Tixi HM20 User manual

TAM-HM-EN

Tixi Alarm Modem

Hardware Manual

HM20 HM21 HM27

HM30 - HM34

HM41 HM47

HM71 HM76

Version 1.2.3

© 2007 Tixi.Com GmbH

July 2007

This manual is protected by copyright. Any further sale is prohibited without the express and written

consent of publisher. This also applies to copies, microfilm copies, translations and the storage and

processing on electronic data-processing systems.

Company and brand names used in this manual may be Registered Trademarks of the appropriate

company, even if not explicitly stated so.

3

Tabel Of Contents

1Alarm Modems At A Glance.........................................................................................................6

1.1 State-Of-The-Art Communication.........................................................................................6

1.2 Easy to retrofit......................................................................................................................6

2Function Overview........................................................................................................................7

2.1 Integrated PLC Protocols.....................................................................................................7

2.2 Alarm Notification with Confirmation ....................................................................................7

2.3 Remote switching via SMS and Express-E-Mail..................................................................7

2.4 PLC Data Logging................................................................................................................8

2.5 Teleservice via PC ...............................................................................................................8

2.6 Web Server inside the Tixi Alarm Modem............................................................................8

2.7 Web Portal with Database and Facility Record....................................................................8

2.8 Pump alarm application example.........................................................................................9

3Model and Equipment Versions ................................................................................................10

3.1 Interfaces and Terminals....................................................................................................10

3.2 Tixi I/O Modules .................................................................................................................10

3.3 Analog Inputs .....................................................................................................................10

3.4 Memory Modules................................................................................................................10

4Sending SMS in a land-line network.........................................................................................11

4.1 Sending SMS to the land-line network...............................................................................11

4.2 Sending SMS to the mobile network..................................................................................12

5Installation and Mounting..........................................................................................................13

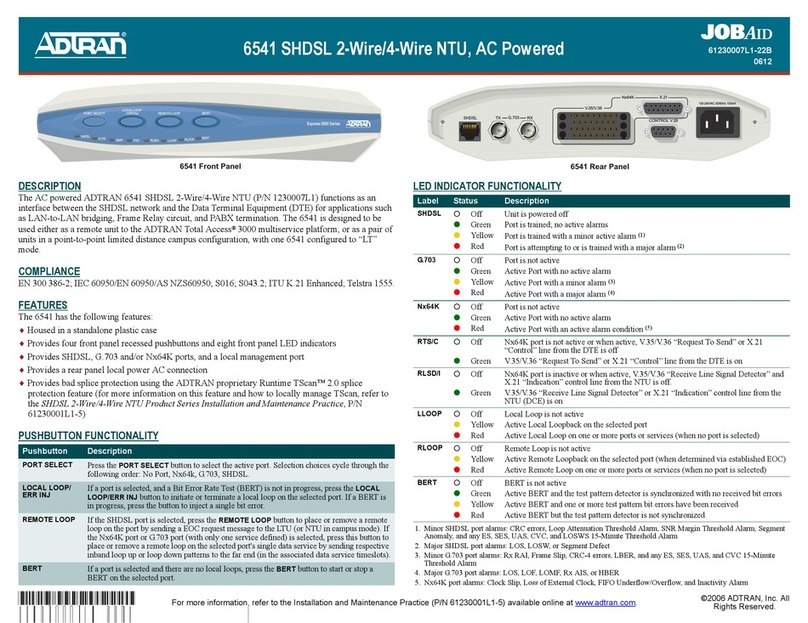

5.1 Overview of Terminals........................................................................................................13

5.2 Meaning of LEDs................................................................................................................14

5.3 Dimensions.........................................................................................................................14

5.4 Installation..........................................................................................................................15

5.5 Connecting to the Telephone Network...............................................................................16

6Interfaces.....................................................................................................................................17

6.1 COM1 – RS232 (jack)........................................................................................................17

6.2 COM2 – RS232 (plug)........................................................................................................17

6.3 COM2 - RS485 / RS422.....................................................................................................17

6.4 COM2 - MPI (Multi Point Interface)....................................................................................21

6.5 COM3 - M-Bus ...................................................................................................................22

6.6 S0 Power Interface.............................................................................................................22

7Digital and analog I/Os...............................................................................................................23

7.1 Digital Input ........................................................................................................................23

7.2 Analog Input.......................................................................................................................23

7.3 Digital Output......................................................................................................................23

7.4 Relay Output ......................................................................................................................23

8Power Supply..............................................................................................................................24

9Operation.....................................................................................................................................25

10 Configuration and projects ....................................................................................................25

10.1 Initial configuration .............................................................................................................25

10.2 Loading projects in the TAM...............................................................................................25

10.3 Loading projects in the TAM remotely................................................................................25

10.4 Operating modes: Modem mode and TiXML mode ...........................................................26

11 Tixi Software............................................................................................................................28

11.1 Secure Login: Access Protection .......................................................................................29

11.2 Remote Access..................................................................................................................29

11.3 TiXML Console: TICO........................................................................................................29

4

12 PLC Communication...............................................................................................................30

12.1 PLC Drivers inside the Tixi Alarm Modem..........................................................................30

12.2 Mitsubishi Alpha XL............................................................................................................31

12.3 Mitsubishi MELSEC FX......................................................................................................32

12.4 Siemens Simatic S7-200 (RS485)......................................................................................33

12.5 Siemens Simatic S7-300/400 (MPI)...................................................................................33

12.6 SAIA Burgess S-Bus..........................................................................................................34

12.7 Carel Macroplus.................................................................................................................35

12.8 ABB AC010........................................................................................................................35

12.9 Allen Bradley Pico GFX......................................................................................................35

12.10 Allen Bradley Pico Serie A + B...........................................................................................36

12.11 Berthel ModuCon ...............................................................................................................36

12.12 Moeller Easy 400/500/600/700...........................................................................................37

12.13 Moeller Easy 800/MFD.......................................................................................................37

12.14 Moeller PS306/316, PS4-200 und PS4-300.......................................................................37

12.15 Moeller XC/XVC.................................................................................................................38

12.16 Moeller easy control...........................................................................................................38

12.17 VIPA...................................................................................................................................39

13 S7-300/400 TS Adapter, MPI (HM7x)......................................................................................40

13.1 Simatic PG/PC Interface ....................................................................................................40

13.2 TS Adapter Parameters......................................................................................................41

14 Appendix..................................................................................................................................42

14.1 Technical Data ...................................................................................................................42

14.2 LEDs, Reset, Update, Error Diagnosis...............................................................................45

14.3 Accessories........................................................................................................................46

14.4 Tixi Alarm Modem Models..................................................................................................48

Security Advice

Intended Target Audience

This manual is aimed exclusively at suitably qualified electrical engineering specialists that are

familiar with the safety standards required for electrical engineering and automation. The engineering,

installation, commissioning, maintenance and testing of devices must only be carried out by qualified

electrical technicians. Unless otherwise stated in this manual or other manuals, any intervention in the

hardware and software of our products must only be carried out by our specialists.

Proper Use

Tixi Alarm Modems are only designed for use in the application fields described in this manual.

Ensure that all the specifications stated in this manual are observed. Unqualified interventions in the

hardware or software, and failure to observe the warnings stated in this manual or on the product may

lead to serious injury or material damage. No liability is accepted in such cases and any warranty

claims become invalid.

Safety Instructions

The safety and accident prevention regulations specified for the application concerned must be

observed during the engineering, installation, maintenance and testing of devices.

This manual contains special instructions that are important for the safe and proper handling of the

device. The warning symbols of the individual instructions have the following meaning:

DANGER:

Means that there is a danger to the life and health of the user if the relevant safety

measures are not taken.

ATTENTION:

Is a warning of possible damage to the device, software or other material damage if the

relevant safety measures are not taken.

5

1Alarm Modems At A Glance

Tixi Alarm Modems are new automatic modems with a large data memory, several functions and

integrated Internet technology. They are designed as intelligent communication computers with a 32-

bit power CPU and a 2 MB non-volatile Flash memory. This can be expanded by up to 64 MB, thus

providing enough space for your data requirements now and in the future.

Tixi Alarm Modems are fully automatic and can

• send alarm and status messages via SMS, Express E-Mail, E-mail or fax

• receive switch commands via SMS or Express E-Mail and forward them to a PLC,

• send the data of a connected PLC/system,

• exchange data between PLC/systems

What's more:

• You can use them as "normal" modems for the remote access of PLCs or systems, and the

programming software of the PLC can generally be used for this.

1.1 State-Of-The-Art Communication

The Tixi Alarm Modem can communicate directly with the PLCs of several manufacturers using the

relevant PLC protocol. Different bus systems are also supported. User-friendly XML-based software

programs enable the required functions to be configured easily. The over twenty-year-old history of

modems being controlled by primitive AT commands can now be forgotten at last.

The wide range of features available on the Tixi Alarm Modems provide solutions for a number of

applications such as the monitoring of temperature, pressures, levels, or the activation of motors,

fans, pumps, slide valves and flaps.

1.2 Easy to retrofit

Tixi Alarm Modems can be integrated in existing systems with a minimum of effort. The

communication protocols of commonly used PLCs are already implemented and so modifications to

the PLC program are normally not required.

6

2Function Overview

2.1 Integrated PLC Protocols

Tixi Alarm Modems can communicate directly with the PLCs of leading manufacturers using the

relevant PLC protocol, and access PLC variables, markers and ports via the PLC programming

interface. This can be achieved without having to adapt the PLC program or load a special function

block for communication.

These protocols are supported:

• ABB

• Allen Bradley

• Berthel

• Carel

• Tixi

• Modbus

• Moeller

• SAIA

• Siemens

• Tixibus

• VIPA

OEM Protocols

Manufacturers (OEM) and customers with special PLCs may take advantage of one of these options:

• Common access to Modbus industrial standard or to the TixiBus protocol

• Tixi.Com implements the appropriate protocol into the Tixi Alarm Modems.

2.2 Alarm Notification with Confirmation

Tixi Alarm Modems are fully automatic and can send status and fault messages to any recipient via

SMS, fax, E-mail or Express E-Mail. Messages can be triggered by PLC variables.

Address book:

The SMS, fax and E-mail addresses (max. 100) are managed in an address book.

Messages:

The message texts (max. 100) can contain up to 100 actual values from the PLC and can be of

any required length when used with faxes and E-mails.

Alarms:

Up to 100 alarms and actions such as switching commands can be defined.

Alarm cascade and acknowledgments:

Any number of freely definable alarm levels can be set up if message acknowledgment is

required. If a message is not acknowledged within a specified time, other recipients can be

notified. This can be cascaded as required.

2.3 Remote switching via SMS and Express-E-Mail

A short command via SMS or Express E-Mail can switch the optional outputs of the Tixi Alarm Modem

and those of a connected PLC. PLC variables can also be set in this way.

The execution of the command can also be acknowledged. 100 SMS switch commands with up to 10

parameters each can be defined as required. PLC variables can be queried simply and quickly by

SMS command without the need for a PC.

7

8

2.4 PLC Data Logging

Tixi Alarm Modems may record any PLC data (variables, ports) and system data with timestamp

inside the non-volatile Flash memory (2 MB - 66 MB). The poll cycle may be adjusted at will, as well

as the extent of data being logged.

The logged data is sent as XML text file or as Excel-compliant CSV via E-mail, Express E-Mail or Fax.

This may be triggered periodically via scheduler, or by a specific event occuring. There may be

several logfiles in use at the same time. The memory acts as a ring buffer.

2.5 Teleservice via PC

A Tixi Alarm Modem can be used to handle the remote maintenance of several controllers via a

telephone line. This is usually possible with the programming software in use. The variables and I/O

ports of the PLC can also be read or written remotely with the Tixi Alarm Editor (TILA). The entire

configuration of the Tixi Alarm Modem can be carried out by remote dial-in and the logged data can

be read “manually".

Secure Login

Optimum security is ensured since unauthorized dial-in attempts are prevented by means of a

login procedure with user name and password. All dial-in attempts are recorded.

2.6 Web Server inside the Tixi Alarm Modem

Web server functionality is implemented inside the Tixi Alarm Modem, so any web browser may be

used to visualize facility status, PLC data and logfiles respective alter these by mouse click.

For that purpose, merely some HTML pages need to lodge inside the modem. Access is done via

telephone network. Static IP addresses are not necessary.

2.7 Web Portal with Database and Facility Record

A variety of PLC systems and Tixi Alarm Modems may me administered by means of a SQL

database. Logged data may be stored, analyzed and visualized here.

Authorized users only are granted access to these data. The database may be adapted to custom

needs with ease and is open to other systems as well.

9

2.8 Pump alarm application example

The following example shows how you can use the wide range of functions of the Tixi Alarm Modem

to handle complex tasks automatically:

Pump alarm:

• Send an E-mail, a fax and an SMS to three different destinations

if input 312 on the PLC closes.

• Wait 10 minutes for a confirmation via SMS.

Service technicians can query status values by SMS (or dial-in and PC).

• Wait for a switching command for pump 2.

• If the SMS confirmation does not come in 10 minutes,

start a new alarm message cascade to other recipients.

• If the switch command for switching on the reserve pump has been received,

switch on the PLC output 17 (or a relay).

• After 5 minutes, send a status message via SMS and E-mail if pump 2 is running or not.

• If not so, send SMS, fax and E-mail to fire brigade and others. Send an alarm notification to a

web-based SQL database.

• Send the last 72 hours logged data as Excel-compliant CSV file to two E-mail recipients or to a

web-based SQL database.

10

3Model and Equipment Versions

3.1 Interfaces and Terminals

The basic functions of HM series Tixi Alarm Modems are identical. Only the type and number of

interfaces and I/Os may vary, according to the model used.

Interface HM20 HM21 HM27 HM3x HM41 HM47 HM71 HM76

COM1 RS232 RS232 RS232 RS232 RS232 RS232 RS232 RS232

COM2 - RS232 RS232 RS232 RS485/422 RS485/422 MPI MPI

Digital inputs - - 2 0…12* - 2 - 2

Analog inputs - - 1 1 - 1 - 1

Digital outputs - - 2 0…4* - 2 - 2

Relay outputs - - 1 - - 1 - -

* Different I/O configurations are available upon request as OEM versions.

3.2 Tixi I/O Modules

As supplies, there are Tixi I/O modules available for the HM series of Tixi Alarm Modems, which allow

the device being expanded by up to 128 additional in- or outputs. Using the Tixi-I/O-Bus, up to 8

extension modules (with up to 128 I/Os) may be connected to the Tixi Alarm Modem. The Tixi-I/O-Bus

may be used for custom applications, too.

I/O Module Description

XP84D 8 digital inputs, 4 digital outputs

XP88D 8 digital inputs, 8 digital outputs

XP84DR 8 digital inputs, 4 relay outputs

3.3 Analog Inputs

Some models of the Tixi Alarm Modem feature a analog input port. In case you need more than one

of such ports, we recommend to connect a small PLC (e.g. a Tixi Alpha XL) to the Tixi Alarm Modem

and utilize the analog inputs of that PLC.

3.4 Memory Modules

Tixi Alarm Modems are equipped with 2 MB flash memory which saves data even without power

supply. Additional memory modules allow to expand this memory to up to 66 MB.

Memory Module Description

XC016 Tixi Flash Memory Module 16 MB

XC032 Tixi Flash Memory Module 32 MB

XC064 Tixi Flash Memory Module 64 MB

11

4Sending SMS in a land-line network

The land-line SMS network makes it possible to also send an alarm message as an SMS message

from an analog modem to mobile and land-line numbers. It is only necessary to select SMS providers

that offer special service centres for this feature.

4.1 Sending SMS to the land-line network

The option of sending SMS messages to the land-line network has up to now only been available

from Deutsche Telekom and the SMS provider Anny Way.

The phone numbers for these SMSCs are as follows:

• Deutsche Telekom: +49-1930-10

• AnnyWay: +49-900-3266900

The following requirements must be fulfilled in order to send an SMS to a land-line network:

• The call number identification (CLIP) function for incoming calls must be activated. (Telekom

service feature CLIP activated.)

• For Deutsche Telekom lines: The land-line connection of the Tixi Alarm Modem must be

registered daily at the SMS service centre as SMS-compatible.

• The terminal device must be SMS compatible.

• The telephone provider must offer the "Land-line SMS" feature.

The sender and the recipient must use the same SMSC (such as Deutsche Telekom or Anny Way) so

that the SMS can be received as a text message. Otherwise it will be converted to a voice mail.

Messages can be sent via the land-line network using both SMSCs.

NOTE:

• As land-line SMS is a relatively new service of the Deutsche Telekom, it may be subject to

modifications and additions. The latest information on the subject can be found at

http://www.sms-im-festnetz.de.

• If you are using a different telephone supplier than Deutsche Telekom AG, you should ask

your supplier which land-line SMS features are supported on your line. The full range of SMS

features provided by the Tixi Alarm modem is currently only supported by lines switched by

Deutsche Telekom AG in the local network.

• In case the requirements for SMS operation in the fixed network aren't met, mobile phone

gateways may be utilized, too. This procedure is described within the next chapter.

12

4.2 Sending SMS to the mobile network

Land-line SMS messages can be sent via the Tixi Alarm Modem to a mobile device (such as mobile

phone or GSM modem) using the SMS service centre of the mobile network supplier. The use of this

SMS service is activated by dialling the appropriate phone number of the SMS service centre. The

phone numbers of different SMS service centres are already stored in the Tixi Alarm Modem. You

simply assign the required supplier to the address entry of the recipient.

The following phone numbers of SMS service centres are used in Germany:

• D1: +49-171-2521002

• D2: +49-172-2278025

• Eplus: +49-177-1167

In Austria, this SMS service centre is to be used:

• Mobilcom Austria: +43-900-664914

The selection list can be expanded at any time. Refer to the TILA and TICO manuals for further

information, as well as to the service section of our website.

NOTE:

• The above list of suppliers is not complete and some phone numbers may be subject to

change. Binding information can be obtained by the mobile network supplier concerned.

• Your selection of SMS service centre should take into account the costs involved (such as for

roaming) in addition to the range of supported mobile networks.

• The SMS service centres noted above may be used by all fixed network connections in

Germany. Hence, they can be used even by those who got a fixed network connection that

supports fixed-network-SMS, according to chapter Fehler! Verweisquelle konnte nicht

gefunden werden. of this manual.

5Installation and Mounting

5.1 Overview of Terminals

Nr. Bezeichnung Bedeutung

1 Line Telephone jack RJ11

2 COM1 (RS232) 9-pin D-Sub jack

3 COM2 (RS232) 9-pin D-Sub plug (HM2x and HM3x only)

3 COM2 (RS485/422) 5 Screw terminals

(configurable via DIP switches, HM4x only)

3 COM2 (S7-MPI) 9-pin D-Sub jack (HM7x only)

4 DC 10...30V

(HM23-M: 18...30 V DC) Power Supply

(2 Screw terminals)

5 Service Button

6 I/Os und LEDs depends on device type

7 Tixi I/O-Bus 6-pin precisision jack for Tixi Bus connections

A detailed depiction of all connectors of all Tixi Alarm Modem models is to be found within chapter

14.4 of this manual.

13

5.2 Meaning of LEDs

The following table holds an overview of the LED indicators meaning.

LED Status Meaning

Device operational

Power

(yellow) No power supply

Processing in progress: message generation, variable changes etc.

Process

(red) Normal Operation, no processing in progress

Line

(green)

(flashes) Outgoing/incoming call: establishing telephone connection

Line

(green) Telephone connection is established

Message ready to send waits inside the device

Data out

(yellow) No message in outbox

TiXML Mode (standard mode)

Modem Mode (device usable as generic modem via COM1)

Modem

Mode

(red) Transparent Mode (device provide transparent connection)

HM7x only:

connection to PLC established

Connect

Data

(flashes) transmits data to/from PLC

Active

Param. modem is configured correctly and logged onto the MPI network

5.3 Dimensions

(all dimension data in mm)

14

5.4 Installation

Mount the modem by pushing or snap fitting it onto a DIN rail (top-hat rail 35 mm).

DANGER:

• The device must only be used in rooms that are dry and clean. Protect the device

from humidity, water splashes or heat.

• The device must not be used in environments containing flammable gases, fumes or

dust.

• Do not subject the device to shock or severe vibration.

15

5.5 Connecting to the Telephone Network

16

elephone

Connection to the telephone network is established by means of the (provided) t

cable and the jack labeled "Line".

The Tixi Alarm Modem utilizes the a/b lines (as shown in adjoining figure). In case that

futher extensions are connected parallely to the same TAE jack, these will become

deactivated.

5.5.1 Testing the Telephone Connection

In order to check the telephone number of the telephone connection used, initially connect a

telephone set (A) to this connection. Now, use another telephone set (B) and dial the telephone

number of connection (A). If the telephone set (A) rings, the number used is correct. Alternatively, the

number of connection (A) may be identified by dialing the number of telephone set (B) from the

connection (A). In case that connection (A) supports calling line recognition (CLIR), telephone set (B)

will ring and display the number of connection (A).

If caölls in both direction are successful, connect the Tixi Alarm Modem to the appropriate telephone

connection. Now, the Tixi Alarm Modem may accept calls, receive messages and may trigger certain

actions by identifying the calling telephone number.

5.5.2 Calling Line Identification: CLIP

In order to trigger actions by means of the number of an incoming call, the telephone connection used

must be able to recognize these numbers. This is done via the CLIP feature, which you can apply for

at your telephone provider.

5.5.3 Connection to a PABX

When connectiong the Tixi Alarm Modem to a PABX, watch the dial prefixes if need be. Additionally,

make sure the PABX supports the CLIP feature if you want to use the related Tixi features.

In case that SMS shall be received via the PABX, it must support the "fixed-network-SMS" feature.

6Interfaces

The serial interfaces COM1 und COM2 are to connect a PC, a PLC or other devices.

6.1 COM1 – RS232 (jack)

1 DCD

RTS 7

DSR 6

CTS 8

RI 9

2 RXD

3 TXD

4 DTR

5 GND

COM1

The RS232 interface COM1 (9-pole D-Sub socket) is

provided on all Tixi Alarm Modem models. It is primarily used

as a programming interface for connecting a PC. A standard

1:1 serial cable can be used for this (not supplied).

6.2 COM2 – RS232 (plug)

5 GND

CTS 8

RI 9

RTS 7

DSR 6

4 DTR

3 TXD

2 RXD

1 DCD

COM2

The 9-pole RS232 interface COM2 (plug) can be used for

connecting a PLC directly and has the same assignment as

the standard RS232 interface of a PC.

Tixi.Com offers several adapters to use with the RS232 interface. Detailed information on these

adapters can be found in chapter Fehler! Verweisquelle konnte nicht gefunden werden. of this

manual.

NOTE:

• As most PLCs require the use of a special serial programming cable, the programming cable

of the PLC manufacturer should be used in all cases.

• Details on how to connect each PLC can be found in chapter Fehler! Verweisquelle konnte

nicht gefunden werden. of this manual.

6.3 COM2 - RS485 / RS422

The HM4x series of Tixi Alarm Modems is equipped with a RS485/422 inteface in order to connect 2-

and 4-wire bus systems. This interface is implemented as a 5 pin screw terminal, which is not

galvanically insulated.

Assignment of the RS485/422, viewed from above.

NOTE:

• We recommend using "Twisted-Pair" cables. For RS422 and 4-wire RS485, two twisted pair

cables are to be used.

17

RS422 Connection

The Receiving Lines are to be connected to

R+ (remote: T+) and

R- (remote: T-),

the Sending Lines to

T+ (remote: R+) and

T- (remote: R-)

according to adjacent figure.

6.3.1 Accessing the DIP Switches

In order to set the operating mode of the RS485/422 interface, DIP switches are to be used. These

are located right beneath the COM2 interface and may be accessed after removing the terminal

cover:

Put a srew driver (with 3 mm blade) into the slit between case and terminal

cover and rotate the screw driver a little bit.

With an audible click, the terminal cover snaps out of the case and may be

removed now.

Below this cover, you will find the DIP switches. Their

exact meaning is described in the following table.

18

19

6.3.2 Setting operating mode via the DIP switches

Operating mode Switch 1 Switch 2 Switch 3 Switch 4 DIP

2-wire RS485 with termination 1 1 1 1 1111

2-wire RS485 w/o termination 0 0 1 1 0011

4-wire RS485 w/o termination 0 0 0 0 0000

4-wire RS485 with termination 1 1 0 0 1100

RS422 0 0 0 0 0000

NOTE:

• RS485 stipulates that the cables should be terminated at both ends of the transmission

section. The termination prevents signal reflections in the cables and in times of no data

transmission enforces a defined idle state on the bus.

• This termination can be implemented using, for example, specific resistors at the screw

terminal. This can also be implemented via the DIP switches on theTixi Alarm Modem.

6.3.3 RS485 2-wire connection

In this operating mode, transmit cables and receive cables are interconnected. If the Tixi Alarm

Modem is installed at the beginning (first station) or end (last station) of the bus system, the bus

system must be terminated by setting the DIP switches accordingly.

The twisted pair cable is to be connected to

T+ to T+ or R+ and for

T- to T- or R-

according to the adjacent figure.

6.3.4 RS485 4-wire connection

The terminals of the 2 twisted-pair cables are wired in the same way as for the RS422 connection.

Both twisted-pair cables must be terminated if the Tixi Alarm Modem is installed at the start or end of

the bus cables. The termination of the receive cables is activated via the DIP switches. The transmit

cables must be terminated externally (see figure, arrow).

The twisted pair cables are to be connected

according to the adjacent figure.

For termination of the sending line, put a

resistor (120 Ohm/0,5 W) between the T+ and

T- terminals.

ATTENTION:

Always ensure that the end devices are terminated correctly.

Incorrect or missing termination may give rise to communication faults.

20

This manual suits for next models

8

Table of contents