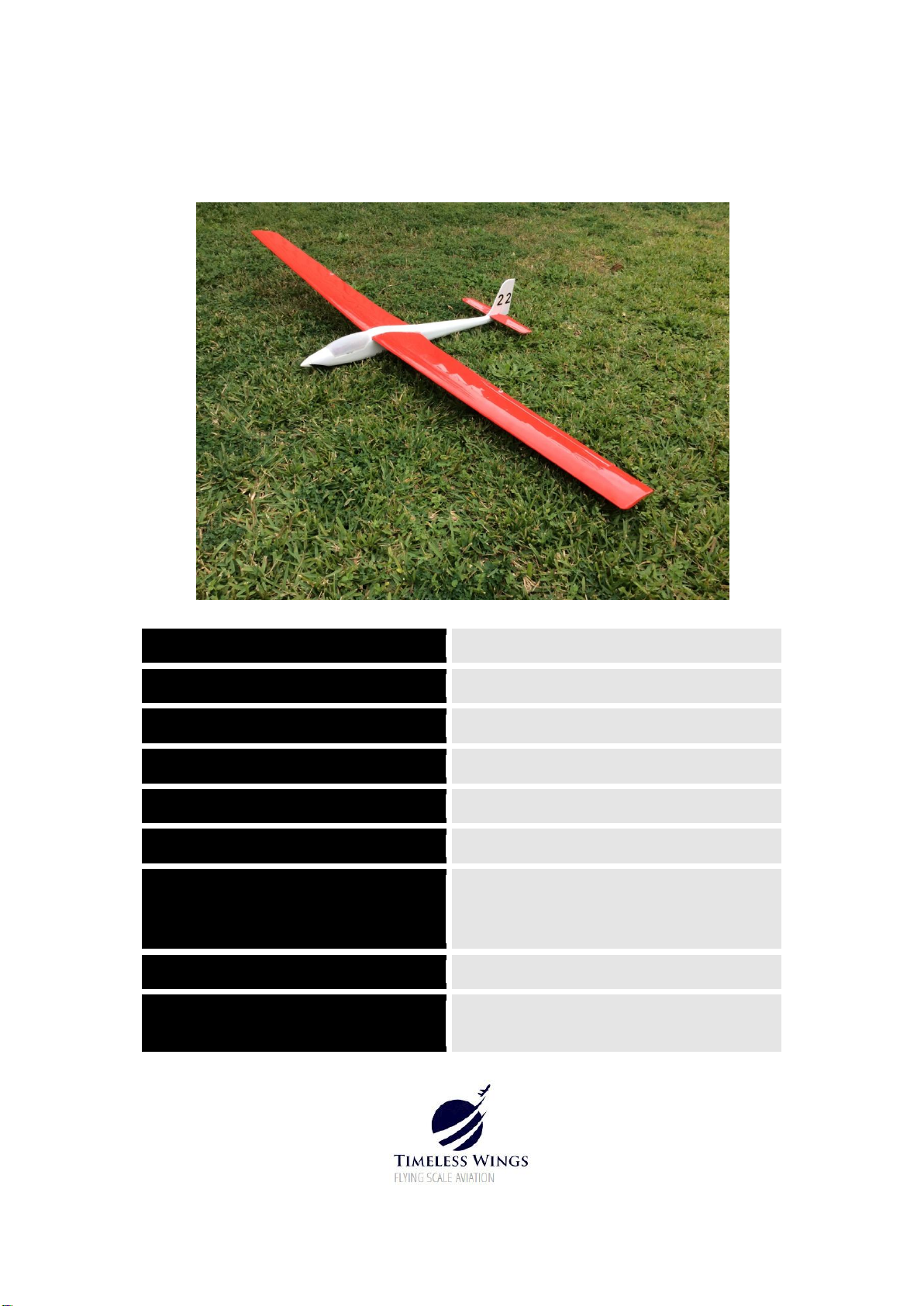

Timeless Wings SLINGSBY DART 17 Instructions for use

1

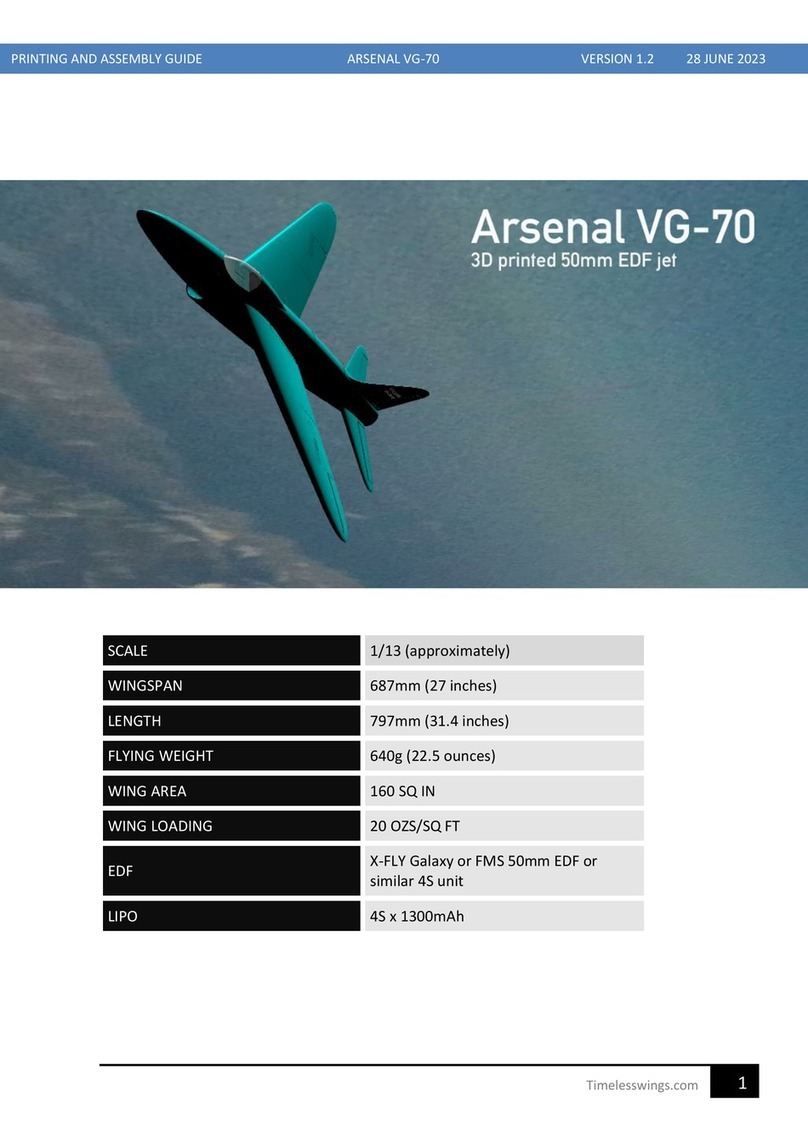

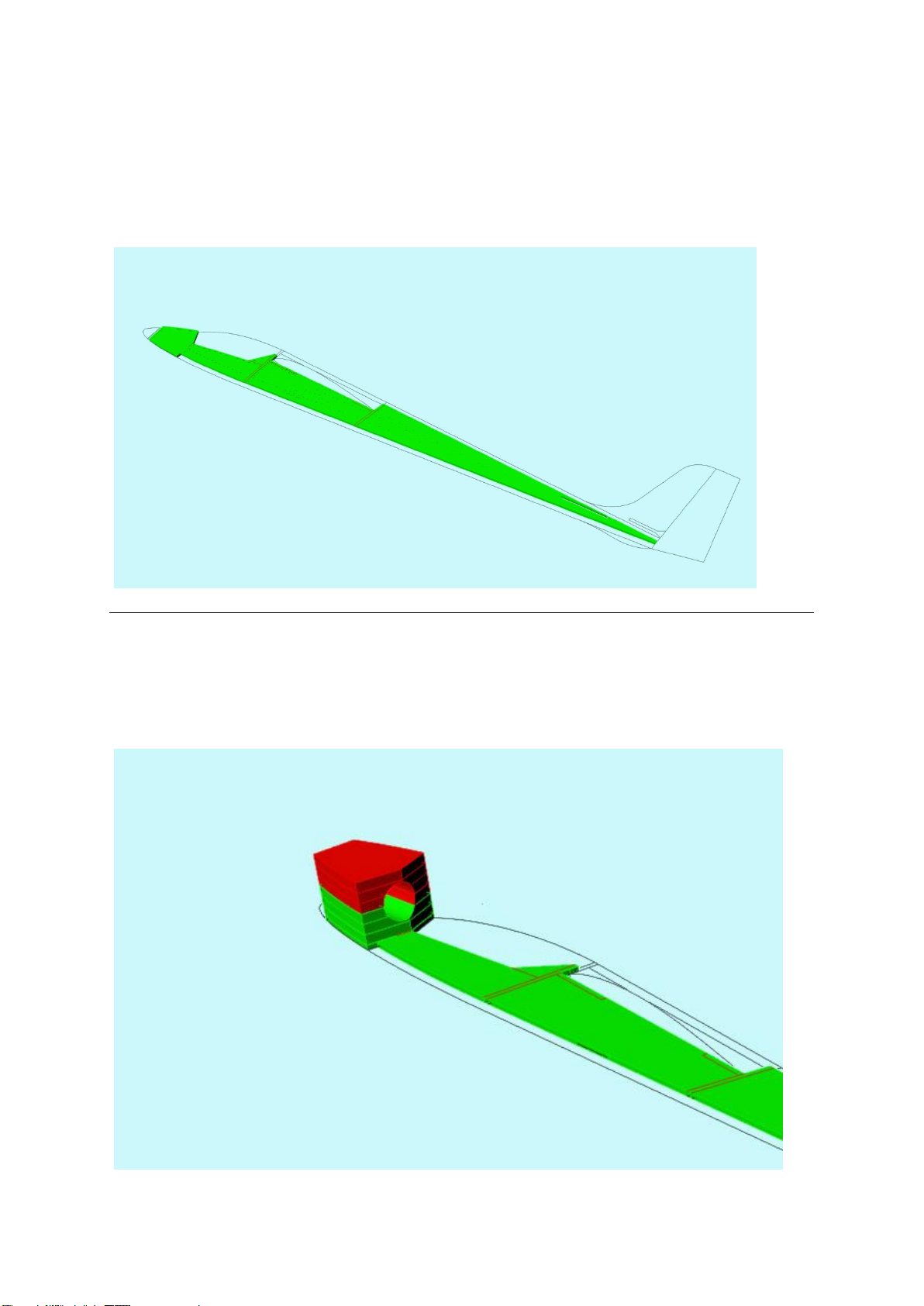

SLINGSBY DART 17

CONSTRUCTION MANUAL Version 1.1

SCALE

1/10

WING SPAN

1700mm (67 inches)

WEIGHT

19 OZS

WING AREA

330 SQ INS

WING AIRFOIL

SELIG 3021

WING LOADING

8.3 OZS/SQ FT

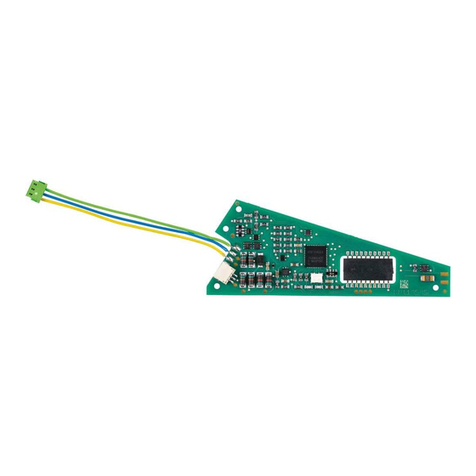

MOTOR & PROP

2040 brushless in-runner R/C car motor

driving a 5.1 x 3.1 inch folding prop, or

up to 28mm outrunner (with mods)

LIPO

2S x 1300mAh

POWER

Measured 104W @13.2A, Surpass Hobby

2040 in-runner, 3200kv, on 2S

2

PRELIMINARY NOTES

This model came about in early 2020 during a period of Corona Virus restrictions,

and was designed to use items at hand at the time. Specifically, it was designed to be

a small balsa build to use the diminutive 5.1 x 3.1 inch folding props I had on hand.

These suit a 2mm to 2.3mm shaft, so originally an old Hacker B20 motor was fitted.

This has been recently replaced with an inexpensive contemporary Surpass Hobby

20mm R/C car motor with a 2.3mm shaft, which works really well in this application.

Although designed for a 20mm in-runner, the nose is wide enough to fit up to a

28mm outrunner if desired, but some modifications will be required. The

construction notes assume previous experience building similar models.

Despite its small size, this model is very efficient with its Selig 3021 airfoil and keeps

up very well with the larger gliders at our field. Penetration is especially good.

Whilst clearly only “semi-scale”, this model was designed to keep the character of

the original Dart with its small tail volume compared to the wing. This necessitates a

Centre of Gravity further forward than you would normally expect. A small amount

of lead ballast will likely be necessary to achieve the CG on the plans. The first flight

of the prototype was with a much too rearward CG, which, combined with large

control throws made for a very unstable model! The CG on the plans should

definitely be adhered to!

This Dart could easily be built as a slope-soarer by using a solid balsa nose instead of

the motor. This construction manual assumes that the builder is familiar with

“traditional balsa construction methods”. The construction notes and plans have

some small changes from the original prototype which reflect improvements, and

should take precedence over any differences noted compared to the photographs.

The manual will assume that a kit of all parts has been cut before assembly

commences. Metric and imperial sizes are used interchangeably. The parts layout

files are recommended only. These, and the plans may be used as desired for private

purposes. For commercial use, please contact the designer.

Graham Reddin

Sydney, Australia

May 2021

E: [email protected]om

W: https://timelesswings.com/

3

FUSELAGE CONSTRUCTION

1. Mark the position of formers on the fuselage sides, then pin the right fuselage side to

the building board (50mm thick Styrofoam insulation with baking paper on top works

well as a building board). Note that the left and right fuselage sides are different

because of the staggered position of the pushrod exits.

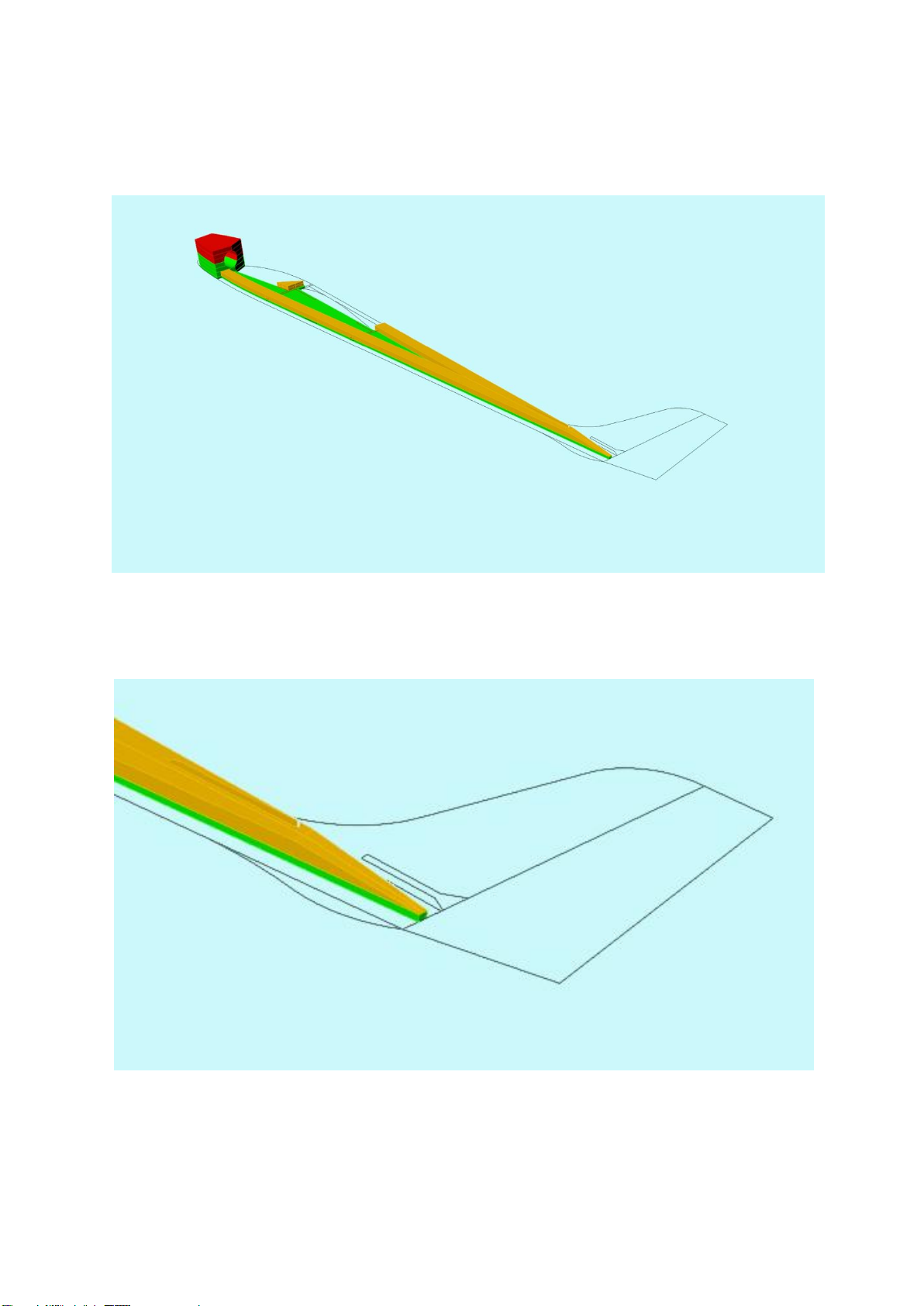

2. Make up the noseblock assembly in two halves, by gluing 3 LHS pieces together (shown

in red), and 3 RHS together (shown in green). The location of the motor cut-out is now

drawn on front and back (refer to plan for location) then removed using a coping saw.

The two halves can then be glued together, then glued to the fuselage RHS.

4

3. Glue the 6.4mm balsa fuselage doublers to the fuselage RHS as shown. Separately, glue

the 6.4mm balsa fuselage doublers to the fuselage LHS.

_____________________________________________________________________

4. Chamfer the rear of the fuselage doublers where the sides will be drawn together

5

5. Glue the fuselage formers all in position as shown, along with the 3.2mm ply wing

mounting plates and motor mount formers.

_____________________________________________________________________

6. Glue fuselage LHS assembly to fuselage RHS assembly.

6

7. Glue the 6.4mm balsa forward fuselage bottom sheeting in place, as well as scrap

1/16”x 1/8”balsa wing seating strips (which are to allow for the wing dihedral).

8. Glue the rear fuselage sides together, then glue in the 1/8” OD plastic sleeves for the

pushrods. Note that these are crossed to give the best geometry.

7

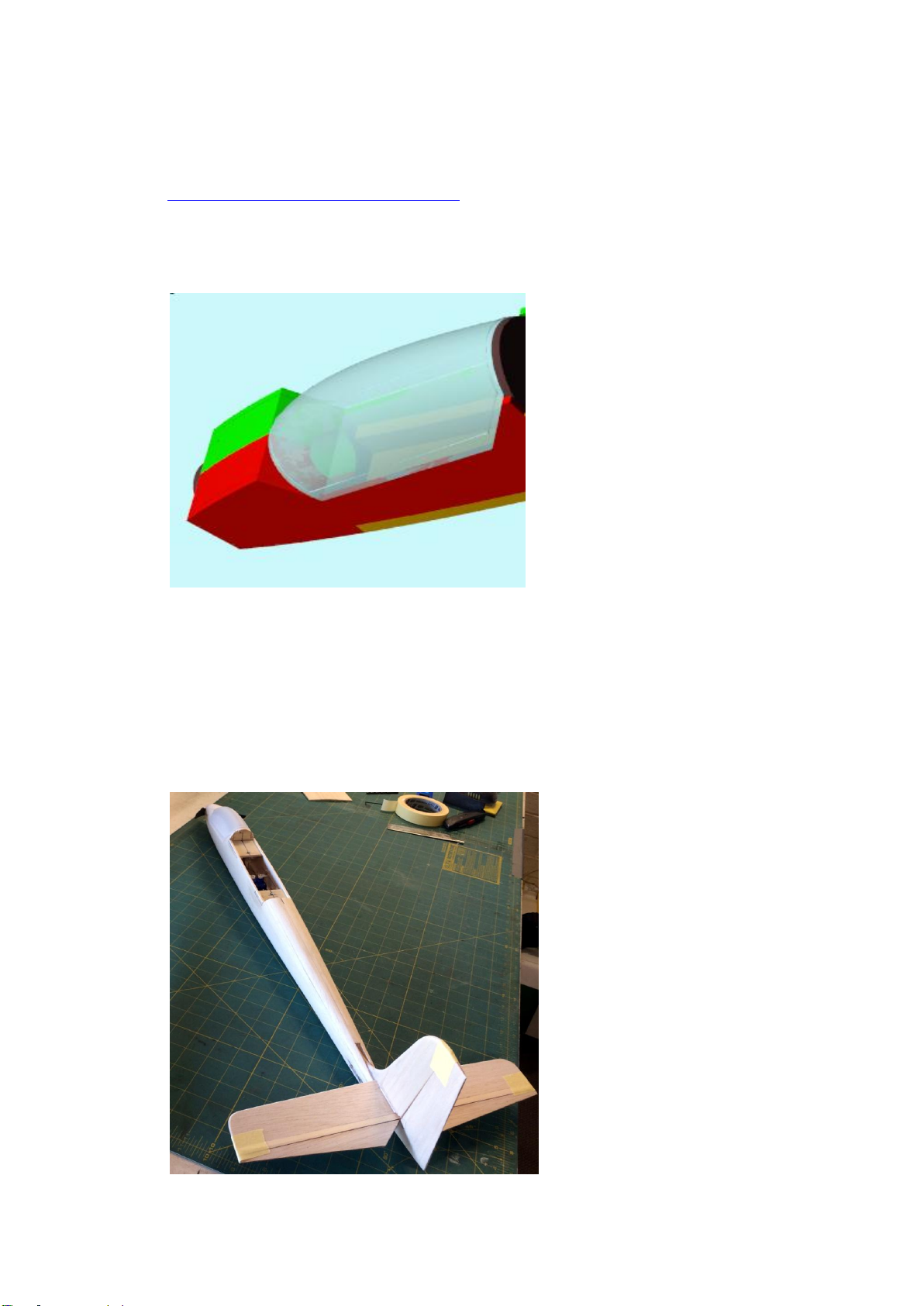

9. Before the fuselage is shaped you will need to complete the canopy, which is used as a

shaping guide for the forward fuselage. The prototype model used a 3D printed

canopy, from 2 x 0.4m layers of clear PLA –canopy file available from here:

https://timelesswings.com/downloads

The 2 layers of clear PLA may distort if left in a hot car, but should be fine for normal

use on the model. If preferred, PETG can be used for printing as it is more heat

resistant. Those without access to a 3D printer may wish to form the canopy from

foam or balsa, hollowed as appropriate.

_____________________________________________________________________

10. Add the remaining 6.4mm balsa fuselage top and bottom sheeting, leaving a slot in the

rear section for the fin. Generously carve and sand fuselage to approximate the shape

shown on the plans. Shape the fin and rudder then glue the 3/16” balsa fin in position.

Make up the tailplane and elevator from 1/8” balsa and 1/8” x 1/4” bass or spruce (as

shown on plan) shape, and glue to fin. Note: the tailplane and elevator should be

hinged before assembly. (Prototype used iron-on film as a hinge). Fit skid under rear

fuselage.

8

WING CONSTRUCTION

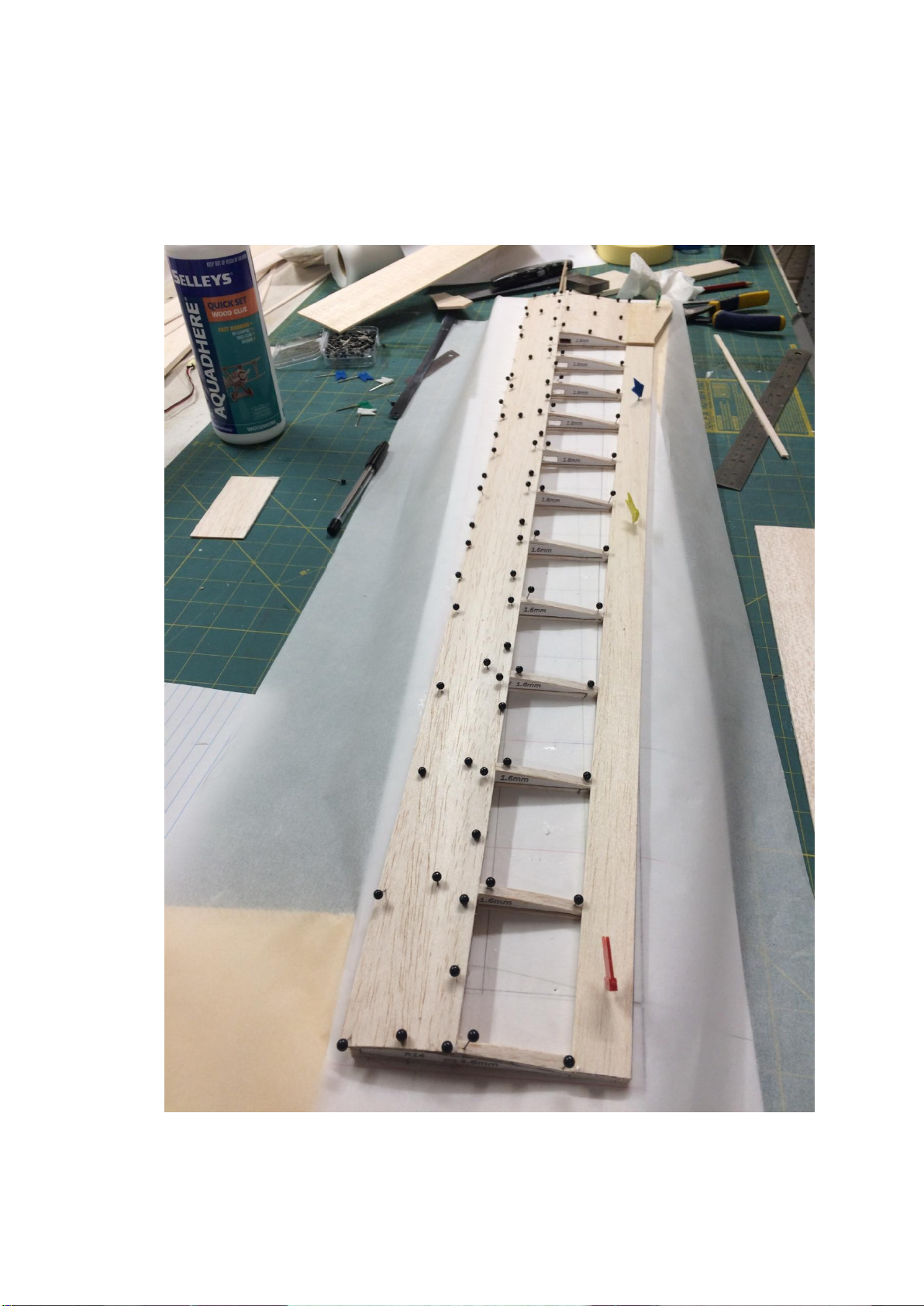

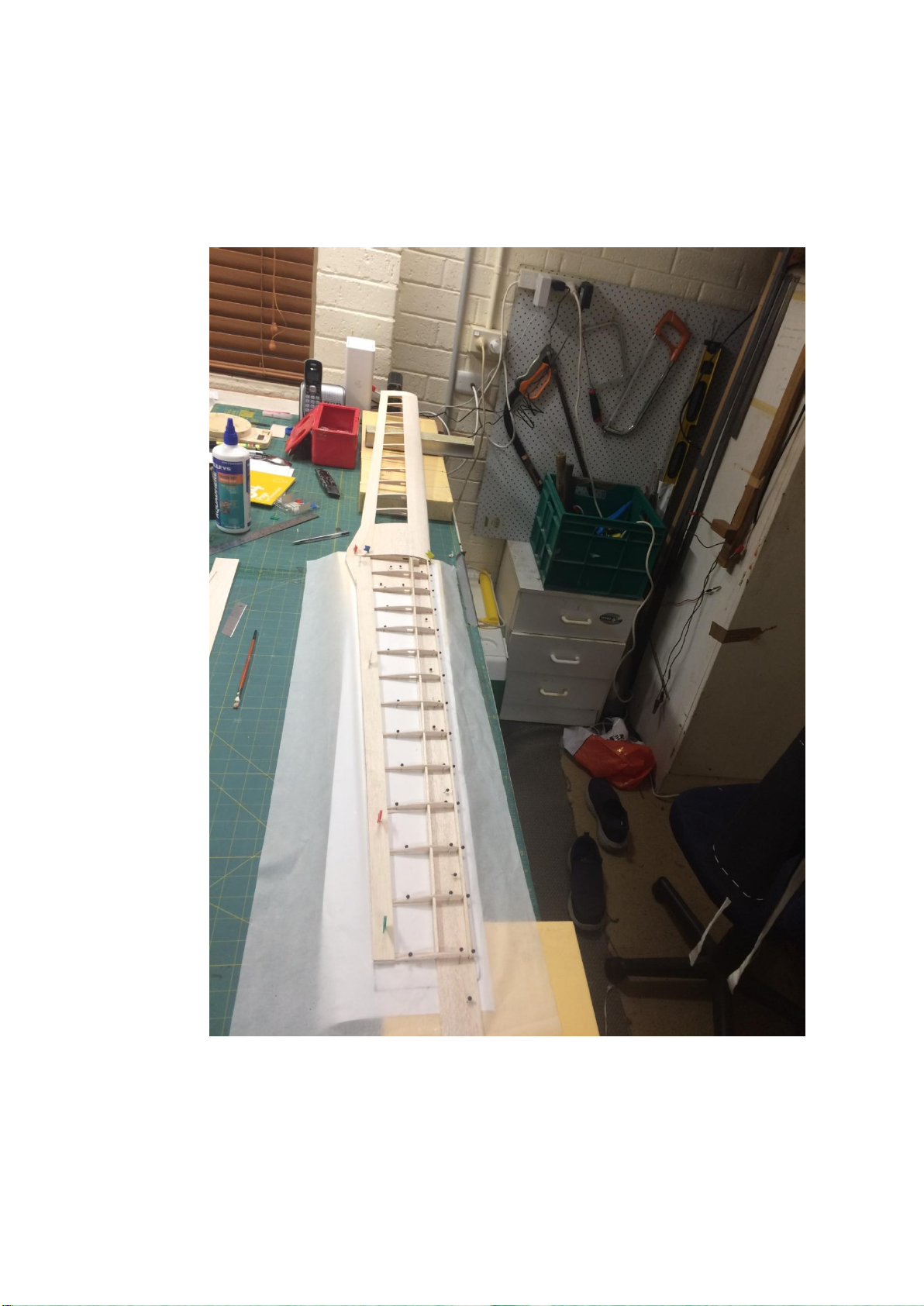

11. Tape the left wing plan to the building board with a layer of baking paper on top, then

pin in place the 1/16” sheeting and 1/4” trailing edge , and glue cap strips in place as

show below.

9

12. Glue the front and rear dihedral braces to the spar, then thread the ribs onto the spar

and glue this assembly into position over the sheeting and cap-strips. PVA works well

here. Glue the false LE in place.

10

13. Fit and glue front and rear sections of 1/8” (3.2mm) balsa root rib R1, as well as TE

doubler and scrap ¼” square balsa front wing bolt reinforcement.

11

14. Glue on the LE sheeting using PVA.

12

15. Trim and sand the LE and wingtip and fit 6.4mm balsa LE left and WINGTIP. Sand to

shape. Thread the aileron servo extension lead through the appropriate holes in the

ribs. Depending on how you choose to fit the wing servos, you may add the servo

mount sheeting and reinforcements now, or after the two wing halves are joined.

Underside of left wing shown below.

13

16. Build the right wing over the plan, propping up and joining the left wing to the right

wing during construction before the top sheeting is added. A hole is made in the

bottom RHS centre-section sheeting for the aileron servo leads to exit.

14

17. Once the wing structure has been completed, drill holes for 2 x 4mm wing bolts (use

location shown on the plans) then present wing up to fuselage, marking the position on

the ply fuselage wing mount plates where the bolts come through. Drill and tap holes

for the 4mm bolts in the ply or for alternative blind retention nuts.

15

18. Make up the fuselage over-wing fairing as shown on the plans, and temporarily fit in

place to shape. The model is now structurally complete, and should look something like

this:

16

FITOUT

19. Decide how you wish to hinge the ailerons; then cut out from the wing and bevel to

suit. The prototype used clear tape, top-hinged. The rudder can be hinged according to

preference. Fit the aileron servo attachments of choice, if not already done earlier.

The prototype was covered with HobbyKing iron-on covering, which goes on easily and

gives a great result. HXT900 servos are fitted side by side in the prototype. Smaller

servos would be fine too. Fit control horns and associated connectors etc.

17

Fit the motor and radio gear. Air holes for motor cooling have not been added at this point

in time, but should be considered for motor longevity. If using a 3D-printed canopy, hollow

the bottom with a soldering iron to fit the flight battery. Rare earth magnets were used to

hold canopy in place. The fairing over the top of the wing is held on with clear tape.

18

FLYING

Control throws (all measured at widest point of surface)

ELEVATOR: 8mm UP /4mm DOWN. AILERONS: 8mm UP/4mm DOWN. RUDDER: 20mm

LEFT/RIGHT. Expo to taste.

The importance of a forward Centre of Gravity position cannot be emphasised enough with

this model! Do balance as shown on the plan, even if a small amount of lead in the nose is

necessary, as it probably will be. The CG shown gives a neutrally stable model which

performs well, and is responsive with good glide and penetration. It flies faster than a

floater like a Radian or Aquila, but does not disgrace itself in their company especially once

the wind picks up.

This model would perform well on the slope without a motor too. On the flat field it has

done basic aerobatics including loops and rolls.

Enjoy!

A short flight video can be found here:

https://www.youtube.com/watch?v=oBufEUaoIu4

19

Table of contents

Other Timeless Wings Toy manuals

Popular Toy manuals by other brands

RC Groups

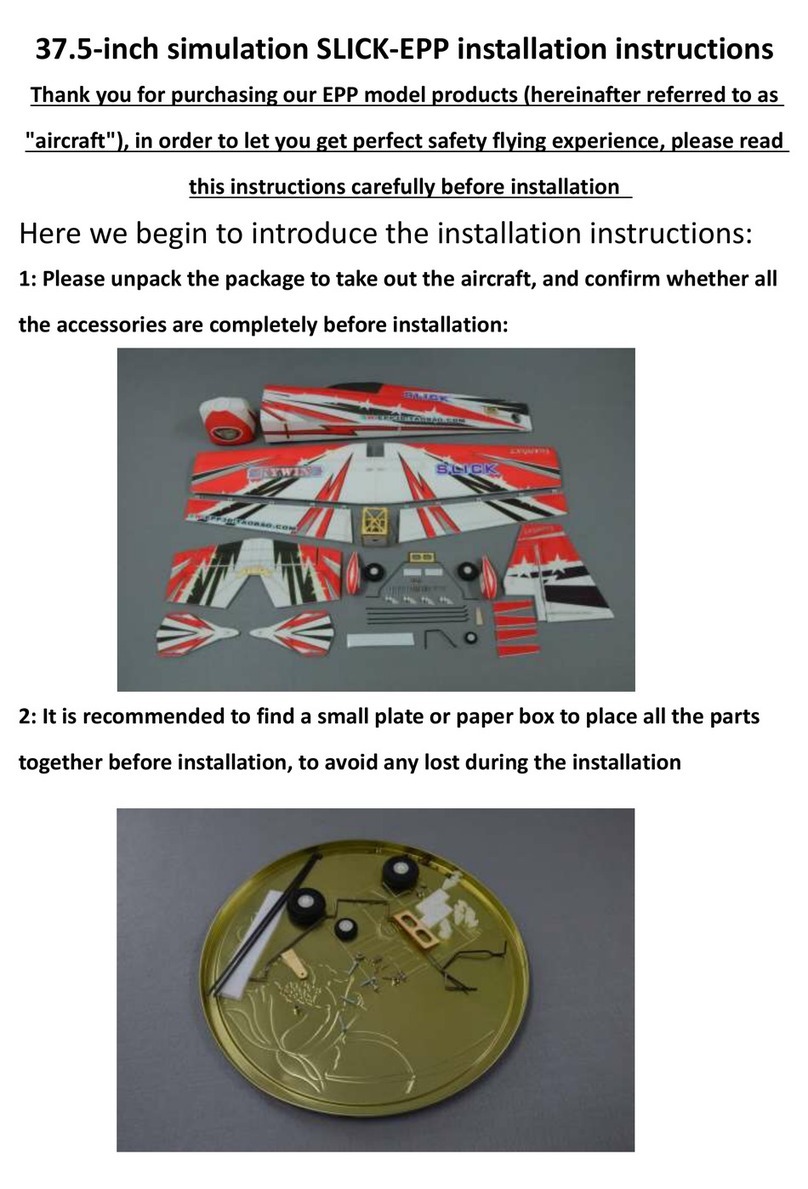

RC Groups SLICK-EPP installation instructions

Minicraft Models

Minicraft Models USAF WC-130J manual

marklin

marklin 46717 instruction manual

Fisher-Price

Fisher-Price FORD F-150 L6348 Owner's manual & assembly instructions

LEGO

LEGO Klando 2015 Campus 4000018 Assembly guide

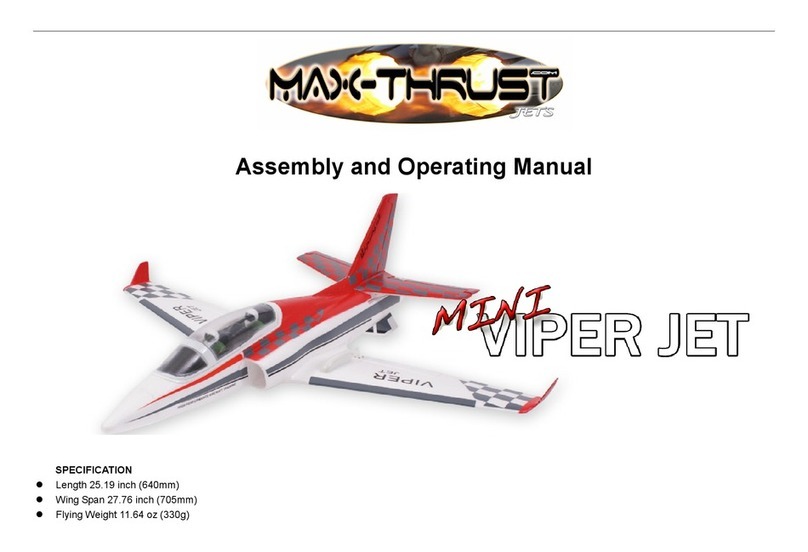

Max-Thrust

Max-Thrust Mini Viper Jet Assembly and operating manual