Square 1 Design TR210-14 User manual

FOREWORD

This manual explains the proper maintenance of Square 1 Design Finish Rollers, as well as the daily

lubrication and periodic inspection procedures. Please read this manual thoroughly even though you

may already be familiar with other Square 1 Design Finish Rollers, because this manual contains the

most current information about Square 1 Design Finish Rollers. This manual has been based on the

standard Square 1 Design Finish Roller. If you have any questions on modifications to your equipment,

please contact Square 1 Design & Manufacture, Inc., or your sales representative. Square 1 Design &

Manufacture, Inc. reserves the right to make any changes or modifications to this manual or Square 1

Design Finish Rollers without giving previous notice and without incurring any obligation.

FOREWORD

This manual explains the proper maintenance of Square 1 Design Roof Truss Finish Roller as well as

the daily lubrication and periodic inspection procedures. Please read this manual thoroughly even

though you may already be familiar with other Square 1 Design equipment, because it contains the most

current information about the Square 1 Design Truss Roller. This manual has been based on the

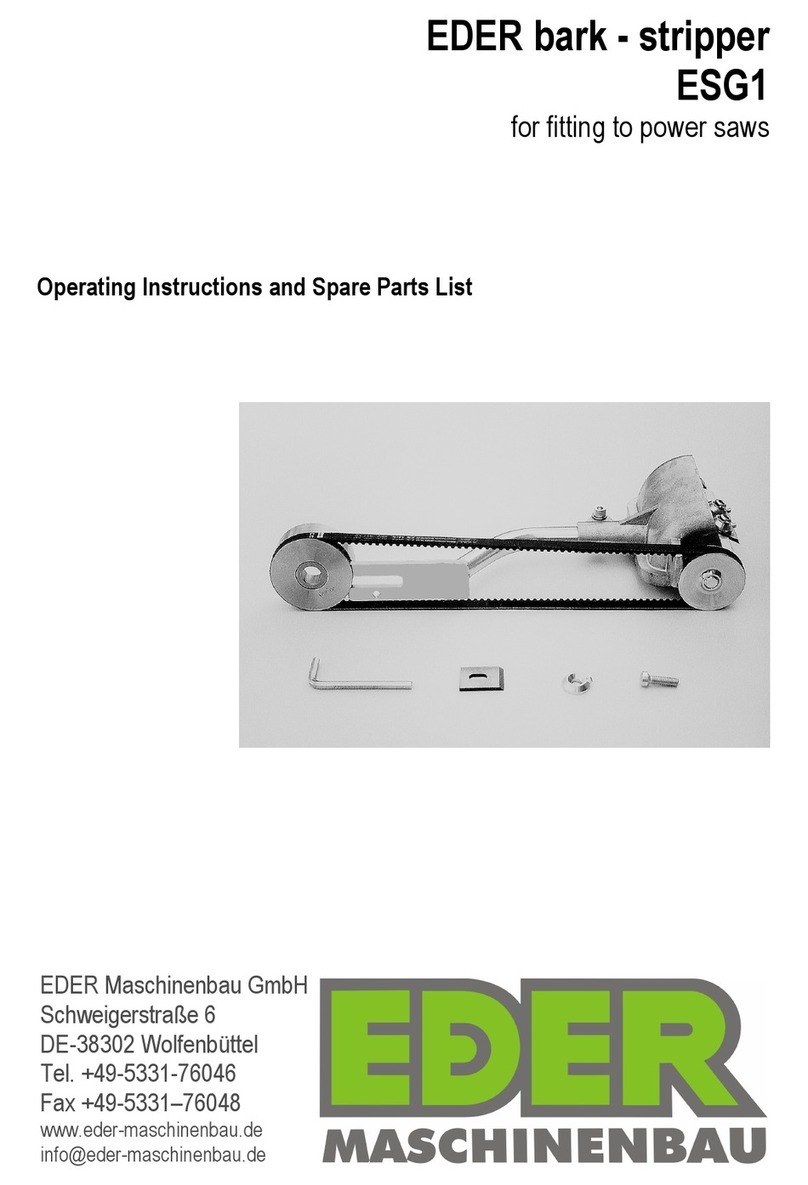

SQ-1 ROOF TRUSS FINISH

ROLLER

Operators Manual

Roof Truss

Roller

TR210-14

TR212-14

TR214-14

TR215-14

TR216-14

ALWAYS DISCONNECT AND LOCK OUT ANY POWER SOURCES WHEN ADUSTING OR REPAIRING ANY EQUIPMENT.

1

FOREWORD

This manual explains the proper maintenance of Square 1 Design Roof Truss Finish Roller as well as

the daily lubrication and periodic inspection procedures. Please read this manual thoroughly even

though you may already be familiar with other Square 1 Design equipment, because it contains the most

current information about the Square 1 Design Roof Truss Finish Roller. This manual has been based on

the standard Square 1 Design Roof Truss Finish Roller. If you have any questions on modifications to

your equipment, please contact Square 1 Design., or your sales representative. Square 1 Design reserves

the right to make any changes or modifications to this manual or its Roof Truss Finish Roller without

giving notice and without incurring obligation.

ALWAYS DISCONNECT AND LOCK OUT ANY POWER SOURCES WHEN ADUSTING OR REPAIRING ANY EQUIPMENT.

2

CONTENTS

Foreword Page 1

Before Initial Operation Page 3

General Description Page 4

Operation of Roof Truss Finish Roller Page 5

Safety and Maintenance Page 5

Safety Guidelines Page 6

Safety Checklist Page 7

Maintenance Page 8

General Operation Page 9

Drive Chain Adjustment Page 9

Right Chain Adjustment Page 9

Left Chain Adjustment Page 9

Roller Adjustment Page 10

Repair and Replacement Page 11

Electrical Page 11

Safety Switches Page 11

Control Panel Page 12

Motors Page 13

Mechanical Page 13

Drive Assembly Page 13

Chain Removal Page 14

Drive Sprocket Removal Page 14

Roller Sprocket Removal Page 14

Idler Sprocket Removal Page 15

Rollers Page 15

Top Bearing Removal Page 15

Top Roller Removal Page 16

Bottom Bearing Removal Page 16

Bottom Roller Removal Page 16

Ordering Replacement Parts Page 17

Warranty Information Page 18

Detail N: Non-Panel Side Page 19

Detail M: Panel Side Page 20

Detail K & L: Idler Assembly Both Sides Page 21

Replacement Parts List Page 22

ALWAYS DISCONNECT AND LOCK OUT ANY POWER SOURCES WHEN ADUSTING OR REPAIRING ANY EQUIPMENT.

3

BEFORE INITIAL OPERATION

•Please read this manual thoroughly. This will give you a complete understanding of a Square

1 Design Roof Truss Finish Roller and permit you to operate it correctly and safely.

•Identify and inform ALL employees who will operate or be near the Square 1 Design

equipment of ALL safety concerns in this manual and on the production floor. It is very

important from the employees, employers, and manufacturers standpoint that employee’s

safety comes above all else. The employer should make sure any employee who either operates

or works near the equipment has been properly trained and given written notice of any and all

safety concerns on the production floor.

•Always perform pre-operation check and periodic maintenance. This will help prevent

sudden malfunctions (due to poorly maintained equipment), improve work efficiency, and help

insure safe working conditions.

ALWAYS DISCONNECT AND LOCK OUT ANY POWER SOURCES WHEN ADUSTING OR REPAIRING ANY EQUIPMENT.

4

GENERAL DESCRIPTION

The Square 1 Design Finish Roller is designed to be a continuously operating machine. It is

designed to be used in conjunction with a conveyor system to increase the assembly

speed of finished roof trusses. The standard Square 1 Design Roof Truss Finish Roller operates at a

constant work speed of 98’ per minute. The Square 1 Design Roof Truss Finish Roller’s heavy design will

allow it to finish press even the heaviest gauge plate quickly and easily.

The model # and serial #’s are located on the Inside of the Electrical Panel of the Square 1 Design Finish

Roller. This information will be needed when contacting Square 1 Design & Manufacture Inc. for service

information. Any information that is needed can be obtained by contacting your sales representative or:

SQUARE 1 DESIGN & MANUFACTURE, INC.

1 Clark Road

Shelbyville, IN 46176

Phone: +1-866-647-7771

Fax: +1-866-646-5771

ALWAYS DISCONNECT AND LOCK OUT ANY POWER SOURCES WHEN ADUSTING OR REPAIRING ANY EQUIPMENT.

5

OPERATION OF THE ROOF TRUSS FINISH ROLLER

The Square 1 Design Roof Truss Finish Roller is very simple to operate and maintain. Square 1 Design

suggests that operation of the Square 1 Design equipment proceed in the following manner:

1. Everyone near the machine read the manual so general safety guidelines can be identified.

2. Everyone near the machine identify the safety devices and how they operate.

3. Perform daily, weekly and monthly safety and maintenance analysis.

4. Correct any problems before operation of the equipment.

5. Check the area before beginning to be certain no employees or obstacles are near the

machine.

6. Once the machine is started check the safety devise operation.

SAFETY AND MAINTENANCE

•Employee safety is a key concern at Square 1 Design manufacturing and should also be at your

production facility. It is important to stress safety concerns around any type of production

equipment because serious injury can occur without the proper training and supervision.

•Square 1 Design suggests that any employee who will operate or work around this equipment

be given the opportunity to read this manual and receive training from qualified personnel at

your facility.

•With proper maintenance, the equipment and work area become safer. So, in accordance with

common safety practices, proper maintenance is just as important. Square 1 Design has the

following list of general safety and maintenance guidelines that should accompany any safety

standards your company has established.

ALWAYS DISCONNECT AND LOCK OUT ANY POWER SOURCES WHEN ADUSTING OR REPAIRING ANY EQUIPMENT.

6

SAFETY GUIDELINES

1. Cleanliness: The area surrounding the Square 1 Design Roof Truss Finish Rollers must be

checked daily for any obstructions such as loose lumber or plates that could affect the normal

operation of the machine.

2. Operate new equipment with special caution: People are sometimes overconfident that

new equipment will work just like old equipment. This is not always true; a special caution

should be taken around the Square 1 Design Roof Truss Finish Rollers.

3. Proper equipment use: The proper equipment should be worn by individuals working on or

near the Square 1 Design Roof Truss Finish Rollers to prevent injury. Loose fitting clothing that

can be caught in the machine or on a truss itself should NOT be worn. Gloves should NOT be

worn. Safety glasses must be worn for the protection of the employees. Employees without the

proper equipment should not be allowed near the Square 1 Design Roof Truss Finish Roller. It is

management’s responsibility to enforce these guidelines. It also becomes the employee’s

responsibility to make sure these guidelines are enforced.

4. Safety bars should be identified and proven to be in proper working order: All

employees who will be working on or near the Square 1 Design Roof Truss Finish Rollers should

know how the safety features work. Each employee should also confirm the machine is

operating properly. If any employee notices the equipment may be malfunctioning in any way, a

supervisor is to be notified immediately. The power to the equipment is to be locked down until

the problem can rectified.

5. Disconnect and lock out all power sources before any maintenance or repair is to

take place: It is important for the equipment’s power to be disconnected and locked out to

prevent an accidental start up, whether by another employee or workers error.

6. Never stand between a Square 1 Design Roof Truss Finish Roller and a TRUSS! This

can result in injury or death. Be smart do not stand between the machine and the object it is

getting ready to press.

7. Follow the safety checklist every day: The following checklist should be followed every day to

ensure employee safety and a safe working environment.

ALWAYS DISCONNECT AND LOCK OUT ANY POWER SOURCES WHEN ADUSTING OR REPAIRING ANY EQUIPMENT.

7

SAFETY CHECKLIST

Daily:

A. Check safety bars to assure they move freely and easily.

B. Check to make sure the machine stops properly when the safety bars are moved.

C. Check for unusual noise, overheating, oil leaks or other unusual characteristics.

D. Check the area surrounding the Square 1 Design Roof Truss Finish Roller for cleanliness.

E. Perform daily maintenance

F. Be sure area is clear of people when starting the machine.

G. Check to be sure everyone around the Square 1 Design Roof Truss Finish Roller is wearing the

proper equipment.

Weekly:

A. Check the bearings for wear.

B. Visually inspect motors and gearboxes for excessive dirt, heat, or dust.

C. Check ventilation openings to assure they are not clogged by dirt or dust

D. Check all bolts, nuts, and screws and tighten as needed.

E. Check drive chain tension and tighten as required.

F. Check oil level in the drive unit and add proper amount if necessary.

G. Use compressed air to remove sawdust and dirt build-up on the system and around the

bearings. *

* Wear eye protection when using the compressed air.

ALWAYS DISCONNECT AND LOCK OUT ANY POWER SOURCES WHEN ADUSTING OR REPAIRING ANY EQUIPMENT.

8

MAINTENANCE

As mentioned earlier, keeping the Square 1 Design Roof Truss Finish Roller well maintained makes the

work environment safer and allows reliable production for many years. Maintenance on the

Square 1 Design Roof Truss Finish Roller consists of lubricating the machine and chain and tightening all

nuts and bolts. The following maintenance schedule MUST be followed.

Motors:

The bearings require no additional lubricant throughout the life of the motor.

Drive Unit:

During the oil change process, the magnetic drain plug should be thoroughly cleaned and

reinstalled to prevent leakage.

Chain:

Non-detergent petroleum base oil every 18 hours should be used.

Grease Fittings:

General-purpose grease should be used every 80-120 hours.

Nuts & Bolts:

All nuts and bolts must be checked and tightened before operation on the Square 1 Design Roof

Truss Finish Roller.

ALWAYS DISCONNECT AND LOCK OUT ANY POWER SOURCES WHEN ADUSTING OR REPAIRING ANY EQUIPMENT.

9

GENERAL OPERATION

Operating a Square 1 Design Roof Truss Finish Roller is a relatively simple job. The Square 1 Design Roof

Truss Finish Rollers are designed to be continuous running machines. There are several adjustments that

will be a part of daily operation. This section lists these adjustments as well as instructs the user on how

to perform them. One thing that must ALWAYS be remembered is to:

DRIVE CHAIN ADJUSTMENT

All models of the Square 1 Design Roof Truss Finish Rollers have a drive train on both ends. All rollers are

pre-set at Square 1 Design for a standard 2 x 4, and chain tension is pre-set. You may want to feel the

tension in the chain when it arrives, so you know the correct tension of the chain.

RIGHT DRIVE TRAIN ADJUSTMENT

•Adjustment is begun by removing the nut and lock washer holding the right end chain guard

closed. Prop open the chain guard to allow enough space to work free of any obstructions.

Loosen the locknut holding the idler sprocket adjustment screw in place.

•The idler sprocket may then be adjusted by turning the bolt clockwise to increase tension. Turn

the bolt counter clockwise to decrease tension. A little slack is desirable as it allows the chain

links seat themselves on the sprocket teeth. This will reduce wear on the on the sprocket and

bearings.

•After adjustment is complete, the locknut must be tightened to maintain proper tension. Close

the chain guard and replace the lock washer and nut.

LEFT DRIVE TRAIN ADJUSTMENT

•Adjustment is begun by removing the nut and lock washer holding the left end chain guard

closed. Prop open the chain guard to allow enough space to work free of any obstructions.

•Loosen the 4 mounting bolts holding the left gear reducer to the base. Chain tension is increased

by turning the adjustment bolts clockwise and reduced by turning the adjustment bolts

counterclockwise. A little slack is desirable as it will allow the chain links to seat themselves. You

must be sure the drive sprocket is still in line with the roll sprocket.

•After adjustment is complete the 4 mounting bolts must be tightened to maintain proper

tension. Close the chain guard and replace the lock washer and nut.

ALWAYS DISCONNECT AND LOCK OUT ANY POWER SOURCES WHEN ADUSTING OR REPAIRING ANY EQUIPMENT.

10

ROLLER ADJUSTMENT

The Square 1 Design Roof Truss Finish Rollers have up to 4 1/2” of total roller adjustment. The top roller

is the only adjustable roller. The bottom roller remains stationary and is set at 32” high from the floor,

unless ordered otherwise.

•To adjust the top roller height both end guards must be opened. The drive chain idler sprocket

adjustment must be loosened to allow plenty of slack in the drive chain. Care must be taken

during upper roller adjustment to assure there is enough slack in the chain to allow full roller

adjustment. Depending on the amount of movement, you may want to move each end up a

little at a time. The bearings are self-aligning, but to avoid going too far, it is best to move each

end a little at a time.

•To lower the top roller, loosen the bottom roller adjustment nuts on both ends of the roller

assembly. Begin by turning the top roller adjustment nuts counter clockwise to lower each end

of the roll. When the roll is at the correct height, tighten the adjustment nuts to lock the roll in

place.

•To raise the top roller, loosen the bottom roller adjustment nuts on both ends of the roller

assembly. Begin by turning the top roller adjustment nuts clockwise to raise each end of the roll.

When the roll is at the correct height, tighten the adjustment nuts to lock the roll in place.

•Readjust the chain drive to the proper tension, close the guards, unlock the machine and test

run the Square 1 Design Finish Roller.

Note: When adjusting the roller height, raise the roll so that a piece of the lumber you are going to use

can be inserted between the rolls. Insert two pieces of the lumber in at each end of the roll. Now, lower

the roll onto the lumber. When the lumber can be wiggled from side to side, but cannot be pulled out,

the roll is at the correct height.

ALWAYS DISCONNECT AND LOCK OUT ANY POWER SOURCES WHEN ADUSTING OR REPAIRING ANY EQUIPMENT.

11

REPAIR AND REPLACEMENT

In the case that a part of the machine is not working properly, this section lists how to remove and

replace the correct part from the Square 1 Design Roof Truss Finish Roller. If parts are needed it is

recommended that you contact Square 1 Design & Manufacture, Inc. at the address list on page 17.

ELECTRICAL

The following sections cover the electrical portions of the Square 1 Design Roof Truss Finish Roller. The

following sections cover the electrical portions of the Square 1 Design Roof Truss Finish Roller. Listed

throughout this section contain a parts list and breakout of each item. Replacement parts are available

as individual components or as complete units. Square 1 Design machines use SO multi-conductor cable

with sealed fittings. Any repairs should be done using the same materials.

SAFETY SWITCHES

There are 2 safety switches on each machine. These are available through Square 1 Design &

Manufacture, Inc. If they should ever need to be replaced contact Square 1 Design & Manufacture Inc.

to make sure they are installed properly. Please contact Square 1 Design for the parts list, breakout, and

schematic to determine the information needed.

REMOVAL OF SAFETY SWITCHES

•The safety switches are set to work with the safety bars. Remove the screws, nuts, and lock

washers holding the switch in place. Loosen the conduit locknut and unscrew the switch from

the conduit.

•The wiring can now be disconnected, and a new switch can be installed using the schematic as a

guide.

•Reverse the instructions to reinstall the safety switches. Set the actuator arm against the safety

bar.

•Test and make sure the safety bar is working before attempting to use the machine.

ALWAYS DISCONNECT AND LOCK OUT ANY POWER SOURCES WHEN ADUSTING OR REPAIRING ANY EQUIPMENT.

12

CONTROL PANEL

This unit is available as a complete control panel, a starter, or component parts for starters. For a parts

list, breakout, and schematic to determine the information needed.

REMOVAL ON THE CONTROL PANEL

•To remove the control panel, first disconnect the wiring inside the box to all motors, switches,

and input voltage. Remove the conduit locknuts inside and pull the conduit free from the panel.

•The control panel can now be removed by unfastening the 4 nuts and bolts mounting it to the

mounting bracket.

•Reverse the procedure to install the panel.

•Refer to the schematic in provide in the electrical panel for the rewiring.

•Make sure the machine is operating correctly prior to running production.

STARTER REMOVAL

•Remove the control panel from mounting bracket. The starter can now be removed from the

panel by unfastening the screws holding it in place. If you desire to replace component parts

refer to the parts listing and breakout for disassembly and the part number.

•Reverse the procedure to install the starter back into the control box.

•Reinstall the panel.

•Refer to the schematic provide in the electrical panel for the rewiring.

•Make sure the machine is operating correctly prior to running production.

SWITCH REMOVAL

•All 3 switches (Stop, Foreword, & Reverse) can be replaced using the same procedures. First

disconnect the wiring to the back of the switch inside the control box. Unscrew the ring bezel

from the front of the switch. Remove the name plate and push the switch through the panel.

•Reverse the procedure for reinstalling the switch on the front panel. Be extra cautious the

buttons match the direction the machine runs when reinstalling (The Stop button reads “Stop”

etc.).

•Refer to the schematic in provide in the electrical panel when making the connections.

•Make sure the machine is operating correctly prior to running production.

ALWAYS DISCONNECT AND LOCK OUT ANY POWER SOURCES WHEN ADUSTING OR REPAIRING ANY EQUIPMENT.

13

MOTORS

The motors are available as a complete unit or in component parts. Refer to the parts list breakouts, and

schematics listed below to determine the information needed.

MOTOR REMOVAL

•Both motors (left and right drive) may be removed and replaced by the same method. Begin by

disconnecting the electrical connections inside the connection box mounted on the side of the

motor. This can be done by unscrewing 4 nuts holding the cover on the connection box. The

connection box cover is connected to the conduit. It can be set aside for reassemble. Remove

the drive sprocket and the 4 bolts holding the motor to the mounting plate and carefully remove

the motor from the plate.

•Reverse the procedure for reinstalling the motor the motor mounting plate. Refer to the

schematic inside the cover of the motor to make the electrical connections. Make sure the

machine runs properly before running the machine in production.

MECHANICAL

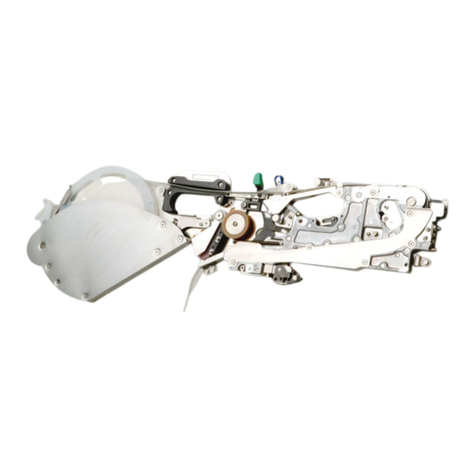

The following section covers the mechanical portion of the Square 1 Design Roof Truss Finish Roller.

Exhibits listed throughout this section contain parts lists and breakouts of common replacement parts.

Some replacement parts are available as individual components and other are available only as a

complete unit. Contact Square 1 Design & Manufacture Inc. Or your sales representative for more

information.

DRIVE ASSEMBLY

The drive assembly contains several components that are available as replacements. The list provided

below should give you all the information you need when repairing mechanical aspects of the Square 1

Design Roof Truss Finish Roller.

ALWAYS DISCONNECT AND LOCK OUT ANY POWER SOURCES WHEN ADUSTING OR REPAIRING ANY EQUIPMENT.

14

CHAIN REMOVAL

•Remove the chain guard by removing the fasteners.

•Locate the master link in the chain making sure it is in a location with easy access. Reduce the

tension on the chain. Remove the master link by unsnapping the retaining clip and removing the

link plate. Slide the master link out of the chain.

•Reverse the procedure to reassemble. Make sure the machine is operating correctly prior to

running production.

DRIVE SPROCKET REMOVAL

•Remove the chain guard by removing the fasteners.

•Remove the chain from the train assembly. Loosen the two setscrews. The sprocket can then be

removed using the correct size puller. The sprocket will now slide off. It may be necessary to use

the fine grade emery paper to remove any burrs from the shaft before reassembly.

•Reverse the procedure for reassemble. Make sure the machine is operating correctly prior to

running production

ROLLER SPROCKET REMOVAL

•Remove the chain guard by removing the fasteners.

•Remove the chain from the drive train. Unscrew the 3 bolts from the sprocket. Insert 2 bolts in

the tapped holes and tighten until the sprocket is free from the taper lock busing. Pull the taper

lock bushing form the roller shaft then remove the sprocket. It may be necessary to use fine

grade emery paper to remove burrs from the shaft before reassembly.

•Reverse the procedure before reassembly. Make sure the machine is operating correctly prior to

running production.

ALWAYS DISCONNECT AND LOCK OUT ANY POWER SOURCES WHEN ADUSTING OR REPAIRING ANY EQUIPMENT.

15

IDLE SPROCKET REMOVAL

•Remove the chain guard by removing the fasteners.

•Remove the chain from the drive train and disconnect the grease tube fittings. Slide the

sprocket bracket down to remove it from the mounting channel.

•To remove the sprocket, loosen the 2 set screws holding the shaft in position. The shaft then

may be pressed free from the housing. Care must be taken not to damage the sprocket bracket.

•The bushing can then be pressed out of the sprocket. If the shaft has worn through the body of

the sprocket, the sprocket will also need to be replaced.

•Reverse the procedure for reassemble and grease prior to start up. Make sure the machine is

operating correctly prior to running production.

ROLLERS

The rollers and bushings are replaceable items. Refer to the parts list and breakouts to determine the

replacement parts required.

TOP BEARING REMOVAL

•Remove the chain guard by removing the fasteners.

•Adjust the roller up in order to insert 3 roller braces made from 2” thick lumber between the

rollers. Lower the roller into the fittings. If the bearing being removed is in the drive side, you

will need to remove the drive sprocket before starting the bearing removal.

•First, unfasten the 4 bolts. Remove the bearing side supports. Remove the grease insert from

the bearing block. Loosen the roll adjustment bolts. Pop the pin out of the nut holding the roll

adjustment rod to the bearing block off from the shaft with the correct tools.

•Check the bearing housing for damage. If the bearing has worn through the housing it will have

to be replaced.

•To remove the bearing, use an arbor slightly smaller the OD of the bearing, and press it out of

the housing. When pressing a new bearing into the housing, caution must be taken to prevent

damage to the bearing. After the bearing is installed in the housing, the grease holes must be

drilled. Use the housing as a guide for the drilling.

•Remove all burrs from the ID of the bearing.

•Check the shaft for burrs before reassembly.

•Reverse the procedure to reassemble and reseal all fittings before start-up. Make sure the

machine is operating correctly prior to running production.

ALWAYS DISCONNECT AND LOCK OUT ANY POWER SOURCES WHEN ADUSTING OR REPAIRING ANY EQUIPMENT.

16

TOP ROLLER REMOVAL

•Follow the directions to remove the bearing blocks.

•Grind off weld tacks holding side frame panels to the top frame supports. Grind side supports

from head assembly. Unfasten bolts from either side to remove the head assembly.

•Repeat this procedure for the other side.

•Place slings around the roller and attach a crane or hoist of proper capacity and lift the roller

from the unit.

•Reverse the procedure to reassemble and grease all fittings before start-up.

BOTTOM BEARING REMOVAL

•Remove the chain guard by removing the fasteners.

•If the bearing being removed is on the drive side of the Roof Truss Finish Roller, you will need to

remove the drive sprocket before starting the bearing removal.

•Remove the top roll. Disconnect the grease inserts to the bottom roll. Remove the bottom brace

from the top roll by removing bolts. Suspend the bottom roll with the device that will be used to

remove it from the frame. Unfasten the 6 bolts.

•Remove the bearing side supports. Pull the bearing block off the shaft with the correct tools.

Check the bearing housing for damage.

•If the bearing has worn through the housing it will have to be replaced.

•To remove the bearing, use an arbor slightly smaller the OD of the bearing, and press it out of

the housing. When pressing a new bearing into the housing, caution must be taken to prevent

damage to the bearing.

•After the bearing is installed in the housing, the grease holes must be drilled. Use the housing as

a guide for the drilling.

•Remove all burrs from the ID of the bearing.

•Check the shaft for burrs before reassembly.

•Reverse the procedure to reassemble and reseal all fittings before start-up.

•Make sure the machine is operating correctly prior to running production.

BOTTOM ROLLER REMOVAL

•Follow the directions to remove the bottom bearing blocks.

•Lift roll from the unit using the suspension equipment already holding the roll.

•Reverse the procedure to reassemble and grease all fittings before start-up.

ALWAYS DISCONNECT AND LOCK OUT ANY POWER SOURCES WHEN ADUSTING OR REPAIRING ANY EQUIPMENT.

17

ORDERING REPLACEMENT PARTS

Replacement parts can be ordered by calling, emailing, or faxing:

SQUARE 1 DESIGN & MANUFACTURE, INC.

1 Clark Road

Shelbyville, IN 46176

Phone: +1-866-647-7771

Fax: +1-866-646-5771

When ordering parts, you must include the part number of the replacement part

and the serial and model #’s of your Square 1 Design Roof Truss Finish Roller.

ALWAYS DISCONNECT AND LOCK OUT ANY POWER SOURCES WHEN ADUSTING OR REPAIRING ANY EQUIPMENT.

18

WARRANTY

Square 1 Design & Manufacture, Inc. warrants the equipment manufactured by it, to be free from

defects in materials or workmanship for one (1) year from the date of delivery to the original purchaser.

This is provided the equipment had been properly installed, operated, used, cared for, adjusted, cleaned

and lubricated by the owner. All equipment claimed to be defective shall be returned to Square 1 Design

& Manufacture, Inc. charges prepaid. All collect shipments will be refused. If upon inspection Square 1

Design & Manufacture Inc. determines to its satisfaction, that any part of the equipment is defective,

Square 1 Design & Manufacture, Inc, at its option, correct the defect by repair or replacement.

This warranty shall not apply if the original equipment had been altered or modified by any person other

than Square 1 Design & Manufacture Inc. This Warranty shall not apply to starters, motors, gear

reducers, or microswitches that are component parts of the equipment. Those separate component

parts are governed by separate warranties of the respective component manufacturers, which

warranties of the respective component manufacturers which warranties may be shorter than or longer

than the one (1) year warranty granted by Square 1 Design & Manufacture, Inc. upon request by the

owner. Any repairs are available from Square 1 Design & Manufacture Inc. upon request by owner. Any

repair or replacement of such component parts shall be governed solely by manufacturer, and it shall be

owner’s responsibility to enforce any warranty claims directly with such component part manufacturer.

EXCEPTION FOR THIS WARRANTY AS EXPRESSLY STATED, SQUARE 1 DESIGN & MANUFACTURE, INC.

MAKES NO OTHER WARRANT EXPRESSED OR IMPLIED. ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE IS HEREBY DISCLAIMED.

Square 1 Design & Manufacture Inc. shall not be liable for damages, direct, consequential, or incidental,

or for delays, if such occur as a result of defects in material or workmanship.

SQUARE 1 DESIGN & MANUFACTURE INC.

PURCHASE DATE: ________________________________

MODEL NUMBER: _______________________________

SERIAL NUMBER: ________________________________

ALWAYS DISCONNECT AND LOCK OUT ANY POWER SOURCES WHEN ADUSTING OR REPAIRING ANY EQUIPMENT.

19

Non-Panel Side

This manual suits for next models

4

Table of contents

Popular Industrial Equipment manuals by other brands

Matsing

Matsing MS-MBA-4.4-SH2-SH2 instruction manual

Shini

Shini SAL-G Series manual

Kutzner + Weber

Kutzner + Weber ZUK 130 installation instructions

Kistler

Kistler 9708A Series instruction manual

Transforming Technologies

Transforming Technologies IN1202-22 Operation manual

ABB

ABB HT565469 Operation manual

Dodge

Dodge Torque-Arm II TA0107LM Installation and instruction manual

Hanskamp

Hanskamp MultiDos 035-000-000 Series Installation and operating instructions

SUHNER ABRASIVE

SUHNER ABRASIVE TAM Technical document

ABB

ABB HT842659 Operation manual

Ortlinghaus

Ortlinghaus 0086-237 Series Translation of original operating manual

ABB

ABB HT612770 Operation manual