TABLE OF CONTENTS

Description and Specifications ....................................................................................................................................1, 2

Installation Restrictions....................................................................................................................................................2

Cautions ..........................................................................................................................................................................2

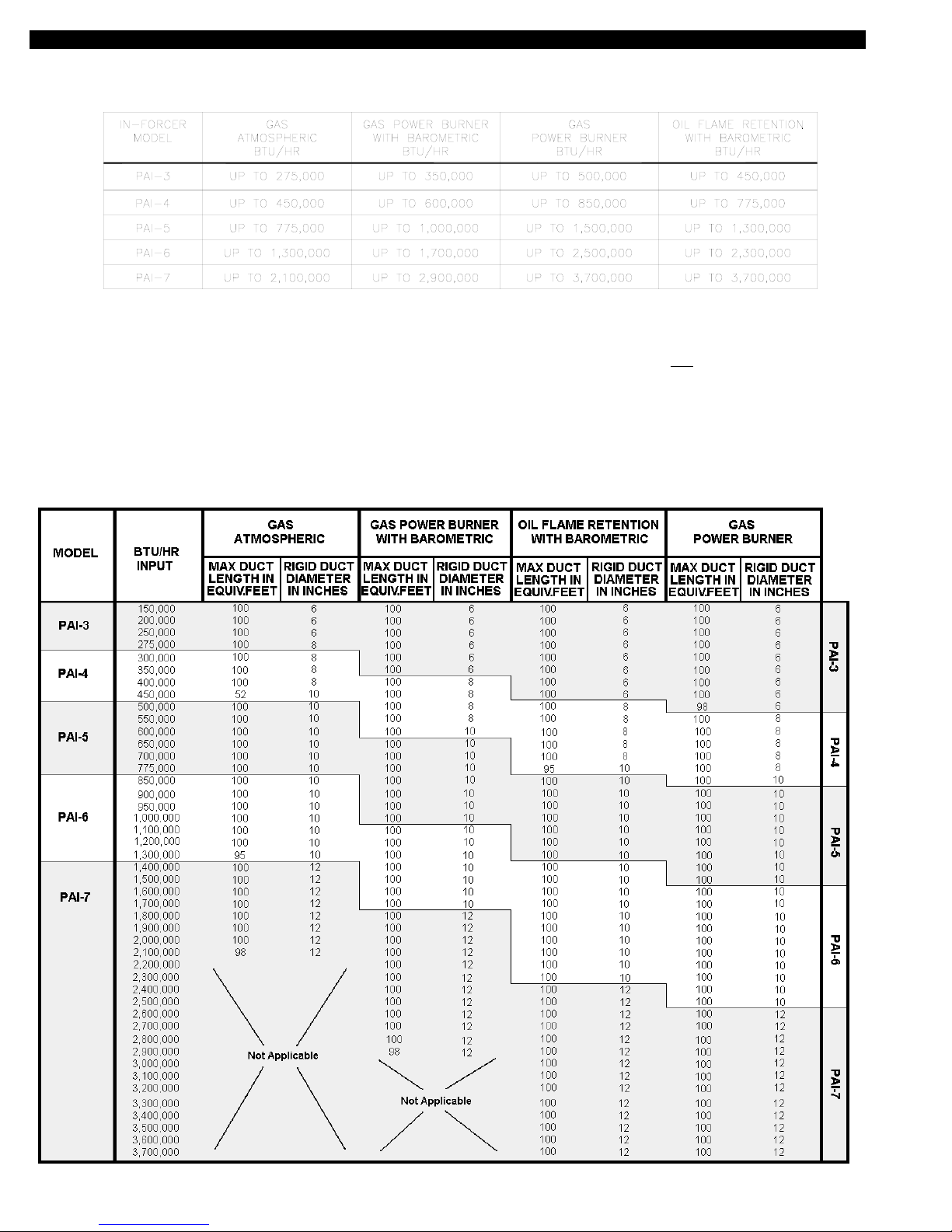

IN-FORCER Selection Table ...........................................................................................................................................3

Safety Inspection of a Previously Used Appliance..........................................................................................................4

Commercial IN-FORCER Terminology ............................................................................................................................4

Intake Hood Locations - Wall or Roof Mount ..................................................................................................................5

Installation

Tools Required ...............................................................................................................................................................5

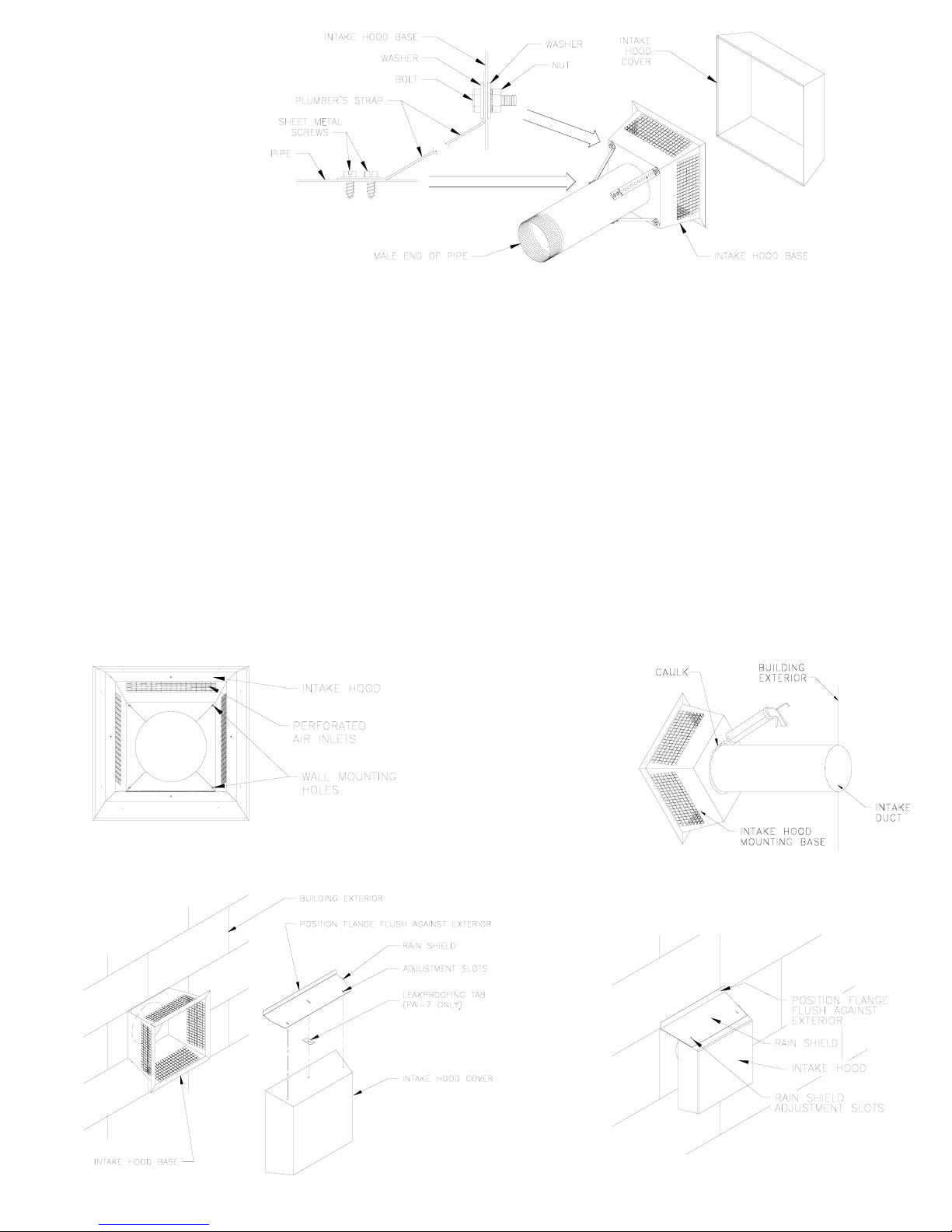

Installation of Intake Hood

Roof Mount of Intake Hood...........................................................................................................................5, 6

Wall Mount of Intake Hood................................................................................................................................6

IN-FORCER Mounting.....................................................................................................................................................7

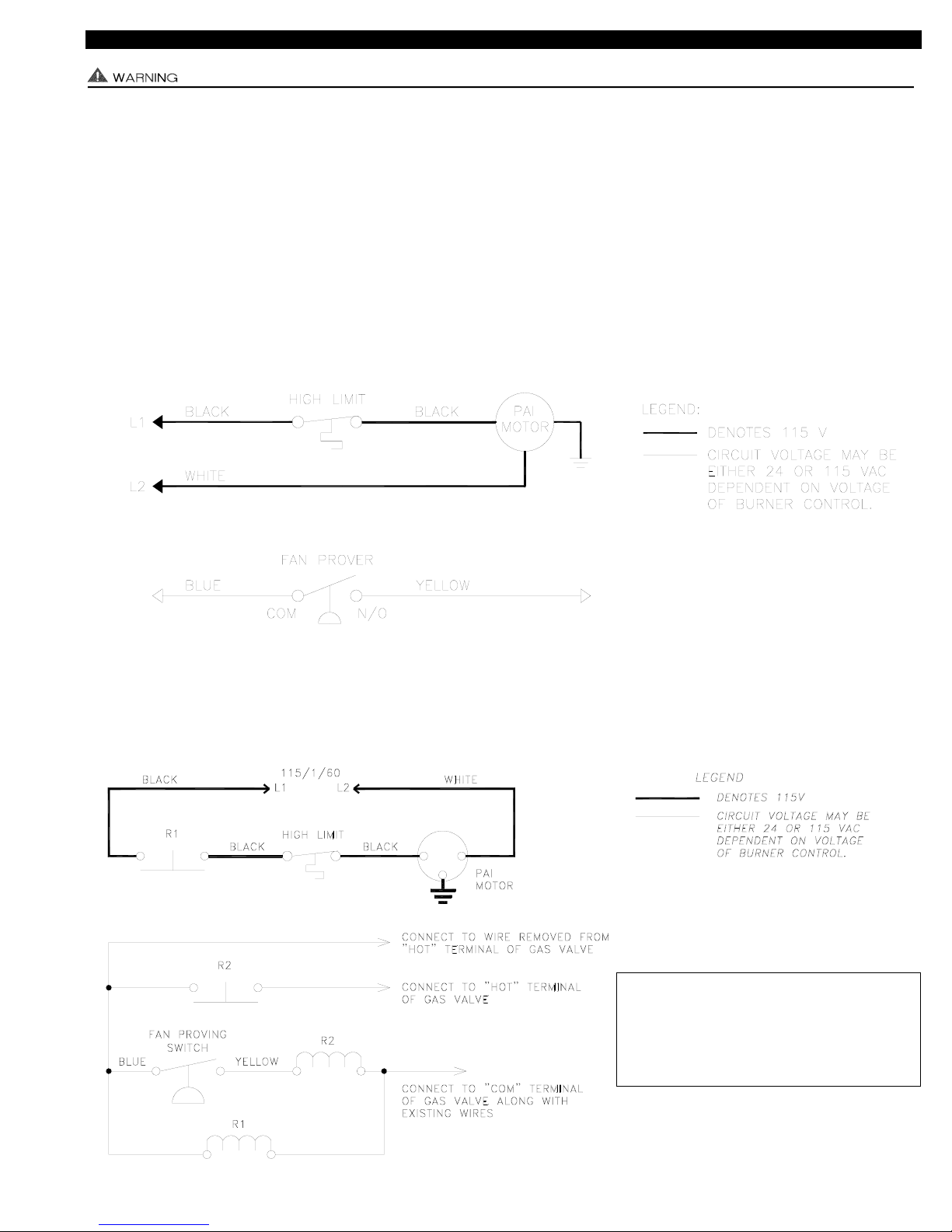

Electrical Wiring

IN-FORCER Internal Wiring Schematic ............................................................................................................8

IN-FORCER Fan Prover and Motor Isolation Relay Diagram ..........................................................................8

24 VAC Wiring with Single Appliance ...............................................................................................................9

115 VAC Wiring with Single Appliance..............................................................................................................9

Oil Wiring with Single Appliance .....................................................................................................................10

Oil & Gas Wiring with up to Four Appliances & the Optional MAC-4 .............................................................10

System Operation Check Out........................................................................................................................................11

Maintenance ..................................................................................................................................................................11

Trouble Shooting .........................................................................................................................................11, 12, 13, 14

How To Obtain Service, Warranty & Replacement Parts........................................................................................14, 15

IN-FORCER Fan Curves...............................................................................................................................................15

IN-FORCERTM is a trademark of Tjernlund Products, Inc. for IN-FORCER air intakes.

DESCRIPTION

The IN-FORCER combustion air intake systems are designed and Listed for use with atmospheric or induced combustion gas and oil

heating equipment. The IN-FORCER functions as the source of combustion air, eliminating the need for louvered openings. The

IN-FORCER assures intake air is supplied by monitoring the air flow with a Fan Proving Switch. The main burner will be interrupted if

a malfunction occurs.

ICATIONS

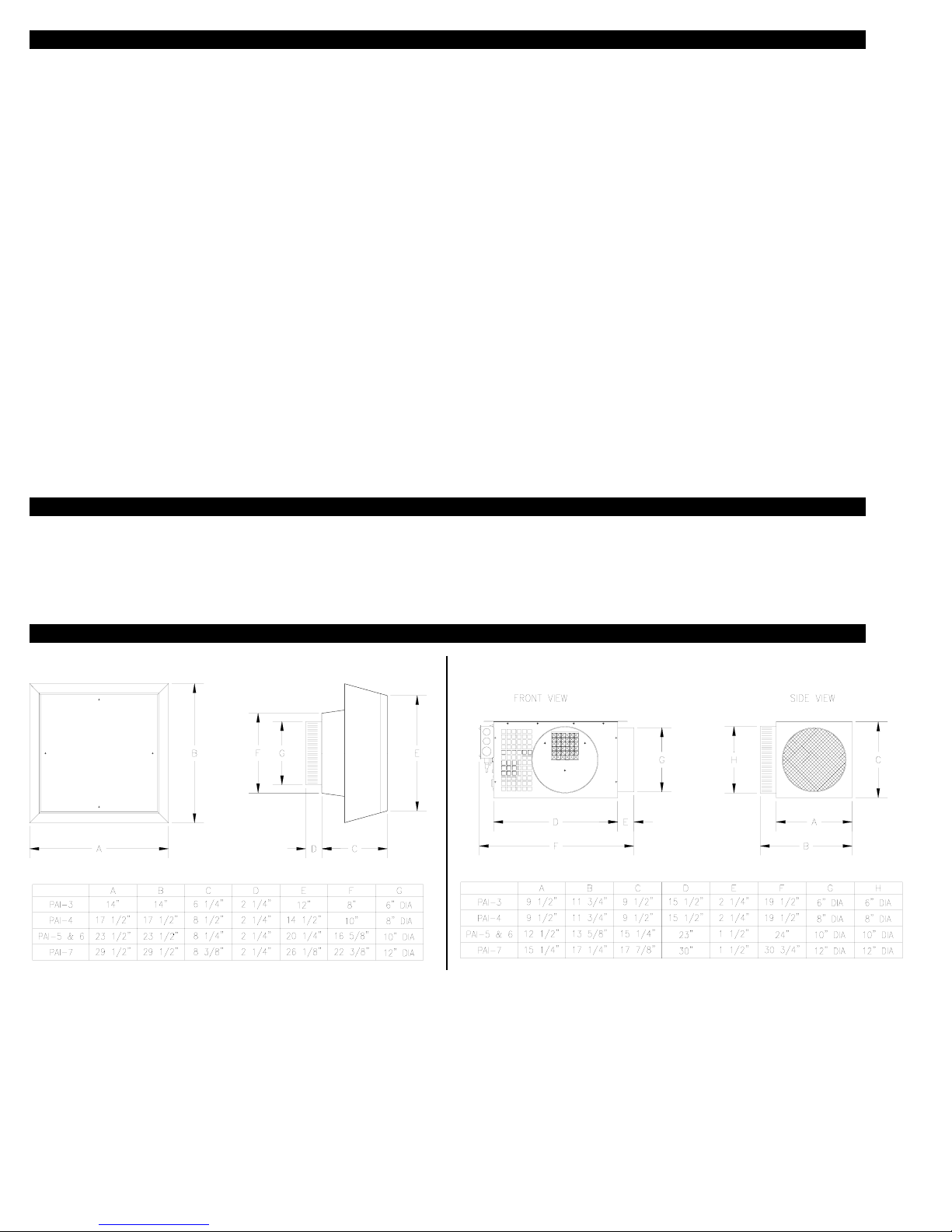

DIMENSIONS & SPECIFICATIONS

PAI-3 Motor: 115/1/60, 3000 RPM, 95 watts, 1.26 FLA, Thermal Protection

PAI-4 Motor: 115/1/60, 3300 RPM, 166 watts, 1.51 FLA, Thermal Protection

PAI-5 Motor: 115/1/60, 1725 RPM, 1/4 HP, 5.4 Amps, Thermal Protection

PAI-6 Motor: 115/1/60, 1725 RPM, 1/3 HP, 5.8 Amps, Thermal Protection

PAI-7 Motor: 115/208/230/1/60, 1725 RPM, 1 HP, 12.6/6.3/6.2 Amps, Thermal Protection

24-Volt Control Circuits: All models require a relay to activate the IN-FORCER motor. Tjernlund P/N 950-1040 is applicable to all

models except the PAI-7. The PAI-7 requires P/N 950-1016.

115 Volt Control Circuits: IN-FORCERS may be directly wired into a heating appliance control circuit as long as the contacts of the

circuit can handle the additional load of the IN-FORCER motor. For installations that require a relay, Tjernlund P/N 950-0480 is applic-

able to all models except the PAI-7. The PAI-7 requires P/N 950-0483.

1

INTAKE HOOD DIMENSIONS IN-FORCER POWERED INTAKE DIMENSIONS