Caley Coaches CL02/2a Building Instructions

Page 2

the kit with a compensated chassis. If you are not, please return the compensation pack to me with

a note of your name and address and I'll be happy to forward the required bearings and modified

instructions to enable you to build rigid chassis.

N.B. Numbers in brackets following a part name are the quantity supplied when other than 1; numbers

preceding a part name are identification numbers which will be found along side the part on the

appropriate etch. Wire etc. will be found taped to the box lid.1 Loco body etch containing :-

1 Footplate, 2 Footplate valances (2), 3 Buffer beam, 4 Drag beam, 5A 812 cab sides (2), 5B 652 cab sides

(2), 6 Cab front, 7 Cab floor side supports (2), 8 Cab floor rear support, 9 Cab floor, 10 Splasher box

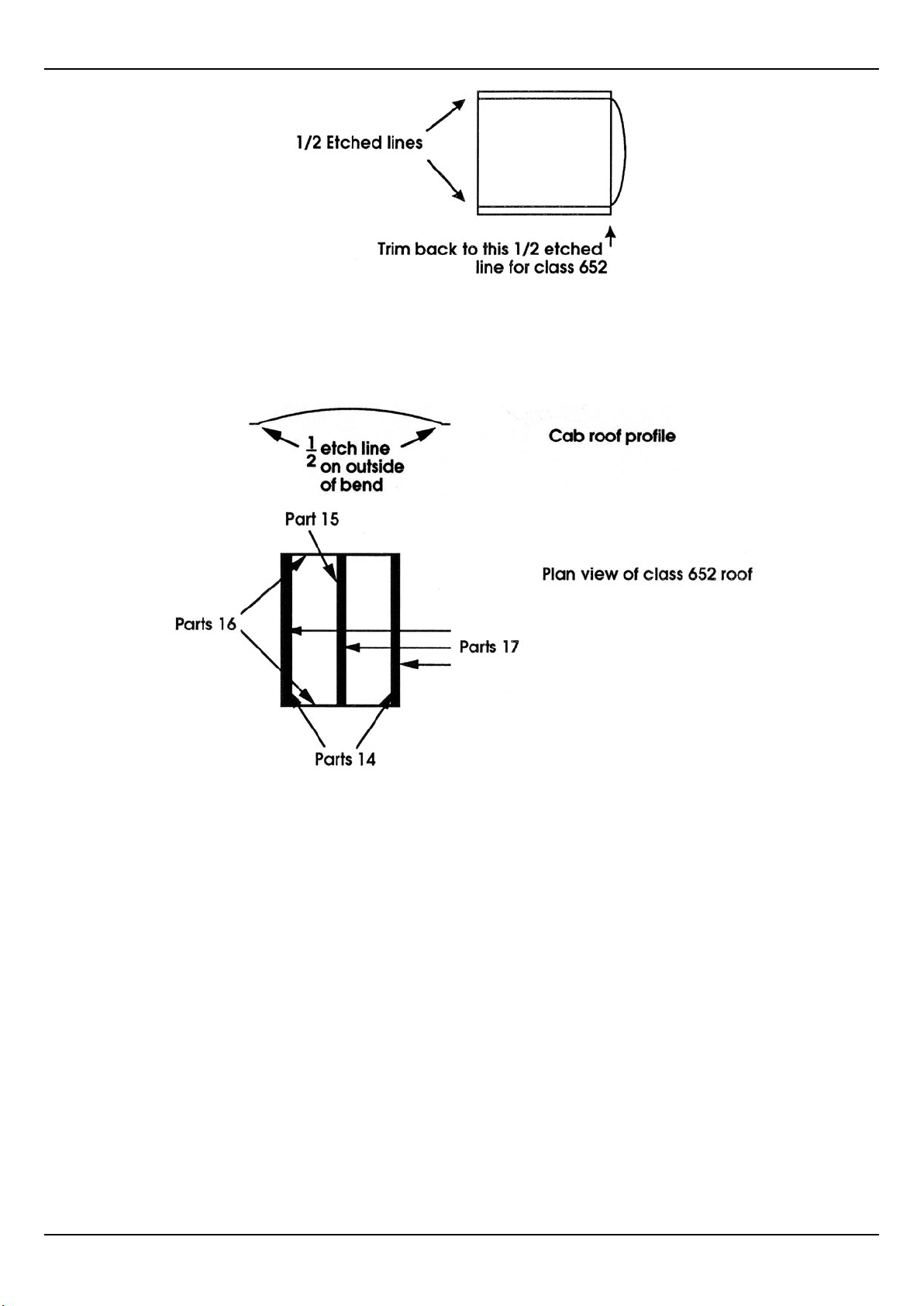

sides (2), 11 Splasher box tops (2), 12 Cab roof, 13 812 roof rear strip, 14 Roof front and rear strips (2), 15

Roof centre strip, 16 Roof gutter strips (2), 17 Cab roof stanchions (4), 18 652 upper frames (2), 19F 812

front upper frames (2), 19R 812 rear upper frames (2), 20 Middle splasher sides (2), 21 Middle splasher

tops (2), 22 Front splasher/sandbox sides (2), 23 Front splasher/sandbox tops (2), 24 Smokebox front,

25 Smokebox rear saddle, 26 Firebox front, 27 Centre steps (2), 28 Rear lower steps (2), 29 Rear upper

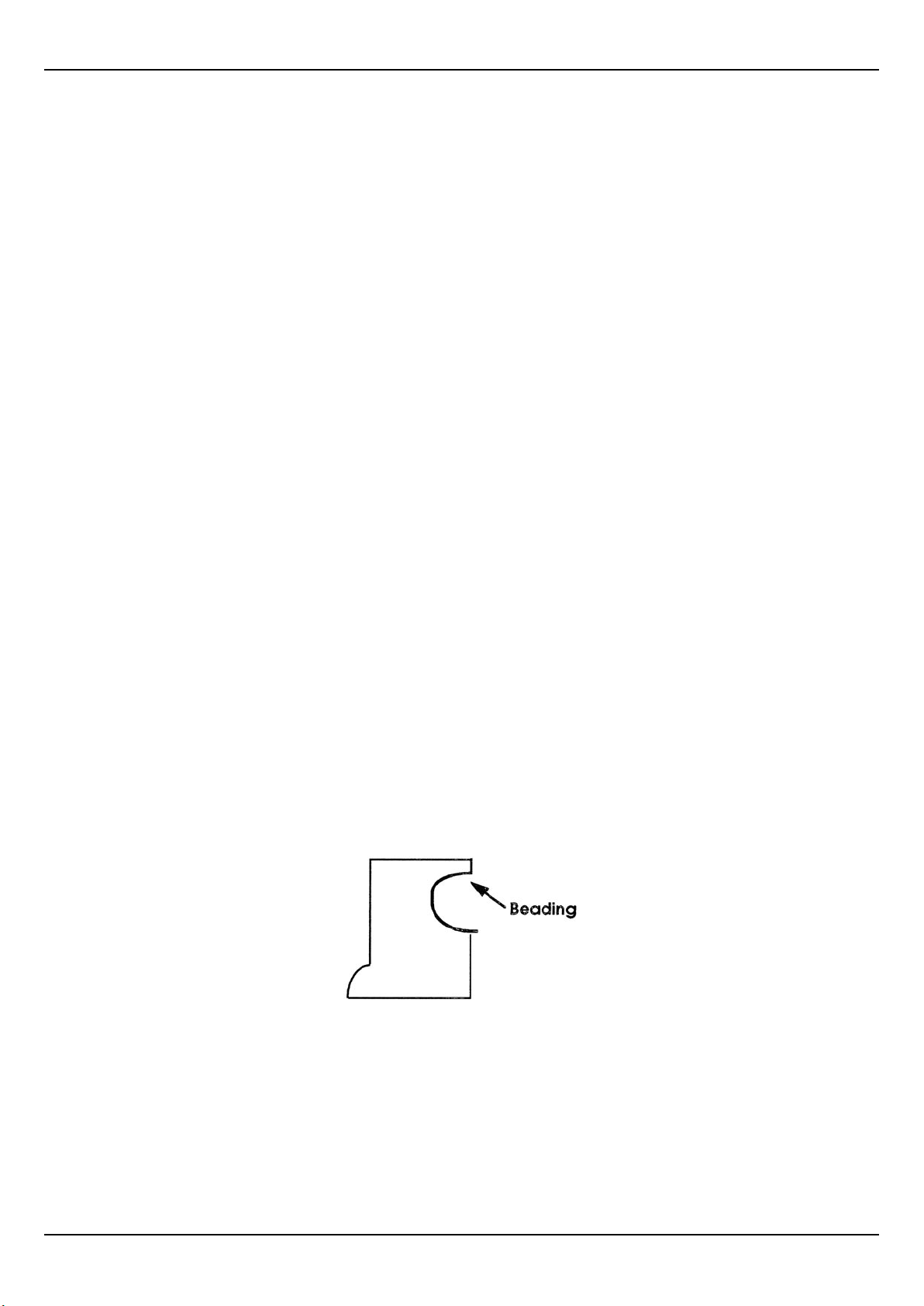

steps (2), 30 Spectacle surrounds (2), 31 Cab opening beadings (2), 32 Boiler bands (5), 33 Reversing rod

(652), 33B Reversing rod (812), 34 Reversing lever, 35 Strips for lamp irons (3).

2 Additional etched loco body parts :-

Boiler/smokebox/firebox, Inner smokebox wrapper, Outer smokebox wrapper.

3 Loco chassis etch containing :-

Chassis frames (2), Brake blocks (6), Brake hangers (6), 7 Brake pull-rods (2), Centre wheel balance

weights (2), Outer wheel balance weights (2), Class 812 centre axle coil springs (2), S1- S4 Frame spacers

(1 each of OO, EM and P4)

4 Steel coupling rod etch.

5 Cast fittings :-

Chimney, Standard dome, Flat topped dome, Smokebox door, Smokebox door dart, Backhead,

Ramsbottom safety valve, Ross pop safety valve, Steam chest cover, Sandbox fillers (2), Reversing lever,

Cylinder lubricators (2 each of two different styles), Sandboxes (2), Westinghouse pump, Westinghouse

pipe, Steam pipe, Vacuum pipe.

6 Turned brass fittings :-

Buffers (2), Short handrail knobs (3), Medium handrail knobs (6), Whistle.

7 Miscellaneous parts:-

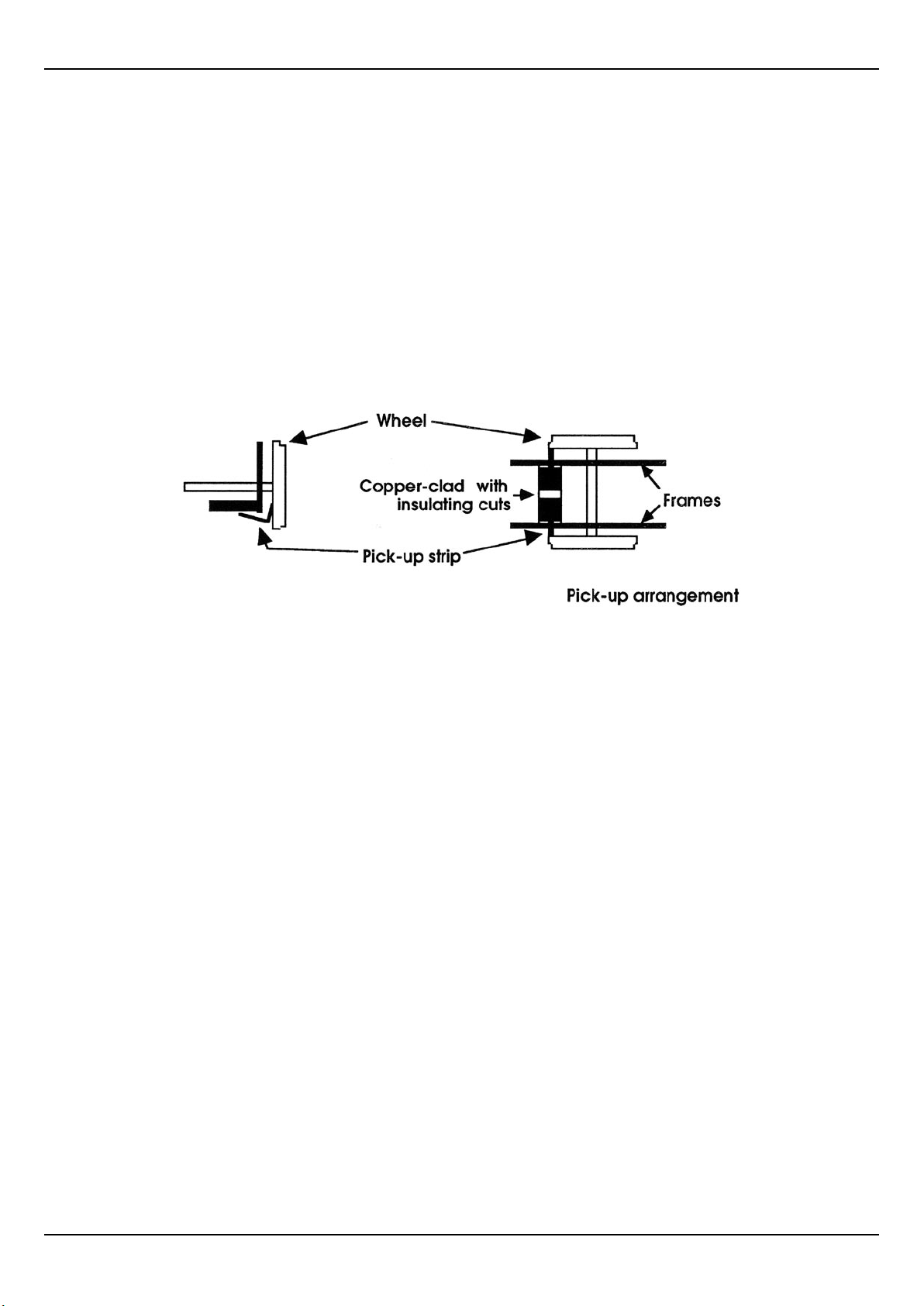

Compensation pack, Boiler tube, 0.45mm wire (4), 0.9mm wire (2), Brass rod, Copper-clad strip, Phosphor-

bronze strip, 10BA nuts (2), 10BA bolts (2), Insulated wire.

Section 2 Footplate

2.1 Remove the footplate (part 1) from the body etch, remove and store carefully the lamp-iron strips

(part 35) contained within it.

2.2 Solder the footplate valances (part 2) into the locating grooves on the underside of the footplate,

checking that the footplate overhang is equal front and rear. Note that the cab end of the footplate

is the end with the chassis mounting nearest the end to the part and the step mounting brackets

on the valance go below the cab.

2.3 Solder the buffer beam (part 3) below the front of the footplate and to the valances.