EN

W415-2884 / A / 09.21.20 7

general information

Certified to Canadian and American National Standards: CSA 2.22-XXXX / ANSI Z21.50-XXXX for Vented Decorative Gas Appliances

Certifié selon les normes Nationales Canadiennes et Américaines: CSA 2.22-XXXX / ANSI Z21.50-XXXX pour les Appareils à gaz décoratif à évacuation

Direct vent, vented gas fireplaces. Approved for bedroom, bathroom and bed-sitting room installation. Suitable for mobile home installation, if installed in accordance with the current

standard CAN / CSA Z240MH Series gas equipped mobile homes in Canada, or, in the United States, the Manufactured Home Construction and Safety Standard, Title 24 CFR, Part

3280. When this US Standard is not applicable, use the Standard for Fire Safety Criteria for Manufactured Home Installations, Sites and Communities, ANSI / NFPA 501A. This appliance

must be installed in accordance with local codes, if any; if none, follow the current ANSI Z223.1 or CSA B149. For use with barrier WXXX-XXXX. Follow installation instructions.

Foyer à gaz ventilé. Homologué pour installation dans une chambre à coucher, une salle de bain et un studio. Approprié pour installation dans une maison mobile si son installation

conforme aux exigences de la norme CAN / CSA Z240MH Séries de maisons mobile équipées au gaz en vigueur au Canada, ou, aux États-Unis selon la norme 24 CFR, Part 3280,

Manufactured Home Construction and Safety Standard. Dans le cas ou cette norme d’États-Unis n’est pas pertinentes, utiliser la norme NFPA 501A, Fire Safety Criteria for Manufactured

Home Installations, Sites and Communities. Installer l’appareil selon les codes ou règlements locaux ou, en l’absence de tels règlements, selon les codes d’installation ANSI Z223.1 ou

CSA B149 en vigueur. Utiliser uniquement avec l’écran WXXX-XXXX. Suivre les instructions d’installation.

9700539 (WSL) 4001658 (NAC) 4001657 (NGZ) 4001659 (WUSA)

WOLF STEEL LTD. 24 Napoleon Road, Barrie, ON, L4M 0G8 Canada

XXXX XXXX XXXX XXXX

MODEL / MODÈLE

Altitude

Input

Reduced Input

P4

Élévation

Alimentation

Alimentation Réduite

P4

Manifold Pressure: 3.5” w.c. (NG)

Minimum Supply Pressure: 4.5” w.c. (NG)

Maximum Supply Pressure: 7”* w.c. (NG)

Pression au Collecteur: 3,5” d’une colonne d’eau (GN)

Pression d’Alimentation Min.: 4,5” d’une colonne d’eau (GN)

Pression d’Alimentation Max.: 7” ** d’une colonne d’eau (GN)

** Maximum inlet pressure not to exceed 13”.

Manifold Pressure: 10” w.c. (P)

Minimum Supply Pressure: 11” w.c. (P)

Maximum Supply Pressure: 13”* w.c. (P)

Pression au Collecteur: 10” d’une colonne d’eau (P)

Pression d’Alimentation Min.: 11” d’une colonne d’eau (P)

Pression d’Alimentation Max.: 13” * d’une colonne d’eau (P)

** Pression d’alimentation maximale ne devait pas dépasser 13”.

0-XXXXft (0-XXXXm)

Minimum clearance to combustible materials:

Top, sides & back: per standoff spacers for framing and finishing

materials. For non-combustible framing and finishing materials,

see installation manual.

Top X”

Floor X”

Sides X”

Back X”

Vent top X”

Vent sides & bottom X”

Recessed depth X”

*** Mantel X” from appliance opening

Dégagements minimaux des matériaux combustibles:

Dessus, côtés et arrière: selon les espaceurs de dégagements

pour les matériaux d’ossature selon le manuel du propriétaire

pour les matériaux de finition.

Dessus X”

Plancher X“

Côtés X”

Arrière X“

Dessus du conduit d’évent X”

Côtés et dessous du conduit d’évent X”

Profondeur d’encastré une face X”

*** Tablette X” de l’ouverture de l’appareil

WARNING: Do not add any material to the appliance which will come in contact with the

flames, other than that supplied by the manufacturer with the appliance.

AVERTISSEMENT: N’ajoutez pas à cet appareil aucun matériau devant entretien

contact avec les flammes autre que celui qui est fourni avec cet appareil par le fabricant.

*** Maximum horizontal extension:

X”. See installation manual for

greater extensions, minimum vent

lengths and maximum vent lengths.

*** L’extension horizontale maximale: X”.

Référez au manuel d’installation pour des

extensions plus grandes, les longueurs

d’évacuation minimaux et maximum.

The appliance must be vented using the appropriate Napoleon vent kits. See installation

manual for venting specifications. Proper reinstallation and resealing is necessary after servicing

the vent-air intake system.

L’appareil doit être ventilé à l’aide de l’ensemble d’évacuation propre à Napoleon. Référez au

manuel d’installation pour les spécifications d’évacuation. Il est nécessaire de bien réinstaller et

resceller l’évacuation après avoir executer l’entretien du système de prise d’air.

Serial Number / N° de Série:

W385-XXXX

REFERENCE# 161746

XXXX

VENTED DECORATIVE GAS APPLIANCE: NOT A SOURCE OF

HEAT, NOT INTENDED FOR USE AS A HEATING

APPLIANCE, NOT FOR USE WITH SOLID FUEL.

APPAREIL À GAZ DÉCORATIF À ÉVACUATION: N’EST PAS

UNE SOURCE DE CHALEUR; N’EST PAS DESTINÉ À ÈTRE

UTILISÉ COMME UN APPAREIL DE CHAUFFAGE; NE

CONVIENT PAS AUX COMBUSTIBLES SOLIDES.

FOR USE WITH GLASS DOORS CERTIFIED WITH THIS APPLIANCE ONLY.

POUR UTILISATION UNIQUEMENT AVEC LES PORTES EN VERRE

CERTIFIÉES AVEC L’APPAREIL.

XX,XXX XX,XXX

XX,XXX XX,XXX

For natural gas when equipped with No. XX drill size orifice.

For propane when equipped with No. XX drill size orifice.

Convient au gaz naturel quand l’appareil est muni d’un injecteur de diamètre no. XX.

Convient au propane quand l’appareil est muni d’un injecteur de diamètre no. XX.

Electrical rating: 115V, 60HZ. Less than 12 amperes. Spécifications électriques: 115V, 60HZ. Moins de 12 ampère.

XX.X% XX.X%

XXXX XXXX XXXX XXXX

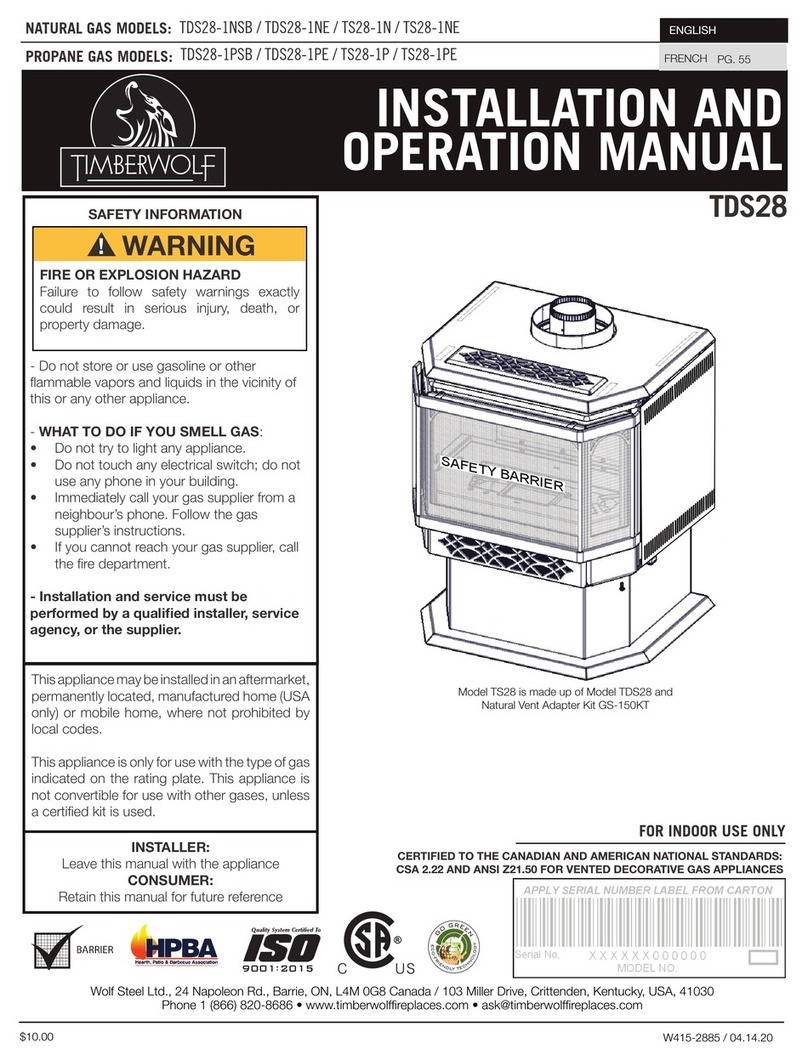

1.3 rating plate information

This illustration is for reference only. Refer to the rating plate on the appliance for accurate information.

NOTE: The rating plate must remain with the appliance at all times. It must not be removed.

Élévation

m

ntat

n

lim

ntati

n R

it

P

.5” w.c.

N

”* w.c.

NG

” d’une colonne d’eau (GN)

,5” d’une colonne d’eau

N

)4,5” d’une colonne d’eau (GN)

” ** d’une colonne d’eau

N

)7” ** d’une colonne d’eau (GN)

an

r

r

:

10” w.c.

P

Minimum Supply Pressure:

11” w.c.

P

Maximum Su

l

Pressure:

13”* w.c.

P

ression au

ollecteur:

10” d’une colonne d’eau

P

)10” d’une colonne d’eau (P

r

n

m

ntat

n

n.:

ession d’Alimentation Min.:

11” d’une colonne d’eau

P

)11” d’une colonne d’eau (P

ress

on

mentat

on

ax.:

Pression d’Alimentation Max.:

13” * d’une colonne d’eau (P)13” * d’une colonne d’eau (P

** Pression d’alimentation maximale ne devait pas dépa** Pression d’alimentation maximale ne devait pas d

ustible materials:tible materials:

spacers for framing and finishingspacers for framing and finishing

raming and finishing materials,aming and finishing materials,

Dégagements minimaux des mgements minim

Dessus, côtés et arrôtés e

T, NOT INTENDED FOT INTENDED F

APPLIANCE, NOT FOR UCE, NOT FOR

APPAREIL À GAZ DÉCORATIF À ÉVAAPPAREIL À GAZ DÉCORATIF À ÉV

UNE SOURCE DE CHALEUR; N’ESTUNE SOURCE DE CHALEUR; N’ES

UTILISÉ COMME UN APPAREILUTILISÉ COMME UN APPAREIL

CONVIENT PAS AUX COMCONVIENT PAS AUX COM

FOR USE WITH GLASS DOORS CERTIFIED WITH GLASS DOORS CERTIFIE

POUR UTILISATION UR UTILISATION

1.4 mobile home installation

This appliance must be installed in accordance with the manufacturer’s instructions and the Manufactured

Home Construction and Safety Standard, Title 24 CFR, Part 3280, in the United States or the Mobile Home

Standard, CAN/CSA Z240 MH Series, in Canada. This appliance is only for use with the type(s) of gas

indicated on the rating plate.

This mobile/manufactured home listed appliance comes factory equipped with a means to secure the appliance. Built

in appliances are equipped with 1/4” (6.4mm) diameter holes located in the front left and right corners of the base.

Use appropriate fasteners, inserted through the holes in the base to secure. For free standing products contact your

local authorized dealer / distributor for the appropriate securing kit. For mobile home installations, the appliance must

be fastened in place. It is recommended that the appliance be secured in all installations. Always turn off the pilot and

the fuel supply at the source, prior to moving the mobile home. After moving the mobile home and prior to lighting the

appliance, ensure that the logs are positioned correctly.

This appliance is certified to be installed in an aftermarket permanently located, manufactured (mobile) home,

where not prohibited by local codes.

This appliance is only for use with the type of gas indicated on the rating plate. This appliance is not convertible

for use with other gases, unless a certified kit is used.

Conversion Kits

This appliance is field convertible between Natural Gas (NG) and Propane (P).

To convert from one gas to another, consult your Authorized dealer/distributor.