TKH PAPI 801 User manual

CEDD AGL

Airfield Ground Lighting

Installation and Maintenance Instructions

PAPI Halogen (801)

03-71093

V2.2

HALOGEN AGL

Airfield Ground Lighting

©TKH Airport Solutions 2023. All rights reserved. All specifications subject to change without notice.

2

Preface

•Please read carefully and understand the contents of this manual.

•Failure to read the manual may result in serious injury, or serious damage to equipment.

•Make sure these instructions are always accessible for all users and ensure that you have read and

understood the contents.

Document Information

Name : 05_HALOGEN_AGL_PAPI_801_User_Manual_03-71093_V2.2

Version

Date

Description

V2.2

28.11.2023

Original

For the latest version of this document see https://www.tkh-airportsolutions.com/airfield-products/ or scan:

Copyright © TKH Airport Solutions 2023

All rights reserved for TKH Airport Solutions. No part of this publication may be reproduced, modified, stored in a retrieval system, or

transmitted, by any means or in any form without the written permission of the copyright owner.

The content of this document is property of TKH Airport Solutions. Proprietary rights of TKH Airport Solutions B.V. or USE System

Engineering Holding B.V. or their affiliated companies include the following: The specified (product) information herein and all related data

and information are proprietary and confidential to TKH Airport Solutions B.V. or USE System Engineering Holding B.V. and are the

subject of trade secrets and copy licensed from TKH Airport Solutions B.V. or USE System Engineering Holding B.V. The related data and

information are provided in confidence, and all use, disclosure, copying, transfer and storage, except as authorized in the written License

Agreement from TKH Airport Solutions B.V or USE System Engineering Holding B.V. to the user, is strictly prohibited.

The English version of this document is the original version; this language version is verified by the manufacturer. All other language

versions are translations of the original English language version.

©TKH Airport Solutions 2023. All rights reserved. All specifications subject to change without notice.

3

Contents

1. About this manual ........................................................................................................................................... 4

1.1 Symbols used...................................................................................................................................... 4

1.2 Storing the manual.............................................................................................................................. 5

1.3 Limitations of the Document ............................................................................................................... 5

1.4 Terms and Abbreviations.................................................................................................................... 6

1.5 Liability and Warranty.......................................................................................................................... 6

1.6 Manufacturer Details........................................................................................................................... 6

2. Safety.............................................................................................................................................................. 7

2.1 Safety.................................................................................................................................................. 7

2.2 Qualified Personnel............................................................................................................................. 7

2.3 Intended use ....................................................................................................................................... 8

2.4 Installation........................................................................................................................................... 8

2.5 Operation ............................................................................................................................................ 9

2.6 Action in the event of a system or component malfunction ................................................................ 9

3. General Recommendations .......................................................................................................................... 10

3.1 Receiving, Storage and Unpacking................................................................................................... 10

3.2 Electrical Connection ........................................................................................................................ 10

3.3 Base Earthing.................................................................................................................................... 10

4. About the PAPI 801....................................................................................................................................... 11

4.1 Mode of Operation ............................................................................................................................ 12

5. Description of the PAPI unit.......................................................................................................................... 13

5.1 PAPI specification ............................................................................................................................. 13

5.2 Assembly Drawing ............................................................................................................................ 15

5.3 List of spare parts.............................................................................................................................. 15

6. Installation and Maintenance ........................................................................................................................ 17

6.1 Installation instructions...................................................................................................................... 17

6.2 Adjusting the correct light output plane............................................................................................. 18

6.3 Adjusting the red filter ....................................................................................................................... 19

6.4 Maintenance...................................................................................................................................... 20

6.5 Replacing the red filter...................................................................................................................... 21

©TKH Airport Solutions 2023. All rights reserved. All specifications subject to change without notice.

4

1. About this manual

This manual contains technical information about the PAPI System (801). The manual is intended to be used

for installation and maintenance of the PAPI units in a PAPI system with four or eight units, or in an APAPI

system with two PAPI units.

1.1 Symbols used

The following marking conventions are used in this manual to draw attention to specific topics or actions:

DANGER! - This sign indicates a hazardous situation that, if not avoided,

will result in death or serious injury.

WARNING - This sign indicates a hazardous situation that, if not avoided,

could result in death or serious injury.

CAUTION - This sign indicates a hazardous situation that, if not avoided,

could result in minor or moderate injury.

NOTICE - is used in this manual to indicate a situation that could result in

damage to property or equipment.

The following symbols are used in pictures for explanation or an action:

©TKH Airport Solutions 2023. All rights reserved. All specifications subject to change without notice.

5

The following symbols are used on equipment and in this manual to warn of potential hazards:

DANGER of electrical shock or arc flash. Failure to observe this warning

will result in serious injury or death.

WARNING or CAUTION: where this symbol is used on the equipment, it is

mandatory to consult the manual to find out the nature of potential hazards

and any actions which have to be taken to avoid them.

1.2 Storing the manual

•This manual is a part of your product. Store the manual in a location that can be easily accessed by

personnel working on the product.

•It is the responsibility of the company operating this equipment to ensure that its personnel is provided

with a copy of this manual.

1.3 Limitations of the Document

TKH Airport Solutions reserves the right to revise this document without notification.

The data provided in this document is based on the most recent information at the time of publication. TKH

Airport Solutions is continually seeking to ensure that its products are developed to the latest technological

standards. As a result, it is possible that there may be some differences between the product and the

information in this manual.

For further information regarding adjustment, maintenance or repair which is not described in this document,

please contact the Customer Service department of TKH Airport Solutions.

The information in this document concentrates solely on use of the products as intended by the manufacturer.

©TKH Airport Solutions 2023. All rights reserved. All specifications subject to change without notice.

6

1.4 Terms and Abbreviations

This document may include the terms and abbreviations as listed below.

AGL Airfield Ground Lighting

EASA European Aviation Safety Agency

ICAO International Civil Aviation Organization

IEC International Electrotechnical Committee

LED Light Emitting Diode

PAPI Precision Approach Path Indicator

APAPI Abbreviated Precision Approach Path Indicator

1.5 Liability and Warranty

TKH Airport Solutions cannot be held responsible for injuries or damage resulting from non-standard,

unintended use, faulty or improper installation of its equipment, or failure to follow the instructions and safety

guidelines in this manual. The safety of any system incorporating the PAPI System (801) is the responsibility of

any site installation, commissioning, maintenance, and operational personnel using the system.

Disregarding the safety instructions in this manual will result in the loss of

warranty in case of damage.

Refer to the general TKH Airport Solutions Terms and Conditions document supplied with your sales order

contract for a complete liability and warranty description.

1.6 Manufacturer Details

TKH Airport Solutions

Elektrostraat 17

7483 PG Haaksbergen

The Netherlands

•Tel.: +31 (0)53 5741456

•Email: info@tkh-airportsolutions.com

•Internet: www.tkh-airportsolutions.com

For service requests, please contact the TKH Airport Solutions Customer Service department:

•Email: service@tkh-airportsolutions.com

©TKH Airport Solutions 2023. All rights reserved. All specifications subject to change without notice.

7

2. Safety

2.1 Safety

This section contains general safety instructions for using your TKH Airport

Solutions equipment. Some safety instructions may not apply to the

equipment in this manual. Note all warnings and follow all instructions

carefully. Failure to do so may result in personal injury, death, or property

damage.

To use this equipment safely,

•Refer to the International Standard IEC 61820, Electrical installation for lighting and beaconing of

aerodromes - Constant current series circuits for aeronautical ground lighting - System design and

installation requirements, and to the International Standard IEC 61821, Electrical installations for lighting

and beaconing of aerodromes - Maintenance of aeronautical ground lighting constant current series

circuits for instructions on safety precautions.

•Observe all safety regulations. To avoid injuries, always remove power prior to making any wire

connections and touching any live part. Refer to the International Standards IEC 61820 & IEC 61821.

•Read and become familiar with the general safety instructions provided in this section of the manual

before installing, operating, maintaining, or repairing this equipment.

•Read and carefully follow the instructions given throughout this manual for performing specific tasks and

working with specific equipment.

•Store this manual within easy reach of personnel installing, operating, maintaining, or repairing this

equipment.

•Follow all applicable safety procedures required by your company, industry standards, and government

or other regulatory agencies.

2.2 Qualified Personnel

The term "qualified personnel" is defined here as a person who thoroughly understands the equipment and its

safe installation, operation, maintenance, and repair. Qualified personnel are physically capable of performing

the required tasks, familiar with all relevant safety rules and regulations, and have been trained to safely install,

operate, maintain, and repair the equipment. It is the responsibility of the company installing, operating or

maintaining this equipment to ensure that its personnel meet these requirements.

©TKH Airport Solutions 2023. All rights reserved. All specifications subject to change without notice.

8

2.3 Intended use

Use of this equipment in ways other than described in the datasheet and

this manual may result in personal injury, death, or property damage. TKH

Airport Solutions cannot be held responsible for injuries or damage

resulting from non-standard, unintended application of its equipment. This

equipment is designed and intended only for the purpose described in this

manual. Uses not described in this manual are considered to be

unintended use. Unintended use may result from taking the following

actions:

•making changes to equipment that have not been recommended or described in this manual or using

parts that are not genuine TKH Airport Solutions replacement parts or accessories

•using materials or auxiliary equipment that are inappropriate or incompatible with your TKH Airport

Solutions equipment

•allowing unqualified personnel to perform any task

2.4 Installation

A thorough understanding of system components and their requirements

will help you install the system safely and efficiently. Failure to follow these

safety procedures can result in personal injury or death.

Read the safety and installation sections of all system component manuals

before installing your equipment.

•Allow only qualified personnel to install TKH Airport Solutions equipment and auxiliary equipment. Use

only approved equipment. Using unapproved equipment in an approved system may void agency

approvals and will void the warranty.

•Make sure all equipment is rated and approved for the environment in which you are using it.

•Follow all instructions for installing components and accessories.

•Do not hold or carry the light assemblies by the cables.

•Install all electrical connections according to to local codes and regulations, provided they are not in

contradiction with the general rules.

•Use only electrical wire of sufficient gauge and insulation to handle the rated current and voltage

demand. All wiring must meet local codes.

•Route electrical wiring along a protected path. Make sure the wires will not be damaged by moving

equipment and animals (e.g. rodents).

•Protect components from damage, wear, and harsh environmental conditions.

•Allow sufficient room for maintenance, panel accessibility (power products), and cover removal (power

products).

•Protect equipment with safety devices as specified by applicable safety regulations.

•If safety devices must be removed for maintenance, re-install them immediately after the work is

completed and check them for proper functioning.

©TKH Airport Solutions 2023. All rights reserved. All specifications subject to change without notice.

9

2.5 Operation

Only qualified personnel (see section 2.2 Qualified Personnel) should

operate this equipment. Read all system component manuals before

operating this equipment. A thorough understanding of system components

and their operation will help you operate the system safely and efficiently.

•Before starting this equipment, check all safety interlocks, fire-detection systems, and protective devices

such as panels and covers. Make sure all devices are fully functional. Do not operate the system if these

devices are not working properly. Do not deactivate or bypass automatic safety interlocks or locked-out

electrical disconnects or pneumatic valves.

•Never operate equipment with a known malfunction.

•Do not attempt to operate or service electrical equipment if standing water is present.

•Use this equipment only in the environments for which it is rated. Do not operate this equipment in humid,

flammable, or explosive environments unless it has been rated for safe operation in these environments.

•Never touch exposed electrical connections on equipment while the power is ON.

•Never look directly in the light source while the power is ON.

•For fixtures/spare parts marked with the photobiological safety symbol avoid prolonged staring in the

switched ON fixture.

2.6 Action in the event of a system or component malfunction

Do not operate a system that contains malfunctioning components. If a

component malfunctions, turn the system OFF immediately.

•Disconnect and lock out electrical power.

•Allow only qualified personnel to make repairs. Repair or replace the malfunctioning component

according to instructions provided in its manual. Allow only qualified personnel to perform maintenance,

troubleshooting, and repair tasks. Only persons who are properly trained and familiar with TKH Airport

Solutions equipment are permitted to service this equipment.

•Follow the recommended maintenance procedures in your equipment manuals.

•Connect all disconnected equipment ground cables and wires after servicing equipment. Ground all

conductive equipment.

•Use only approved TKH Airport Solutions replacement parts. Using unapproved parts or making

unapproved modifications to equipment may void agency approvals, impair specified performance and

create safety hazards.

•Check interlock systems periodically to ensure their effectiveness.

•Do not attempt to service electrical equipment if standing water is present. Use caution when servicing

electrical equipment in a high-humidity environment.

•Use tools with insulated handles when working with electrical equipment.

©TKH Airport Solutions 2023. All rights reserved. All specifications subject to change without notice.

10

3. General Recommendations

3.1 Receiving, Storage and Unpacking

1 Upon receipt of goods at the site store, check all packaging for visible damage. Every damaged box

should be opened and its contents inspected for damage. If equipment is damaged, a claim form shall

be filled with the carrier immediately. It may then be necessary for the carrier to inspect the equipment.

2 Store the light assembly preferably in its original packaging in a protected area. When stored unpacked,

please take care not to damage the cable insulation.

3 Unpack the light assembly at the installation site to avoid damage during transportation and handling.

3.2 Electrical Connection

The light assemblies covered by this manual are designed for connection to 6.6-A series circuits via one or two

L-830 or L-831 series transformers. The current to the light should not exceed 6.6 A + 5%. The series

transformers are to be ordered separately.

3.3 Base Earthing

Whatever the chosen installation method, it is strongly recommended to earth the base, especially in locations

presenting a risk of lightning strikes. Failure to earth the base correctly will void the warranty for all damages

occurring as a result of voltage surges.

©TKH Airport Solutions 2023. All rights reserved. All specifications subject to change without notice.

11

4. About the PAPI 801

The PAPI system is a simple and reliable visual aid which enables the pilot to establish and maintain an exact

glide path. The system secures the safe and accurate guidance for the pilot throughout the final approach

phase to touch-down, both day and night.

A standard PAPI system comprises a wing bar of 4 light units located alongside the runway on its left, at the

glide path origin and facing the approach. If further horizontal guidance is required, a second wing bar on the

opposite side of the runway can be established.

An APAPI system comprises a wing bar of 2 light units.

On approach, pilots are presented with a red/white light pattern that informs them instantly of their vertical

position relative to the designated glide path, enabling them to adjust the rate of descent to acquire the correct

glide slope or, if necessary, fly a low or high approach in complete safety.

PAPI and APAPI Light pattern

This TKH Airport Solutions PAPI 801 can be supplied as 2-light units (2 x 200W Pk30d) or as 3-light units (3 x

200W Pk30d). As an option, the units can be supplied with heating elements on the lenses to prevent ice and /

or mist.

©TKH Airport Solutions 2023. All rights reserved. All specifications subject to change without notice.

12

4.1 Mode of Operation

The optical system divides the light beam of the units in an upper half showing white and a lower half showing

red. The transition at the centre of the vertical range is of so short a duration that the lights give an eye-

catching click within a range of less than 3 minutes of arc.

Schematic illustration of the PAPI operation

Location on the Field

PAPI

APAPI

1.

9 m +/- 1 m

1.

6 m +/- 1 m

2.

9 m +/- 1 m

2.

10 m +/- 1 m

3.

9 m +/- 1 m

4.

15 m +/- 1 m

Light beam angles for each light need to be calculated for the airfield,

depending on ILS and approach angles.

©TKH Airport Solutions 2023. All rights reserved. All specifications subject to change without notice.

13

5. Description of the PAPI unit

The main parts in PAPI units are as follows:

•Stainless steel housing

•Stainless steel cover

•3-legged bottom frame, with adjustable legs.

•Lenses

•Red filters with eccentrics for adjustments

•Halogen light sources

•Aluminium reflectors

•Control display for angle adjustment

The PAPI unit is constructed and adjusted to

have the centre of the lamp, edge of red filter,

and centre of lens in one line to secure the sharp

transition.

In the factory, the PAPI unit is adjusted to 0° in

both light directions and perpendicular to the light direction (measured on the control display). The following

are checked and adjusted in that position:

•Light output is also 0°

•Transition sector is completely identical for all (2 or 3) light systems in the PAPI unit

•The transition sector is horizontal

The PAPI unit is now adjusted to a sharp transition between red and white, and the angle on the control

display will be the same as the angle of the light output.

The angle of the light output can now be adjusted by setting the position of the ball joint on the back leg.

5.1 PAPI specification

•The PAPI units can be supplied with light plane height above ground between 350mm and 700mm. The

standard value is 550mm. The height can typically be adjusted ± 20 mm.

•Light output app. 35.000cd (white) / 10.000cd (red) for one 200W light system. To be multiplied with 2,

respectively 3 dependant on the number of lamps in the PAPI unit.

•Lamps: 200W-6,6A- Pk30d-1000Hour

•Weight approximately 40 KG

•Cover in aviation yellow, the rest is black.

•Breakable coupling included

•Foundation bolts are not included as standard. Standard 16mm hot dip galvanized bolts with accessories

can be used or we can offer a stainless foundation kit type 801.530

•Cable entry for each lamp through PG 13,5 gland. Connection directly to male connector on Pk30 bulb as

standard.

•Optional FAA cable can be supplied in length according to customer request

•The PAPI light fixture can optionally be equipped with a heater system including a heater for each lens

and a thermostat. Total power is 75W with an input voltage of 48VAC. The heater kit is to order as type

801.845.

©TKH Airport Solutions 2023. All rights reserved. All specifications subject to change without notice.

14

©TKH Airport Solutions 2023. All rights reserved. All specifications subject to change without notice.

15

5.2 Assembly Drawing

5.3 List of spare parts

Item

Description

Article number

1

Bottom frame

952204/2

2

Breakable coupling

952210/60-120

3

Pipe

952.217.0

4

Nut ½"

P-900515

5

Ball bolt

801203

6.1

Fitting PG 13,5

P-242032

6.2

Protection tube

P-242031

7

Ball bearing

801202

8

Top gasket

9.1

Hook for Lock

P-855503

9.2

Lock without hook

P-855504

9.3

Pin for lock

P-855505

10

Spring for lamp holder

801419

11

Lamp holder

801418

12

Reflector

801416

13

Reflector holder threads

801406

14

Reflector housing

801815

©TKH Airport Solutions 2023. All rights reserved. All specifications subject to change without notice.

16

Item

Description

Article number

15

Filter holder

801412

16

Spring for filter

801410

17

Red light filter

801432

18

Cover / Lid

801814/6

19

Housing

801810/4

20

Lens Ø150

801401

21

Lens holder ring

801403/1

22

FAA cable 2 pol 0.9 m

P-242010

23

Heater system for Halogen PAPI, 3 x 25 W - 42 V*

801845

24

Filter adjustment piece

801413

25

Adjustment holder

801414

26

Back plate for reflectors

801817

27

Ball joint

801222

28

Lamp PK 30d 200 W

P-383007

29

Anchor bolt

801530

30

Angle piece

40-5769

31

Adjustment bar

40-5964

32

Rubber gasket for lens

801433

* Heating system is an option

When the PAPI 801 is configured with 2 lights, a cover plate is mounted in

the center position.

©TKH Airport Solutions 2023. All rights reserved. All specifications subject to change without notice.

17

6. Installation and Maintenance

Before any maintenance is done to the PAPI 801, the main power must be

switched off.

6.1 Installation instructions

If the runway has ILS, the TDZ point for the PAPI system must be the same as the theoretical TDZ point for the

ILS.

If not, the airport authorities can determine the TDZ point, or the minimum distance from the Threshold can be

calculated as follows:

1. The minimum Threshold clearance is 15m.

Runway is horizontal:

Distance from Threshold = L (in m) => L = 15 / tan (α), where α = glide slope angle

2. TDZ is D (in m) lower than Threshold:

Distance from Threshold = L (in m) => L = (15+D) / tan (α), where α = glide slope angle

3. TDZ is D (in m) higher than Threshold:

Distance from Threshold = L (in m) => L = (15-D) / tan (α), where α = glide slope angle

Placed in the TDZ point the PAPI units must have their light output center the light plane in level with the

center of the runway. It means that the top of the foundation must be 550 mm (for a standard height of PAPI

units) lower than the center of the runway. If that is not possible either the TDZ point or the PAPI units must be

displaced.

1. Mount each PAPI unit on a stable concrete foundation by means of 3 anchor bolts. The light output

must be parallel to the runway or have a very small toe-in.

2. Mount the PAPI units on the anchor bolts.

3. Level the bottom frame.

4. By means of the ball joints on each leg, adjust the PAPI unit to the correct light output plane with

the housing approximately levelled.

©TKH Airport Solutions 2023. All rights reserved. All specifications subject to change without notice.

18

6.2 Adjusting the correct light output plane

The ball joints on the 3 legs are adjusted until the PAPI light unit has the correct light output level, and at the

same time the factory adjusted control plane in the PAPI unit is 0° in both light direction and perpendicular to

the light direction. This is measured by means of the high accuracy digital clinometers, see the following figure.

Then the digital clinometer is placed on the control plane in the light direction, and the ball joint on the back leg

is adjusted to the desired angel for each individual PAPI light unit. Be careful not to touch the housing during

the adjustment as angel adjustment is very sensitive.

Please read the manual for the digital clinometers carefully before use to know how to handle this very

sensitive, high-tech device. Please note, that the battery must be changed regularly to maintain the factory

calibration of the digital clinometers.

©TKH Airport Solutions 2023. All rights reserved. All specifications subject to change without notice.

19

6.3 Adjusting the red filter

The filters inside the PAPI can be adjusted in height and horizontal level.

Do not adjust the distance between the filters and the lamp housing. This

distance is pre-set in the factory and fixed.

A correct position of the filters can be seen from the front of the PAPI. The red filters should be aligned

correctly (shown is the PAPI with 2 lights).

The transition line in both the lenses must be at the same height. If not, the filters can be adjusted by eccentric

position screws. To adjust the transition line:

1. Switch the power off.

2. Lift the cover of the PAPI.

3. Adjust the adjustment screws (2) of the applicable filter (1). The adjustment screws (2) can be

found next to the rear side of the halogen bulbs (3).

©TKH Airport Solutions 2023. All rights reserved. All specifications subject to change without notice.

20

4. The adjustment screws are supporting the filter at two positions. The slots in where the filter is

supported are eccentric. By turning the adjustment screws (2) on the back of the PAPI, the filter

height (1) can be adjusted. The spring (3) keeps the filter in position onto the eccentrics (2).

5. When the position of the filter is okay, mount the cover of the PAPI.

6. Switch the power on and adjust the correct light output plane, see 6.2.

6.4 Maintenance

Once a month the PAPI light fixtures should be maintained and controlled as follows:

1. The lenses are cleaned.

2. Reflectors and filters are carefully cleaned with a dry, soft cloth. If a filter is damaged, replace it with

a new filter (see chapter 6.5).

3. Make sure, that the filters are in the correct position in the slots of the eccentric adjustment screws.

If not, adjust the filter (see chapter 6.3).

4. Check that the lamps are working, and that the filament in the lamps is in the correct position (if the

filament in the lamp starts “hanging” the transition sector for the actual light output will have

moved).

5. Use the digital clinometers to control the setting of each PAPI unit, both in the light direction and

perpendicular to the light direction.

6. Switch on the PAPI light in the highest intensity step, and look at the light output from the longest

distance, where the transition from white to red can be seen. The transition must be sharp and

simultaneous for all light system in the PAPI unit.

a. If not, control the position of the filters or

b. Change the lamps (be careful to place the lamp correct)

Table of contents

Other TKH Lighting Equipment manuals

Popular Lighting Equipment manuals by other brands

Clevertronics

Clevertronics LP CWSQLED Series ASSEMBLY, INSTALLATION & MAINTENANCE INSTRUCTIONS

Aqua Creek Products

Aqua Creek Products MIGHTY 400-BLUE manual

Epcom

Epcom X67RB user manual

American DJ

American DJ X-Treme/AS User instructions

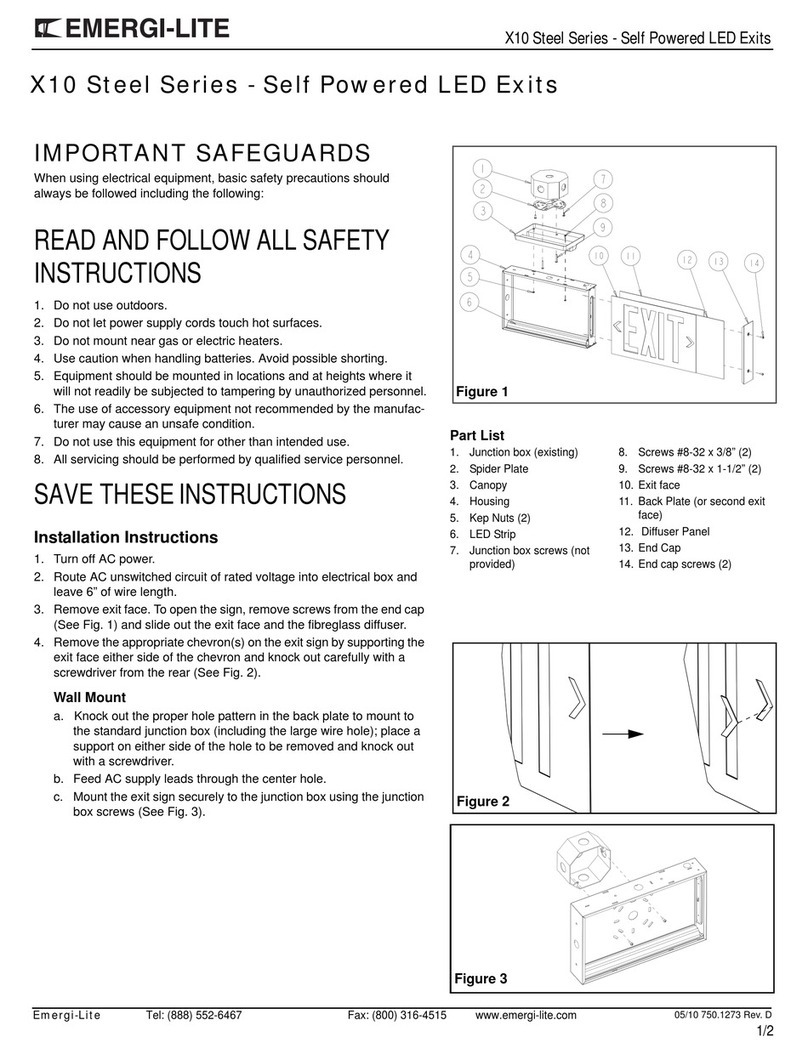

Emergi-Lite

Emergi-Lite X10 Steel Series manual

Robert Juliat

Robert Juliat 1015 B Technical manual

Ecco

Ecco Hide-A-LED 9014 installation instructions

Ikan

Ikan IFD1024 quick start guide

STL

STL K-FORCE F-LKF47 instruction manual

Roger Technology

Roger Technology FIFTHY/24 Instruction and warnings for the installer

ProLights

ProLights Astra Profile600IP user manual

Ballard Designs

Ballard Designs LL323 quick start guide