Time TV-300 User manual

TV-300

MANUAL

TV-300

1G

ENERAL DESCRIPTIONS 2

1.1. Basic working principle 2

1.2. Application range 2

1.3. Technical Specifications 2

1.4. Basic configuration and Optional accessories 2

1.5. Other parameters 3

1.6. Features 3

2TECHNICAL TERMS 4

3C

ONFIGURATION 5

3.1. Description of components 5

3.2. Appearance 6

3.3. Description of main body 6

4I

NSTALLATION OF TRANSDUCER 7

4.1. Installation principle 7

4.2. Install method 7

4.2.1. Installed with bolt 7

4.2.2. Installed with magnetic base 8

4.2.3. Installed with probe 8

5HOW TO USE THE METER 9

5.1. Basic concept 9

5.2. Simple test 9

5.3. How to use the menu 10

5.4. Description of functions 11

5.4.1. Display 11

5.4.2. Analyse 11

5.4.3. View 13

5.4.4. System 13

6HOW TO USE THE ACCESSORIES 15

7T

ROUBLE SHOOTING 16

8M

AINTENANCE 17

APPENDIX 1: VIBRATION STANDARD 18

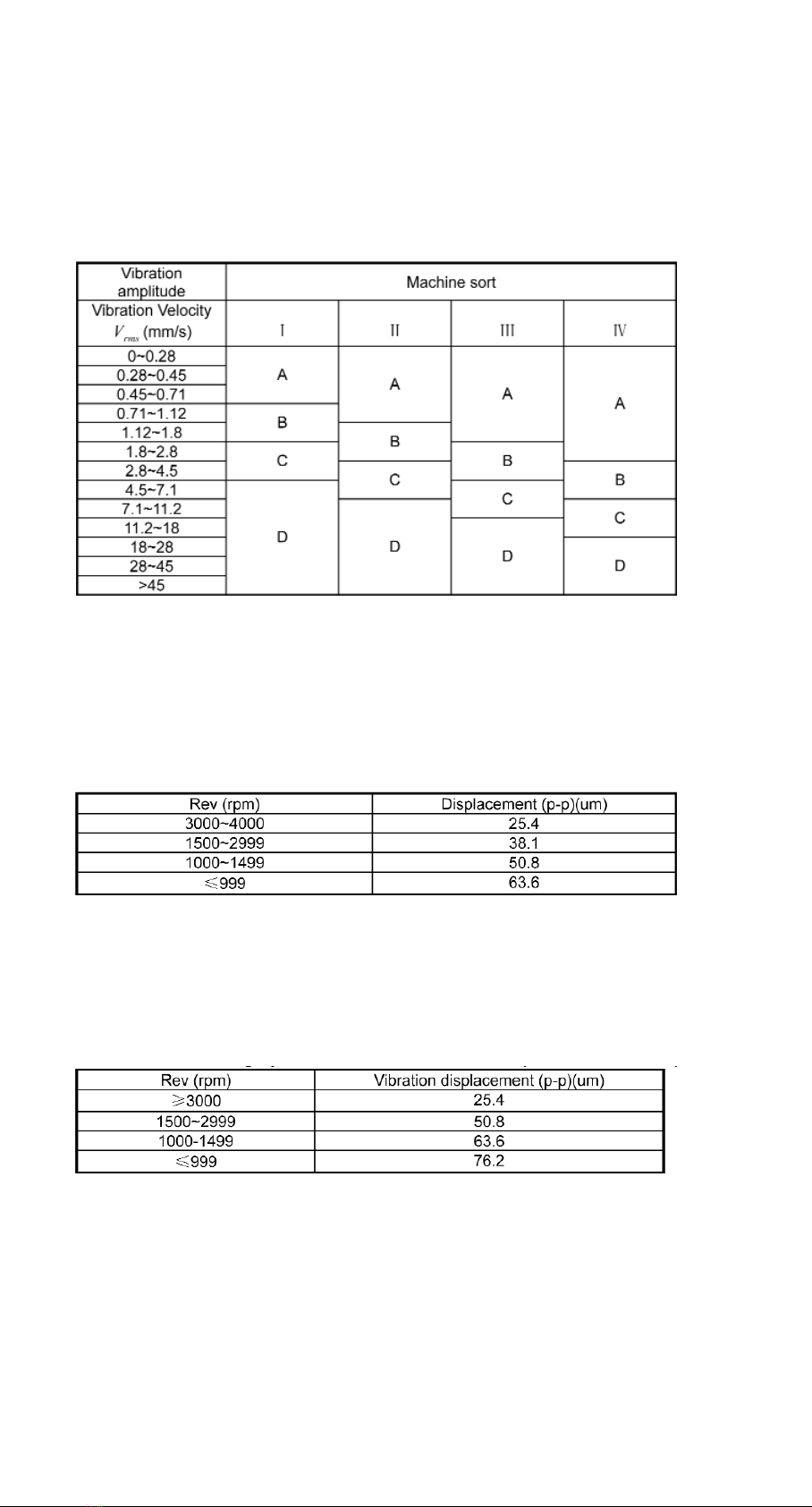

a. Rank of machine vibration (ISO2372) 18

b. Maximum vibration of motor that power larger than 1 horsepower

(NEMA MG1-12.05) 18

c. Maximum vibration of high-power induction drive motor

(NEMA MG1-20.52) 18

d. Maximum vibration of squirrel-cage induction drive motor

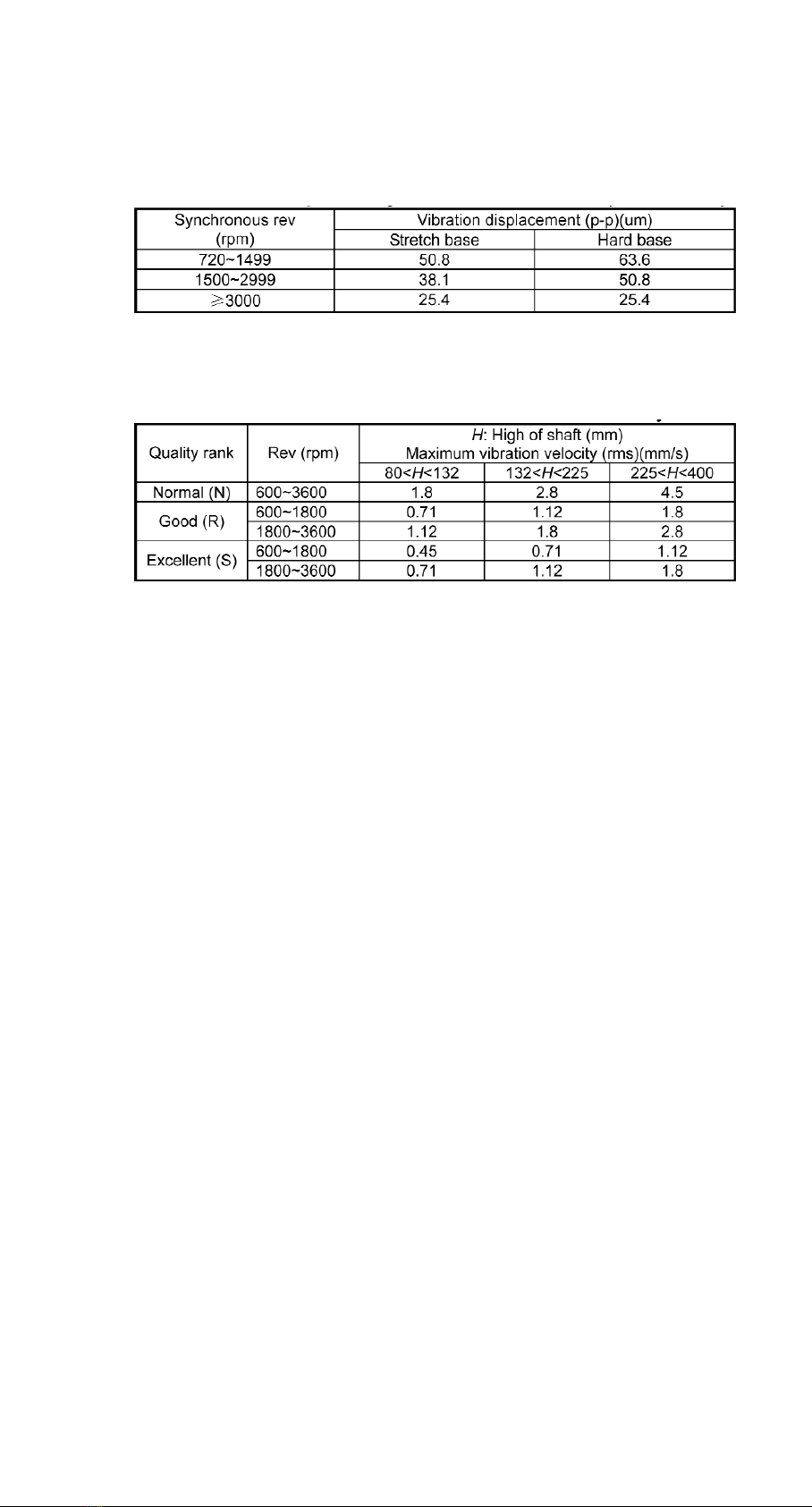

(API STD 541) 19

e. ISO/IS2373 Motor quality standard according as vibration velocity. 19

APPENDIX 2 VIBRATION FREQUENCY AND POSSIBLE REASON 20

Manual TV-300 1

CONTENTS

1.1 . BASIC WORKING PRINCIPLE

TV300 uses piezoelectric acceleration transducer to convert vibration signal into electric

signal. Then by analyzing input signal, results including RMS of velocity values, peak-

peak value of displacement, peak values of acceleration or real-time spectral charts are

displayed or printed out.

1.2. APPLICATION RANGE

The vibration meter is designed to test conventional vibration, especially the vibration

test in rotating and reciprocating machines. It can be used not only to test the

acceleration, velocity, and displacement of vibration as well as rev (or inherent

frequency), but also perform simple failure diagnosis.

The technical specifications of TV300 comply with the requirements of GB 13823.3.

TV300 is widely used in machinery, power, metallurgy, automobile and other industrial

fields.

1.3. TECHNICAL SPECIFICATIONS

- Measurement range

Acceleration: 0.1 m/s2- 392 m/s2 (Peak)

Velocity: 0.01 - 80 cm/s (RMS)

Displacement: 0.001 - 10 mm (Peak - peak)

- The frequency range

Acceleration: 10Hz - 200 Hz, 10Hz - 500 Hz, 10Hz - 1KHz, 10Hz - 10KHz

Velocity: 10Hz - 1KHz

Displacement: 10Hz- 500 Hz

- Accuracy: <±5%

- Temperature range: 0°C ~ 40°C

- Humidity range: <80%

1.4. BASIC CONFIGURATION AND OPTIONAL ACCESSORIES

- Basic configuration

Title Quantity

TV300 main body 1

6V/800mA ~220V/50Hz power adapters 1 (select one of them)

6V/800mA ~110V/50Hz power adapters

Vibration transducer TSV-01 1

Leather wrap 1

Package case 1

Manual 1

- Optional accessories

Title Quantity

Data Management software(with a cable) 1

Printer(with a cable) 1

Magnetic base 1

Probe groupware 1

Long needle 1

2Manual TV-300

1. GENERAL DESCRIPTION

1.5. OTHER PARAMETERS

- Display screen: LCD, 320×200 pixels, with LED backlight

- Battery's parameters:

Li battery, work 20 hours continuously. Charging time 12 hours.

- Dimensions: 171mm×78.5mm×28 mm

- Weight: 230g

1.6. FEATURES

- Three display modes: Common mode, Special mode and Spectrum mode

- The acceleration, velocity, displacement of vibration and rev (or inherent frequency)

can be tested.

- The testing meter can display measurement values in status bar according to alarm`

limit and warning limit.

- Simple failure diagnosis: Automatically raise the alarm and request to enter into

spectrum testing mode when the measurement value is beyond the limit.

- If equipped with printer, measurement value and spectral charts can be printed out.

- Measurement values and spectral charts can be analyzed with PC and software.

- Memory function: It can store 25×62 measurement values and 25 spectral charts.

- Li battery is used: The battery can charge at anytime safely and it can work

continuously for a long time after charging is finish.

- With LED backlight and auto-shutdown function.

Manual TV-300 3

1. Vibration:

A rapid linear motion of object about an equilibrium position, like piston, tuning fork

or motor.

2. Vibration displacement:

The magnitude of a vector from the initial position to a subsequent position assumed

by a body.

3. Vibration velocity:

The rate of speed of vibration.

4. Vibration acceleration:

The rate of change of vibration velocity with respect to time.

5. Vibration frequency:

The number of complete cycles of vibration per unit time.

6. Point number:

One point number correspond to one testing point, TV300 will keep up to 62 historical

results for each point.

7. Patrol test:

Test more than one point in a fixed routine. Each point correspond one testing point.

8. Warning limit:

Remind users that the vibration is beyond the limit of the safe state.

9. Alarming limit:

Remind users that the vibration is beyond the limit of the destruct status.

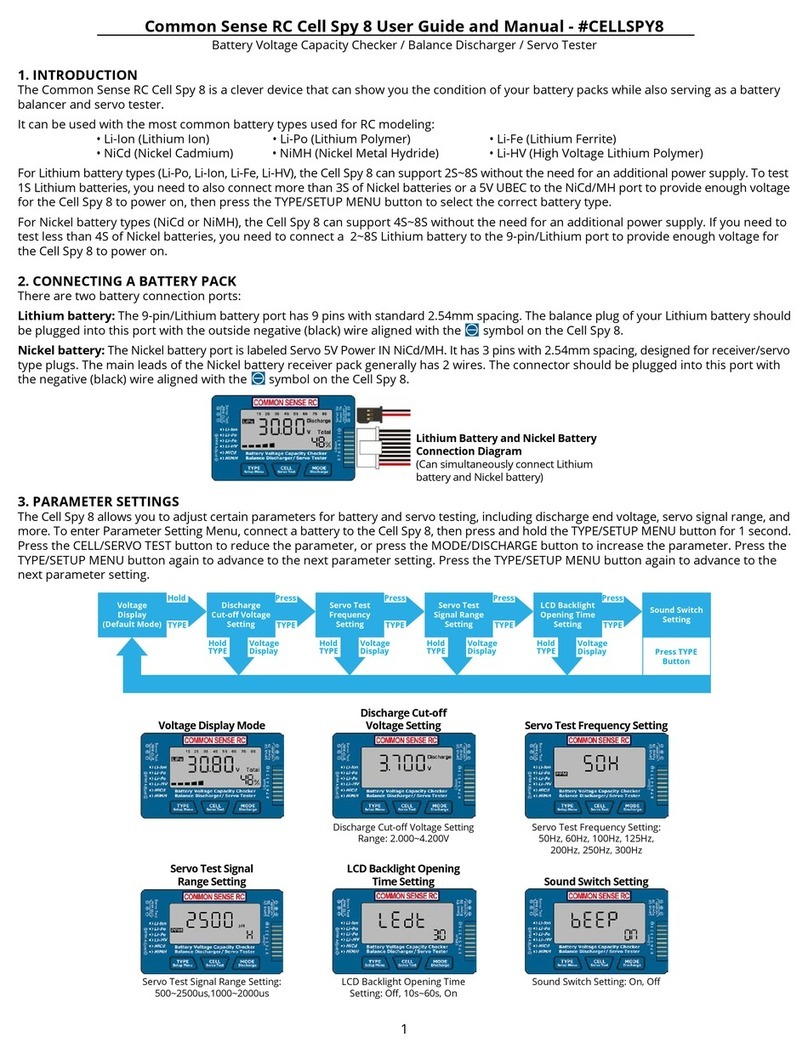

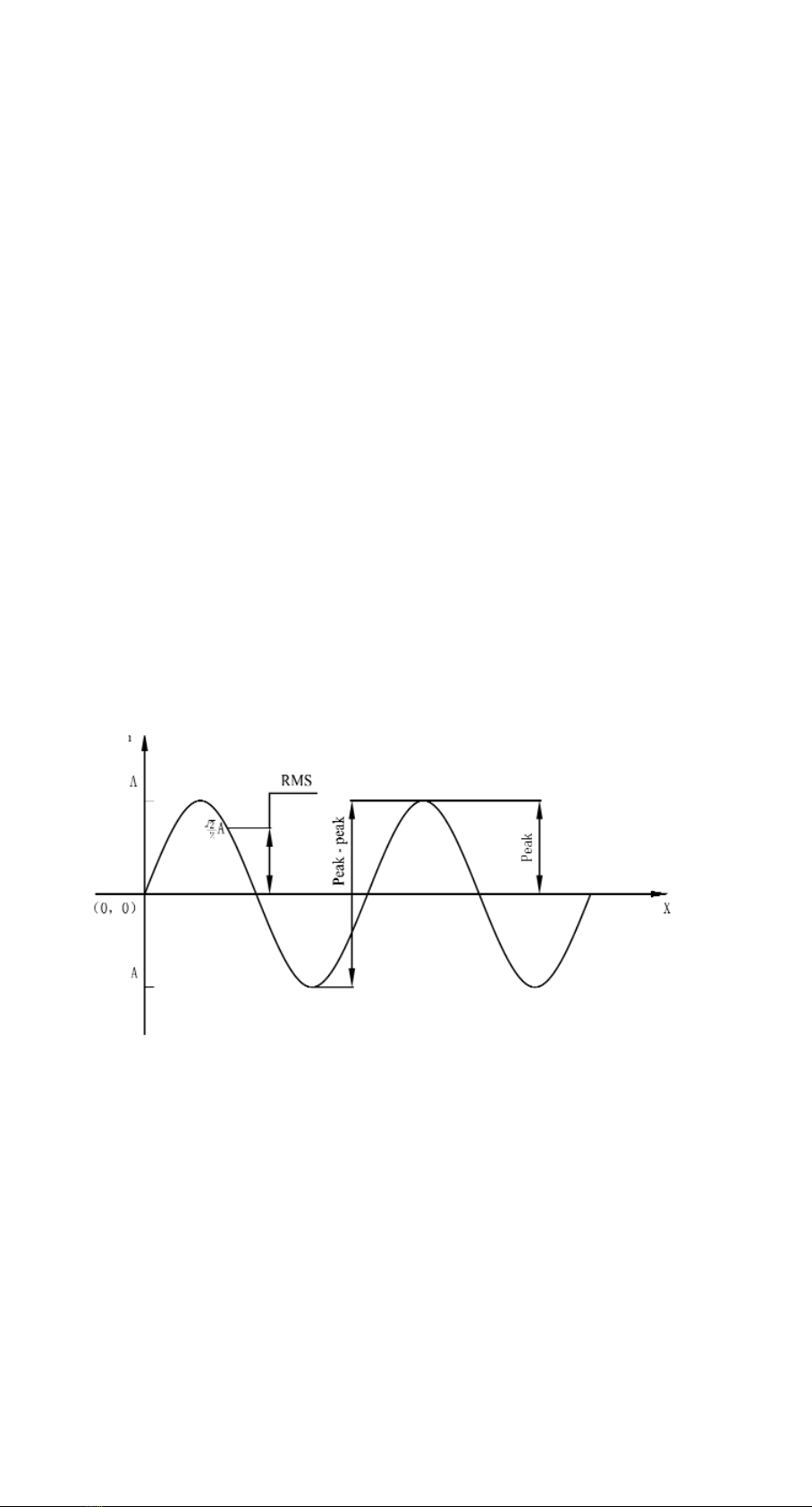

10. RMS, peak values and peak-peak values (see Figure 2-1)

11. Spectral chart:

A chart indicates the magnitude distribution of each frequency in the whole vibration.

Figure 2-1

4Manual TV-300

2TECHNICAL TERMS

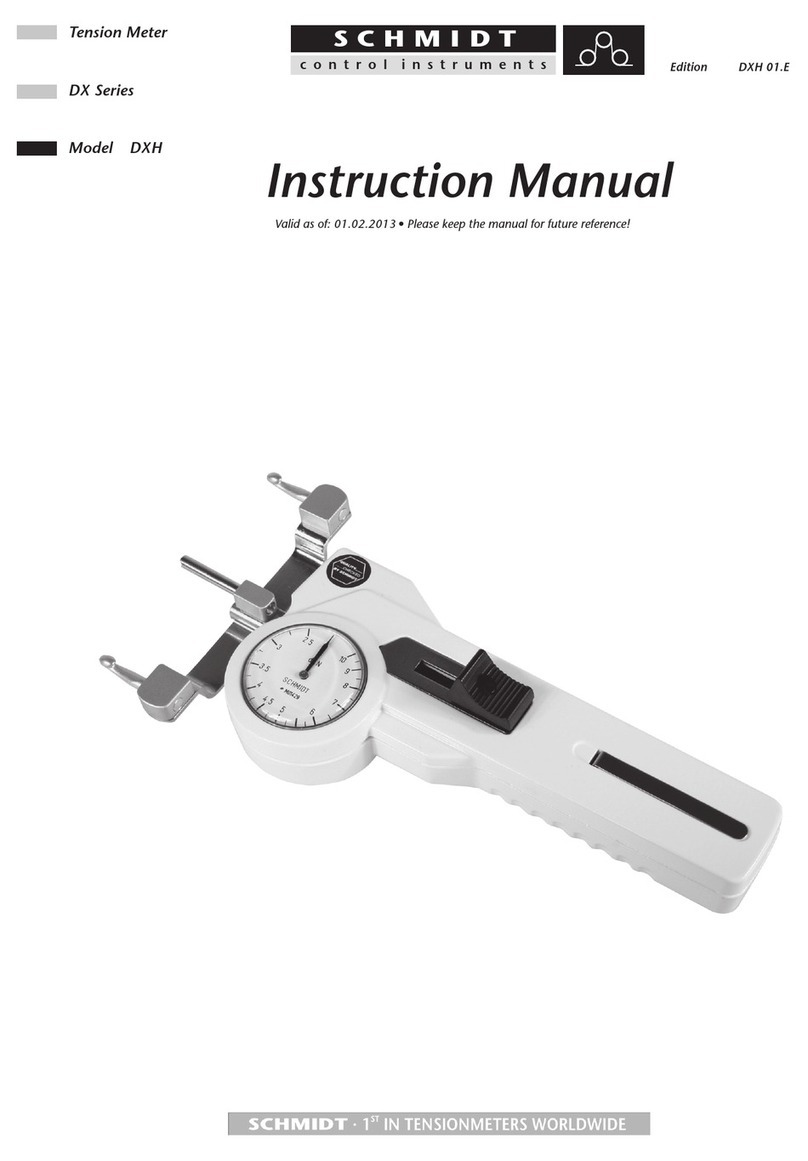

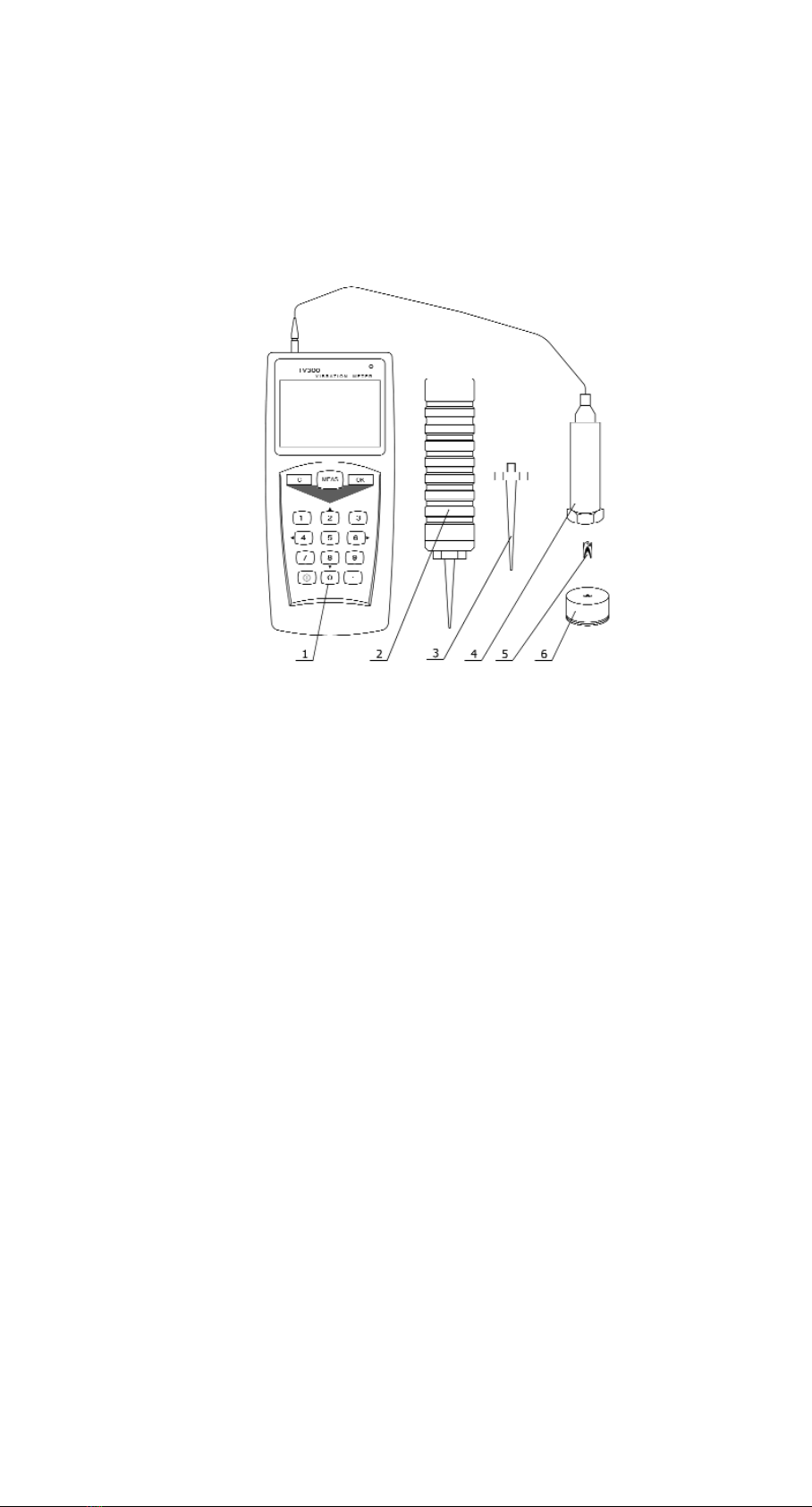

3.1. DESCRIPTION OF COMPONENTS

Figure 3-1

1 Main body

2 Probe groupware

3 Long needle

4 Vibration transducer

5 Bolt

6 Magnetic base

According to different situations, the transducers maybe fixed in the probe groupware

or connected to the magnetic base (see chapter 4 in detail.).

Manual TV-300 5

3CONFIGURATION

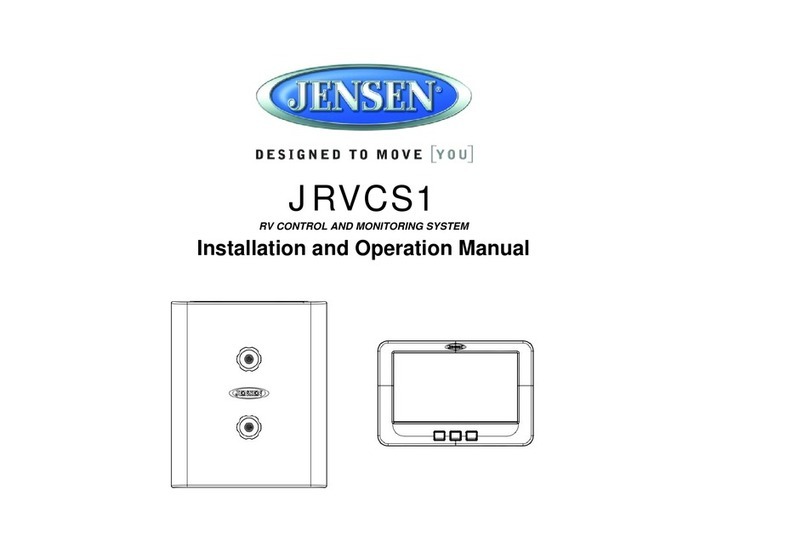

3.2. APPEARANCE

Figure 3-2

3.3. DESCRIPTION OF MAIN BODY

Title

1 Display screen 1

2 Front cover 1

3 LCD 1

4 Keyboard 16

5 Sealed tray 1

6 Plastic frame 1

7 Front PCB 1

8 Back PCB 1

9 Back cover 1

10 Hole cover 2

11 Bolt M3 4

12 Li battery 1

13 Battery holder 1

14 Gasket M2 2

15 Bolt M2 19

6Manual TV-300

Nameplate

A sensitivity

knob- in the

hole

Display

window

Charging indicate light

RS232 socket Charging socket

Transducer socket

Keyboard

4.1. INSTALLATION PRINCIPLE

- The testing position should show the vibration characters of the object to be tested.

- The main axis of the transducers should be consistent with the direction of he object

to be tested.

- The transducers should be in close contact with the object to be tested.

4.2. INSTALL METHOD

Install method/ Install with Install with Install with

Contrast bolts magnetic base probe

Cost None low Rather high

Affection on None When roughness is When caring about

the result worse than Ra1.6, acceleration and the

the result maybe vibration frequency is

not stable. higher than 1KHz, the

result will be smaller.

Convenience Not good good Best

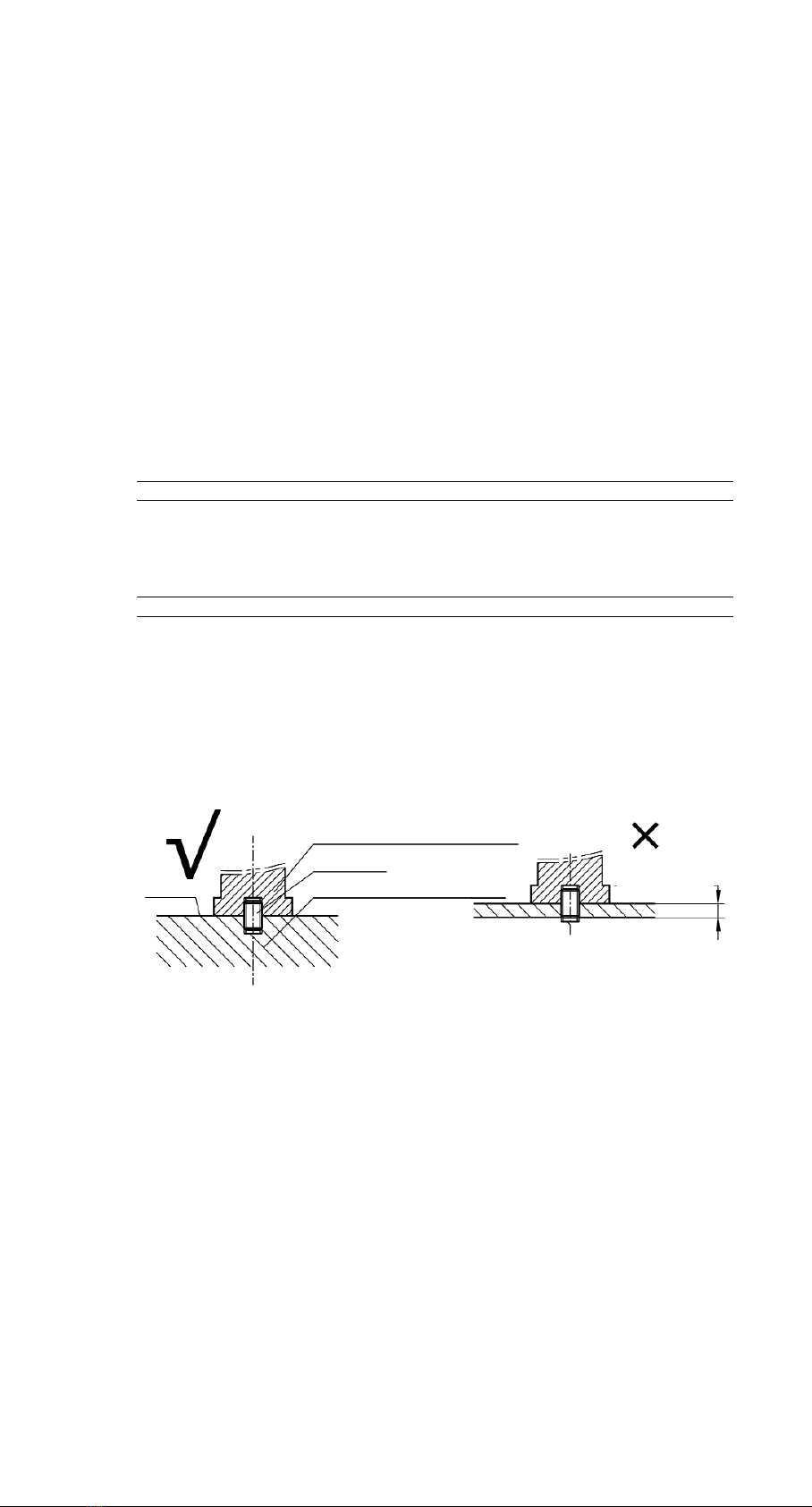

4.2.1. INSTALLED WITH BOLT

Application range: Screw eye has no influence on the running of the object being

tested. Usage: Drill a screw eye 5mm deep in the object being tested. Connect the

transducer to the object by bolts (see Figure 4-1). And this is the method that the

frequency response is best.

Figure 4-1

Manual TV-300 7

4INSTALLATION OF TRANSDUCER

The bolt drills through

the object being tested

Thickness δ

Vibration transducer

Bolt M5

Object being tested

Surface

4.2.2. INSTALLED WITH MAGNETIC BASE

Application range: Magnetic, flat surface, roughness less than Ra1.6, acceleration

less than 20 m/s2.

Usage: Before usage, take off the iron wafer and rubber wafer under magnetic

base (ensure enough suction), and then screw up the magnetic base on transducer

(see Figure 4-2). After usage, put back the iron wafer and rubber wafer to maintain

the magnetism.

Figure 4-2

4.2.3.INSTALLED WITH PROBE

Applications range: Frequency is less than 1KHz; vibration energy is not too small.

Usage: Connect the needle to the transducer directly by using probe groupware

(see figure 4-3)

Figure 4-3

8Manual TV-300

Surface

Vibration transducer

Bolt M5

Magnetic base

Object being tested

The surface is slick and flat The surface is rough The surface is uneven

Surface

Vibration transducer

Hold

Needle

Object being tested

Forming right angles between

the needle and the surface

The needle makes the

surfcace distortion

The mass is

too small

Forming bevel between the

needle and the surface

5.1. BASIC CONCEPT

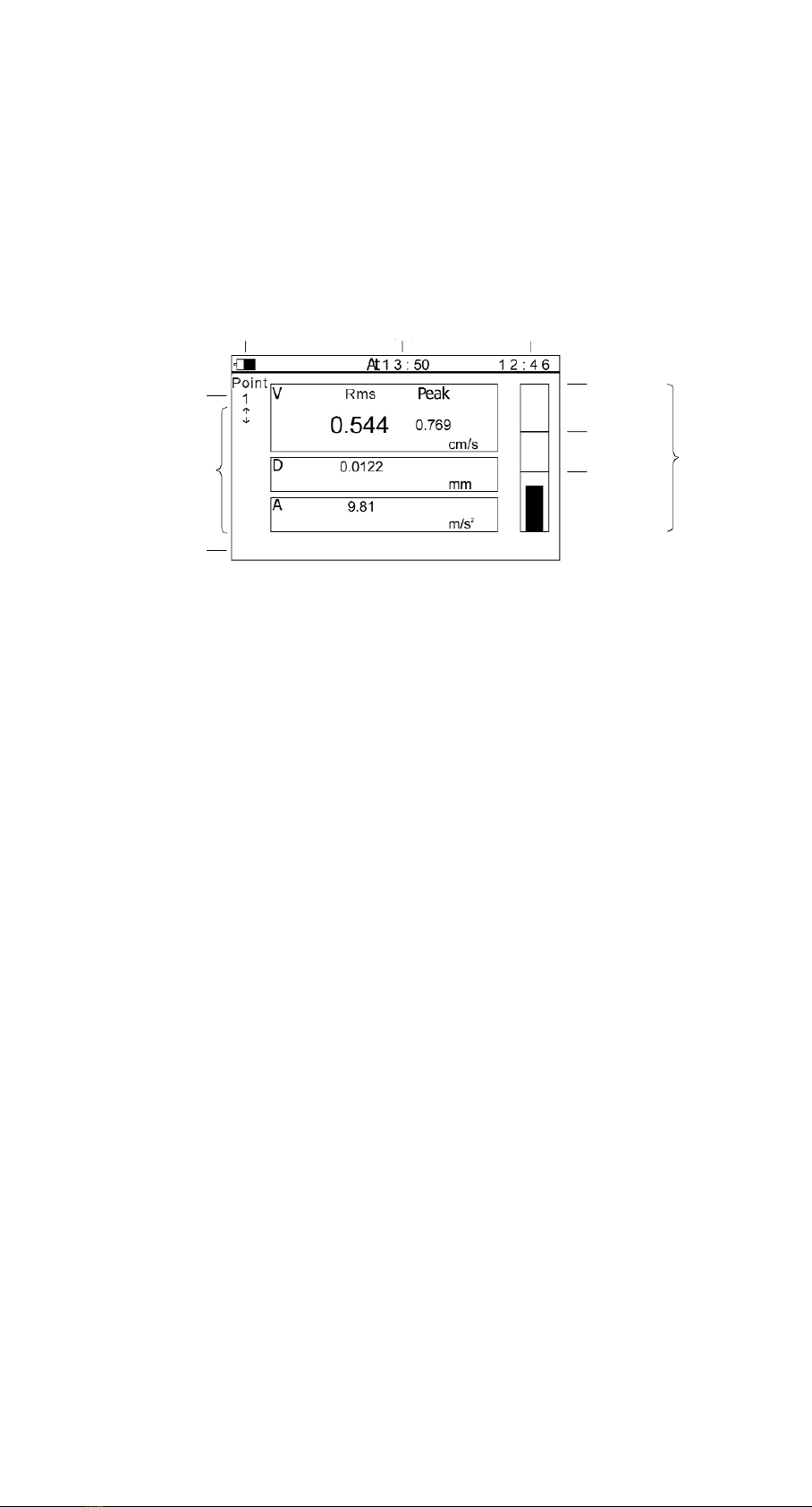

Special display mode is as follows (see Figure 5-1).

Figure 5-1

- Battery status: The full scale indicates the power is 100%.

- Working status: When the measurement goes on, displays one moving column.

When the measurement is finished, displays "at hh : mm".

- Time: Current time.

- Measurement point number: One point number correspond to one testing point,

TV300 will keep up to 62 historical results for each point.

- Measurement values: Indicate the testing results of the acceleration, velocity, and

displacement.

- Status Bar: Indicate the relative relation of testing result, last testing result, warning

limit and alarm limit.

- Main menu: Consist of display, analyse, view and system.

5.2. SIMPLE TEST

- Press “on/off” key to power on;

Press “MEAS” key to start the testing operation (displays one moving column);

Press “MEAS” key again to finish the test;

Read the measurement values

- When testing continuously, the measurement point number can increase

automatically. Users can also choose the measurement point number by Up/Down

keys.

Manual TV-300 9

5HOW TO USE THE METER

Status

bar

Alarm

limit

Warning

limit

The last

measure

result

Time

Working

status

Battery

status

Point

number

Time

Main menu SystemAnalyse ViewDisplay

5.3. HOW TO USE THE MENU

The descriptions of the menu give as follows (adjust): ( indicates the default settings).

Left/Right keys are used to choose in the rows of the menu. Up/Down keys are used to

choose in the columns of the menu. The background color of the fonts in the menu

changing to black indicates the item is chosen. Press “OK” key to confirm the operation

or enter into the submenu, Press “C” key to cancel operation or return to upper menu.

Up, Down, Left, Right keys and Number 2,4,6,8 keys are used alternately. When

operation is on the menu, the direction keys are in use. When numbers are need, the

number keys are available.

10 Manual TV-300

Clock

About

LCD contrast - +

AUTO shotdown

English

Languages

Personal

settings

Display modes

Point increment

No

Yes / No

Common/Special /Spectrum

Veloctiy/Displacemetn / Acceleration

10-200Hz/10-500Hz//10-1KHz /10Hz-10KHz

Alarm limit

Warning limit

Yes

Limit

Transmission

bands

Parameter

Measure settings

System

Delete

Print

All records before

Current record

View

Analyse Print/Auto/Adjust/Zoom

Display

5.4. DESCRIPTION OF FUNCTIONS

5.4.1. DISPLAY

"Display" can change the display modes from common, special and spectrum

modes. It can give convenience for users to look through the data from different

way, but it does not change the default settings of display modes. If users want to

change the default settings of display modes, the submenu "Display modes" in the

menu "System" should be changed.

5.4.2. ANALYSE

When diagnosing the fault, users could use this function. Spectrum chart maybe

display like this. (See Figure 5-2)

Figure 5-2

When the measurement value is higher than the warning limit, TV300 can

automatically give an alarm and request to enter into spectrum testing mode (see

Figure 5-3).

Figure 5-3

Manual TV-300 11

SystemAnalyse ViewDisplay

NoFFT graph: YesDraw

The "Analyse" menu consists of "Print", "Auto", "Adjust" and "Zoom" four sub items.

- Print: Print out current spectral charts.

- Auto:

Peak values of the spectral chart could be automatically captured. And different

peak values could be selected by Left/Right keys. (see Figure 5-4)

Figure 5-4 A B

Figure (a) shows the peak-peak value tested is 62.6Hz, that maybe the rev of the

tested object;

Figure (b) shows the peak value tested is 109.6Hz, that maybe the inherent

frequency of the tested object;

- Manual

The values of different points in the charts can be looked through in the manual

style. The cursor position can be adjusted by Left/Right keys. The amplitude and

frequency of the point, which the cursor indicates, can be displayed.

(see Figure 5-5).

Figure 5-5

- Zoom

In spectrum analysis, the spectrum zoom function can change the frequency

resolution in the range selected by users. Firstly, to select the range of the

frequency----that is the concerned area, press Left/Right keys to move the

cursor. The cursor could move more quickly when the Left or Right key is hold.

Secondly, Up/Down keys could change the frequency resolution. The resolution

could reach 0.25Hz.

Figure 5-6

12 Manual TV-300

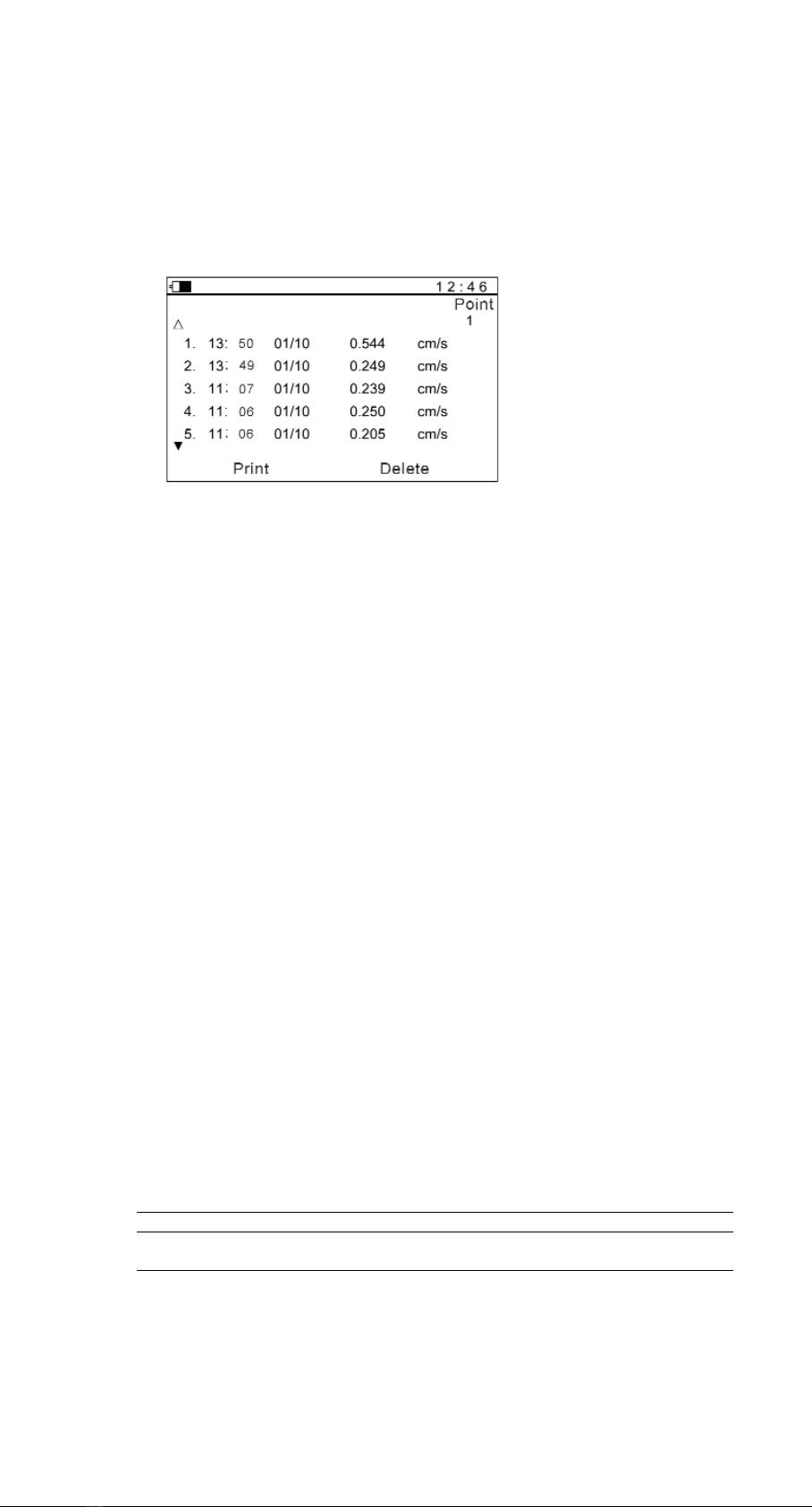

5.4.3. VIEW

Users can look through the measurement results stored in the memory by selecting

"View". The information of each measurement result comprises point number,

testing time and certain results (see Figure 5-7). Users could print out the list. Also,

the data can be deleted.

Figure 5-7

5.4.4. SYSTEM

5.4.4.1. Measurement settings

- Parameter: Velocity, Displacement and Acceleration. Affection of this

setting is shown in 5.4.4.3.

- Transmission bands: According to application, select the bands of frequency.

- Limit: When the limit is set, the meter could display status bar to

inspect the status of the running equipment easily. As

soon as the tested value is beyond the limit, the meter

request to enter into diagnosis (see Figure 5-2).

5.4.4.2. Point increment

If select "Yes", when a testing operation of the current point number is

finished, the point number will increase automatically, and go into the

waiting state of the next point number. Up/Down keys can also change

the testing point number.

If select "No", point number will not increase automatically. When tests

are performed continuously, the measurement results will be regarded

as different testing results of the same testing point number.

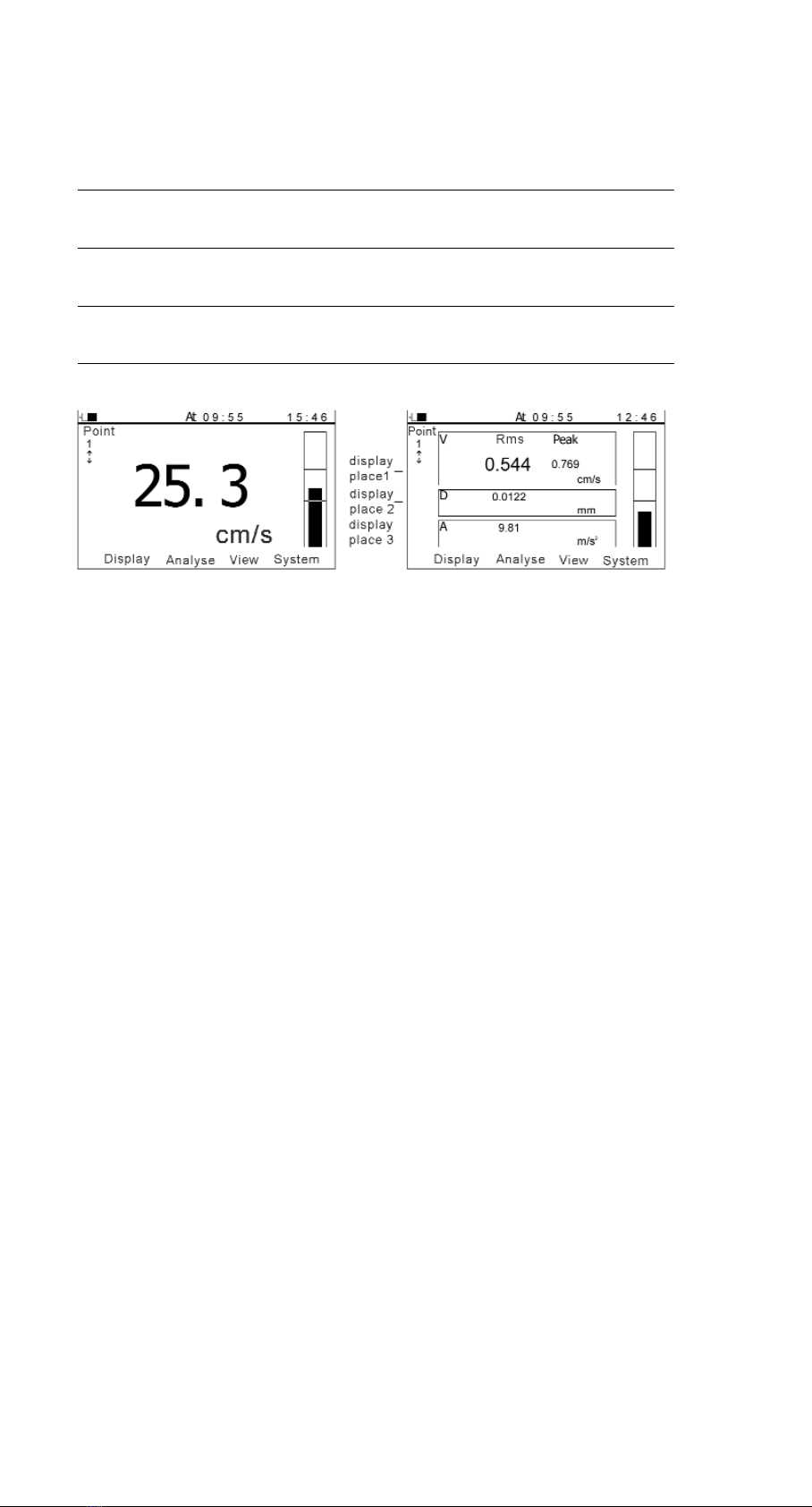

5.4.4.3. Display modes

There are three display modes: Common mode (Table 5-1, Figure 5-8),

Special mode (Table 5-2, Figure 5-9) and Spectrum mode (Figure 5-2).

Table 5-1 Common mode

Selected parameter velocity displacement acceleration

Display area RMS of velocity peak - peak value peak value of

of displacement acceleration

Manual TV-300 13

Display area/ Display area Display area Display Display

Selected parameter 1 (left) 1 (right) area 2 area 3

Velocity RMS of peak value of peak-peak peak value of

velocity velocity value of acceleration

displacement

Displacement peak-peak RMS of RMS of peak value of

value of displacement RMS of acceleration

displacement

Acceleration peak value of RMS of RMS of peak-peak

acceleration acceleration RMS of value of

displacement

Figure 5-8 Velocity-common Figure 5-9 Velocity- special

5.4.4.4. Personal settings

- Languages:

There are two languages available: Chinese and English.

- Auto shutdown:

The meter will shutdown automatically if there is no operation for a

while. And users can set the delay time themselves.

- LCD contrast:

Users can adjust LCD contrast by Left/Right keys.

5.4.4.5. Time

Time is the assistant information of the measurement results. TV300 can

automatically record the time when the test is performed. If the time is

not correct, it should be reset manually.

5.4.4.6. Software information

It consists of the model of the meter and the software identifier.

14 Manual TV-300

TV300 has accessories such as printer and corresponding software. If equipped with

printer, the printing operation can be performed. The data stored in TV300 can be

uploading to PC and do analysis with corresponding software. If PC is equipped with

printer, the data can also be printed out from PC.

TV300 connects to printer or PC through a communication cable. One end is connected

to TV300 through RS232 serial port, and the other end is connected to printer or PC

through a 9-pin connector.

How to use the software can refer to the specifications of the corresponding software.

Manual TV-300 15

6HOW TO USE THE ACCESSORIES

- When the battery cannot charge, check the charging indicating light.

- The measurement value is unstable.

1. Make sure the vibration frequency of the vibration object is in the frequency

range of 10Hz-10kHz.

2. If the magnetic base is used, pay attention to:

a. Make sure the surface of the tested object is flat, and roughness is smaller

than Ra1.6.

b. Make sure the iron wafer below the magnetic base is taken off, and the

magnetic force is enough.

- When enter the non-mother language system because of incorrect operation, users

can change back the mother language referring to the construction of the menu

(see 5.3).

If some trouble cannot be overcome, please contact to TIME Group Inc.

16 Manual TV-300

7TROUBLE SHOOTING

1. Operating environment: Strictly avoid collision, heavy dust, dampness, strong

magnetic field, oil, grease and dirt.

2. How to clean the main body of the meter: Because alcohol and other chemical

liquid can erode the main body of TV300, especial the display window, little water

can be used to clean to meter smoothly.

3. How to use the connector: Don't plug the connector of the transducers, printer or

PC, when TV300 is power on.

4. Calibration: The vibration meter is a high-precision instrument and the environment

will influence on it. So it should be calibrated periodically (half a year or one year). If

the sensitivity has changed, it can be adjusted by rotating the knob which is use to

adjust the sensitivity.

Manual TV-300 17

8MAINTENANCE

A. RANK OF MACHINE VIBRATION (ISO2372)

Note:

(1) Class I is small motor (power less than 15kW). Class I is medium motor (power

between 15kW~75kW). Class ? is high power motor (hard base); Class ? is high power motor (stretch base).

(2) A, B, C, D are vibration rank. "A" means good, "B" means satisfying, "C" means not satisfying, "D" means

forbidden. Vibration velocity should be taken from the three perpendicular axes on the motor shell.

B. MAXIMUM VIBRATION OF MOTOR THAT POWER LARGER THAN 1 HORSEPOWER

(NEMA MG1-12.05)

* For AC motor, rev is maximum synchronous rev. For DC motor, it is maximum power

rev. For motor in series, it is work rev.

C. MAXIMUM VIBRATION OF HIGH-POWER INDUCTION DRIVE MOTOR

(NEMA MG1-20.52)

* National Electric Manufacturers Association (NEMA) establishes two standards

above.

18 Manual TV-300

APPENDIX 1: VIBRATION STANDARD

D. MAXIMUM VIBRATION OF SQUIRREL-CAGE INDUCTION DRIVE MOTOR

(API STD 541)

* American Petroleum Institute (API) established this standard.

E. ISO/IS2373 MOTOR QUALITY STANDARD ACCORDING AS VIBRATION VELOCITY.

Limit of rank "N" is suitable for common motor. When the request is higher than that in

the table, limit can be gotten by dividing the limit of rank "S" with 1.6 or multiples of 1.6.

Manual TV-300 19

Table of contents

Other Time Measuring Instrument manuals