W415-1473 / 04.22.15

EN

7

Expansion / contraction noises during heating up and cooling down cycles are normal and to be expected.

After extended periods of non-operation such as following a vacation or a warm weather season, the appliance may

emit a slight odour for a few hours. This is caused by dust particles on the firebox burning off. Open a window to

sufficiently ventilate the room.

CALIFORNIA PROP 65 WARNING:

Use of this product may produce smoke which contains chemicals

known to the State of California to cause cancer, birth defects, or other

reproductive harm.

If optional ash drawer is purchased, ensure that the ash dump door is

tightly closed, allow the door to snap shut dislodging anything (ashes or

pieces of coal) that may be stuck in the opening.

If outside air is utilized, you should never experience a shortage of combustion air. If you choose not to utilize

outside air and experience draft or smoking problems, you may need to open a door, a window or otherwise provide

some method of supplying combustion air to the appliance.

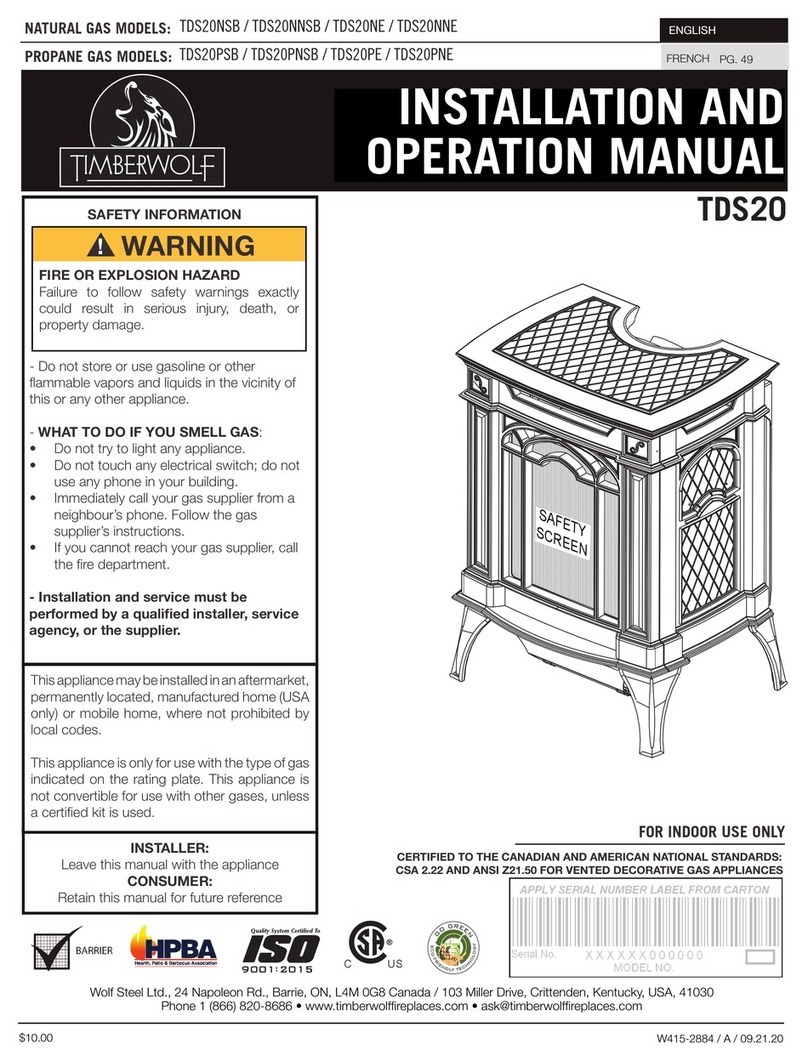

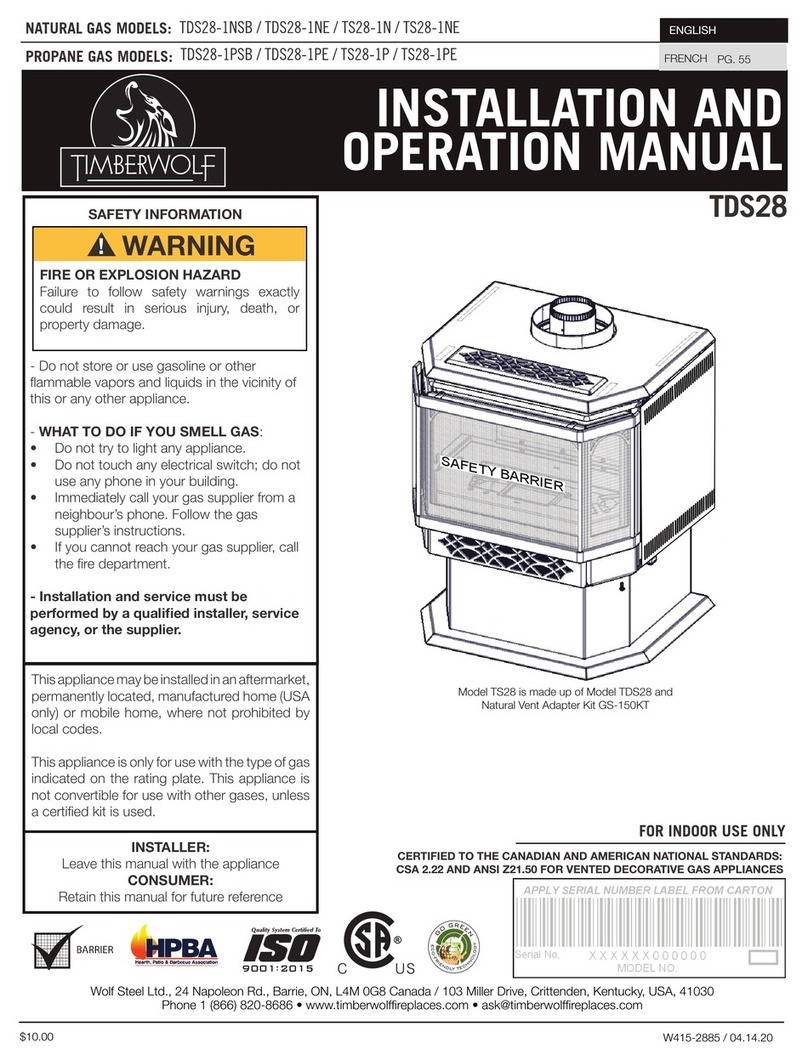

2.5 RATING PLATE INFORMATION

For rating plate location, see

“INSTALLATION OVERVIEW”

section.

This illustration is for reference

only. Refer to the rating plate on the

appliance for accurate information.

8" 8"

18"

8"

C

BACK WALL (M/A)

45°

SIDE WALL (M/L)

FROM HEATER / DU POÊLE

RESIDENTIAL / RÉSIDENTIEL

A. 22IN/PO (560 mm)

B. 12IN/PO (305mm)

C. 8IN/PO (205mm)

BACK WALL (M/A)

SIDE WALL (M/L)

B

A

IF THE STOVE IS TO BE INSTALLED ON ACOMBUSTIBLE FLOOR, IT

MUST BE PLACED ON ANAPPROVED NON-COMBUSTIBLE HEARTH

PAD, THAT EXTENDS 8” (200MM) BEYOND THE STOVE SIDES AND

BACK, AND 18” (455MM) TO THE FRONT.

SI LE PO

Ê

LE EST INSTALL

É SUR UN PLANCHER COMBUSTIBLE, IL DOIT

ÊTRE PLACÉ SUR UNE BASE DE PROTECTION INCOMBUSTIBLE CERTIFÉE

QUI DOIT DÉPASSER LES CÔTÉS ET L’AMÉRE DU

PO

Ê

LE DE 8” (200mm)

ET SE PROLONGER DE 18” (455mm) SUR LE DEVANT.

MINIMUM CLEARANCE TO COMBUSTIBLE MATERIAL USING SINGLE

OR DOUBLE WALLCHIMNEY CONNECTORS / DÉGAGEMENT

MINIMALAUX MATÉRIAUX COMBUSTIBLEAVEC DES CONDUITS DE

RACCORDEMENT À PAROI SIMPLE OU À DOUBLE PAROI

CONTACT LOCAL BUILDING FIRE OFFICIALSABOUT RESTRICTIONS

AND INSTALLATION INSPECTIONS INYOUR LOCALAREA. AMINIMUM

CLEARANCE OF 18 INCHES (457mm) TO THE CHIMNEY CONNECTOR

MAY BE REQUIRED BY THEAUTHORITY HAVING JURISDICTION.

RENSEIGNEZ-VOUS AUPRÈS DESAUTORITÉS LOCALES DU

BÂTIMENT ET DU SERVICE DES INCENDIESAU SUJET DES

RESTRICTIONS ET DES INSPECTIONS D’INSTALLATION DANS VOTRE

RÉGION. UN DÉGAGMENT MINIMAL DE 18 POUCES (457mm)

JUSQU’AU RACCORD DE LA CHEMINÉE PEUT ÊTRE EXIGÉ PAR

L’AUTORITÉ AYANT JURIDICTION.

INSTALLAND USE ONLYIN

ACCORDANCE WITH THE

MANUFACTURER’S INSTRUCTIONS

AND LOCAL BUILDING CODES.

MINIMUM CEILING HEIGHT: 7FT

(2.13m)

HEARTH EXTENSION / COMBUS-

TIBLE FLOOR PROTECTION: IF

INSTALLED ON ACOMBUSTIBLE

FLOOR, UNIT MUST BE PLACED ON

A NON-COMBUSTIBLE FLOOR

PROTECTOR EXTENDING 18”

(455mm) IN FRONT AND 8” (205mm)TO

THE SIDES AND BACK.

CHIMNEY TYPE: MINIMUM 6”

(152mm) DIAMETER APPROVED

RESIDENTIAL TYPE FOR MOBILE

HOME USE A CHIMNEY LISTEDTO

ULC S629 IN CANADA OR UL103HT IN

THE USA.

CHIMNEY CONNECTOR: 6” (152mm)

DIAMETER MINIMUM 24 GAUGE

STEEL MINIMUM CLEARANCE

FROM HORIZONTAL CONNECTOR

AND CEILING 18” (455mm).

DO NOT OBSTRUCT SPACE UNDER

HEATER.

SPECIAL METHODS ARE

REQUIRED WHEN PASSING A

CHIMNEY THROUGH A WALL OR

CEILING. SEE INSTRUCTIONS AND

BUILDING CODES.

DO NOT CONNECT THIS UNIT TO A

CHIMNEY FLUE SERVING

ANOTHER APPLIANCE.

FUEL: FOR USE WITH WOOD ONLY.

DO NOT USE GRATE OR ELEVATE

FIRE. BUILD WOOD FIRE DIRECTLY

ON HEARTH.

WARNING: RISK OF SMOKE

SPILLAGE. OPERATE ONLYWITH

DOOR FULLY CLOSED.

REPLACE GLASS ONLY WITH

CERAMIC GLASS.

DO NOT OVERFIRE. IF HEATER OR

CHIMNEY CONNECTORS GLOW,

YOU ARE OVERFIRING. INSPECT

AND CLEAN CHIMNEY

FREQUENTLY. UNDER CERTAIN

CONDITIONS OF USE CREOSOTE

BUILD-UPMAYOCCUR RAPIDLY.

OPTIONAL BLOWER KIT: EP-62,

115V, 60HZ, 0.82AMP. ROUTE CORD

AWAY FROM UNIT.

DANGER: RISK OF ELECTRICAL

SHOCK. DISCONNECT POWER

BEFORE SERVICING UNIT.

POUR INSTALLATION ETUTILISATION

CONFORMÉMENT AUX INSTRUCTIONS

DU FABRICANT ETAUX CODES LOCAUX

DU BÂTIMENT.

HAUTEUR DE PLAFOND MINIMAL 7PI

(2,13m).

PROLONGEMENT D’ÂTRE/PROTECTION

DU PLANCHER COMBUSTIBLE: SI

INSTALLÉ SUR UN PLANCHER

COMBUSTIBLE, L’APPAREIL DOIT ÊTRE

PLACÉ SUR UNE PLAQUE PROTECTRICE

INCOMBUSTIBLE S’ÉTENDANT SUR 18”

(455mm) À L’AVANT ET8” (205mm) À

L’ARRIÈRE ET SUR LES CÔTÉS.

TYPE DE CHIMNÉE: DIAMÈTRE MINIMAL

DE 6” (152mm) APPROUVÉE POUR USAGE

RÉSIDENTIEL. MAISON MOBILE

EMPLOYEZ UNE CHEMINÉE

HOMOLOGUÉE ULC S629 AU CANADAOU

UL 103HT AUX ÉTATS-UNIS.

RACCORD DE CHEMINÉE: DIAMÈTRE DE

6” (152mm) D’ACIER DE CALIBRE 24

MINIMUM. 18” (455mm) DE DÉGAGEMENT

MINIMAL ENTRE LE RACCORD

HORIZONTAL ET LE PLAFOND.

NE RIEN ENTREPOSER SOUS

L’APPAREIL.

DES MÉTHODES SPÉCIALES SONT

REQUISES LORSQU’UNE CHEMINÉE

TRAVERSE UN MUR OU UN PLAFOND.

VOIR LES INSTRUCTIONS ET LES CODES

DU BÂTIMENT.

NE PAS RACCORDER À LA CHEMINÉE

D’UN AUTRE APPAREIL.

COMBUSTIBLE: POUR USAGE AVEC LE

BOIS SEULEMENT. N’UTILISEZ PAS DE

CHENET OU NE SURÉLEVEZ PAS LE

BOIS. PRÉPAREZ LE FEU DIRECTEMENT

SUR L’ÂTRE.

AVERTISSEMENT: RISQUE

D’ÉCHAPPEMENT DE FUMÉE. TENIR LA

PORTE FERMÉE LORSQUE LE POÊLE

FONCTIONNE. REMPLACEZ LA VITRE PAR

UNE VITRE EN CÉRAMIQUE SEULEMENT.

NE SURCHAUFFEZ PAS L’APPAREIL. SI

L’APPAREIL OU LES RACCORDS

ROUGEOIENT, L’APPAREIL SURCHAUFEE.

INSPECTEZ ET NETTOYEZ LACHEMINÉE

FRÉQUEMMENT. DANS CERTAINES

CONDITIONS, DES DÉPÔTS DE

CRÉOSOTE PEUVENT SE FORMER

RAPIDEMENT.

SOUFFLERIE OPTIONNELLE: EP-62, 115V,

60HZ, 0,82A. TENEZ LE CORDON

ÉLECTRIQUE LOIN DE L’APPAREIL.

DANGER: RISQUE DE SECOUSSE

ÉLECTRIQUE. DÉBRANCHEZ AVANT DE

PROCÉDER À L’ENTRETIEN.

W385-1920

DATE CODE / DE DATE

EPA1900

WOLF STEEL LTD.

24NAPOLEON ROAD, BARRIE,ON, L4M 0G8 CANADA

9700539 (WSL)

4001657 (NGZ)

4001658 (NAC)

4001659 (WUSA)

LISTED SOLID FUEL BURNING SPACE HEATER /

POÊLE À COMBUSTIBLE SOLIDE HOMOLOGUÉ

TESTED TO: / TESTÉ SELON : UL1482 / ULC S627

MODEL / MODÈLE - EPA 1900

15983

HOTWHILEINOPERATION. DO NOT TOUCH. KEEPCHILDREN,

CLOTHINGAND FURNITUREAWAY. CONTACTMAY CAUSE

SKINBURNS.

QUAND L’APPAREIL FONCTIONNE, LA SURFACE DEVIENT

CHAUDE. NE PAS TOUCHER. TENIR LES ENFANTS, LES

VÊTEMENTS ET LES MEUBLES À L’ÉCART. LE CONTACT PEUT

CAUSER DES BRÛLURES À LA PEAU.

CAUTION:

ATTENTION:

U.S. Environmental Protection Agency

Certified to comply with July 1990, particulate emissions

standards/

Certifié conforme à la norme d’ émanation de particles

de juillet 1990

40 CFR Part 60, Subpart AAA

1900 S9

IDE WALL

M

L

TOVE IS TO BE INSTALLED ON ACOMBUSTIBLE FLOOVE IS TO BE INSTALLED ON A COMBUSTIBLE FL

BE PLACED ON ANAPPROVED NON-COMBUSTIBLEE PLACED ON ANAPPROVED NON-COMBUSTIBL

, THAT EXTENDS 8” (200MM) BEYOND THE STOVETHAT EXTENDS 8” (200MM) BEYOND THE STOVE

ACK, AND 18” (455MM) TO THE FRONT.ACK, AND 18” (455MM) TO THE FRONT.

P

LE E

T IN

TAL

É SUR UN PLANCHER COMBÉ SUR UN PLANCHER COM

ÊTRE PLA

É SUR UNE BASE DE PROTECTION INCOMUNE BASE DE PROTECTION INCO

UI DOIT DÉPASSER LES

TÉ

ET L’AM

ET SE PROLONGER DE 18” (455mm) SUR LEET SE PROLONGER DE 1

MINIMUM CLEARANCE TO COMBUSUM CLEARANCE

OR DOUBLE WALLCHIMNEY COOR DOUBLE WALLCHIMN

MINIMALAUX MATÉRIAUX COMMINIMALAUX MATÉRIAUX C

RACCORDEMENT À PAROI SRACCORDEMENT À PAROI

ATION DANS VOTREATION DANS VOTRE

T ÊTRE EXIGÉ PART ÊTRE EXIGÉ PAR

EP-62,

. DISCONNECT POWERDISCONNEC

ORE SERVICING UNIT.ORE SERVICING

UTILISEZ PAS DESEZ PAS DE

EZ LE FEU DIRECTEMENTZ LE FEU DIRECTEMENT

IS

UE

APPEMENT DE FUMÉE. TENIR LAPPEMENT DE FUMÉE. TENIR LA

RTE FERMÉE LORSQUE LE POÊLEE FERMÉE LORSQUE LE POÊLE

ONCTIONNE. REMPLACEZ LA VITRE PARNNE. REMPLACEZ LA VITRE PAR

UNE VITRE EN CÉRAMIQUE SEULEMENT.EN CÉRAMIQUE SEULEMENT.

NE

R

HA

FFEZ PA

L’APPAREIL.

I

L’APPAREIL

LE

RA

RD

UGE

IENT, L’APPAREIL SURCHAUFEE.

ROUGEOIENT, L’APPAREIL SURCHA

IN

PE

TEZ ET NETT

YEZ LA

HEMINÉE

INSPECTEZ ET NETTOYEZ LACHEMIN

FRÉ

UEMMENT. DANS CERTAINES

FRÉQUEMMENT. DANS CERTAINES

ONDITIONS, DES DÉPÔTS DE

CONDITIONS, DES DÉPÔTS DE

CRÉOSOTE PEUVENT SE FORMERCRÉOSOTE PEUVENT SE FORMER

SOUFFLERIE OPTIONNELLE:SOUFFLERIE OPTIONNELLE

60HZ, 0,82A. TENEZ LE CO60HZ, 0,82A. TENEZ LE CO

ÉLECTRIQUE LOIN DE L’ÉLECTRIQUE LOIN DE L

DAN

ER

This wood appliance needs periodic inspection and repair for proper operation.

Consult the owner’s manual for further information. it is against federal

regulations to operate this wood appliance in a manner inconsistent with the

operating instructions in the owner’s manual. / Cet appareil au bois doit faire

l'objet d'une inspection et d'un entretien périodiques pour un fonctionnement

adéquat. Consultez le manuel d'instructions pour plus d'information. Les

règlements fédéraux interdisent d'utiliser cet appareil de chauffage d'une

manière allant à l'encontre des instructions de fonctionnement contenues dans

ce manuel.

U.S. ENVIRONMENTAL PROTECTION AGENCY Certified to comply with

2015 particulate emissions standards. Not approved for sale after May 15,2020.

Certifié conforme à la norme d’ émanation de particles de 2015. Non approuvé

pour la vente après le 15 mai, 2020. 40 CFR Part 60, Subpart AAA. 2.8 Grams

Per Hour / 2015 Crib Wood / 2.8 Grammes par heure / Crib Wood 2015.

W385-2039

MODEL / MODÈLE: 1900