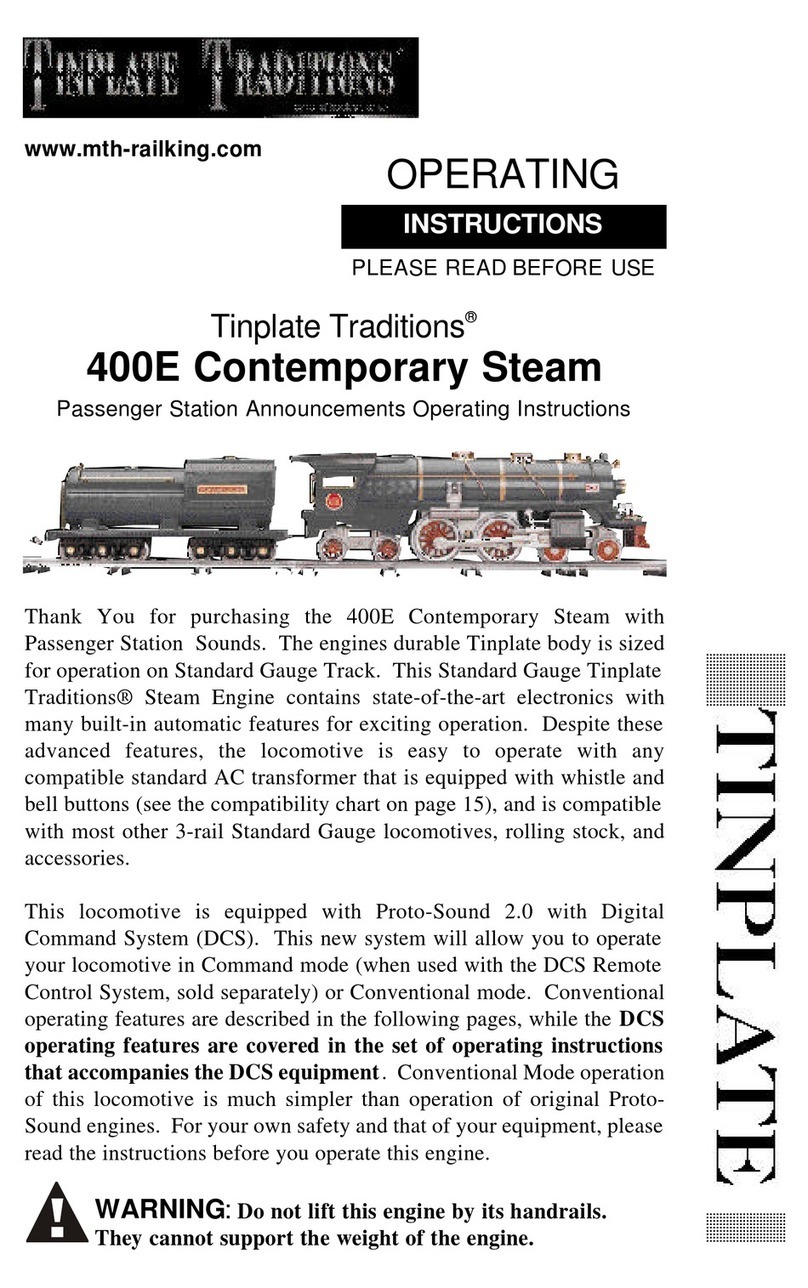

Tinplate Traditions 318E User manual

PLEASE READ BEFORE USE AND SAVE

Tinplate No. 318E

Electric Locomotive

www.mth-railking.com

Contemporary Version

Compatibility

This engine will operate on any traditional

42” STD Gauge track system, including

M.T.H.’s traditional tubular track. It is also

compatible with most standard AC

transformers. (See page 15 for a complete

list of compatible transformers and wiring

instructions.)

Freight Yard Sound

Passenger Station Announcement

OPERATOR’S MANUAL

(3V PS-2)

CAUTION: ELECTRICALLY OPERATED PRODUCT:

Not recommended for children under 10 years of age. M.T.H. recommends adult supervision with children ages 10 - 16.

As with all electric products, precautions should be observed during handling and use to reduce the risk of electric shock.

WARNING:Whenusingelectricalproducts, basicsafetyprecautionsshould beobserved,includingthe following:

Readthismanualthoroughly beforeusingthisdevice.

lM.T.H. recommends that all users and persons supervising use examine the hobby transformer and other electronic equipment

periodically for conditions that may result in the risk of fire, electric shock, or injury to persons, such as damage to the primary cord,

plug blades, housing, output jacks or other parts. In the event such conditions exist, the train set should not be used until properly

repaired.

lDonotoperateyour layoutunattended. Obstructedaccessoriesor stalledtrainsmayoverheat, resultingindamageto yourlayout.

lThistrainsetis intendedforindooruse. Do notuseif waterispresent. Seriousinjury orfatalitymayresult.

lDonotoperatethe hobbytransformerwithdamaged cord,plug,switches,buttons orcase.

lThe transformer was designed to operate on regular US household current (120 volt, 50-60 Hertz). Do not connect to any other

sourceofpower.

lToavoidthe riskofelectrical shock,donot disassemblethetransformer unit. Thereare nouser-serviceableparts inside. If theunit is

damagedcontactM.T.H.Servicefor instructions.

lThetransformeris equippedwith aninternal circuitprotector. If thecircuitprotectortrips,unplug thepower cordfrom theelectrical

wall outlet, check your layout for any short circuits. The circuit breaker will reset automatically when the short is removed from the

circuit.

lUnplugthetransformerfrom theelectricalwalloutlet whennotinuse.

lDonotusethis transformerforotherthan itsintendedpurpose.

Transformer Ratings:

Input: 120 VAC, 60 Hz Only, Output: Z-750: 21VAC 3.75A 78VA; Z-1000: 14VAC 80W or 18VAC 100W

Table of Contents

Set Up Checklist............................................................................................................ 3

Lubrication...................................................................................................... 3

Checking The Battery.................................................................................... 3

Basic Operation.............................................................................................................. 4

Activating Features......................................................................................... 4

Manual Volume Control............................................................................... 5

Proto-Sound® 2.0 Operating Instructions............................................................. 6

Activating Proto-Sound® 2.0 Conventional Mode Features.................. 6

Freight Yard Sounds(FYS)/Passenger Station Announcements (PSA). 6

Tips on using FYS/PSA............................................................................... 7

Speed Control................................................................................................. 7

Locking Locomotive Into A Direction....................................................... 8

Reset To Factory Default.............................................................................. 8

Automatic Sound Effects.............................................................................. 8

Maintenance.................................................................................................................... 9

Lubricating and Greasing Instructions....................................................... 9

Lubricating the Drive and Worm Gear....................................................... 9

Removing the Body........................................................................................ 10

Cleaning The Wheels, Tires and Track....................................................... 11

Headlight Replacement Instructions........................................................... 11

Self Charging Battery Back-Up.................................................................... 12

Troubleshooting Proto-Sound® 2.0 Problems......................................... 13

Transformer Compatibility and Wiring Chart........................................... 15

Additional Features Accessible Of DCS Remote Control System........ 16

Service & Warranty Information................................................................. 17

Limited One-Year Warranty.......................................................................... 17

This product may be protected by one or more of the following patents: 6,019,289; 6,280,278; 6,281,606; 6,291,263;

6,457,681; 6,491,263; 6,604,641; 6,619,594; 6,624,537; 6,655,640.

©2007, M.T.H. Electric Trains, Columbia, MD 21046

Set Up Checklist

Lubricate the locomotive

Check to see whether the battery needs to be charged for full sound effects

Apply power to run as described in the Basic Operating Section of this

manual

3

No. 318E Electric Locomotive

You should lubricate the engine to prevent it from squeaking. Use

light household oil and follow the lubrication points marked “L”

shown below. Do not over-oil. Use only a drop or two on each

pivot point.

Lubrication

p

p

p

DO NOT

OVER OIL

DO NOT

OVER OIL

DO NOT

OVER OIL

Lubrication Points on the Locomotive

Lubricate Pick Up Rollers (L)

Lubricate Wheel Axles (L)

Checking the Battery

You may find, if your locomotive was built several months before you set it up, that

the rechargeable battery has run down and needs to be charged before operating. If

you notice that the sounds are garbled, test and charge the engine as described in the

"Self-Charging Battery Back-Up" on page 12.

44 No. 318E Electric Locomotive

Basic Operation

The Throttle knob controls how fast your train will travel.

Turn the throttle knob up ½-way, until the engine headlight shines bright.

Put the engine into motion by pressing the Direction button on your transformer

once. (hold it for approximately 1 second)

If the engine does not begin to move as soon as you firmly press the Direction

button, you may not have sent enough voltage to the track to make the train move.

Turn the throttle up a bit higher until the train begins to move.

Activating Features

Throttle To increase or decrease track voltage, and therefore train speed, turn the

throttle control knob. Turning clockwise will increase voltage and speed, while

turning counterclockwise will decrease voltage and speed. The engine will maintain

the speed you set after you release the throttle until you turn it again to change the

voltage and speed.

Bell - To sound the bell, in an engine equipped with a bell firmly press and release

the Bell button. To turn the bell off, press and release the Bell button again. The

bell will continue to ring from the time you turn it on until you press and release

the button again to turn it off.

Horn/Whistle - To sound the whistle, firmly press the Horn/Whistle button. The

whistle will sound for as long as you continue to depress the button. It will stop

when you release the button.

Direction - Your train is programmed to start in neutral. The train will always

cycle neutral-forward-neutral-reverse with each press and release of the direction

button. The engine is programmed to restart in neutral each time the track voltage

is turned off for 25 seconds or more.

Cycle Phases

Neutral

Neutral ForwardReverse

5

No. 318E Electric Locomotive

Manual Volume Control

To adjust the volume of all sounds made by this engine, turn the master volume

control knob located under the tender clockwise to increase the volume and

counter-clockwise to decrease the volume.

Proto-Sound Manual Volume Adjustment

Proto-Sound 2.0

Volume Adjustment Knob

Table of contents

Other Tinplate Traditions Toy manuals

Popular Toy manuals by other brands

FUTABA

FUTABA GY470 instruction manual

LEGO

LEGO 41116 manual

Fisher-Price

Fisher-Price ColorMe Flowerz Bouquet Maker P9692 instruction sheet

Little Tikes

Little Tikes LITTLE HANDIWORKER 0920 Assembly instructions

Eduard

Eduard EF-2000 Two-seater exterior Assembly instructions

USA Trains

USA Trains EXTENDED VISION CABOOSE instructions