Trumpf BendMaster 60 User manual

Operator's manual

BendMaster

TruBend Cell 5000

Operator's manual

BendMaster

TruBend Cell 5000

Original operator's manual

Edition 2015-06-01

Order Information Please specify when ordering this document:

Operator's manual

BendMaster

Edition 2015-06-01

Document number B579EN

Address for orders TRUMPF Maschinen Austria GmbH + Co. KG

Technische Redaktion

Industriepark 24

A-4061 Pasching

Fon: +43 7221 603 - 0

Fax: +43 7221 603 - 50

Internet: http://www.at.trumpf.com

E-Mail: [email protected]

For "partly completed machinery" in accordance with the EC

Machinery Directive, this document corresponds to the

assembly instructions.

© TRUMPF Maschinen Austria GmbH + Co. KG

Before you proceed ...

This operator's manual documents the automation components

BendMaster (60) and BendMaster (150) in the TruBend Cell

5000 bending cell for the automatic handling of sheets on the

press brakes of the TruBend Series 5000.

The machine documentation includes:

■Spare parts catalog.

■Circuit diagrams.

■TruBend Series 5000 operator's manual.

■TruTops Bend software manual.

■Handling equipment operator's manual

B579EN 2015-06-01 Before you proceed ... I

II Before you proceed ... 2015-06-01 B579EN

Table of contents

Safety

1 For your safety 1‐3

2 Operational safety 1‐5

2.1 Intended use 1‐5

2.2 Authorized personnel 1‐6

3 Hazards 1‐7

3.1 Dangers due to the switch cabinet 1‐7

3.2 Hazards due to laser radiation 1‐7

3.3 Dangers from magnetic fields 1‐8

Mobile fanning magnet (option) 1‐8

3.4 Hazards when dealing with workpieces 1‐9

Sharp-edged workpieces 1‐9

Dangers due to floating loads 1‐9

3.5 Danger due to increased movement dynam-

ics (optional productivity package)

1‐11

3.6 Dangers due to unexpected movements 1‐12

3.7 Dangers due to Teleservice 1‐12

4 Measures to be taken by the manufacturer 1‐13

4.1 Danger zones and safeguarding device 1‐13

4.2 Danger signs on the machine 1‐16

5 Organizational measures to be taken by

the user

1‐20

5.1 Observing warnings and danger signs 1‐20

5.2 Training and instructing operators 1‐20

Measures applicable worldwide 1‐20

5.3 Adhering to the duty of care when handling

the machine

1‐20

5.4 Pay attention to water protection 1‐21

5.5 Using spare parts, accessories, software and

operating materials

1‐22

B579EN 2015-06-01 Table of contents 0‐1

Chapter 1

6 Overview of residual risks 1‐24

7 Disassembly and disposal 1‐26

BendMaster installation conditions

(60)/(150)

Who does what? 2‐3

1 Planning aid 2‐4

2 Installation site 2‐6

2.1 Space requirements 2‐6

2.2 Floor requirements 2‐6

Surface 2‐6

Floor quality 2‐8

2.3 Weight load 2‐10

2.4 Stress due to vibration 2‐11

2.5 Ambient conditions 2‐11

3 Compressed air supply 2‐13

4 Electrics 2‐14

4.1 Electrical power supply 2‐14

Connected loads 2‐14

Connecting cables 2‐15

4.2 Power supply 2‐15

Residual current device (RCD) 2‐15

Line structures 2‐16

4.3 Network link 2‐17

5 Transport 2‐18

5.1 Preparing transport 2‐18

Transport dimensions 2‐18

5.2 Permitted auxiliary tools 2‐18

5.3 Checking, unloading and transporting the

machine

2‐20

On delivery: check the machine 2‐20

0‐2Table of contents 2015-06-01 B579EN

Chapter 2

Unloading and transporting the machine 2‐20

Description

1 Machine concept 3‐3

2 Technical data 3‐4

2.1 BendMaster 3‐4

2.2 BendMaster axes 3‐5

3 The most important assemblies 3‐6

3.1 Nameplate 3‐6

3.2 Floor lane 3‐7

3.3 Arm 3‐7

3.4 BendMaster switch cabinet 3‐7

3.5 Sheet sensor 3‐8

3.6 Rotational transformer 3‐9

3.7 Safety fencing 3‐9

3.8 Control panel 3‐9

3.9 Easy operation 3‐10

3.10 Sensor gauge fingers at the TruBend Series

5000

3‐11

4-axis sensor gauge finger 3‐12

6-axis sensor gauge finger (optional) 3‐13

Backstop resistor 3‐14

4 Options 3‐15

4.1 Extendable floor lane 3‐15

4.2 Gripper 3‐15

Vacuum gripper 3‐15

Multi-gripper 3‐17

Multiple-circuit suction cups 3‐17

Gripper construction kit 3‐18

4.3 Special gripper 3‐19

Magnetic gripper 3‐19

Linear gripper 3‐19

Pivoted-jaw gripper and pivoted-jaw grip-

per with turning axis

3‐20

4.4 Sheet removal station 3‐21

B579EN 2015-06-01 Table of contents 0‐3

Chapter 3

4.5 Double sheet recognition and double sheet

separation

3‐22

Double sheet recognition 3‐23

Double sheet separation 3‐24

4.6 Regripping station 3‐24

4.7 Gripper changing console 3‐25

4.8 Backlighting table 3‐25

4.9 Productivity package 3‐26

4.10 Mobile fanning magnet 3‐27

4.11 Handling equipment 3‐27

4.12 Store connection 3‐28

4.13 TruTops°Bend 3‐29

5 Options at the TruBend 3‐30

Operation

1 Description of the operating elements 4‐6

1.1 Portable manual control unit 4‐6

Operating elements 4‐6

Menus and submenus 4‐7

1.2 Control panel 4‐9

1.3 Stationary 19" screen 4‐10

2 Operating the BendMaster 4‐11

2.1 Safety information 4‐11

2.2 Status display 4‐11

2.3 Software versions view 4‐13

2.4 User settings 4‐13

Changing settings 4‐13

Creating BIO (BendMaster Information

Object)

4‐15

Creating and modifying users 4‐15

2.5 Operating modes 4‐16

Selecting operating modes 4‐17

Enabling conditions for operation modes 4‐17

2.6 Moving axes of the BendMaster manually 4‐22

2.7 Displaying axis positions 4‐26

2.8 Gripper service 4‐27

0‐4Table of contents 2015-06-01 B579EN

Chapter 4

2.9 Automatic gripper change (option) 4‐28

Picking up a gripper 4‐28

Lay down gripper 4‐31

2.10 Regripping station (option) 4‐32

Moving the axes of the regripping station

manually

4‐32

Setting up the regripping station 4‐33

Removing the regripping station 4‐35

2.11 Setting the backstop resistor regardless of

the program

4‐36

3 Switching on and referencing the Bend-

Master

4‐38

3.1 Switching on the BendMaster 4‐38

3.2 Referencing the BendMaster 4‐39

Referencing the Z, A, B, C, Z1, Z2 axes 4‐40

Referencing the D axis 4‐41

3.3 Referencing TruBend 4‐42

4 Switching off the BendMaster 4‐46

4.1 Stopping BendMaster and TruBend in any

emergency or after a malfunction

4‐46

4.2 BendMaster, switching off 4‐46

5 Travel functions 4‐48

5.1 Executing travel functions 4‐48

6 Running in a TruTops program 4‐50

6.1 From BendMaster control V7.0 and higher:

Settings in TruTops Bend

4‐50

6.2 Procedure for productivity package option 4‐50

Checking the productivity package 4‐50

Calculating suction cup capacities 4‐51

Determining the reduction of the robot

speed

4‐52

6.3 Overview, loading a program 4‐52

6.4 Creating a new BendMaster job from the Tru-

Tops Bend program

4‐53

6.5 Archiving, restoring or deleting jobs 4‐55

Filing away a job 4‐56

Restoring an order 4‐56

Deleting a job 4‐57

B579EN 2015-06-01 Table of contents 0‐5

Changing the backup directory path on

the user interface

4‐58

6.6 Defining job details 4‐59

Defining exposure details 4‐59

Editing the gripper weight 4‐61

6.7 Loading and unloading areas 4‐62

Load job 4‐64

Adjusting an area 4‐64

Copying an area 4‐67

Deleting an area 4‐68

Displaying the area position 4‐68

Displaying the area position 4‐69

Defining area details 4‐69

6.8 Performing the rough recognition process

(Search within area)

4‐72

Searching for an area 4‐72

Searching for further loading stacks 4‐76

Intermediate layer, searching for 4‐77

Procedure in the event of problems with

the rough recognition

4‐77

6.9 Defining stacks 4‐78

6.10 Processing stacks 4‐80

6.11 Creating a tooling plan 4‐84

Checking the TruTops tooling plan 4‐84

Selecting a separation method 4‐85

Selecting double sheet recognition 4‐87

6.12 Setting bending parameters 4‐88

Opening bending parameters 4‐89

Selecting bending support 4‐90

Setting the backgauge sensor system 4‐90

Setting the approach strategy 4‐91

Setting the backstop resistor for single

bending operations

4‐92

6.13 Program, loading 4‐92

Opening the running in program 4‐92

Program steps for running in 4‐93

Selecting an execution method 4‐94

Running in procedure 4‐94

Teaching a point 4‐96

Points, editing 4‐96

Setting the main run indicator manually 4‐98

Deleting a point 4‐99

0‐6Table of contents 2015-06-01 B579EN

Displaying axis positions 4‐100

6.14 Starting a run-in program 4‐100

6.15 Production planning 4‐102

Creating or modifying a production plan 4‐102

Setting the speed and required number 4‐103

Executing the production plan 4‐104

6.16 Connection to storage (option) 4‐105

Defining parts data 4‐105

Defining loading and unloading areas of

the storage stations

4‐105

Moving a storage cart manually 4‐106

Moving the BendMaster semi-automati-

cally

4‐106

Moving a storage cart in automatic mode 4‐108

7 Working at the press brake without Bend-

Master

4‐110

7.1 Working at the press brake without Bend-

Master

4‐110

8 Errors and Messages 4‐111

8.1 Displaying and acknowledging errors and

messages

4‐111

8.2 Troubleshoot an error 4‐111

9 Error handling 4‐113

9.1 Jumpering the sensor finger 4‐113

9.2 Image processing diagnostics 4‐113

Opening the diagnostics tool 4‐119

Recording with Vision Diagnostics 4‐121

Saving the image recorded last 4‐124

Restarting the program 4‐125

9.3 Teleservice 4‐125

10 Solving problems and troubleshooting 4‐126

10.1 Problem: no part recognized 4‐126

Solution: no part identified 4‐127

10.2 Problem: Part underneath detected 4‐128

Solution: part underneath detected 4‐129

10.3 Problem: part interference contour recognized 4‐130

Solution: interference contour recognized 4‐131

B579EN 2015-06-01 Table of contents 0‐7

Maintenance (customer)

1 General guidelines 5‐3

2 Maintenance Overview 5‐5

3 Lubrication 5‐6

3.1 Overview 5‐6

3.2 Maintenance Instructions 5‐7

BendMaster: Z slide 5‐7

Regripping station (option) 5‐8

4 Mechanical elements 5‐10

4.1 Maintenance Instructions 5‐10

Safety fencing 5‐10

Lift gate 5‐10

Transport equipment (option): transport

belt

5‐11

BendMaster: Z axis 5‐11

Regripping station 5‐12

Sheet removal station 5‐13

Press brake: sensor gauge finger 5‐13

Gripper changing console (option) 5‐14

BendMaster: pivoted-jaw gripper (option) 5‐15

5 Electrical components 5‐16

5.1 Overview 5‐16

5.2 Maintenance Instructions 5‐17

BendMaster: control cabinet 5‐17

BendMaster: switch cabinet 5‐18

BendMaster: fan in the C arm 5‐20

BendMaster: fan, Z slide 5‐21

6 Optical components 5‐22

6.1 Overview 5‐22

6.2 Maintenance Instructions 5‐22

BendMaster: sheet sensor 5‐22

0‐8Table of contents 2015-06-01 B579EN

Chapter 5

0‐10 Table of contents 2015-06-01 B579EN

Chapter 1

Safety

1 For your safety 1‐3

2 Operational safety 1‐5

2.1 Intended use 1‐5

2.2 Authorized personnel 1‐6

3 Hazards 1‐7

3.1 Dangers due to the switch cabinet 1‐7

3.2 Hazards due to laser radiation 1‐7

3.3 Dangers from magnetic fields 1‐8

Mobile fanning magnet (option) 1‐8

3.4 Hazards when dealing with workpieces 1‐9

Sharp-edged workpieces 1‐9

Dangers due to floating loads 1‐9

3.5 Danger due to increased movement dynam-

ics (optional productivity package)

1‐11

3.6 Dangers due to unexpected movements 1‐12

3.7 Dangers due to Teleservice 1‐12

B579EN 2015-06-01 Safety 1‐1

4 Measures to be taken by the manufacturer 1‐13

4.1 Danger zones and safeguarding device 1‐13

4.2 Danger signs on the machine 1‐16

5 Organizational measures to be taken by

the user

1‐20

5.1 Observing warnings and danger signs 1‐20

5.2 Training and instructing operators 1‐20

Measures applicable worldwide 1‐20

5.3 Adhering to the duty of care when handling

the machine

1‐20

5.4 Pay attention to water protection 1‐21

5.5 Using spare parts, accessories, software and

operating materials

1‐22

6 Overview of residual risks 1‐24

7 Disassembly and disposal 1‐26

1‐2Safety 2015-06-01 B579EN

1. For your safety

With the CE marking and the EC Declaration of Conformity,

TRUMPF confirms that the machine meets the basic health and

safety requirements of the EC Machinery Directive.

The CE marking is located on the nameplate of the machine.

The EC Declaration of Conformity is delivered along with the

machine.

The machine meets the requirements of safety standard ANSI

B11.3.

This chapter describes the safety concept. The chapter describes

how potential dangers can be avoided. The overview of residual

risks contains measures to be taken by the operator in order to

reduce the residual risks.

Notes

■The operator must adhere to the valid safety and accident

prevention regulations of the respective country and the

safety laws of the state and of the region!

■USA and Canada: TRUMPF also recommends compliance

with the ANSI safety regulations for press brakes.

■Observe the operator's manual for the press brake.

Certain operations can be a source of danger during operation.

The documentation contains warnings before the instructions for

these activities. There are danger signs on the machine.

A warning contains signaling words that have been explained in

the following table:

Signaling word Description

DANGER ... refers to great dangers. If not avoided, it can result

in death and serious injuries.

WARNING ... refers to a dangerous situation. It could lead to seri-

ous injuries, if it is not avoided.

CAUTION ... indicates a potentially dangerous situation. It could

lead to injuries, if it is not avoided.

NOTICE If such a situation is not observed, it can lead to dam-

age to property.

Tab. 1-1

B579EN 2015-06-01 For your safety 1‐3

Regulations and guidelines

Chapter Safety

Warnings and danger signs

Example of a warning:

Suspended load!

Falling loads could lead to severe bodily injury or even

death.

ØObserve safety regulations for the handling of heavy loads.

ØNever walk under a suspended load.

ØUse tested and appropriately sized tackle and means of

transportation.

ØEmploy qualified technicians to transport the machine.

ØCarry out transport in accordance with the transport regula-

tions.

1‐4For your safety 2015-06-01 B579EN

DANGER

This manual suits for next models

2

Table of contents

Other Trumpf Industrial Equipment manuals

Trumpf

Trumpf TruHeat HF 1000 Series User manual

Trumpf

Trumpf PFO 33 User manual

Trumpf

Trumpf OMLOX SATELLITE User manual

Trumpf

Trumpf TC 2020R User manual

Trumpf

Trumpf TruTool S 250 User manual

Trumpf

Trumpf F 300-2 Plus User manual

Trumpf

Trumpf TRUPUNCH 5000 User manual

Trumpf

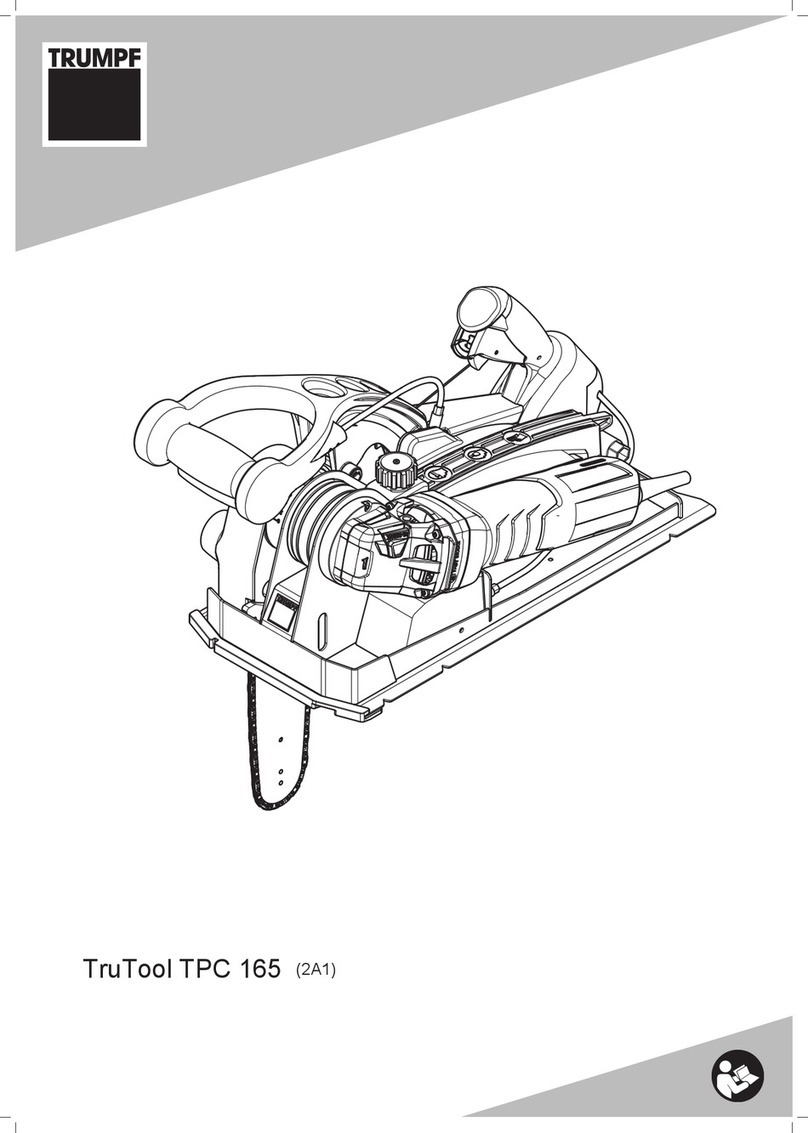

Trumpf TruTool TPC 165 (2A1) User manual

Trumpf

Trumpf Track&Trace User manual

Trumpf

Trumpf TruPlasma RF 1001 User manual