Tiras MLT110 User manual

1

FIRE ALARM SYSTEMS

ADDRESSABLE COMBINED SMOKE AND

HEAT DETECTOR DETECTO MLT110

Passport

AAZCh. 425238.005 PS

DSTU ISO 9001:2015

Serial number:

Firmware version:

2

Contents

1 List of abbreviations ........................................................................................................................3

2 Purpose.............................................................................................................................................3

3 Declarations of manufacturer ........................................................................................................3

4 Technical characteristics .................................................................................................................3

5 Connection........................................................................................................................................ 5

6 Settings .............................................................................................................................................6

7 Operation..........................................................................................................................................6

8 Packaging .........................................................................................................................................7

9 Operation, storage, and transportation conditions.....................................................................7

10 Acceptance certificates..................................................................................................................8

11 Warranty obligations.....................................................................................................................8

12 Limitation of liability ......................................................................................................................8

13 Information on repair ...................................................................................................................8

14 Information on declarations of conformity to technical regulations and certificates........... 9

15 Disposal...........................................................................................................................................9

3

This passport refers to addressable combined optical smoke and heat detector (further -

ACD) DETECTO MLT110 (with short circuit isolator) and contains information on the design,

and operation rules of ACD, which are used as part of addressable fire alarm systems, based

on the fire alarm control panels Tiras PRIME A.

ACD meets the requirements of DSTU EN54-5, DSTU EN54-7 and DSTU EN54-17 standards.

1 List of abbreviations

SCI - short circuit isolator;

FCP –Fire alarm control panel Tiras PRIME A;

AFAS –addressable fire alarm system;

AI –addressable interface;

OC - open collector;

RI –remote indicator.

2 Purpose

2.1 ACD is intended for use in the AFAS to detect a smoke and/or an increase of ambient

temperature in premises and generate a fire alarm signal. ACD has plastic housing.

3 Declarations of manufacturer

3.1 The ACD design meets the requirements of the quality management system, which

contains the set of design rules for all its elements.

All components of ACD are used as intended and under the conditions of their operation

correspond to the environmental conditions outside the housing in accordance with class 3k5

IEC 60721-3-3.

4 Technical characteristics

4.1 The list of ACD terminals and their functions is given in Table 1

Table 1

Terminal

name

Functional

L+

AI positive wire connection terminal

L1-

AI negative wire connection terminal

L2-

Connection terminal for an AI negative wire. This terminal is absent in

ACD DETECTO SMK100 (Fig.1)

KT1

Connection terminal for ROSD. This terminal is absent in ACD DETECTO

SMK100 (Fig.1)

In ACD DETECTO SMK110 "L1-" and "L2-" terminals are separated by SCI.

4

Figure 1 –ACD view from the side of the contact

4.2 Technical features of ACD are given in Table 2.

Table 2

Feature name

Value

General

Dimensions WxHxD, mm

-diameter

-height

110

50

Net weight, kg

0,12

Enclosure protection degree

ІР30

Meantime to failure, hours, not less

40 000

Average lifetime, years, not less

10

Time to detect faults, s, not more than

10

Power supply

Supply voltage through AI, V

20 –25

Maximum current consumption, standby mode/alarm mode, mA

0,13/0,20

Temperature class

Operation temperature range, class A2, оС

54 –70

Operating temperature range, class B, оС

69 –85

Operating temperature range, class A2R, at a growth rate of 10 to 30 K/min, оС

54 –70

SCI

Maximum SCI opening voltage, V

15,0

Minimum SCI recovery voltage, V

4,2

Maximum Current through SCI in the closed state, mA

65

Maximum SCI opening current, mA

75

Maximum leakage current through SCI (in the open state), mA

4,2

Maximum transient resistance of SCI in the closed state, Ohm

0,09

L+

L1-

L2-

KT1

These holes are absent in

DETECTO SMK100

Holes for cable

connection to ASD

Mounting holes in

ASD upper cover

5

4.3 LED indicators are used to indicate the operation modes and ACD status, combined

with one light guide mounted in the cover:

-blinking green one time in four seconds - an indication of the standby mode;

-blinking green with an interval of 0.5 s (for not more than 4 s) –an indication of the

ACD registration process in AI;

-blinking red with a period of 0.5 s –an indication of fire alarm mode;

-double blinking red –an indication of the fault status;

-blinking green and red alternately - ACD is marked for visual search in a zone.

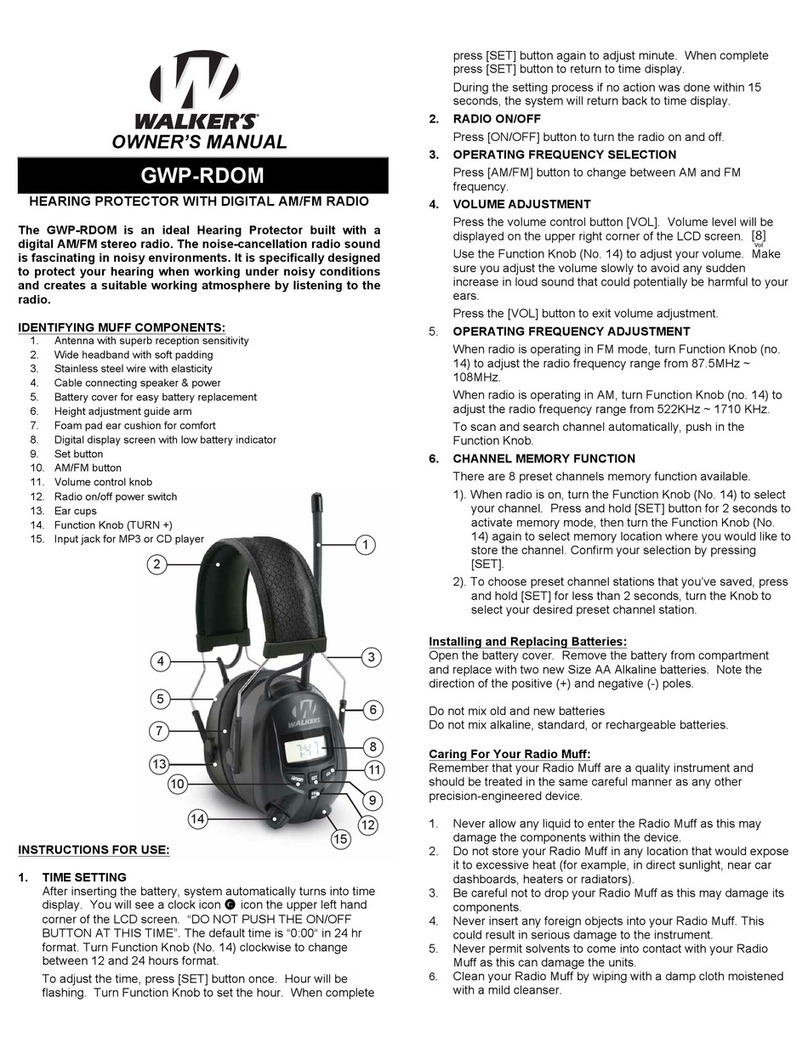

5 Connection

5.1 To install ACD it is need to do the following:

1) unpack ACD, disconnect the base from it;

2) install the base on a flat surface, fasten it with screws according to Figure 3, after

tightening the base must not be deformed.

3) fix AI wires in screw terminals of a base according to Fig. 2 and Table 1. There are four

terminals in the base of ACD;

4) align the ACD with the base, turn it clockwise until it lowers in the base, then turn it in

the same direction to restrict movement.

Figure 3 –Terminals on the ACD base

5.2 If according to the project RI is powered from AI, its negative contact should be

connected to the screw terminal "2" (KT1), and the positive one –to the screw terminal "1"

(L+) (Fig. 3a, the presence of Rlim (current limiting resistor) depends on the type of RI and its

operating current). it is allowed to connect the LED through the resistor Rlim instead of RI, the

Rlim resistance must be at least 10 kОhm. It is required to select the light-emitting diode for RI,

it should have small current consumption (about 2 mA).

Warning! When calculating the total current consumption of AI, take into account the

current consumption of RI in the switched on state. The maximum length of the wires

connecting the RI to the ACD must not exceed 3 m.

If the power supply of remote indication devices is provided from external PS, connect

ACD according to fig. 3b. The negative wire from the PS is connected to the "LGND" terminal

Mounting holes

to fix a base

Holes to enter cable

in a base

L+

КТ1

L2-

L1-

6

of the FCP. The output voltage of PS should not exceed 30 V and should provide the operating

current of RI.

L1-

L2-

КТ1

L+

АІ

Rlim

L1-

L2-

КТ1

L+

АІ

Rlim

PS

LGND of FCP

24 V

а) б)

Figure 3 –RI or LED connection to ACD

5.3 There are special slots at the side surface of ACD for the case when the cable must go

inside the base from aside, the corresponding slots must be cut out. These slots are marked

with the letters: "A", "B", "C", "D" (Fig. 1, Fig. 2).

5.4 Wires can be connected to the ACD terminals base only when there is no voltage on

the AI.

6 Settings

6.1. When the supply voltage appears on the AI on the connected ACD, the automatic

registration indication is switched on (see item 4.3). Then ACD switches to the standby mode

if there are no conditions for the fault formation (for example, the SCI operation).

ACD is distributed in a zone and the necessary class is adjusted according to the FCP

operation manual.

6.2 ACD can be configured for the classes listed in Table.2. By default, class A2 is set in

ACD.

7 Operation

7.1 In the standby mode, the ACD indicator blinks green. When the smoke from the

surrounding area enters the smoke chamber and reaches the threshold concentration or the

temperature in premise reaches the trigger threshold, the ACD switches to a fire alarm state

and sends a message to the FCP, setting the ACD indication to the fire alarm mode.

If the ACD is in a fault state (double blinking red), it will not switch to a fire alarm state at

any concentration of smoke.

Reset the fire alarm message on the FCP (according to the FCP operation manual) to

return the ACD to the standby mode from the fire alarm mode.

7.2, ACD periodically monitors the contamination level of the smoke chamber during

operation, and when the threshold value is reached it switches to fault mode. To prevent this

fault, please clean the smoke chamber at least once every 6 months.

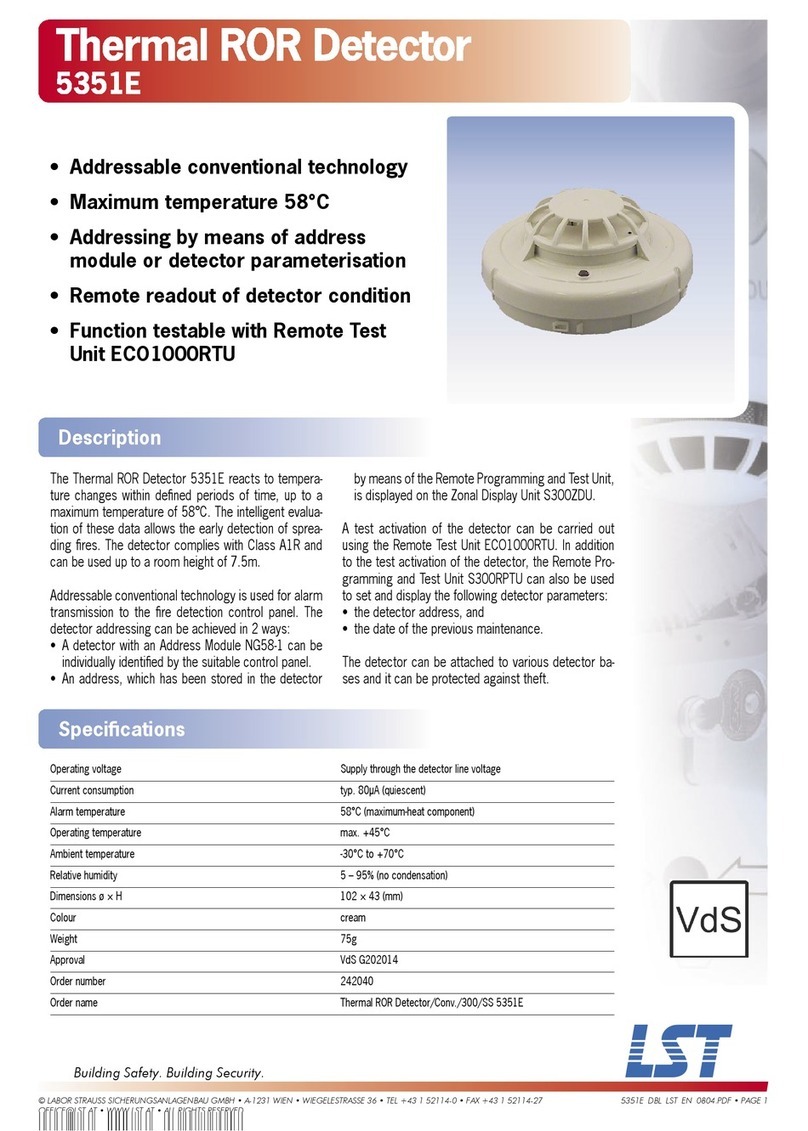

To clean the smoke chamber, do the following:

7

1) remove the detector holding it by the protrusions on the body, turn it counterclockwise

and separate from the base;

2) unscrew the 2 screws from the contacts on the detector housing (Fig. 1) and remove

the top cover;

3) remove the protective grid (Fig. 2) from the smoke chamber, then remove the cover

of the smoke chamber, pulling it away from the base (Fig. 5);

4) use a brush to clean the surface inside the base and cover of the smoke chamber, blow

them with clean air;

5) reassemble the smoke chamber, install and secure the top cover;

6) put the ACD in its base.

Figure 5 –Smoke chamber of ACD opened

8 Packaging

8.1 After ACD unpacking do the following:

- visually inspect the device and make sure there is no mechanical damage on it;

- check the delivery scope according to table 3.

Table 3

Name

Code

Number

Note

ACD DETECTO MLT110

AAZCh.425238.005

1

Passport

AAZCh. 425238.005 PS

1

One passport for each

20 ACDs

9 Operation, storage, and transportation conditions

The ACD is intended for continuous 24h operation in the premises under the regulated

climatic conditions. Operating temperature range: - 10°С.. 55°Сat relative humidity not more than

93%.

Packaged ACDs are stored in warehouses under the following conditions: air temperature

range: - 50°С.. 55°С, relative humidity must not exceed 98% at a temperature of 35°С. There must

be no aggressive impurities in the air causing corrosion in the premise where the ACDs are stored.

Packaged ACDs are transported by low-tonnage shipments at any distance by road and rail in

closed vehicles in accordance with the rules of transportation applicable to each type of transport.

When placing and securing boxes with packed ACDs during transportation, ensure a stableposition

Smoke chamber

cover

Smoke chamber

base

8

of the boxes to prevent shifting and bumps between them. During loading and transportation, the

requirements of handling signs on the packaging must be met.

10 Acceptance certificates

ACD DETECTO MLT110 meets the requirements of regulatory and technical documents

and is suitable for operation complete with FCP Tiras PRIME A.

The date of acceptance (stamp) is on the last page of the passport.

11 Warranty obligations

The manufacturer guarantees ACD compliance with the requirements of regulatory and

technical documents during the warranty period of operation under the conditions of

transportation, storage, and the operation specified in this passport.

The warranty period is 36 months and starts at the date of sales specified in the operating

documents for the ACD or in other accompanying documents (sales contract, invoice, bill, etc.).

If you cannot provide a document confirming the date of sale of the ACD, the warranty period

starts from the date when the device was produced.

___________________ ____________________

(date of sale) (seller’s signature) stamp

12 Limitation of liability

The manufacturer has the right to refuse the ACD warranty service under disputed

circumstances. The manufacturer also has the right to make a final decision on whether the

ACD is subject to warranty service or not.

These are the actions and damages that lead to loss of warranty service:

1) damage caused by natural phenomena (fire, flood, wind, earthquake, lightning, etc.);

2) damage caused by the violation of the installation rules or improper ACD operating

conditions, including in particular:

-poor grounding;

-overvoltage;

-high humidity and vibration;

3) damage caused by other objects, liquids, insects, etc. getting inside the ACD;

4) mechanical damage to the ACD components (chips, dents, cracks, broken contact

connectors, etc.);

5) damage caused by unauthorized repair;

6) damage caused by the violation of transportation, storage, and operation rules;

7) change, delete, erase or damage the device serial number (or stickers with serial

numbers on the ACD).

13 Information on repair

The ACD is repaired by the manufacturer. ACDs for which the warranty period has not

expired and which have been operated in accordance with the operating documents for the

device are repaired free of charge. If you want to repair, ACD, send it to the manufacturer with

a document indicating the date of the sale, and a letter describing the malfunction, the place

of ACD operation, and the contact phone number of the person for repair

9

14 Information on declarations of conformity to technical regulations and

certificates

ACD DETECTO MLT110 meets the requirements of mandatory technical regulations,

namely:

-Technical regulations on electromagnetic compatibility of equipment;

-Technical regulations restricting the use of certain hazardous substances in electrical

and electronic equipment.

Certificate of compliance with the requirements of DSTU EN 54 series standards issued

by the State Certification Center of the SES of Ukraine.

The Quality Management System of Tiras-12 LTD is certified in accordance with DSTU ISO

9001: 2015.

The full text of declarations of compliance with technical regulations and certificates are

available on the website https://tiras.technlogy.

15 Disposal

After the expiry of the service life of the detector its utilization is carried out in accordance

with the current legislation, separate from household waste.

In accordance with the EU Directive 2012/19/EU on waste electrical and

electronic equipment, the disposal of detector should be done separately from

household waste. To dispose of the detector, it must be delivered to a point of

sale or a local processing point.

This manual suits for next models

1

Table of contents