactive power

Bus 2: voltage, frequency, active power, reactive power

Some status

★Status, including as below,

Module status, ATS status

★SNYC, including as below,

Voltage difference, frequency difference, angle difference, MSC status

★Alarm

Display all alarm information (warning alarm, trip alarm).

★Event log

Make records about all events (trip alarm, power on events and Bus switch events) and the real

time when events occur.

★Others, including,

Time and Date, input/output ports status.

★About, including,

Issue time of software and hardware version, product PD number.

4.3.2 USER MENU AND PARAMETERS SETTING MENU

Press key for more than 3s to enter into user manual.

★Parameter

After entering the correct password (factory default password is 00318) you can enter parameter

settings screen.

★Language

Selectable Chinese, English and others (default: Espanol)

Parameter setting including as following,

★Battery setting

★Bus settings

★Breaker settings

★Input port settings

★output port settings

HGM9580 BUS TIE BUS PARALLEL UNIT

HGM9580 Bus Tie Bus Parallel Unit ISSUE 2014-02-16 Version 1.0 Page 11 of 33

★Module settings

★Synchronization settings

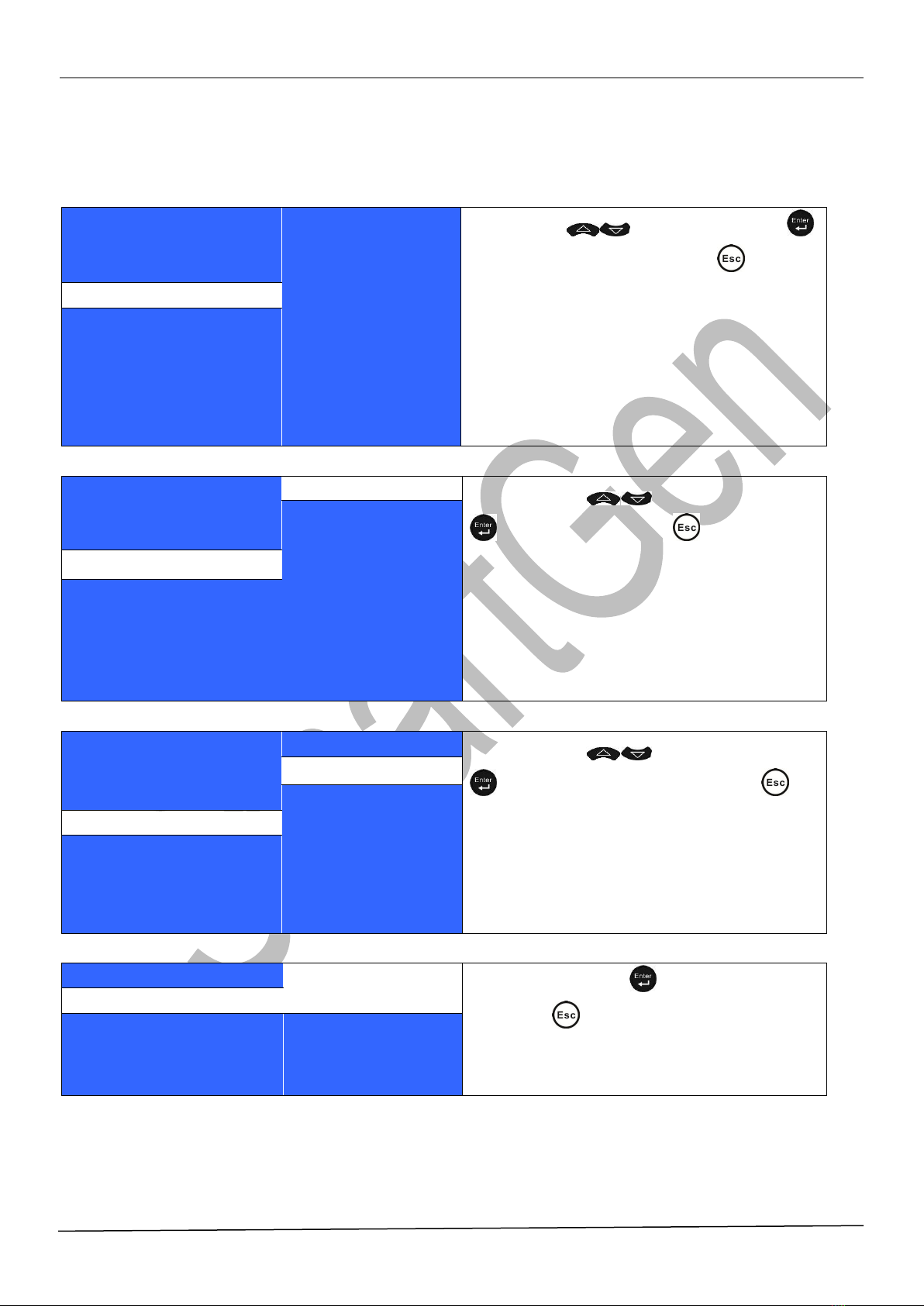

Example:

Return

Battery setting

Bus setting

> Close Delay

> Open Delay

Form1: Use to scroll settings,

to enter settings (form 2), to exit

settings menu.

Breaker setting >

Input setting

Output setting

Module setting

Synchronization setting

Return

Battery setting

Bus setting

>Close Delay

Form 2: Use to scroll settings,

to enter settings, to return to

previous menu. (form 1)

> Open Delay

Breaker setting >

Input setting

Output setting

Module setting

Synchronization setting

Return

Battery setting

Bus setting

> Close Delay

Form 3: Use to scroll settings,

to contirm settings (form 4), to

return to previous menu. (form 1)

> Open Delay

Breaker setting >

Input setting

Output setting

Module setting

Synchronization setting

> Close Delay

00003

Form 4:Press to enter settings

(form 5), to return to previous menu.

(form 6).

> Open Delay

HGM9580 BUS TIE BUS PARALLEL UNIT

HGM9580 Bus Tie Bus Parallel Unit ISSUE 2014-02-16 Version 1.0 Page 12 of 33

> Close Delay

00003

Form 5: Press to change cursor position,

are used for changing cursor value,

to confirm setting (form 4), to exit setting

(form 4).

> Open Delay

> Close Delay

00003

Form 6: Use to scroll settings. to

enter settings (form 4), to return to previous

menu. (form 1).

> Open Delay

HGM9580 BUS TIE BUS PARALLEL UNIT

HGM9580 Bus Tie Bus Parallel Unit ISSUE 2014-02-16 Version 1.0 Page 13 of 33

4.4AUTO OPERATION

Auto mode is selected by pressing the button; a LED besides the button will illuminate to

confirm the operation.

1. When remote start input is active:

a) If either of the two buses is deactivate, then bus close signal will be initiated and the bus will be

paralleled with the other bus;

b) If both of Bus 1 and Bus 2 are active, the controller will adjust frequency and voltage to

synchronize bus with bus; when synchronism requirements has been achieved, bus close

signal will be initiated and the bus will be paralleled with the other bus.

2. When remote start input is deactivate, then bus open relay activate and the bus split from the

other bus.

Note: The bus voltage is regarded as active if it has exceeded the dead bus voltage (the dead

bus voltage is configurable); otherwise, it is regarded as deactivate.

HGM9580 BUS TIE BUS PARALLEL UNIT

HGM9580 Bus Tie Bus Parallel Unit ISSUE 2014-02-16 Version 1.0 Page 14 of 33

4.5MANUAL OPERATION

Manual mode is selected by pressing the button; a LED besides the button will illuminate

to confirm the operation.

1. Press button:

If either of the two buses is deactivate, then bus close signal will be initiated and the bus will be

paralleled with the other bus.

If both of Bus 1 and Bus 2 are active, the controller will adjust frequency and voltage to

synchronize bus with bus; when synchronism requirements has been achieved, bus close

signal will be initiated and the bus will be paralleled with the other bus.

2. Press button, then bus open relay activates and the bus split from the other bus.

HGM9580 BUS TIE BUS PARALLEL UNIT

HGM9580 Bus Tie Bus Parallel Unit ISSUE 2014-02-16 Version 1.0 Page 15 of 33

5 PROTECTIONS

5.1 WARNING ALARMS

Warnings are not shutdown alarms and do not affect the operation of the gen-set. Warning alarms

does not lead to shutdown. Warning alarms types are as follows:

No

Type

Description

1

Battery Over Volt

When the controller detects that the battery voltage has exceeded

the pre-set value, it will initiate a warning alarm.

2

Battery Under Volt

When the controller detects that the battery voltage has fallen

below the pre-set value, it will initiate a warning alarm.

3

Bus Breaker Fail

When the controller detects that the bus close status is not

configured in the input port, it will initiate a warning alarm.

4

Digital Input

When the digit input port is set as User Configured and the action

select “Warn”, it will initiate a warning alarm.

5

Fail to sync

When the controller does not detect synchronization signal within

the pre-set synchronization time, it will initiate a warning alarm.

6

Min Sets Not

Reached

When the controller detects fewer modules on the MSC link than

the minimum number configured in the unit, it will initiate a warning

alarm. There are 2 possible reasons: a) Communication line

between the controllers disconnects, which interrupts

communication.

b) Other parallel gen-sets controllers have not been powered on.

HGM9580 BUS TIE BUS PARALLEL UNIT

HGM9580 Bus Tie Bus Parallel Unit ISSUE 2014-02-16 Version 1.0 Page 16 of 33

5.2TRIP ALARM

On initiation of the trip condition the controller will de-energize the ‘Close Generator’ Output

without stop the generator.

Trip alarm as following,

No

Type

Description

1

Digital Input

When the digit input port is set as User Configured and the action

select “Trip”, it will initiate a trip alarm.

2

Fail to sync

When the controller does not detect synchronization signal within

the pre-set synchronization time, it will initiate a trip alarm.

3

Bus Breaker Fail

When the controller detects that the bus breaker is failed, it will

initiate a trip alarm.

4

MSC Too Few Sets

When the controller detects fewer modules on the MSC link than

the minimum number configured in the unit, it will initiate a trip

alarm. There are 2 possible reasons: a) Communication line

between the controllers disconnects, which interrupts

communication.

b) Other parallel gen-sets controllers have not been powered on.

5

Bus 1 Phase

Sequence Wrong

When the controller detects a bus 1 phase rotation error, it will

initiate a trip alarm.

6

Bus 2 Phase

Sequence Wrong

When the controller detects a bus 2 phase rotation error, it will

initiate a trip alarm.

7

MSC ID Error

When the controller detects the same ID on the MSC Bus, it will

initiate a trip alarm.

8

Volt Bus Error

When the controller detects that the genset has already closed but

there is no voltage on bus, it will initiate a trip alarm.

HGM9580 BUS TIE BUS PARALLEL UNIT

HGM9580 Bus Tie Bus Parallel Unit ISSUE 2014-02-16 Version 1.0 Page 17 of 33

6 WIRING CONNECTION

HGM9580 controller’s rear as following:

Description of terminal connection:

NO.

Functions

Cable

Size

Remark

1

DC input B-

2.5mm2

Connected with negative of starter battery.

2

DC input B+

2.5mm2

Connected with positive of starter battery. If wire

length is over 30m, better to double wires in

parallel. Max. 20A fuse is recommended.

3

COM Output 7,8

2.5mm2

Connected with B+.

4

Aux. output 7

1.5mm2

B+ is supplied by 3 point, rated 16A.

5

Aux. output 8

1.5mm2

B+ is supplied by 3 point, rated 16A.

6

Aux. output 1

1.5mm2

B+ is supplied by 2 point,

rated 7A.

Details see form 2.

7

Aux. output 2

1.5mm2

B+ is supplied by 2 point,

rated 7A.

8

Aux. output 3

1.5mm2

B+ is supplied by 2 point,

rated 7A.

9

Reserved

/

This is reserved terminals, do not connect to wire.

10

Aux. input 1

1.0mm2

Ground connected is

active (B-)

Details see form 3.

11

Aux. input 2

1.0mm2

Ground connected is

active (B-)

12

Aux. input 3

1.0mm2

Ground connected is

active (B-)

HGM9580 BUS TIE BUS PARALLEL UNIT

HGM9580 Bus Tie Bus Parallel Unit ISSUE 2014-02-16 Version 1.0 Page 18 of 33

NO.

Functions

Cable

Size

Remark

13

Aux. input 4

1.0mm2

Ground connected is

active (B-)

14

Aux. input 5

1.0mm2

Ground connected is

active (B-)

15

Aux. input 6

1.0mm2

Ground connected is

active (B-)

16

Input COM

/

17-18

Reserved

/

This is reserved terminals, do not connect to wire.

19

Aux. input 7

1.0mm2

Ground connected is

active (B-)

Details see form 3.

20

Aux. output 4

1.5mm2

Normally close outputs,

rated 7A.

Details see form 2.

21

Public points of relay

22

Normally open outputs,

rated 7A.

23

MSC1 CAN

/

Impedance-120Ω shielding wire is recommended,

its single-end earthed.

24

MSC1 CAN H

0.5mm2

25

MSC1 CAN L

0.5mm2

26

MSC2 CAN

/

Impedance-120Ω shielding wire is recommended,

its single-end earthed.

27

MSC2 CAN H

0.5mm2

28

MSC2 CAN L

0.5mm2

33

RS485

/

Impedance-120Ω shielding wire is recommended,

its single-end earthed.

34

RS485+

0.5mm2

35

RS485-

0.5mm2

36

Aux. output 5

2.5mm2

Normally close outputs,

rated 7A.

Details see form 2.

37

2.5mm2

Normally open outputs,

rated 7A.

38

2.5mm2

Public points of relay

39

Aux. output 6

2.5mm2

Normally open outputs,

rated 7A.

40

2.5mm2

Public points of relay

41

Bus 2 A-phase voltage

sensing input

1.0mm2

Connected to A-phase of Bus 2 (2A fuse is

recommended).

42

Bus 2 B-phase voltage

sensing input

1.0mm2

Connected to B-phase of Bus 2 (2A fuse is

recommended).

43

Bus 2 C-phase voltage

sensing input

1.0mm2

Connected to C-phase of Bus 2 (2A fuse is

recommended).

44

Bus 2 N-wire input

1.0mm2

Connected to N-wire of Bus 2.

45

Bus 1 A-phase voltage

sensing input

1.0mm2

Connected to A-phase of Bus 1 (2A fuse is

recommended).

46

Bus 1 B-phase voltage

sensing input

1.0mm2

Connected to B-phase of Bus 1 (2A fuse is

recommended).

HGM9580 BUS TIE BUS PARALLEL UNIT

HGM9580 Bus Tie Bus Parallel Unit ISSUE 2014-02-16 Version 1.0 Page 19 of 33

NO.

Functions

Cable

Size

Remark

47

Bus 1 C-phase voltage

sensing input

1.0mm2

Connected to C-phase of Bus 1 (2A fuse is

recommended).

48

Bus 1 N-wire input

1.0mm2

Connected to N-wire of Bus 1.

NOTE: USB ports in controller rear panel are configurable parameter ports, user can directly

program controller via PC.

HGM9580 BUS TIE BUS PARALLEL UNIT

HGM9580 Bus Tie Bus Parallel Unit ISSUE 2014-02-16 Version 1.0 Page 20 of 33

7 SCOPES AND DEFINITIONS OF PROGRAMMABLE PARAMETERS

7.1CONTENTS AND SCOPES OF PARAMETERS

Form 1

No.

Items

Parameters

Defaults

Description

Battery Setting

1

Rated Voltage

(0-60.0)V

24.0

Standard for checking battery

over/under voltage.

2

Over Voltage

(0-200)%

120%

Setting value is rated voltage’s

percentage, return value (default:

115%) and delay value (default: 60s)

can be set.

3

Under Voltage

(0-200)%

85%

Setting value is rated voltage’s

percentage, return value (default: 90%)

and delay value (default: 60s) can be

set.

Bus Setting

1

AC System

(0~3)

0

0: 3P4W; 1: 3P3W;

2: 2P3W; 3: 1P2W.

2

Volt. Trans.(PT)

(0-1)

0

0: Disable; 1:Enable

Switch Setting

1

Close Time

(0~20.0)s

5.0

Pulse width of switch on. When it is 0,

means output constantly.

2

Open Time

(0~20.0)s

3.0

Pulse width of switch off.

Module Setting

1

Power On Mode

(0~1)

0

0: Manual mode 1: Auto mode

2

Module Address

(1~254)

1

Controller’s address during remote

sensing.

3

Stop Bit

(0~1)

0

0: 2 stop bits; 1: 1 stop bit

4

Language

(0~2)

0

0: Simplified Chinese 1: English

2: Others

5

Password

(0~65535)

00318

For entering advanced parameters

setting.

Flexible Input Ports

Flexible Input Port 1

1

Contents Setting

(0~50)

28

Remote OnLoad. See form 3

2

Active Type

(0~1)

0

0: Closed to active

1: Open to active

Flexible Input Port 2

1

Contents Setting

(0~50)

0

User defined. See form 3

2

Active Type

(0~1)

0

0: Closed to active

1: Open to active

3

Arming

(0~2)

2

0: From paralleling 1: Always 2:Never

Table of contents

Other Smartgen Industrial Equipment manuals