TLV LA13 User manual

172-65133M-04 (LA Series) 1 October 2021

Thermostatic Air Vent for Steam

LA13 •LA13L

LA21

Copyright © 2021 by TLV CO., LTD.

All rights reserved

172-65133M-04 (LA Series) 1 Oct 2021

1

Contents

Introduction ...................................................................................1

Safety Considerations...................................................................2

Operation...................................................................................... 3

Specifications................................................................................4

Configuration.................................................................................5

Installation.....................................................................................6

Maintenance..................................................................................7

Disassembly/Reassembly .............................................................8

Troubleshooting ..........................................................................11

TLV EXPRESS LIMITED WARRANTY .......................................12

Service........................................................................................14

Introduction

Thank you for purchasing the TLV thermostatic air vent for steam.

This product has been thoroughly inspected before being shipped from the

factory. When the air vent is delivered, before doing anything else, check the

specifications and external appearance to make sure nothing is out of the

ordinary. Also be sure to read this manual carefully before use and follow the

instructions to be sure of using the air vent properly.

The air vent for steam is of a revolutionary design that uses a high-

performance X-element. This is a new type of valve mechanism in which a

thermoliquid is sealed inside the X-element and the valve opens or closes

based on the difference between the saturation temperatures of the

thermoliquid and the water. The X-element is very sensitive to changes in

temperature and responds with great accuracy, quickly discharging air and

the large quantities of condensate created immediately after operation start-

up, thereby greatly reducing start-up time. It also reacts with great sensitivity

to the hot air accumulated during operation, preventing air-locking.

The superior features of the X-element help increase heating efficiency and

reduce manpower requirements for maintenance and bypass blowdown.

If detailed instructions for special order specifications or options not contained

in this manual are required, please contact TLV for full details.

This instruction manual is for the models listed on the front cover. It is needed

not only for installation but for subsequent maintenance, disassembly

/reassembly and troubleshooting. Please keep it in a safe place for future

reference.

172-65133M-04 (LA Series) 1 Oct 2021

2

Safety Considerations

Read this section carefully before use and be sure to follow the instructions.

Installation, inspection, maintenance, repairs, disassembly, adjustment and valve

opening/closing should be carried out only by trained maintenance personnel.

The precautions listed in this manual are designed to ensure safety and prevent

equipment damage and personal injury. For situations that may occur as a result

of erroneous handling, three different types of cautionary items are used to

indicate the degree of urgency and the scale of potential damage and danger:

DANGER, WARNING and CAUTION.

The three types of cautionary items above are very important for safety: be sure

to observe all of them as they relate to installation, use, maintenance, and repair.

Furthermore, TLV accepts no responsibility for any accidents or damage

occurring as a result of failure to observe these precautions.

Symbols

Indicates a DANGER, WARNING or CAUTION item.

DANGER

Indicates an urgent situation which poses a threat of death or

serious injury

WARNING

Indicates that there is a potential threat of death or serious injury

CAUTION

Indicates that there is a possibility of injury or equipment / product

damage

CAUTION

Install properly and DO NOT use this product outside the

recommended operating pressure, temperature and other

specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions that may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

Take measures to prevent people from coming into direct contact

with product outlets.

Failure to do so may result in burns or other injury from the discharge

of fluids.

When disassembling or removing the product, wait until the

internal pressure equals atmospheric pressure and the surface of

the product has cooled to room temperature.

Disassembling or removing the product when it is hot or under

pressure may lead to discharge of fluids, causing burns, other injuries

or damage.

Be sure to use only the recommended components when

repairing the product, and NEVER attempt to modify the product

in any way.

Failure to observe these precautions may result in damage to the

product and burns or other injury due to malfunction or the discharge

of fluids.

Use only under conditions in which no freeze-up will occur.

Freezing may damage the product, leading to fluid discharge, which

may cause burns or other injury.

Use only under conditions in which no water hammer will occur.

The impact of water hammer may damage the product, leading to fluid

discharge, which may cause burns or other injury.

172-65133M-04 (LA Series) 1 Oct 2021

3

Operation

Principles of air discharge:

1. Start-up Air Discharge

Initially, the X-element is open and air in piping is

quickly vented, significantly shortening equipment

start-up time.

2. Closed Position

When steam flows in, the increased temperature

causes the X-element to close immediately. If the

temperature around the X-element is near steam

saturation temperature, the vent will remain closed.

3. Discharge During Operation

When the temperature of the X-element decreases

due to inflowing air, the X-element contracts opening

the vent and allowing air discharge.

Condensate

Air

172-65133M-04 (LA Series) 1 Oct 2021

4

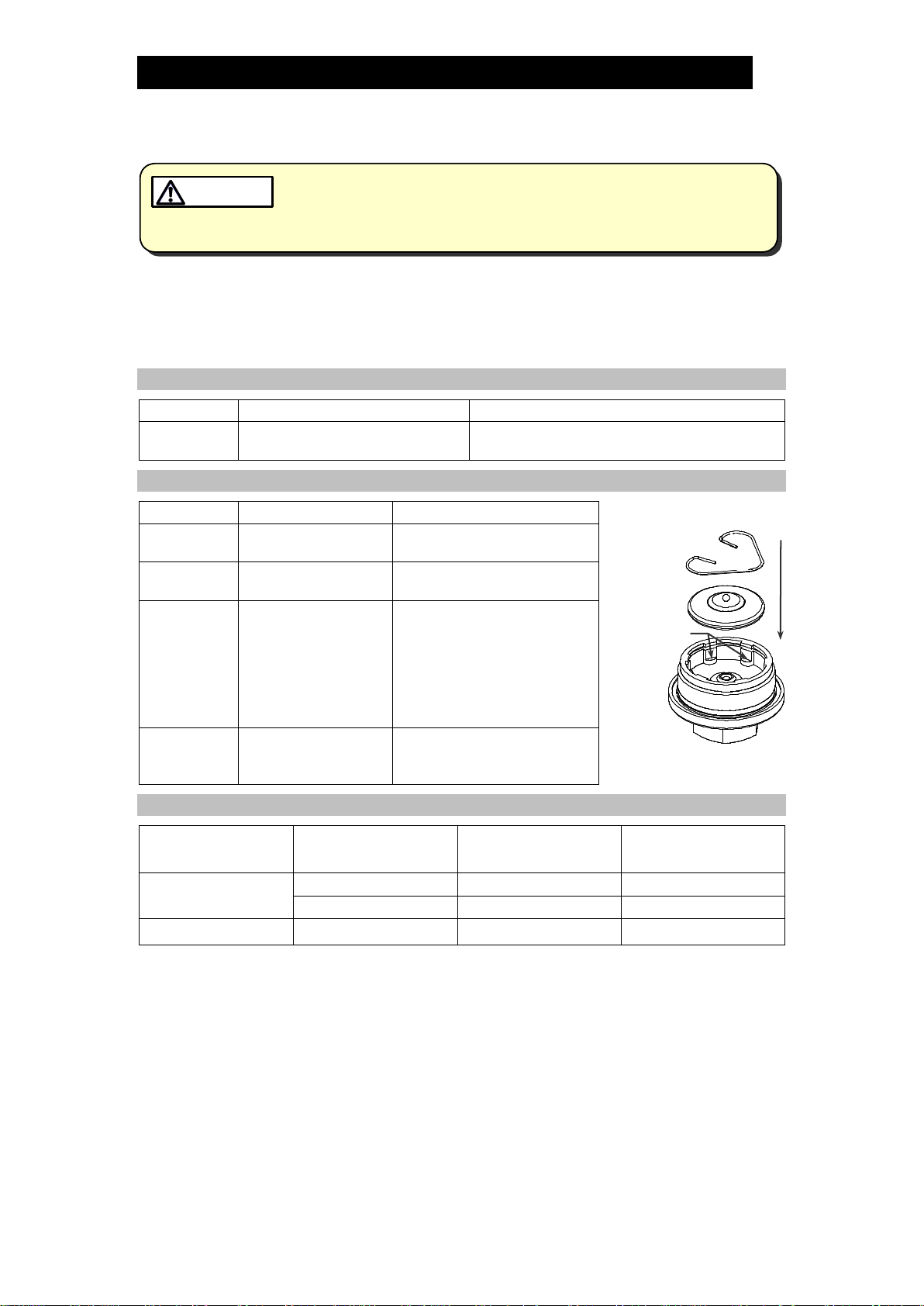

Specifications

Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

CAUTION

Use only under conditions in which no freeze-up will occur. Freezing

may damage the product, leading to fluid discharge, which may cause

burns or other injury.

CAUTION

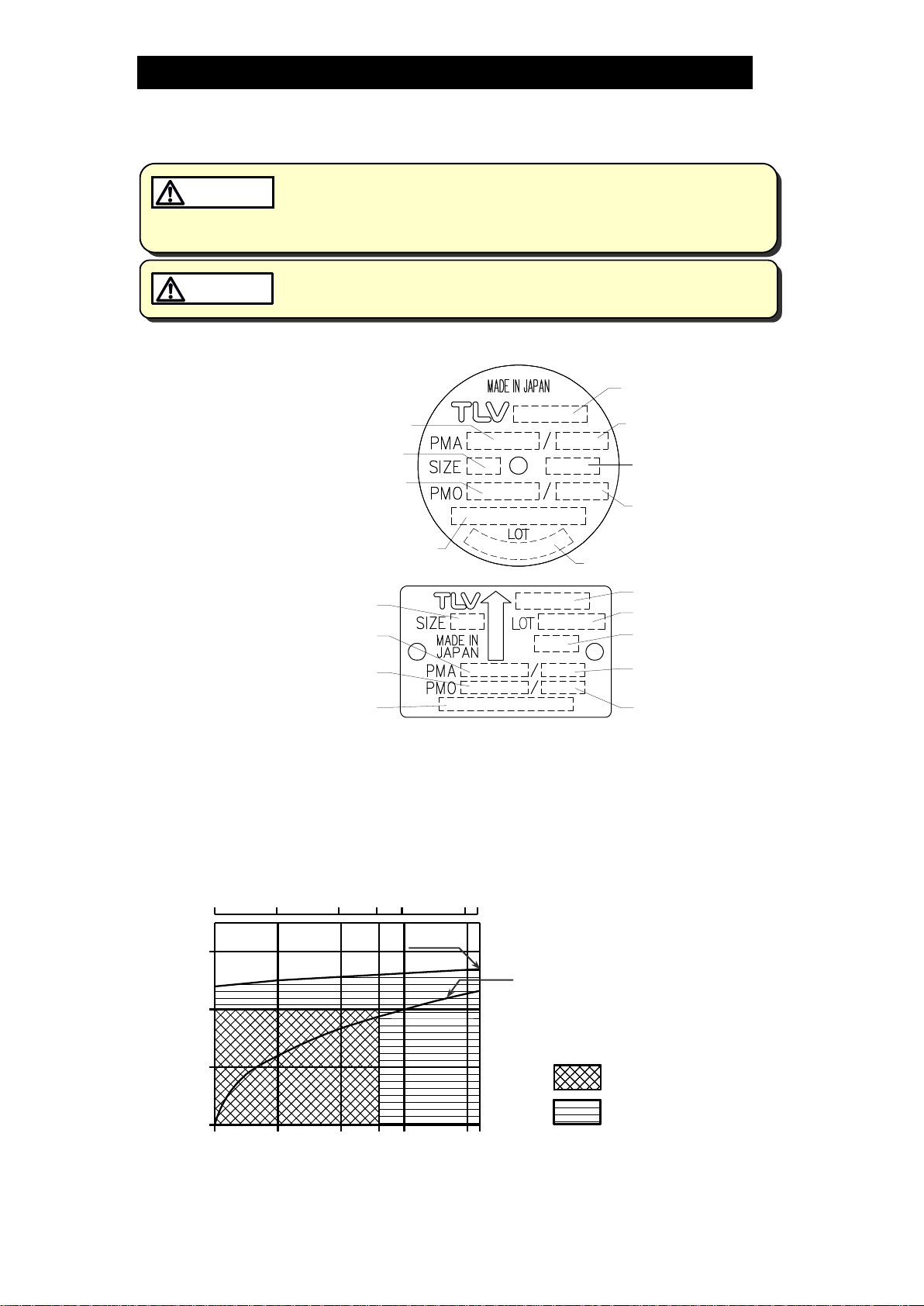

Refer to the product nameplate for detailed specifications.

LA13L

Production Lot No.

Valve No.**

Model

Maximum Allowable

Temperature (TMA)*

Nominal Diameter***

Maximum Operating

Temperature (TMO)

Maximum Allowable

Pressure*

Maximum Operating

Pressure

X-element Type

LA13/LA21

Model

Production Lot No.

X-element Type

Maximum Allowable

Temperature (TMA)*

Maximum Operating

Temperature (TMO)

Nominal Diameter

Maximum Allowable

Pressure*

Maximum Operating

Pressure

Valve No.**

*Maximum allowable pressure (PMA) and maximum allowable temperature (TMA) are PRESSURE

SHELL DESIGN CONDITIONS, NOT OPERATING CONDITIONS.

**Valve No. is displayed for products with options. This item is omitted from the nameplate when there

are no options.

Maximum Operating Temperature

235 C

: LA13/LA13L

: LA21

0510 13 15 20 21

250

220

200

150

100 00.5 1.0 1.3 1.5 2.0 2.1

Operating Pressure (kg/cm2G)

Operating Pressure (MPaG)

Temperature (

C)

Saturated Steam Curve

Operating Temperature Range

172-65133M-04 (LA Series) 1 Oct 2021

5

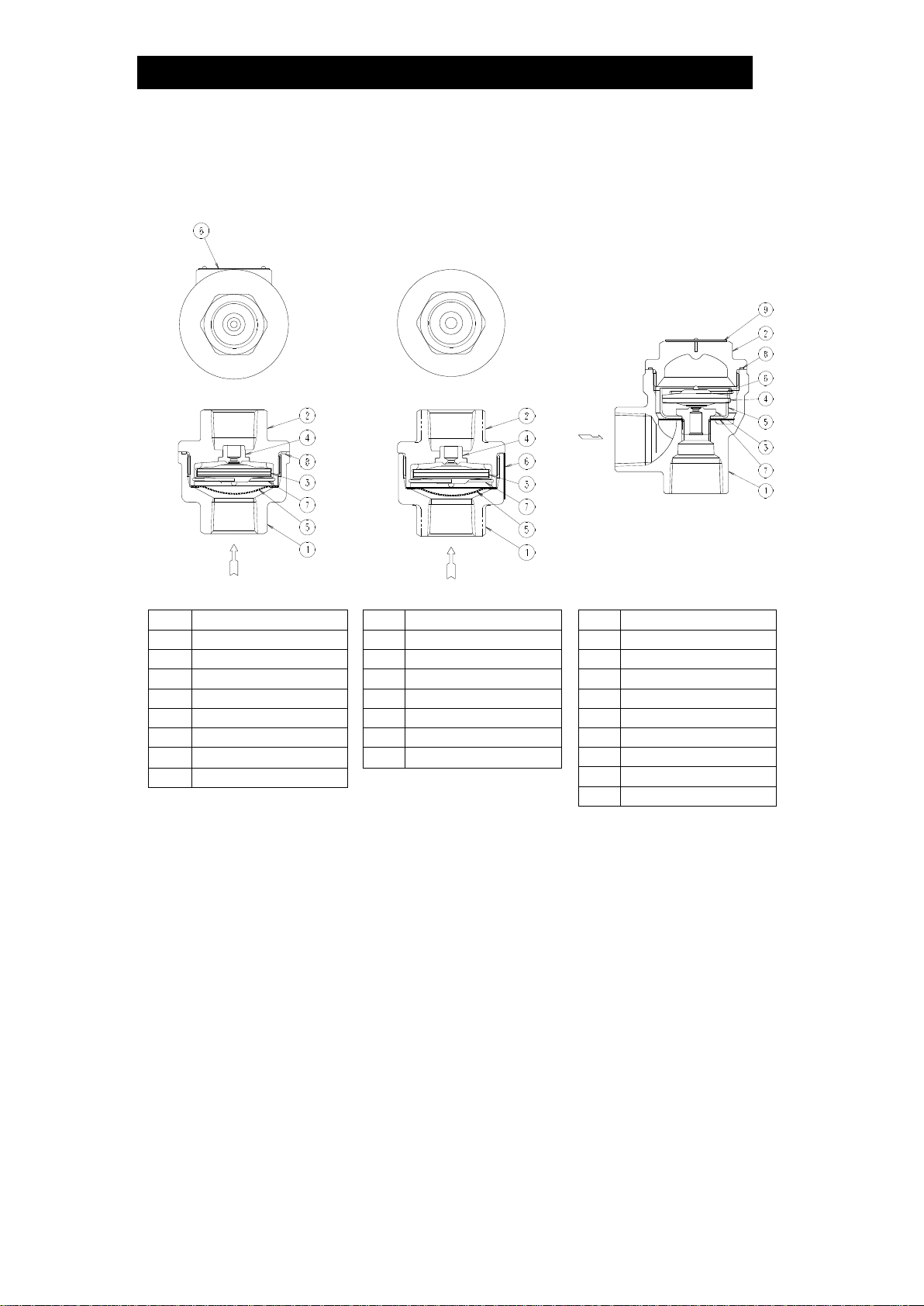

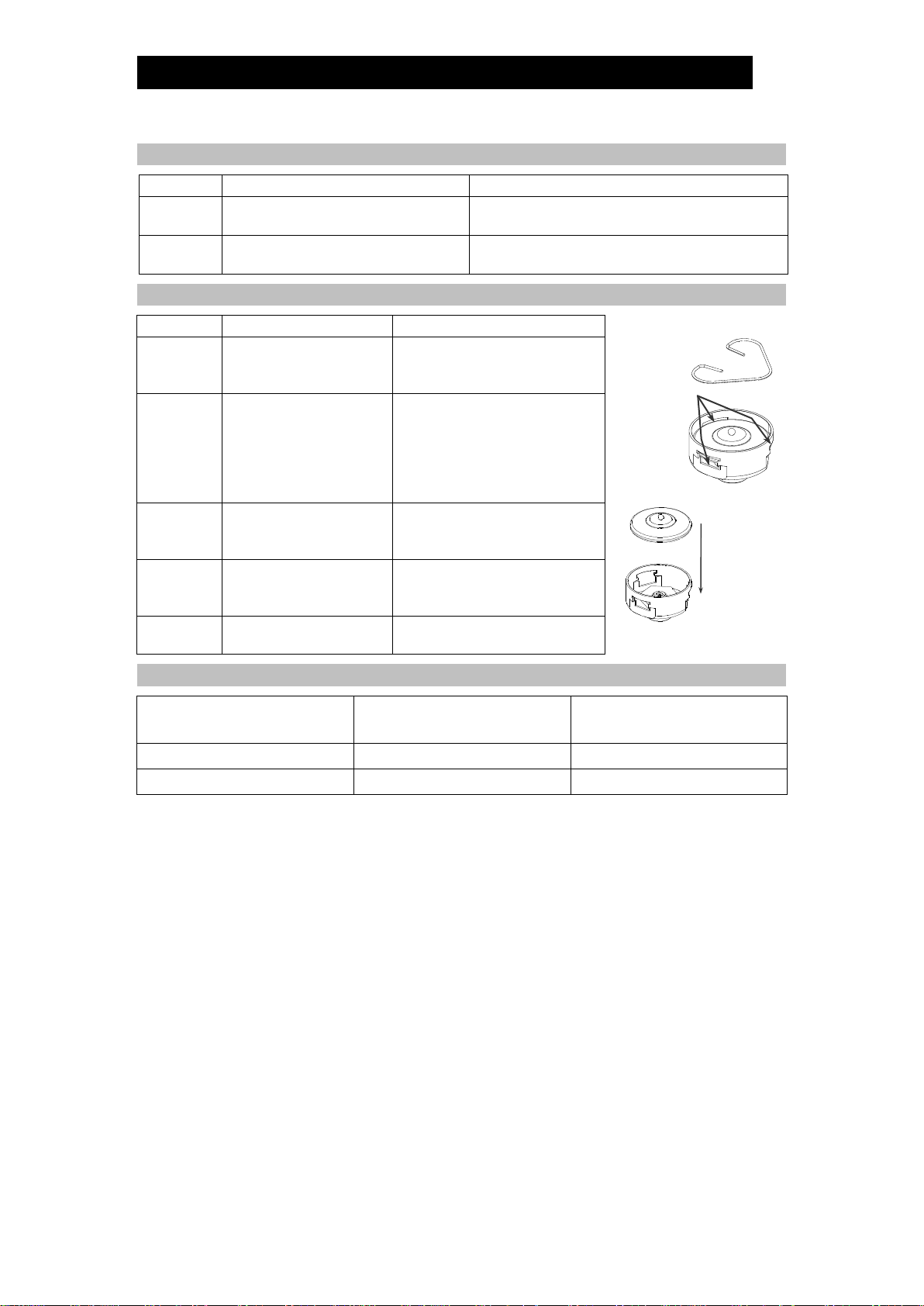

Configuration

LA13

LA21

LA13L

NO.

NAME

1

Body

2

Cover

3

X-element

4

Valve Seat

5

Screen

6

Nameplate

7

Spring Clip

8

Cover Gasket

NO.

NAME

1

Body

2

Cover

3

X-element

4

Valve Seat

5

Screen

6

Nameplate

7

Spring Clip

NO.

NAME

1

Body

2

Cover

3

Valve Seat

4

X-element

5

X-element Guide

6

Spring Clip

7

Screen

8

Cover Gasket

9

Nameplate

172-65133M-04 (LA Series) 1 Oct 2021

6

Installation

Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

CAUTION

Take measures to prevent people from coming into direct contact with

product outlets. Failure to do so may result in burns or other injury from

the discharge of fluids.

CAUTION

Installation, inspection, maintenance, repairs, disassembly, adjustment and valve

opening/closing should be carried out only by trained maintenance personnel.

1. Before installation, be sure to remove all protective seals from the product.

2. Before installing the air vent, blow out the inlet piping to remove any piping

scraps, dirt and oil. Close the inlet valve after blowdown.

3. When using the air vent to remove air from steam equipment, install at a point

where air tends to collect (essentially, a place away from the steam inlet). To

increase the effectiveness of air removal, also install an air vent in front of the

steam equipment (at the primary side).

4. Install the air vent vertically, making sure the arrow on the air vent is pointing in

the direction of flow.

5. Be sure to connect the pipe to the discharge side at the outlet. If air, etc. is

discharged from the outlet, connect a pipe leading to a drain, etc. so the

discharge does not affect operations. Do not submerge the outlet pipe in water;

this may result in air vent failure if the pipe sucks up water containing rust and

scale.

6. Open the inlet valve and check to make sure that the air vent functions properly.

If there is a problem, determine the cause using the “Troubleshooting” section in this

manual.

Sample Installation

Equipment Equipment

LA13/LA21 LA13/LA21

Drainage Pit Drainage Pit

L

A

1

3

L

L

A

1

3

,

172-65133M-04 (LA Series) 1 Oct 2021

7

Maintenance

Take measures to prevent people from coming into direct contact with

product outlets. Failure to do so may result in burns or other injury from

the discharge of fluids.

CAUTION

Be sure to use only the recommended components when repairing the

product, and NEVER attempt to modify the product in any way. Failure to

observe these precautions may result in damage to the product or burns

or other injury due to malfunction or the discharge of fluids.

CAUTION

Operational Check

A visual inspection according to the following items should be done on a daily basis

to determine whether the air vent is operating properly or has failed. Periodically (at

least biannually) the operation should also be checked by using a stethoscope,

thermometer or TLV Pocket TrapMan.

If the air vent should fail, it may cause damage to piping and equipment, resulting in

faulty or low quality products or losses due to steam leakage.

Normal

:

The sound of flow can be heard while air is discharged. When

air discharge finishes, the valve closes along with slight

discharge of steam.

Blocked

(Discharge

Impossible)

:

No air is discharged. The air vent is quiet and makes no noise,

and its surface temperature is low.

Blowing

:

Live steam continuously blows from the outlet and there is a

continuous metallic sound.

Steam Leakage

:

Live steam is leaking through the outlet, accompanied by a

high-pitched sound.

Parts Inspection

When parts have been removed, or during periodic inspections, use the following

table to inspect the parts and replace any that are found to be defective.

Procedure

Gasket: Check for warping or damage

Screen: Check for clogging or corrosion damage

X-element: Check for damage

Valve seat: Check for damage

Check inside of body for rust and scale

Check X-element valve and valve seat for rust and scale or oil film,

and also check for wear

172-65133M-04 (LA Series) 1 Oct 2021

8

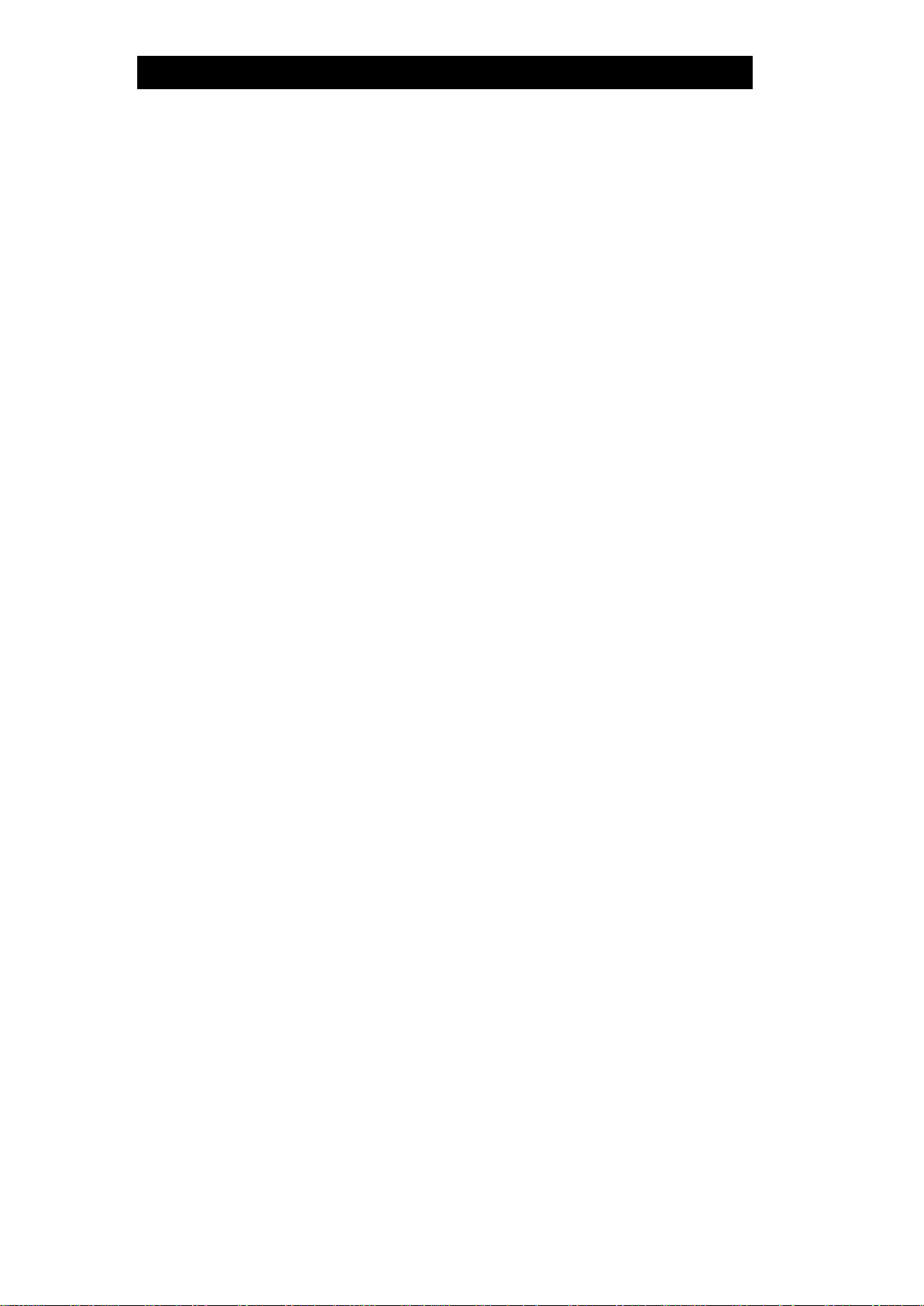

Disassembly/Reassembly

When disassembling or removing the product, wait until the internal

pressure equals atmospheric pressure and the surface of the product

has cooled to room temperature. Disassembling or removing the

product when it is hot or under pressure may lead to discharge of fluids,

causing burns, other injuries or damage.

CAUTION

Use the following procedures to remove components. Use the same procedures in

reverse to reassemble. Installation, inspection, maintenance, repairs, disassembly,

adjustment and valve opening/closing should be carried out only by trained

maintenance personnel.

Removing/Reattaching Body (LA13/LA21)

Part

During Disassembly

During Reassembly

Body

Remove with a socket wrench

Consult the table of tightening torques and

tighten to the proper torque

Removing/Reassembling Parts Inside Cover (LA13/LA21)

Part

During Disassembly

During Reassembly

Figure A

Spring Clip

Slot

Screen

Remove without

bending

Being careful not to bend it,

insert with the right side up

Spring Clip

Remove with needle-

nose pliers

Fit securely into the spring

clip slots

X-element

Grasp the ball on the

top of the X-element

with pliers and

remove

Make sure the side of the

X-element with the ball on it

is facing up and insert,

keeping the X-element level

and making sure it does not

catch on the cover (see

Figure A)

Cover

Gasket

(LA13 only)

Remove the gasket

and clean sealing

surfaces

Replace the gasket only if

warped or damaged

Table of Tightening Torques (LA13, LA21)

Part

Size

mm

Torque

N∙m

Distance Across Flats

mm

Body/Cover (LA13)

15

80

27

20, 25

80

41

Body/Cover (LA21)

10, 15

120

27

(1 Nm 10 kgcm)

NOTE:-LA13: DO NOT coat threaded portions with anti-seize

-LA21: Coat all threaded portions with anti-seize

-If drawings or other special documentation were supplied for the product, any torque

given there takes precedence over values shown here.

172-65133M-04 (LA Series) 1 Oct 2021

9

Removing/Reattaching Cover (LA13L)

Part

During Disassembly

During Reassembly

Cover

Remove with a socket wrench

Consult the table of tightening torques and

tighten to the proper torque

Cover

Gasket

Remove the gasket and clean

sealing surfaces

Replace the gasket only if warped or

damaged

Removing/Reassembling Parts Inside Body (LA13L)

Part

During Disassembly

During Reassembly

Figure B

Spring Clip

Slot

Figure C

Spring Clip

Use needle-nose pliers

to remove, or remove

by hand

Insert securely into the slots in

the X-element guide (see

Figure B)

X-element

Grasp the ball on the

top of the X-element

with pliers and remove

Make sure the side of the

X-element with the ball on it is

facing up and insert, keeping

the X-element level and

making sure it does not catch

on the guide (see Figure C)

Valve Seat

Remove with a socket

wrench

Consult the table of tightening

torques and tighten to proper

torque

X-element

Guide

Remove without

bending

Fix with the valve seat and

make sure the X-element can

be inserted smoothly

Screen

Remove without

bending

Reinsert without bending

Table of Tightening Torques (LA13L)

Part

Torque

N∙m

Distance Across Flats

mm

Cover

80

32

Valve Seat

35

19

(1 Nm 10 kgcm)

NOTE: -LA13L: DO NOT coat threaded portions with anti-seize.

-If drawings or other special documentation were supplied for the product, any torque

given there takes precedence over values shown here.

172-65133M-04 (LA Series) 1 Oct 2021

10

Exploded View

LA13

LA21

LA13L

Body Body Cover

Screen Screen Cover Gasket

Spring Clip

X-element X-element X-element

Spring Clip Spring Clip

Cover

Gasket Cover Valve Seat

X-element

Guide

Screen

Body

Nameplate

Nameplate

Cover

172-65133M-04 (LA Series) 1 Oct 2021

11

Troubleshooting

When disassembling or removing the product, wait until the internal

pressure equals atmospheric pressure and the surface of the product

has cooled to room temperature. Disassembling or removing the

product when it is hot or under pressure may lead to discharge of fluids,

causing burns, other injuries or damage.

CAUTION

When the product fails to operate properly, use the following table to locate and

remedy the cause.

Problem

Cause

Remedy

No air is discharged

(blocked) or discharge

is poor

The X-element is stuck to the

valve seat

Clean parts

The valve seat is blocked

Clean the valve seat, or replace

with a new valve seat (LA13L) or

cover

The screen is clogged

Clean parts

The air vent operating pressure

exceeds the maximum specified

pressure, or there is insufficient

pressure differential between the

air vent inlet and outlet

Compare specifications and

actual operating conditions

Steam is discharged or

leaks from the outlet

(blowing)

(steam leakage)

There is rust or scale between the

X-element valve and valve seat

Clean parts

The X-element valve and valve

seat are damaged

Replace with a new X-element

and/or cover (LA13L: also the

valve seat)

The X-element is broken

Replace with a new X-element

Improper installation

Correct the installation

Air vent vibration

Lengthen the inlet piping and

fasten it securely

Steam is leaking from

a place other than the

outlet

Gasket deterioration or damage

Replace with a new gasket

Improper tightening torques were

used

Tighten to the proper torque

172-65133M-04 (LA Series) 1 Oct 2021

12

TLV EXPRESS LIMITED WARRANTY

Subject to the limitations set forth below, TLV CO., LTD., a Japanese corporation

(“TLV”), warrants that products which are sold byit, TLV International Inc. (“TII”) or one of

its group companies excluding TLV Corporation (a corporation of the United States of

America), (hereinafter the “Products”) are designed and manufactured by TLV, conform

to the specifications published by TLV for the corresponding part numbers (the

“Specifications”) and are free from defective workmanship and materials. The party

from whom the Products were purchased shall be known hereinafter as the “Seller”. With

regard to products or components manufactured byunrelated third parties (the

“Components”), TLV provides no warranty other than the warranty from the third party

manufacturer(s), if any.

Exceptions to Warranty

This warranty does not cover defects or failures caused by:

1. improper shipping, installation, use, handling, etc., by persons other than TLV,

TII or TLV group company personnel, or service representatives authorized by

TLV; or

2. dirt, scale or rust, etc.; or

3. improper disassembly and reassembly, or inadequate inspection and

maintenance by persons other than TLV or TLV group company personnel, or

service representatives authorized by TLV; or

4. disasters or forces of nature or Acts of God; or

5. abuse, abnormal use, accidents or any other cause beyond the control of TLV,

TII or TLV group companies; or

6. improper storage, maintenance or repair; or

7. operation of the Products not in accordance with instructions issued with the

Products or with accepted industry practices; or

8. use for a purpose or in a manner for which the Products were not intended; or

9. use of the Products in a manner inconsistent with the Specifications; or

10. use of the Products with Hazardous Fluids (fluids other than steam, air, water,

nitrogen, carbon dioxide and inert gases (helium, neon, argon, krypton, xenon

and radon)); or

11. failure to follow the instructions contained in the TLV Instruction Manual for the

Product.

Duration of Warranty

This warranty is effective for a period of one (1) year after delivery of Products to the

first end user. Notwithstanding the foregoing, asserting a claim under this warranty

must be brought within three (3) years after the date of delivery to the initial buyer if

not sold initially to the first end user.

ANY IMPLIED WARRANTIES NOT NEGATED HEREBY WHICH MAY ARISE BY

OPERATION OF LAW, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE AND ANY EXPRESS WARRANTIES NOT

NEGATED HEREBY, ARE GIVEN SOLELY TO THE INITIAL BUYER AND ARE LIMITED IN

DURATION TO ONE (1) YEAR FROM THE DATE OF SHIPMENT BY THE SELLER.

Exclusive Remedy

THE EXCLUSIVE REMEDY UNDER THIS WARRANTY, UNDER ANY EXPRESS WARRANTY

OR UNDER ANY IMPLIED WARRANTIES NOT NEGATED HEREBY (INCLUDING THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE), IS REPLACEMENT; PROVIDED: (a) THE CLAIMED DEFECT IS REPORTED TO

THE SELLER IN WRITING WITHIN THE WARRANTY PERIOD, INCLUDING A DETAILED

172-65133M-04 (LA Series) 1 Oct 2021

13

WRITTEN DESCRIPTION OF THE CLAIMED DEFECT AND HOW AND WHEN THE

CLAIMED DEFECTIVE PRODUCT WAS USED; AND (b) THE CLAIMED DEFECTIVE

PRODUCT AND A COPY OF THE PURCHASE INVOICE IS RETURNED TO THE SELLER,

FREIGHT AND TRANSPORTATION COSTS PREPAID, UNDER A RETURN MATERIAL

AUTHORIZATION AND TRACKING NUMBER ISSUED BY THE SELLER. ALL LABOR

COSTS, SHIPPING COSTS, AND TRANSPORTATION COSTS ASSOCIATED WITH THE

RETURN OR REPLACEMENT OF THE CLAIMED DEFECTIVE PRODUCT ARE SOLELY THE

RESPONSIBILITY OF BUYER OR THE FIRST END USER. THE SELLER RESERVES THE

RIGHT TO INSPECT ON THE FIRST END USER’S SITE ANY PRODUCTS CLAIMED TO BE

DEFECTIVE BEFORE ISSUING A RETURN MATERIAL AUTHORIZATION. SHOULD SUCH

INSPECTION REVEAL, IN THE SELLER’S REASONABLE DISCRETION, THAT THE

CLAIMED DEFECT IS NOT COVERED BY THIS WARRANTY, THE PARTY ASSERTING THIS

WARRANTY SHALL PAY THE SELLER FOR THE TIME AND EXPENSES RELATED TO

SUCH ON-SITE INSPECTION.

Exclusion of Consequential and Incidental Damages

IT IS SPECIFICALLY ACKNOWLEDGED THAT THIS WARRANTY, ANY OTHER EXPRESS

WARRANTY NOT NEGATED HEREBY, AND ANY IMPLIED WARRANTY NOT NEGATED

HEREBY, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE, DO NOT COVER, AND NEITHER TLV, TII NOR ITS TLV

GROUP COMPANIES WILL IN ANY EVENT BE LIABLE FOR, INCIDENTAL OR

CONSEQUENTIAL DAMAGES, INCLUDING, BUT NOT LIMITED TO LOST PROFITS, THE

COST OF DISASSEMBLY AND SHIPMENT OF THE DEFECTIVE PRODUCT, INJURY TO

OTHER PROPERTY, DAMAGE TO BUYER’S OR THE FIRST END USER’S PRODUCT,

DAMAGE TO BUYER’S OR THE FIRST END USER’S PROCESSES, LOSS OF USE, OR

OTHER COMMERCIAL LOSSES. WHERE, DUE TO OPERATION OF LAW,

CONSEQUENTIAL AND INCIDENTAL DAMAGES UNDER THIS WARRANTY, UNDER ANY

OTHER EXPRESS WARRANTY NOT NEGATED HEREBY OR UNDER ANY IMPLIED

WARRANTY NOT NEGATED HEREBY (INCLUDING THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE) CANNOT BE

EXCLUDED, SUCH DAMAGES ARE EXPRESSLY LIMITED IN AMOUNT TO THE PURCHASE

PRICE OF THE DEFECTIVE PRODUCT. THIS EXCLUSION OF CONSEQUENTIAL AND

INCIDENTAL DAMAGES, AND THE PROVISION OF THIS WARRANTY LIMITING REMEDIES

HEREUNDER TO REPLACEMENT, ARE INDEPENDENT PROVISIONS, AND ANY

DETERMINATION THAT THE LIMITATION OF REMEDIES FAILS OF ITS ESSENTIAL

PURPOSE OR ANY OTHER DETERMINATION THAT EITHER OF THE ABOVE REMEDIES IS

UNENFORCEABLE, SHALL NOT BE CONSTRUED TO MAKE THE OTHER PROVISIONS

UNENFORCEABLE.

Exclusion of Other Warranties

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED,

AND ALL OTHER WARRANTIES, INCLUDING BUT NOT LIMITED TO THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE,

ARE EXPRESSLY DISCLAIMED.

Severability

Any provision of this warranty which is invalid, prohibited or unenforceable in any

jurisdiction shall, as to such jurisdiction, be ineffective to the extent of such invalidity,

prohibition or unenforceability without invalidating the remaining provisions hereof,

and any such invalidity, prohibition or unenforceability in any such jurisdiction shall

not invalidate or render unenforceable such provision in any other jurisdiction.

172-65133M-04 (LA Series) 1 Oct 2021

14

Service

For Service or Technical Assistance: Contact your TLV representative or your regional TLV

office.

In Europe:

Daimler-Benz-Straße 16-18, 74915 Waibstadt, Germany

Tel:

Fax:

[49]-(0)7263-9150-0

[49]-(0)7263-9150-50

Units 7 & 8, Furlong Business Park, Bishops Cleeve, Gloucestershire GL52

8TW, U.K.

Tel:

Fax:

[44]-(0)1242-227223

[44]-(0)1242-223077

Parc d’Ariane 2, bât. C, 290 rue Ferdinand Perrier, 69800 Saint Priest,

France

Tel:

Fax:

[33]–(0)4-72482222

[33]-(0)4-72482220

In North America:

13901 South Lakes Drive, Charlotte, NC 28273-6790, U.S.A.

Tel:

Fax:

[1]-704-597-9070

[1]-704-583-1610

In Mexico and Latin America:

Av. Jesús del Monte 39-B-1001, Col. Hda. de las Palmas, Huixquilucan,

Edo. de México, 52763, Mexico

Tel:

Fax:

[52]-55-5359-7949

[52]-55-5359-7585

In Oceania:

Unit 8, 137-145 Rooks Road, Nunawading, Victoria 3131, Australia

Tel:

Fax:

[61]-(0)3-9873 5610

[61]-(0)3-9873 5010

In East Asia:

36 Kaki Bukit Place, #02-01/02, Singapore 416214

Tel:

Fax:

[65]-6747 4600

[65]-6742 0345

Room 5406, No. 103 Cao Bao Road, Shanghai, China 200233

Tel:

Fax:

[86]-(0)21-6482-8622

[86]-(0)21-6482-8623

No.16, Jalan MJ14, Taman Industri Meranti Jaya, 47120 Puchong,

Selangor, Malaysia

Tel:

Fax:

[60]-3-8065-2928

[60]-3-8065-2923

252/94 (K-L) 17th Floor, Muang Thai-Phatra Complex Tower B,

Rachadaphisek Road, Huaykwang, Bangkok 10310, Thailand

Tel:

Fax:

[66]-2-693-3799

[66]-2-693-3979

#302-1 Bundang Technopark B, 723 Pangyo-ro, Bundang, Seongnam,

Gyeonggi, 13511, Korea

Tel:

Fax:

[82]-(0)31-726-2105

[82]-(0)31-726-2195

In the Middle East:

Building2W,No.M002, PO Box371684,DubaiAirportFreeZone,Dubai, UAE

Email:

sales-m[email protected]

In Other Countries:

881 Nagasuna, Noguchi, Kakogawa, Hyogo 675-8511, Japan

Tel:

Fax:

[81]-(0)79-427-1818

[81]-(0)79-425-1167

Manufacturer:

881 Nagasuna, Noguchi, Kakogawa, Hyogo 675-8511, Japan

Tel:

Fax:

[81]-(0)79-422-1122

[81]-(0)79-422-0112

This manual suits for next models

2

Table of contents

Other TLV Fan manuals

Popular Fan manuals by other brands

Termozeta

Termozeta AIRZETA LIVING PLUS instruction manual

Hinkley

Hinkley IVER 56 instruction manual

Monte Carlo Fan Company

Monte Carlo Fan Company Ceiling Fans owner's manual

Becker

Becker SV 5.250 operating instructions

Vortice

Vortice VORT HRW 30 MONO EVO WiFi Instruction booklet

Hardware House

Hardware House 162272 Owner's instruction manual