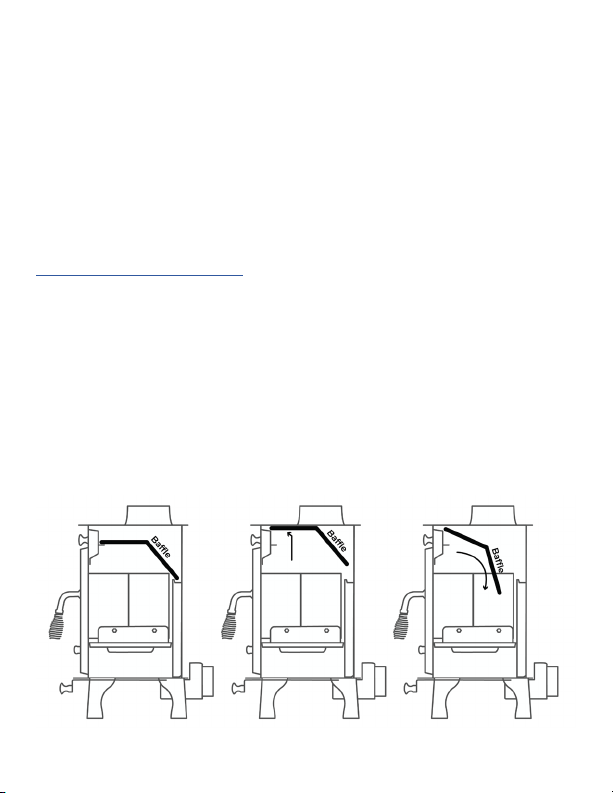

9

until the bottom is free from the rear air plate. Allow the rear of the bae to drop

below the rear air plate, then lower the bae into the rebox. Remove the bae

from the rebox by turning it 90 degrees so it ts through the door. See gure 2.1.

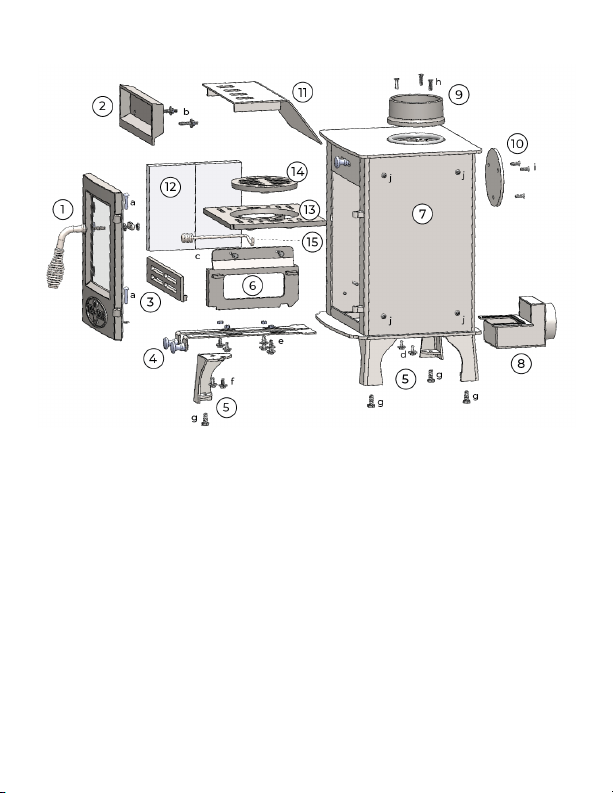

NOTE: Due to shipping weight restrictions, the door glass, rebricks, bae, coal bar,

legs, ue ange, and air-controls ship in a separate box for the Dwarf 5kW.

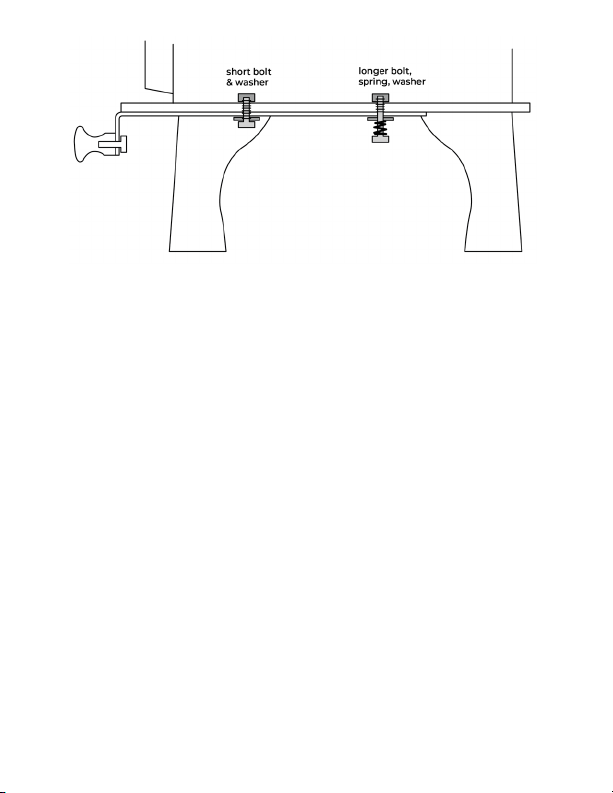

3. INSTALL THE DOOR HANDLE (if not already installed): For some models,

the door handle is shipped inside of the stove to protect both the handle and the

door from damage in transit. Locate your door handle and remove the outer jam

nut, cam latch, inner jam nut, and lock washer. Open your stove’s door and insert

the threaded end of the spring handle through the door handle hole. First install

the lock washer and then the inner nut on the threaded end of the spring handle,

inside of the door. Tighten the inner jam nut fairly snug against the lock washer.

Turn the door handle back and forth to test the t of the jam nut. Operation

should be smooth with a bit of resistance, not wobbly.

Turn the spring handle to face straight down. Place the cam latch on the threaded

end of the handle inside of the door with the long end protruding past the left

edge of the door. en thread the outer nut against the cam latch. Grasp the door

handle with your right hand, and use your right thumb to press the cam latch

upward to prevent it from turning. Use a crescent wrench in your left hand to

tighten the outer jam nut rmly against the cam latch to lock the handle in place.

Close and latch your stove door to test its t. e door should feel snug against

your stove’s body, not wobbly, and your handle should operate smoothly and easily.

Test several points around your door gasket by closing a dollar bill between the

door and the stove. You should feel some resistance when you pull the bill out.

If the bill cannot be pulled out easily, your door is too tight. If the bill falls out

with no resistance, then your door is not tight enough. If your door needs to be

adjusted, remove the outer jam nut and the cam latch. Tighten the inner jam nut

to tighten the door against the stove body, or loosen it to loosen the door. Install

the cam latch and outer jam nut as before, and retest your door’s t.

If you’d like a video walkthrough, watch our Door Maintenance video at

tinywoodstove.com/videos

Close the door and gently set the stove on its back.