TKR Group PNP 90 UN 2.0 User manual

Pneumatic, hydraulic

Universal Riveting Tool

PNP 90 UN 2.0

Instruction manual

Anleitung Stanznietwerkzeug PNP_90_UN2.indd 1 22.07.11 14:08

2

1. Information regarding this manual 3

2. Explanation of symbols 3

3. Designations 4

1. Operating principles 4

2. Scope of Supply and Accessories 5

3. Safety instructions 6

4. Principles for Handling the Tool Kit PNP 90 UN 2.0 7

5. Maintenance 8

6. Warranty 9

1. Technical Data Pump PNP 90 UN 2.0 10

2. Technical Data Hydraulic Actuator HP 35 UN 10

3. Technical Data Riveting Tool Kit RIVKIT UN 2.0 11

4. Technical Data Rivet Clamp 12

1. Startup 14

2. Riveting Tool Preparation and Connection of the Hydraulic Actuator 15

3. Safe Set-Up and Positioning of Equipment 17

4. Connecting the Tool to the Hydraulic Actuator 18

5. Riveting Tool Kit RIVKIT UN 2.0 – Fitting and Intended Use 19

1. Pressing out Rivets 20

2. Punching and Calibration of Holes for Flow Form Rivets 21

3. Setting of Flow Form Rivets 22

4. Installation of Semi-Tubular Punch Rivets 23

5 Checking Riveting Results 24

6. Cleaning the Riveting Tools 24

7. Completing an Operation and Riveting Tool Storage 25

1. Hydraulic pump maintenance 26

2. Replacement Part List 28

3. Troubleshooting 30

4. Declaration of Conformity 31

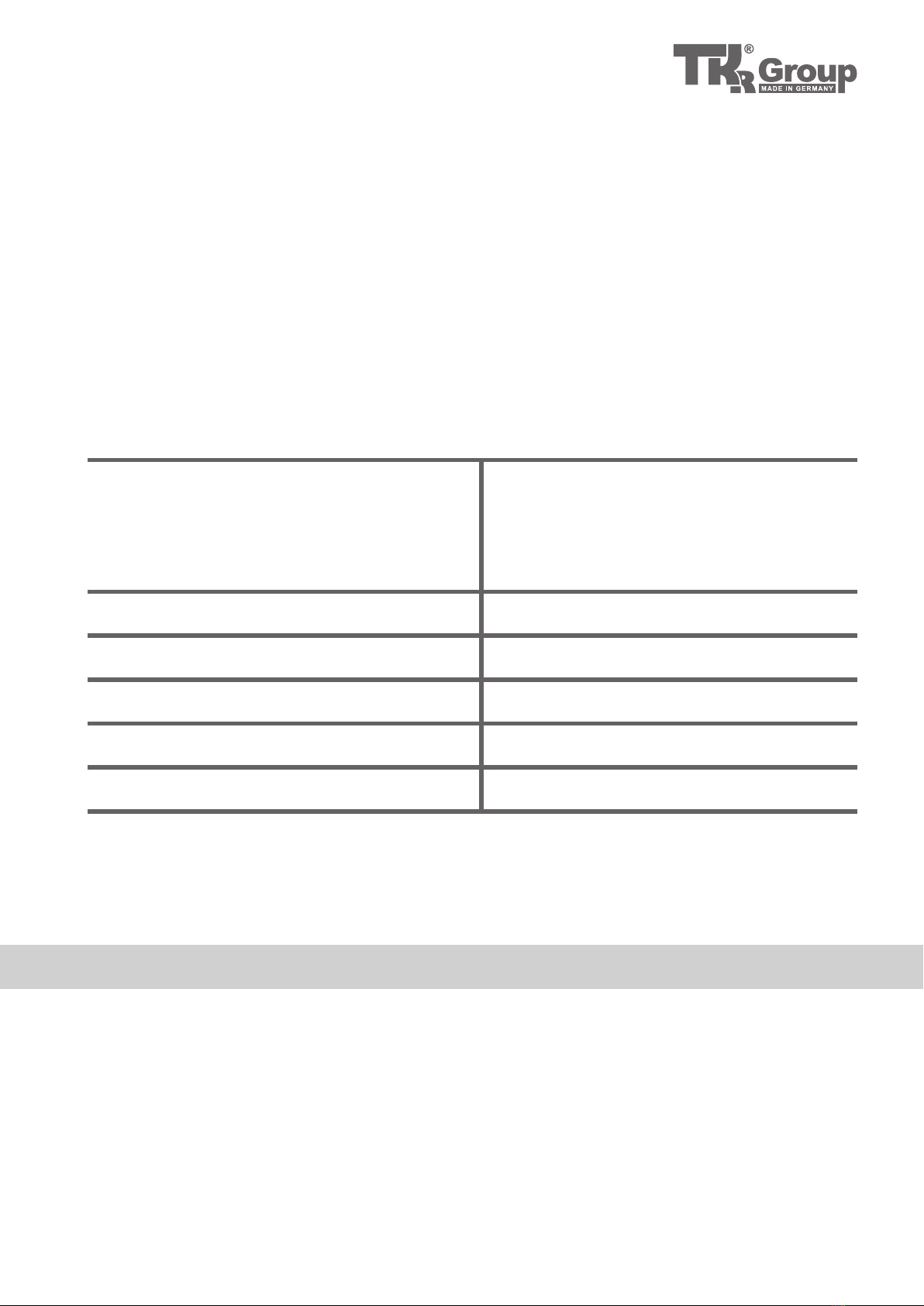

1.

2.

3.

4.

5.

6.

Accessories and spare parts:

www.tkr-powertools.com

Anleitung Stanznietwerkzeug PNP_90_UN2.indd 2 22.07.11 14:08

3

1.1 Information regarding this manual

Observe

Instruction manual

Observe

General instructions

Wear face mask

Wear gloves

1.2 Explanation of symbols

In this instruction manual, some sections use internationally recognised warning symbols, warning

notes and general instructional symbols.

The individual symbols are explained below. Follow all instructions and safety rules.

Warning!

General source of danger

Warning!

Hand could become

trapped

Warning!

Fingers could become

trapped

Warning!

Danger of environmental

contamination

Warning!

System under pressure

Please note the

following!

Arrow to clarify compres-

sion

Arrow showing direction

For further information

see chapter...

Audibly engage

Information

Legislation stipulates that workers handling hydraulically-

driven riveting tools must be protected. If desired, trai-

ning can be provided at TKR in Gevelsberg or on site at

the customer.

State of the technology

This riveting tool represents state-of-the-art technology.

To ensure the functionality of the equipment, it must be

operated in a proper and safe manner.

Read instruction manual

Read the instruction manual carefully before using the

riveting tool.

Handling

All handling necessary to ensure correct operation is

described in the instruction manual. No work method

other than that expressly approved by the manufacturer

may be used.

Faults

In the event of a fault, the user or owner may only carry

out repair work for faults for which the relevant maintenance

process is laid out in the instruction manual.

Anleitung Stanznietwerkzeug PNP_90_UN2.indd 3 22.07.11 14:08

1.3.1

A

E

B

C

D

F

4

AType designation

BSerial number

CManufacturer‘s designation,

production date

DMaximum permissible

operating pressure (oil)

ECE mark

FSymbol to read the

instruction manual

1.3 Designations

Designations on the stamping and riveting tool

2.1 Operating principles

The pneumatic/hydraulic universal tool PNP90-UN 2.0

was specially developed for all common riveting opera-

tions in thin sheet metal structures.

The equipment‘s universal technology enables adaption

of various attachments for different applications.

The basic tool kit comprises the pneumo-hydraulic pressure

intensifier PNP 90 and a hydraulic actuator with hose

package. The kit is completed by an NB 40 rivet clamp

and a fully equipped RIVKIT UN 2.0 riveting tool kit.

The hydraulic pump is a pneumatically driven pressure

intensifier with a pressure ratio of 1:100. This means that

hydraulic output pressure of 600 bars is generated with

input air pressure of 6 bars. When the equipment‘s pre-

set final pressure is reached, the pump stops automatical-

ly and keeps this pressure constant. The hydraulic pump

has a pneumatically controlled pressure relief valve.

The hydraulic actuator is connected to the hydraulic

pump via a high-pressure hose. The hose is connected

to the pump via a leak-free quick release coupling. The

coupling can only be connected to the equipment when

it is depressurised.

The two pneumatic control lines are also connected to

the pump. Make sure that the black and the blue hose

are inserted into the couplings with the relevant mar-

kings.

Compressed air can be connected to

the equipment as soon as the hydraulic

hose and the control lines are connected to

the pump.

The hydraulic actuator is equipped with a control val-

ve that activates pump operation. The operating lever

is equipped with a safety catch to prevent unintended

operation.

If the valve is activated, the pump begins to run and the

hydraulic plunger extends.

If the operating lever is released, the pump is deactivated

and the hydraulic plunger retracts to its original position.

Anleitung Stanznietwerkzeug PNP_90_UN2.indd 4 22.07.11 14:08

5

2.2 Scope of Supply and Accessories

Scope of supply basic kit PNP 90 UN 2.0

1x Pressure intensifier PNP 90

1x Hydraulic actuator HP 35 UN

1x Rivet clamp NB 40

1x Riveting tool kit RIVKIT-UN 2.0

2x Locking bolts

1x Owner‘s Manual

Technical Specifications

Filling capacity 280 ccm

Branded hydraulic oils as per DIN 51524

ATF as per DIN 51562-1

Viscosity approx. 68 mm²/s at 40 °C,

Example: Shell Tellus TX 68, Dexron, Mercon, Hydroclear

6 bar / 87 psi

Quality class 2 as per ISO 8573-1

5–50 °C / 41 –122 °F

Protective gloves, face mask

LPAI < 75 db(A)

Permissible hydraulic oil

Max. air pressure

Compressed air

Ambient temperature

Prescribed safety clothing

Noise emissions level

The effective value of the acceleration assessed at the hydraulic tool measured in accordance with ISO/FDIS B662-

11 is < 2.5 m/s²

Accessories (not part of the basic kit)

1x Rivet clamp NB 115

1x Rivet clamp NB 230

1x Pop rivet adaptor RIVPULL 2.0**

1x Oval hole punch tool PUNCH-OV**

** in preparation

Anleitung Stanznietwerkzeug PNP_90_UN2.indd 5 22.07.11 14:08

6

2.3 Safety instructions

The hydraulic tool kit is strictly approved only

for the purposes intended by the manufacturer.

Only genuine accessories may be used. Use

of non-genuine tools or accessories presents a

major safety hazard.

Ensure that only trained and instructed

personnel use the equipment!

Use of the equipment by personnel that have

not been trained and instructed is prohibited.

Ensure that the instruction manual is made

available to operating personnel.

Observe the applicable national regulations for

prevention of accidents.

Do not use any hoses or fittings that are not

permitted for the equipment's operating

pressure.

Protective gloves and a face mask must strictly

be worn for all applications of the equipment,

because metallic parts can break up and fly

off with high energy if the tool is faulty or

operated incorrectly.

As a result, there is a risk of severe bodily injury!

See also ANSI Z87.1-1989.

Never throw the tool or allow it to fall.

Never misuse the tool or lend it to untrained

personnel.

The tool must only be used in ambient

temperatures of above 5 °C and up to a

maximum of 50 °C.

The tool must never be used in potentially

explosive areas.

Anleitung Stanznietwerkzeug PNP_90_UN2.indd 6 22.07.11 14:08

7

2.4 Principles for Handling

the PNP 90 UN 2.0 Tool Kit

Risk of injury

Route all supply lines in a manner that prevents

people from tripping over them. Correctly rou-

te and attach the compressed air hose. If a

compressed air hose whips around wildly, it

could cause severe physical injury.

Before starting work, check the preset air

pressure! Incorrectly set air pressure could

cause equipment damage or physical injury!

Max. air pressure

Make sure that the maximum permissible ope-

rating air pressure of 6 bar / 87 psi is never

exceeded. Check the setting of the pressure re-

gulating valve before each riveting operation!

Clean compressed air

Make sure that the pump is always supplied

with clean and dry compressed air. Moisture

and contamination could cause equipment

malfunction and/or damage. Only use com-

pressed air of quality class 2 as per ISO 8573-1.

Always disconnect the riveting tool from

pressure when leaving the work site!

Warranty

The manufacturer accepts no liability for damage

or injury caused by improper repair or use of re-

placement parts made by other manufacturers.

Incorrect usage of the riveting tool that leads

to equipment damage invalidates the warranty.

Declaration of Conformity

Riveting tool PNP 90 UN 2.0 has been tested

and manufactured in accordance with European

guidelines. The Declaration of Conformity has

been included with this instruction manual.

The compressed air supply must be dis-

connected from the equipment before

any adjustment or maintenance work is

performed.

6.4

Anleitung Stanznietwerkzeug PNP_90_UN2.indd 7 22.07.11 14:08

8

2.5 Maintenance

The tool‘s hydraulic system, pneumatic

control systems, hoses and couplings

must all be kept free of dirt and other

contamination. Foreign bodies in the hy-

draulic fluid or in the control air can cau-

se the tool system to malfunction.

All maintenance and service work on the

stamping and riveting tool must only be

performed with the pump disconnected.

All maintenance and service work on the

pump must only be performed with the

air disconnected and the oil drained.

Normally, pump maintenance only entails a re-

gular oil change (see 2.2 for permissible oils).

All other necessary maintenance work and/or

repairs should be performed by the manufac-

turer or properly trained personnel.

With normal use of the pump, hydraulic oil

should be changed every 80 operating hours

or every 12 months. Make sure that used oil

is disposed of as required by national environ-

mental legislation.

6.1

Oil that is not properly disposed of could

harm the environment.

The user must only perform the maintenance

and repair measures outlined in this instruction

manual.

Maintenance and repair work not covered in

this instruction manual may only be performed

by professionals with proper training by TKR.

For further information on servicing and trai-

ning, please contact us at our Service address:

TKR Automotive GmbH

Am Waldesrand 9–11

D-58285 Gevelsberg (Germany)

Phone +49 2332 66607-60

Fax +49 2332 66607-90

Email info@www.tkrgroup.com

Internet www.tkrgroup.com

Anleitung Stanznietwerkzeug PNP_90_UN2.indd 8 22.07.11 14:08

9

Stamping and riveting tools from TKR Automotive GmbH come with a 12-month war-

ranty against material and manufacturing defects.

This does not cover wearing parts (rivet mandrels, rivet dies, spacing bolts and spacing

sleeves) or hydraulic oil.

The warranty period begins on the date of delivery, as specified on the invoice or de-

livery note.

The warranty is valid for the user/customer provided that the tool is obtained from an

authorised sales outlet and is used as described in the instructions and for the purposes

for which it was designed.

The warranty becomes invalid if the tool is used for purposes other than those for

which it was designed.

In addition, the warranty becomes invalid if the tool is not used as described in the

instruction manual.

In the event of defect or fault, TKR Automotive GmbH shall only repair or replace faulty

parts at its own discretion.

Your supplier and service partner:

TKR Automotive GmbH

Am Waldesrand 9–11

D-58285 Gevelsberg (Germany)

Phone +49 2332 66607-60

Fax +49 2332 66607-90

Email info@www.tkrgroup.com

Internet www.tkrgroup.com

2.6 Warranty

Anleitung Stanznietwerkzeug PNP_90_UN2.indd 9 22.07.11 14:08

104.7

246.5

50

104.7

246.5

50

104.7

246.5

50

3.2.1 3.2.2

3.2.3

330

213

230

330

213

230

330

213

230

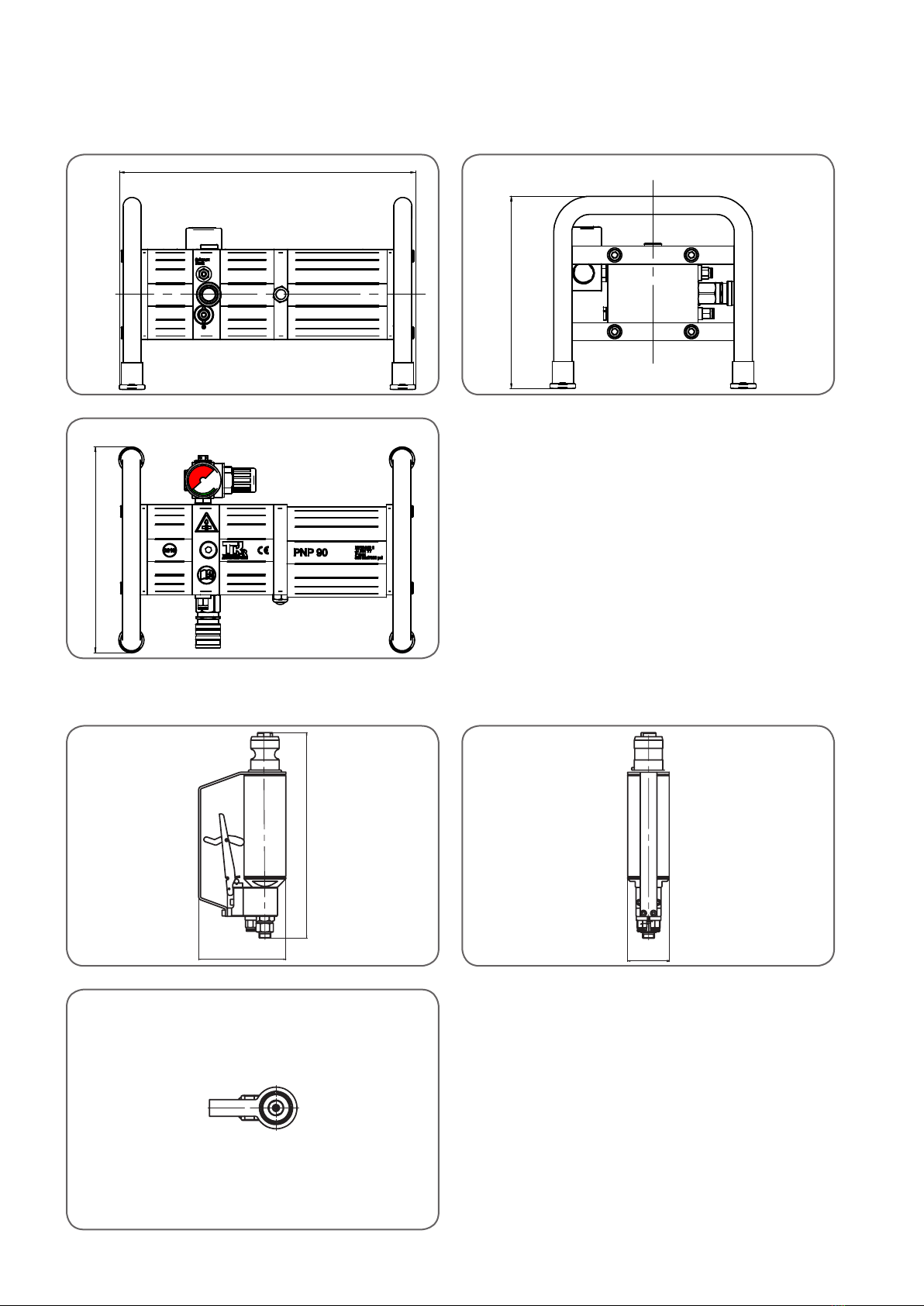

3.1.1

3.1.3

3.1.2

10

246.5 mm

50 mm

104.7 mm

2 kg

600 bar

15 mm

Length

Width

Height (incl handle)

Weight

Max. operating pressure

Travel

Hydraulic actuator HP 35 UN

3.2 Technical Data Hydraulic Actuator HP 35 UN

3.1 Technical Data Pump PNP 90 UN 2.0

330 mm

230 mm

213 mm

8 kg

5.5 bar

550 bar

Length

Width

Height (incl handle)

Weight

Max. input pressure

Max. operating pressure

Pump PNP 90 UN 2.0

Length and weight without hoses

Anleitung Stanznietwerkzeug PNP_90_UN2.indd 10 22.07.11 14:08

3.3.1

A

C

E

G

I

L

K

H

F

D

B

M

N

WZS-TKR-00000024

12

3

11

3.3 Technical Data Riveting Tool Kit RIVKIT UN 2.0

Kit number Item/Description/Article number Item/Description/Article number

Riveting Tool Kit RIVKIT UN 2.0

Kit: BGR-TKR- ASetting head, 3 mm rivet BClosing head, 3 mm rivet

00000024 BGR-TKR-00000244 01-00000707

Kit: BGR-TKR- CSetting head, 5 mm rivet DClosing head, 5 mm rivet

00000023 BGR-TKR-00000245 01-00000706

Kit: BGR-TKR- ESetting head, flow form rivet FClosing head, flow form rivet

00000048 Marked with 3 rings Marked with 3 rings

01-00000917 01-00000918

Kit: BGR-TKR- GPunch and calibration mandrel HPunch and calibration die

00000098 Marked with 2 rings Marked with 2 rings

01-00000922 01-00000923

Kit: BGR-TKR- IExtraction mandrel KExtraction die

00000128 Marked with 1 ring Marked with 1 ring

01-00000788 01-00000784

LReplacement elastomer rings MSet of fitting spanners

06-00000112

BGR-TKR-00000239

Kit: BGR-TKR NSpacing adaptor composed of:

00000025 1Bushing, 01-00000744

2Spacing bolt 01-00000704

3Spacing sleeve 01-00000705

Anleitung Stanznietwerkzeug PNP_90_UN2.indd 11 22.07.11 14:09

106

158.8

80

45

25

106

158.8

80

45

25

106

158.8

80

45

25

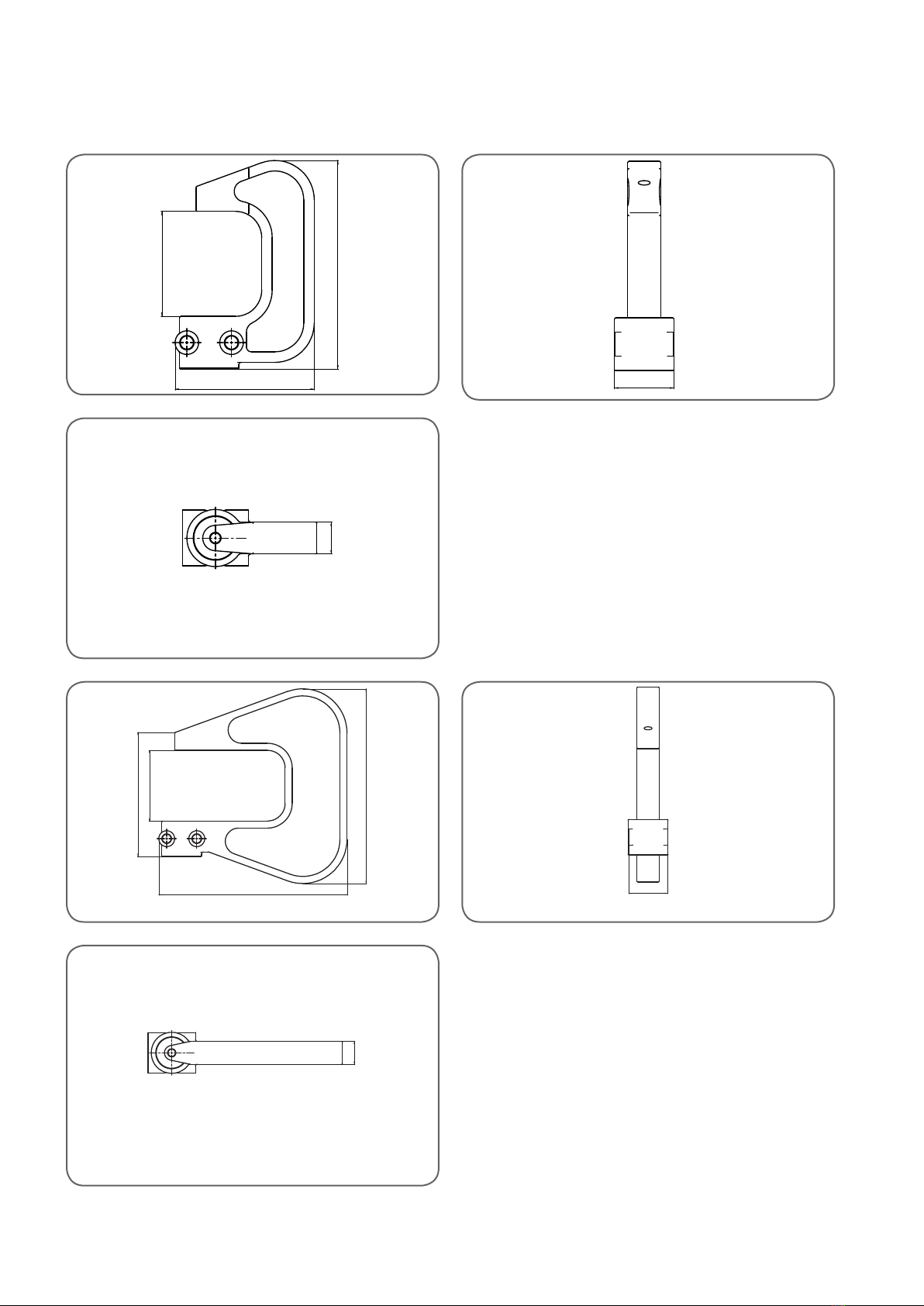

3.4.1

3.4.3

3.4.2

213

220.3

44

80

140.2

25

213

220.3

44

80

140.2

25

213

220.3

44

80

140.2

25

3.4.4

3.4.6

3.4.5

12

Rivet clamp NB 40

3.4 Technical Data Rivet Clamp

Rivet clamp NB 115

Anleitung Stanznietwerkzeug PNP_90_UN2.indd 12 22.07.11 14:09

140

364.1

347.2

44.5

30

140

364.1

347.2

44.5

30

140

364.1

347.2

44.5

30

3.4.7

3.4.9

3.4.8

13

Article number 05-00000026 05-00000031 05-00000027

Length* 106 mm 213 mm 364.1 mm

Width 45 mm 44 mm 44.5 mm

Height 158.8 mm 220.3 mm 347.9 mm

Clamp opening 80 mm 80 mm 140 mm

Opening depth 40 mm 115 mm 230 mm

Weight* 1.5 kg 3 kg 9.5 kg

Rivet clamp NB 230

Rivet clamp NB 401Rivet clamp NB 115 Rivet clamp NB 230

*Length and weight without hoses 1Included in the basic kit

Technical data

Anleitung Stanznietwerkzeug PNP_90_UN2.indd 13 22.07.11 14:09

4.1.1

4.1.44.1.3

14

G1/4“

The equipment is supplied from the factory without a

compressed air connection. The pressure regulator has a

G1/4“ (internal thread) connection thread.

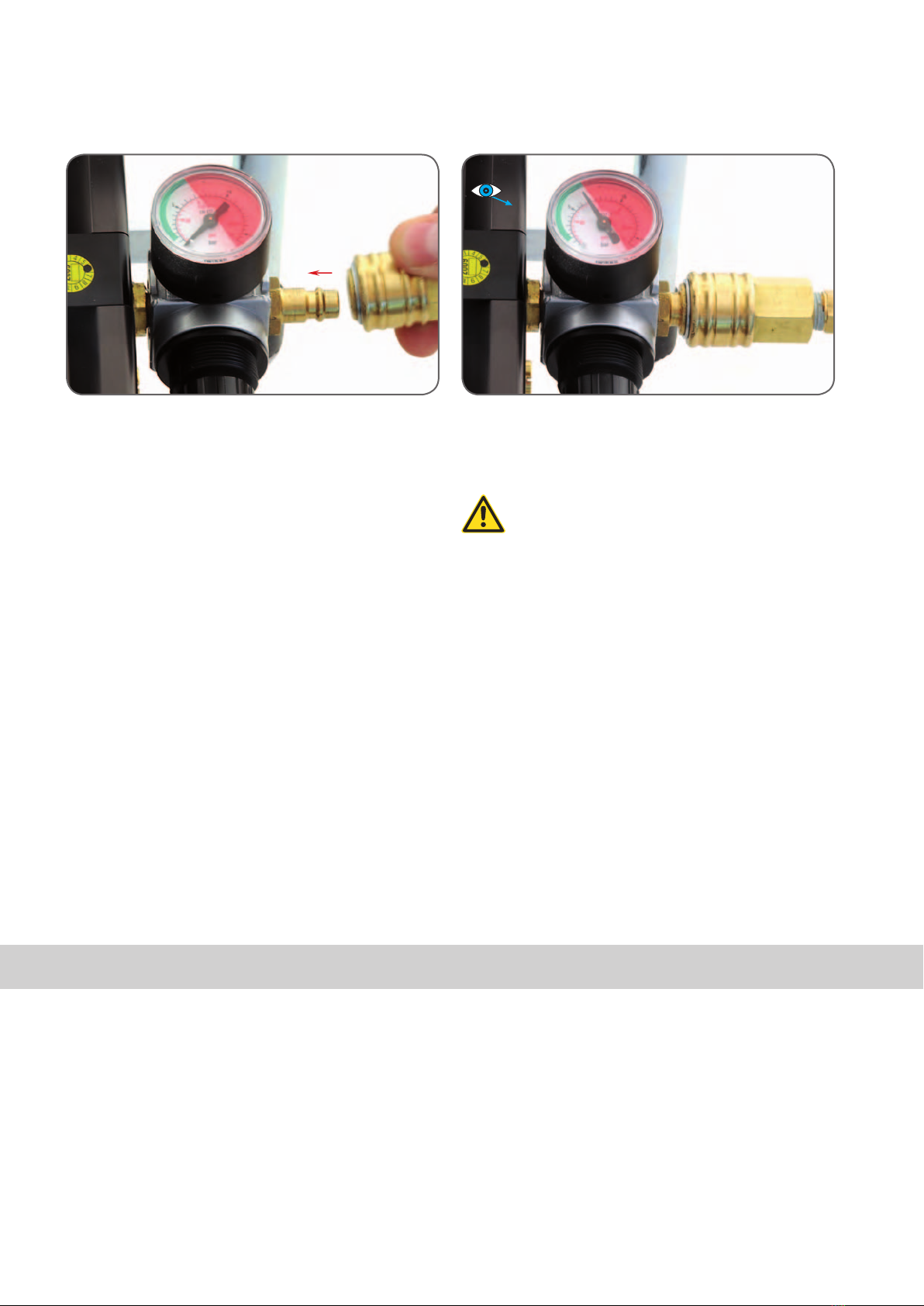

4.1.1/4.1.2

The pressure regulator is supplied with a closing cap fit-

ted. Remove the closing cap.

4.1.3/4.1.4

Use a compressed air connection with R1/4“ thread and

seal. Screw this into the regulator.

4.1 Startup

4.1.2

R1/4“

Anleitung Stanznietwerkzeug PNP_90_UN2.indd 14 22.07.11 14:09

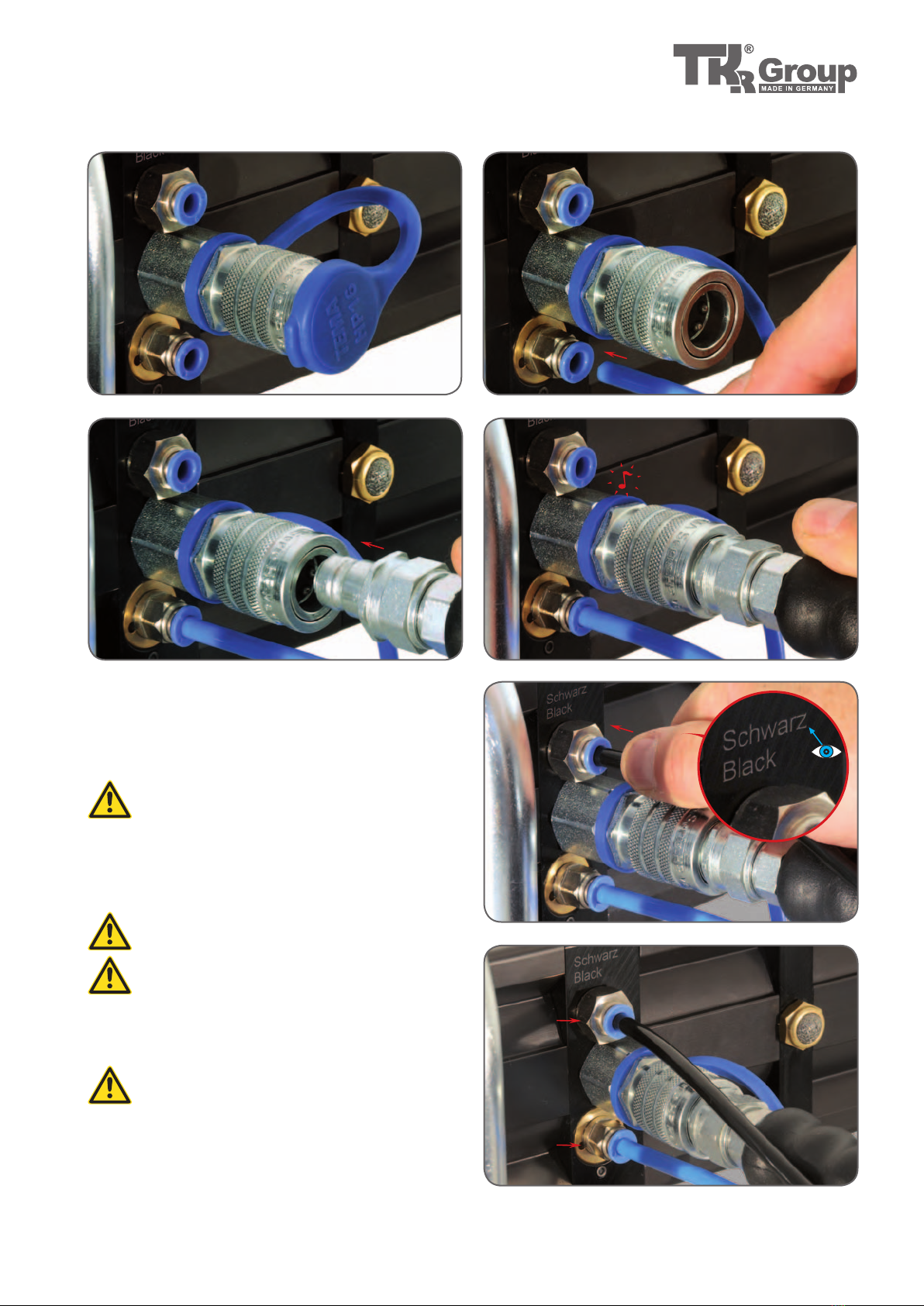

4.2.1 4.2.2

4.2.3 4.2.4

15

4.2 Riveting Tool Preparation and

Connection of the Hydraulic Actuator

Before using the equipment, check the

condition of the hydraulic actuator with

add-on component and hoses. Risk of

severe physical injury if the pump or the

rivet clamp is damaged.

Check the hoses and couplings for damage.

In the event of any noticeable damage,

the hydraulic components must be re-

placed. Damaged hoses or couplings

could cause severe injury!

Incorrectly attached hoses could come

loose and cause severe physical injury.

4.2.5

4.2.6

4.2.5

Connect the pneumatic hoses. Make sure that the black

hose is attached to the marked coupling.

black

blue

Anleitung Stanznietwerkzeug PNP_90_UN2.indd 15 22.07.11 14:09

4.2.84.2.7 max. 6 bar / 87 psi

16

4.2 Riveting Tool Preparation and

Connection of the Hydraulic Actuator

4.2.8

Never use pressure over the permitted va-

lue of 6 bar or 87 psi. This could cause

damage to the equipment or even physical

injury.

4.2.7

Connect compressed air to the pressure regulating valve

and set the pressure.

Anleitung Stanznietwerkzeug PNP_90_UN2.indd 16 22.07.11 14:09

7

3

4.3.1

4.3.2

4.3.3

17

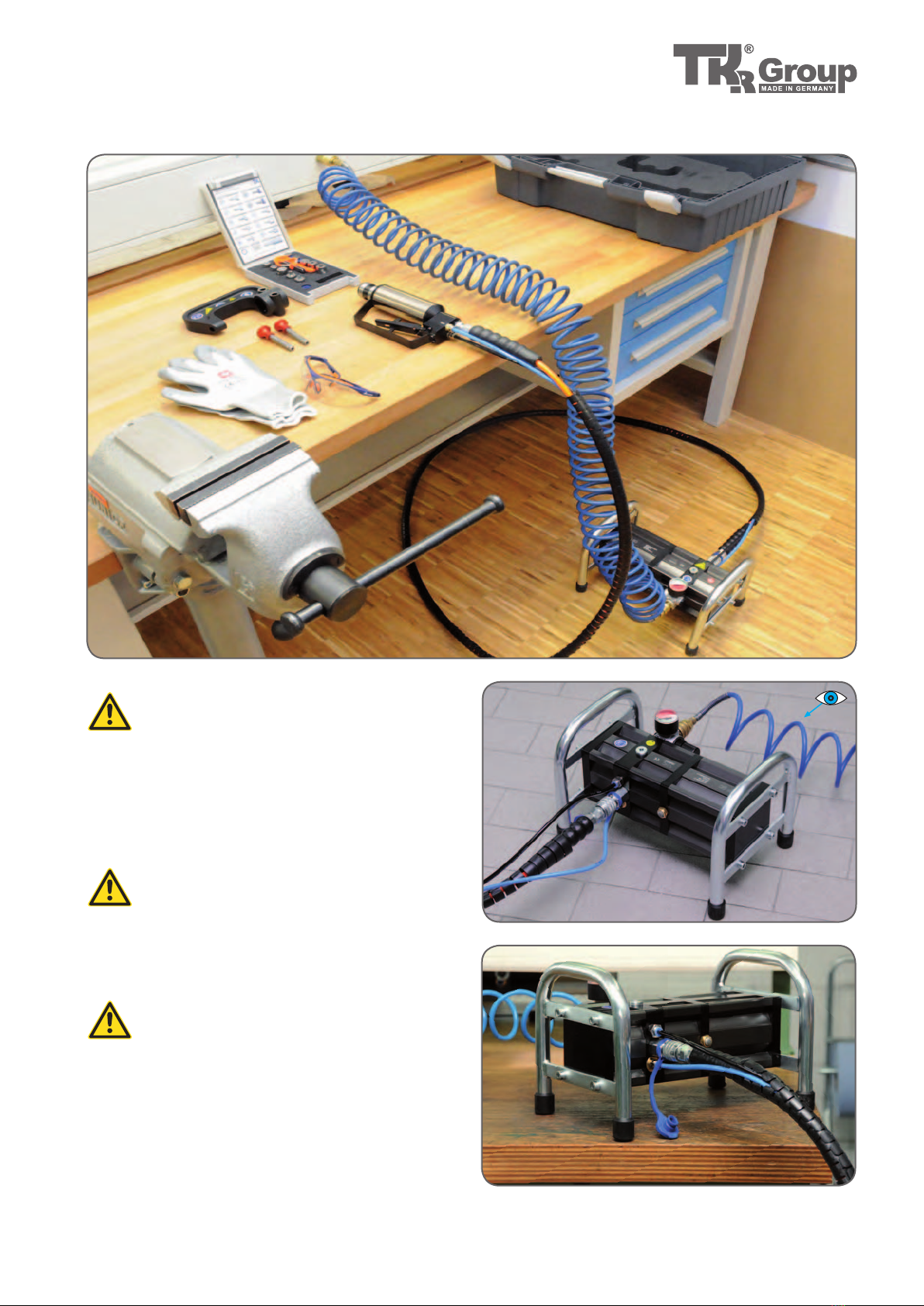

4.3 Safe Set-Up and Positioning of Equipment

Ensure that the high-pressure pump is

always placed on a non-slip surface and

that the hoses are routed in a way that

prevents them from getting damaged

or pinched off. The hoses must also be

routed in a way that prevents people

from tripping over them.

Make sure that the pump and hydraulic

actuator are set up in a work area that

is free from heat sources (max. 50°C /

120°F), corrosive liquids, greases and

oils.

Before using the equipment, make sure

that the pump is standing on a secure

surface.

Anleitung Stanznietwerkzeug PNP_90_UN2.indd 17 22.07.11 14:09

4.4.1 4.4.2

4.4.3

4.4.5

4.4.4

18

4.4 Connecting the Tool to the Hydraulic Actuator

Warning!

The mounting adaptor on the hydraulic

actuator must be clean and free from

damage!

The locking bolts must also be free from

contamination and damage.

The mounting hole in each tool must be

free from contamination and damage!

Warning!

Damaged or defective locking pins must

not be used!

4.4.1/4.4.2

Select tool and prepare locking pins. The tool is carefully

pushed onto the mounting adapter by the mounting

hole. The indexing pin in the mounting adaptor must

engage in the corresponding slots in the mounting hole.

4.4.3./4.4.4/4.4.5

The two locking pins are inserted into the locking holes

with the release button pressed.

The tool must be pressed gently in the direction of the

clamp while doing so. The pin must lock automatically

once inserted and must not fall out of the locking hole

by itself.

The tool is now ready for use.

Anleitung Stanznietwerkzeug PNP_90_UN2.indd 18 22.07.11 14:09

4.5.1 4.5.2

4.5.3

4.5.4

19

4.5 Riveting Tool Kit RIVKIT UN 2.0 –

Fitting and Intended Use

Three rivet clamps are currently available for use

with the RIVKIT UN 2.0 riveting tool kit:

Rivet clamp Art. No.

Opening depth

NB 40105-00000026 up to 40 mm

NB 115 05-00000031 up to 115 mm

NB 230 05-00000027 230 mm

1Included in the basic kit

4.5.1/4.5.2

Screw the riveting tool needed for the working process

into a holder in the rivet clamp as required. Hand-tighten

the riveting head using the special spanners provided. Do

not use force. Counterhold the nut using a screwdriver

if necessary.

4.5.3/4.5.4

Screw the corresponding counterpart to the rivet insert

into the opposite side of the rivet clamp (plunger rod)

with the spacing bushing and bolt, and hand-tighten.

Do not use force!

Each time rivet inserts are to be fitted,

the bolt and die must be checked for a

correct match first!

Refer to the usage matrix in the RIVKIT

UN 2.0 case for details.

Check that the riveting heads are firmly

seated after each riveting operation. Rivet

inserts that have come loose present a

hazard and can lead to destruction of the

equipment.

Anleitung Stanznietwerkzeug PNP_90_UN2.indd 19 22.07.11 14:09

5.1.2 01-00000788

5.1.4 5.1.5

5.1.6

5.1.1

7

5.1.3 01-00000784

20

5.1 Pressing out Rivets

Old or defective rivets often need to be removed from

the sheet metal structure when repairing body panels.

5.1.1 – 5.1.6

To avoid having to drill out these rivets, the olds rivet can

be pressed out of the sheet metal structure using the

extraction mandrel art. no. 01-00000788 and extraction

die art. no. 01-00000784 (kit BGR-TKR-00000128),

thereby minimising damage.

Anleitung Stanznietwerkzeug PNP_90_UN2.indd 20 22.07.11 14:09

Other manuals for PNP 90 UN 2.0

1

Table of contents

Popular Nail Gun manuals by other brands

Craftsman

Craftsman 18178 - Full Head Framing Nailer Operator's manual

Makita

Makita AN621 instruction manual

DeVillbiss Air Power Company

DeVillbiss Air Power Company 2by4 Contractor Series Operation manual

Aeropro

Aeropro DA64R operating instructions

Ozito

Ozito OZSNG16A Operation manual

HIKOKI

HIKOKI NV 90HMC Handling instructions